Core XY mystery

Posted by n9jcv

|

Core XY mystery May 03, 2017 09:41PM |

Registered: 10 years ago Posts: 211 |

I recently built a corexy. It is running pretty well. In some of my final calibration, I noticed one area that is off.

Say you print a tall square object. Looking from the front of the bed, If the object is 150mm tall, If I check the left side of the object to the bottom of the object I find that the object is not a square 90 degree angle, it is slightly less. Meaning that the upper layers drift very slightly to the right. Over 150mm object, I measured the drift at about 1.5mm.

So the first thing I checked was the bed, to see if it was moving up and down or at a slight diagonal. To the best of my measuring abilities, it is moving squarely down, and not drifting to the side.

Here is a writeup on my printer;

n9jcv Hypercube

I then checked the frame by measuring the rectangles/squares diagonally and they all appear to be exact, at least to the best of my measuring

I can not think of what else would cause this. Any ideas?

Thanks

Say you print a tall square object. Looking from the front of the bed, If the object is 150mm tall, If I check the left side of the object to the bottom of the object I find that the object is not a square 90 degree angle, it is slightly less. Meaning that the upper layers drift very slightly to the right. Over 150mm object, I measured the drift at about 1.5mm.

So the first thing I checked was the bed, to see if it was moving up and down or at a slight diagonal. To the best of my measuring abilities, it is moving squarely down, and not drifting to the side.

Here is a writeup on my printer;

n9jcv Hypercube

I then checked the frame by measuring the rectangles/squares diagonally and they all appear to be exact, at least to the best of my measuring

I can not think of what else would cause this. Any ideas?

Thanks

|

Re: Core XY mystery May 04, 2017 12:23AM |

Registered: 11 years ago Posts: 5,780 |

Are the Z axis guide rails perpendicular to the X and Y axis rails?

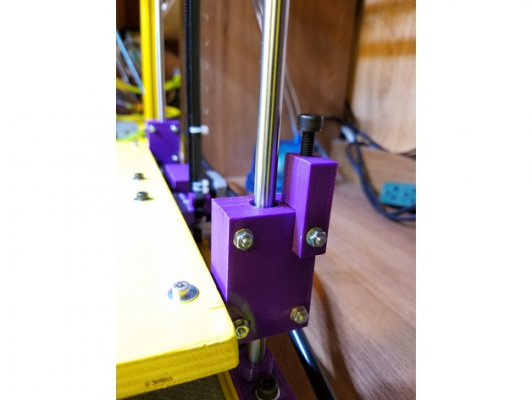

Why does this Z guide rail look tilted?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Why does this Z guide rail look tilted?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Core XY mystery May 04, 2017 11:57AM |

Registered: 10 years ago Posts: 211 |

I measure the edge of the bed to the side frame at top and bottom and it is the same distance from the side, so i believe that is square. The end stop adjuster is a separate piece that mounts on the bearing holder and i believe the adjuster is not sitting square.

Circles print completely circular so I believe belt tensions are good.

Circles print completely circular so I believe belt tensions are good.

|

Re: Core XY mystery May 04, 2017 12:28PM |

Registered: 6 years ago Posts: 2 |

That plate under your heatbed looks like it is wood. Is it?

If so, it might shrink due to heating, and cause stress or even movement in the connections between this plate and the heatbed.

Maybe you can test this by waiting with printing after heatup until all materials have settled, so this possibke shrink happens before printing, not while printing

If so, it might shrink due to heating, and cause stress or even movement in the connections between this plate and the heatbed.

Maybe you can test this by waiting with printing after heatup until all materials have settled, so this possibke shrink happens before printing, not while printing

|

Re: Core XY mystery May 04, 2017 02:35PM |

Registered: 10 years ago Posts: 211 |

|

Re: Core XY mystery May 04, 2017 07:33PM |

Registered: 8 years ago Posts: 338 |

|

Re: Core XY mystery May 04, 2017 08:43PM |

Registered: 10 years ago Posts: 211 |

|

Re: Core XY mystery May 04, 2017 08:44PM |

Registered: 10 years ago Posts: 211 |

|

Re: Core XY mystery May 04, 2017 10:05PM |

Registered: 8 years ago Posts: 338 |

|

Re: Core XY mystery May 05, 2017 12:11AM |

Registered: 10 years ago Posts: 211 |

So I slowed it way down to 30mm/s for everything moves, fill perimiters 20mm for first layer

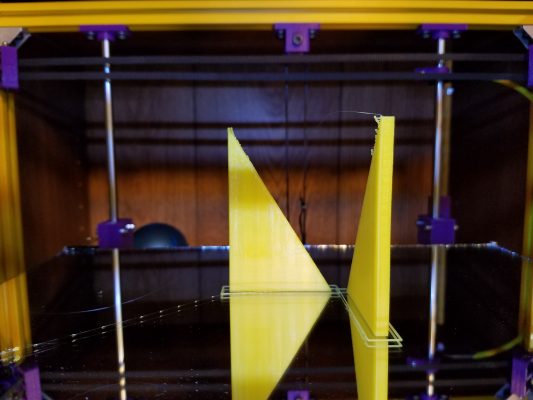

Still same result. Below is a pic of the objects printed. two tall triangles 90 degrees to each other

The triangle that goes from front to back measures at a right angle sides a and b

The triangle that was sitting from left to right has the issue. The top of the triangle is pushed towards the right. Making the a/b angle measure about 89 degrees

The triangle is 80mm tall, and I measure about .85mm shift to the right.

