My CoreXY build log

Posted by TE78

|

Re: My CoreXY build log June 29, 2020 12:44PM |

Registered: 7 years ago Posts: 18 |

So after a few iterations of one part, I've got the bed mountings made and put into place. No doubt the wisdom of those much more experienced with 3d printer building will point out the flaws in this design, and no doubt this may get changed/developed further, but here is where I am at the moment.

As mentioned before, I have incorporated the actual bed-levelling adjustment screws into the Z-axis carriages, and these screws will level the bed by actually levelling the frame that the bed is attached to. So now the mounting system to attach the bed to the frame only has to control/manage the thermal expansion of the Ali' bed.

Mark's (the Digital Dentist) blog gave great inspiration with the Kinematic (not sure if I've spelt that right) method of mounting his bed which allowed for thermal expansion without compromising keeping the bed securely mounted. His way incorporated both the levelling and the attachment mechanisms, whereas I am keeping them separate.

At the moment (all things are subject to change/improvement!!) I have a 300x300x5mm piece of Ali plate for the bed. Sadly it's not tooling-grade plate, but it is what I have so it will do for the moment. I made up a drill-guide that would clamp to the edge of the plate that allowed me to both drill and tap the edge for 3 M2.5 holes for mounting (1 in the middle of one edge, and 2 at either side of the opposite edge). Then I turned some brass hex bar to make 3 stand-off's, threaded one end of each M5, and cross-drilled/milled them for either a 2.7mm hole or a slot. Then I turned some stainless-steel to make the pins that would just be a nice sliding fit into these holes/slot, and also threaded the other end M2.5.

Then it was just a case of drilling the Bed-frame for mounting these brass stand-off's, and then milling slots into the side of the bed to allow for a spanner to tighten the nuts holding the stand-off's.

Here's how the front left fixed Bed-mount looks;

(although it may look as though these brass stand-off's are not fully tightened down, they are. It's just that I put a slight chamfer on the bottom of the hex to "break" the edge)

This is the right Bed-mount on the front, and as you can see the slot should allow for approx 0.8mm expansion; (I've calculated that I need max of 0.6mm expansion)

Then here's the rear Bed-mount (and as you can see I had a little whoopsy and snapped a drill, so the 2nd attempt is slightly off centre), and this one has just a hole in the brass stand-off which allows for expansion only in the front-to-back direction;

Then this is just a shot showing the access slot milled for tightening the stand-off nut;

So next on the agenda is to make some mounts for the X & Y steppers (or is that the A & B steppers?) that will hopefully include the means of adjusting/tensioning the belts, and also installing the rest of the belt path. Then hopefully I will have got an extruder, hotend, etc and then I can start on designing/building a carriage to hold them.

Thanks for watching

Tim

As mentioned before, I have incorporated the actual bed-levelling adjustment screws into the Z-axis carriages, and these screws will level the bed by actually levelling the frame that the bed is attached to. So now the mounting system to attach the bed to the frame only has to control/manage the thermal expansion of the Ali' bed.

Mark's (the Digital Dentist) blog gave great inspiration with the Kinematic (not sure if I've spelt that right) method of mounting his bed which allowed for thermal expansion without compromising keeping the bed securely mounted. His way incorporated both the levelling and the attachment mechanisms, whereas I am keeping them separate.

At the moment (all things are subject to change/improvement!!) I have a 300x300x5mm piece of Ali plate for the bed. Sadly it's not tooling-grade plate, but it is what I have so it will do for the moment. I made up a drill-guide that would clamp to the edge of the plate that allowed me to both drill and tap the edge for 3 M2.5 holes for mounting (1 in the middle of one edge, and 2 at either side of the opposite edge). Then I turned some brass hex bar to make 3 stand-off's, threaded one end of each M5, and cross-drilled/milled them for either a 2.7mm hole or a slot. Then I turned some stainless-steel to make the pins that would just be a nice sliding fit into these holes/slot, and also threaded the other end M2.5.

Then it was just a case of drilling the Bed-frame for mounting these brass stand-off's, and then milling slots into the side of the bed to allow for a spanner to tighten the nuts holding the stand-off's.

Here's how the front left fixed Bed-mount looks;

(although it may look as though these brass stand-off's are not fully tightened down, they are. It's just that I put a slight chamfer on the bottom of the hex to "break" the edge)

This is the right Bed-mount on the front, and as you can see the slot should allow for approx 0.8mm expansion; (I've calculated that I need max of 0.6mm expansion)

Then here's the rear Bed-mount (and as you can see I had a little whoopsy and snapped a drill, so the 2nd attempt is slightly off centre), and this one has just a hole in the brass stand-off which allows for expansion only in the front-to-back direction;

Then this is just a shot showing the access slot milled for tightening the stand-off nut;

So next on the agenda is to make some mounts for the X & Y steppers (or is that the A & B steppers?) that will hopefully include the means of adjusting/tensioning the belts, and also installing the rest of the belt path. Then hopefully I will have got an extruder, hotend, etc and then I can start on designing/building a carriage to hold them.

Thanks for watching

Tim

|

Re: My CoreXY build log July 08, 2020 02:45PM |

Registered: 7 years ago Posts: 18 |

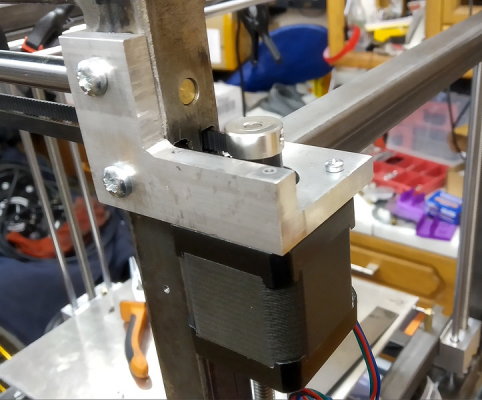

A piece of Ali' angle was suitably cut into 2 sections to make up the Stepper Motor brackets for the X & Y (or A &  , and was milled out to accept the Stepper shaft and also drilled for it's mounting screws. A couple more milling operations gave it the required shape for mounting onto the side uprights, and a couple of M5 clearance mounting holes were installed. Then those mounting holes were marked up on the uprights of the printer frame, and drilled/tapped M5.

, and was milled out to accept the Stepper shaft and also drilled for it's mounting screws. A couple more milling operations gave it the required shape for mounting onto the side uprights, and a couple of M5 clearance mounting holes were installed. Then those mounting holes were marked up on the uprights of the printer frame, and drilled/tapped M5.

Here is a couple of views of the mounts in place, showing it with some GT2 belt in place and with just 2 screws holding it in place temporarily;

The other mount (essentially identical, but a mirror image)

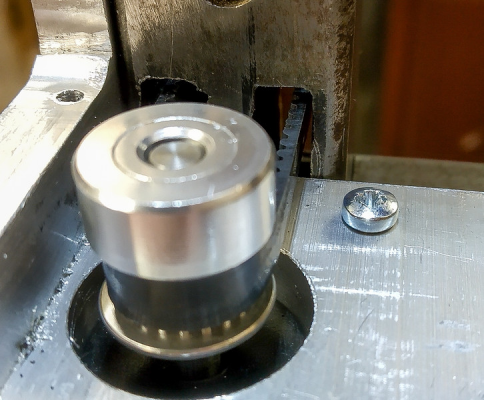

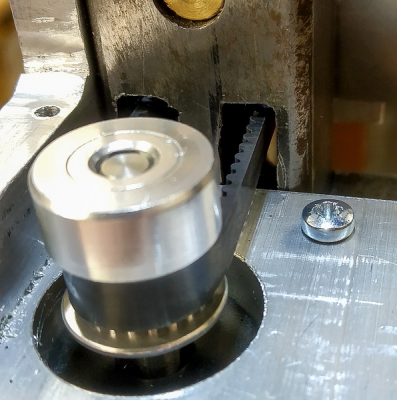

With the belt in place, I made a quick visual check to see if I had calculated correctly and the stepper itself is aligned so that the belt will run parallel as the carriage runs from front to back. The good news was that I had got it very close, the stepper motor mount needs to be shimmed out by about 0.5mm (as measured by my Mk1 eyeball, LOL!!) with this particular belt. Here's a couple of closer pics, 1st up is when the X carriage is furthest away from the steppers and you can see the gap to the right of the belt as it goes thru the frame;

Then this was with the X-carriage in the nearest position, and even though the camera angle changed slightly, you can see that the belt has moved to the left slightly (about 0.5mm);