So I am really certain the motors,drivers not skipping steps. I went back made all kinds of measurements. In the rear, I measure the distance between the 8mm rods and the extrusion, at the top and the bottom, they are within .1mm of each other.

But I know/can see from the printing result, that the bed moved .8mm to the left (looking from the front) as it traveled the 80mm in Z. So perhaps my measurements, methods and tools have too much error to measure this? I am thinking about moving the bottom of both z smooth rods to the right by 1mm. If they are out of alignment, and I can not measure, doing this should help to clear my issue. Although for the total z of about 265, it could be more than 1mm, but at least this may give me an indication.

Any other ideas before I try moving them?

Thanks

Edited 1 time(s). Last edit at 05/05/2017 12:32AM by n9jcv.

Still same result. Below is a pic of the objects printed. two tall triangles 90 degrees to each other

The triangle that goes from front to back measures at a right angle sides a and b

The triangle that was sitting from left to right has the issue. The top of the triangle is pushed towards the right. Making the a/b angle measure about 89 degrees

The triangle is 80mm tall, and I measure about .85mm shift to the right.

So I am really certain the motors,drivers not skipping steps. I went back made all kinds of measurements. In the rear, I measure the distance between the 8mm rods and the extrusion, at the top and the bottom, they are within .1mm of each other.

But I know/can see from the printing result, that the bed moved .8mm to the left (looking from the front) as it traveled the 80mm in Z. So perhaps my measurements, methods and tools have too much error to measure this? I am thinking about moving the bottom of both z smooth rods to the right by 1mm. If they are out of alignment, and I can not measure, doing this should help to clear my issue. Although for the total z of about 265, it could be more than 1mm, but at least this may give me an indication.

Any other ideas before I try moving them?

Thanks

Edited 1 time(s). Last edit at 05/05/2017 12:32AM by n9jcv.

|

Re: Core XY mystery May 05, 2017 02:00AM |

Registered: 10 years ago Posts: 211 |

|

Re: Core XY mystery May 05, 2017 02:28AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Core XY mystery May 05, 2017 07:33AM |

Registered: 11 years ago Posts: 5,780 |

Have you considered the possibility that the XY plane is tilted? Or maybe it isn't a plane?

Is the printer frame square? You can check by measuring diagonals. If you can verify that the frame is square, the alignment becomes much easier. Building the frame squarely allows you to use it as the reference to set up the guide rails in all three axes. Use metal spacers to set the ends of the guide rails equal distances from the parallel frame members.

You're relying on the accuracy of printed plastic parts to position the rails parallel to each other. I would not trust the plastic to be accurate. If I were building a Z axis like yours, I would have made the Z axis rail mounts clamp the rails against the horizontal frame members at the top and bottom of the axes, metal on metal. That way you can be sure that the rails are coplanar. Then use a metal spacer to set one of them parallel to the nearest vertical frame member, and finally use another spacer to set the other rail parallel to the first. Now you know the Z rails are parallel. Similar techniques can be used to ensure that the Y axis rails are coplanar and parallel to each other.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Is the printer frame square? You can check by measuring diagonals. If you can verify that the frame is square, the alignment becomes much easier. Building the frame squarely allows you to use it as the reference to set up the guide rails in all three axes. Use metal spacers to set the ends of the guide rails equal distances from the parallel frame members.

You're relying on the accuracy of printed plastic parts to position the rails parallel to each other. I would not trust the plastic to be accurate. If I were building a Z axis like yours, I would have made the Z axis rail mounts clamp the rails against the horizontal frame members at the top and bottom of the axes, metal on metal. That way you can be sure that the rails are coplanar. Then use a metal spacer to set one of them parallel to the nearest vertical frame member, and finally use another spacer to set the other rail parallel to the first. Now you know the Z rails are parallel. Similar techniques can be used to ensure that the Y axis rails are coplanar and parallel to each other.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Core XY mystery May 05, 2017 11:49PM |

Registered: 10 years ago Posts: 211 |

So thanks for the input

I can understand concern about plastic parts, but I do not believe that is the issue here. I did measure the diagonals, using a tape, the most accurate way I have to measure large diagonals, and they are all within 1mm of each other.

Here is another way I am looking at it.

First, the xy corexy movement rods/belts, etc they form a plane for the print head. This plane is in no way guaranteed to be level/perpendicular to the frame, But it is guaranteed my print head is moving in a horizontal plane.

Second, my bed is a plane. 3 point leveled bed, which has been proven level at all 3 leveling point/screws on the bed.

So now I know my corexy and my print bed are in the same plane. I believe all this to be true.

Now, When I print the triangles above, the triangle on the left, the top of the triangle moves over to the right by .8mm, the triangle is 80mm tall. So to me this indicates the bed must have moved down to the left by .8mm over the 80mm.