Here's a pic looking up from under the X-carriage

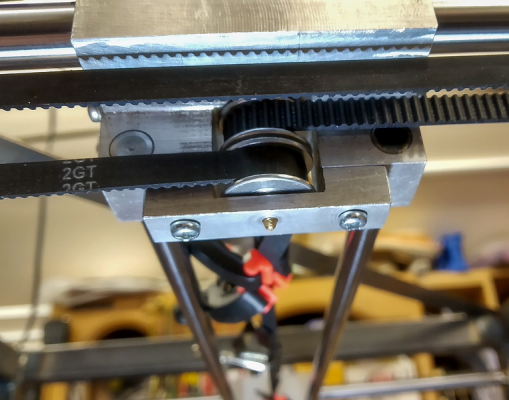

I also have worked a little on the belt path across the back of the printer. There's still some work to be done on this, but this is how it stands at the moment (this part has been un-mounted in order to photograph it, normally this is firmly attached at the back of the frame, I forgot to take a snap of it in-situ);

There are 4 ball-raced, GT2 pulleys mounted on long M5 grubscrews. The 25mm box-section has been drilled & tapped M5, the outer pulleys do not need precise drilling as the parts of the belts that run on them do not have to remain parallel. But the inner pulleys are more critical. The inner pulley mounting holes were drilled at exactly the same distances as the the X-carriage GT2 bearing pulleys, and as they are the exact same pulleys as the carriage uses, I know that no matter what belt-thickness is used, these will remain exactly aligned and parallel.

The work I need to do on this is to improve from the temporary grub screws holding the pulleys in place in the frame, at the moment there's nothing to stop them rotating and screwing themselves out and allowing the pulleys to come loose.

I need to get some GT2 belt, as the 2 pieces I have are from different sources and one of them is too short, so I will order enough to make both belts from, then once I have that belt I can make up the shims to align the steppers to keep the critical parts of the belt path truly parallel.

Thanks for watching,

Tim

, and was milled out to accept the Stepper shaft and also drilled for it's mounting screws. A couple more milling operations gave it the required shape for mounting onto the side uprights, and a couple of M5 clearance mounting holes were installed. Then those mounting holes were marked up on the uprights of the printer frame, and drilled/tapped M5.

, and was milled out to accept the Stepper shaft and also drilled for it's mounting screws. A couple more milling operations gave it the required shape for mounting onto the side uprights, and a couple of M5 clearance mounting holes were installed. Then those mounting holes were marked up on the uprights of the printer frame, and drilled/tapped M5.Here is a couple of views of the mounts in place, showing it with some GT2 belt in place and with just 2 screws holding it in place temporarily;

The other mount (essentially identical, but a mirror image)

With the belt in place, I made a quick visual check to see if I had calculated correctly and the stepper itself is aligned so that the belt will run parallel as the carriage runs from front to back. The good news was that I had got it very close, the stepper motor mount needs to be shimmed out by about 0.5mm (as measured by my Mk1 eyeball, LOL!!) with this particular belt. Here's a couple of closer pics, 1st up is when the X carriage is furthest away from the steppers and you can see the gap to the right of the belt as it goes thru the frame;

Then this was with the X-carriage in the nearest position, and even though the camera angle changed slightly, you can see that the belt has moved to the left slightly (about 0.5mm);

Here's a pic looking up from under the X-carriage

I also have worked a little on the belt path across the back of the printer. There's still some work to be done on this, but this is how it stands at the moment (this part has been un-mounted in order to photograph it, normally this is firmly attached at the back of the frame, I forgot to take a snap of it in-situ);

There are 4 ball-raced, GT2 pulleys mounted on long M5 grubscrews. The 25mm box-section has been drilled & tapped M5, the outer pulleys do not need precise drilling as the parts of the belts that run on them do not have to remain parallel. But the inner pulleys are more critical. The inner pulley mounting holes were drilled at exactly the same distances as the the X-carriage GT2 bearing pulleys, and as they are the exact same pulleys as the carriage uses, I know that no matter what belt-thickness is used, these will remain exactly aligned and parallel.

The work I need to do on this is to improve from the temporary grub screws holding the pulleys in place in the frame, at the moment there's nothing to stop them rotating and screwing themselves out and allowing the pulleys to come loose.

I need to get some GT2 belt, as the 2 pieces I have are from different sources and one of them is too short, so I will order enough to make both belts from, then once I have that belt I can make up the shims to align the steppers to keep the critical parts of the belt path truly parallel.

Thanks for watching,

Tim

Sorry, only registered users may post in this forum.