So just now, I put the bed at the top - z0. I held a piece of extrusion horizontal (z0) between my front and rear vertical extrusions. The extrusion in the same plane as the bed. I measured the edge of the bed to the extrusion. 67.13mm. Now I drop the bed to z80. I measure from the bed to the extrusion (now at z80) and I measure 67.2. So to me the bed has not moved left to right or viceversa.

So how could my triangle have drifted by .8mm? I can't seem to wrap my head around this.

If the rods were bent, or not in the same position at z0 and z80, I should see that with the above bed measures. But I see basically no movement. Only .07mm which is more likely to be measuring error.

Any other ideas?

I have printed many triangles, the results always the same. If it were skipping steps, It would not always veer .8mm to the right. More likely one would end up with a wavy edge as the missed steps would in theory be spread 50% on one side and 50% on another, corexy makes this more random. A simple cartesian bed moving in the y plane back and forth, if steps are missed it is likely they would be missed in both the plus and minus direction, and not just one direction.

I can understand concern about plastic parts, but I do not believe that is the issue here. I did measure the diagonals, using a tape, the most accurate way I have to measure large diagonals, and they are all within 1mm of each other.

Here is another way I am looking at it.

First, the xy corexy movement rods/belts, etc they form a plane for the print head. This plane is in no way guaranteed to be level/perpendicular to the frame, But it is guaranteed my print head is moving in a horizontal plane.

Second, my bed is a plane. 3 point leveled bed, which has been proven level at all 3 leveling point/screws on the bed.

So now I know my corexy and my print bed are in the same plane. I believe all this to be true.

Now, When I print the triangles above, the triangle on the left, the top of the triangle moves over to the right by .8mm, the triangle is 80mm tall. So to me this indicates the bed must have moved down to the left by .8mm over the 80mm.

So just now, I put the bed at the top - z0. I held a piece of extrusion horizontal (z0) between my front and rear vertical extrusions. The extrusion in the same plane as the bed. I measured the edge of the bed to the extrusion. 67.13mm. Now I drop the bed to z80. I measure from the bed to the extrusion (now at z80) and I measure 67.2. So to me the bed has not moved left to right or viceversa.

So how could my triangle have drifted by .8mm? I can't seem to wrap my head around this.

If the rods were bent, or not in the same position at z0 and z80, I should see that with the above bed measures. But I see basically no movement. Only .07mm which is more likely to be measuring error.

Any other ideas?

I have printed many triangles, the results always the same. If it were skipping steps, It would not always veer .8mm to the right. More likely one would end up with a wavy edge as the missed steps would in theory be spread 50% on one side and 50% on another, corexy makes this more random. A simple cartesian bed moving in the y plane back and forth, if steps are missed it is likely they would be missed in both the plus and minus direction, and not just one direction.

|

Re: Core XY mystery May 06, 2017 07:59AM |

Registered: 8 years ago Posts: 338 |

|

Re: Core XY mystery May 06, 2017 08:08AM |

Registered: 7 years ago Posts: 45 |

Instead of printing the triangles at the traditional X & Y positions, parallel to the edge of the bed, turn them 45 degrees on the platform. Doing that should isolate the X & Y motors to single motions and you can then take them out of the equation. You might also try a tall calibration cube on the same 45 degree rotation if you haven't already done so. This way, if the sides are smooth but it's still tilted then you know it's relegated to only a Z axis issue.

Take all this for what it's worth as I've only been doing this for a few months though I am also building a Hypercube and hope not to encounter the same problem.

Take all this for what it's worth as I've only been doing this for a few months though I am also building a Hypercube and hope not to encounter the same problem.

|

Re: Core XY mystery May 06, 2017 08:12AM |

Registered: 11 years ago Posts: 5,780 |

Adjusting the bed so it is parallel to the XY plane doesn't mean the Z axis is perpendicular to the XY plane. If the Z axis guide rails aren't parallel it may cause some twist in the bed motion that would shift the print. The effect on prints would get worse as the print is positioned further away from the Z axis rails.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Core XY mystery May 06, 2017 09:36AM |

Registered: 10 years ago Posts: 344 |

|

Re: Core XY mystery May 06, 2017 10:34AM |

Registered: 10 years ago Posts: 211 |

|

Re: Core XY mystery May 06, 2017 10:41AM |

Registered: 11 years ago Posts: 250 |

Put a Bubble Level on the bed and watch it as it goes down.

Does the bubble move from the original spot as the print progresses?

My other thought, is there is no real support on the left and right side of the table, kinda balanced in the middle by the belts.

If there is any play in the Z axis rails, the bed may shift(Tilt) (like your video shows) - Your Z axis might not be rigid enough.

Edited 1 time(s). Last edit at 05/06/2017 10:42AM by Mogal.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

Does the bubble move from the original spot as the print progresses?

My other thought, is there is no real support on the left and right side of the table, kinda balanced in the middle by the belts.

If there is any play in the Z axis rails, the bed may shift(Tilt) (like your video shows) - Your Z axis might not be rigid enough.

Edited 1 time(s). Last edit at 05/06/2017 10:42AM by Mogal.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Core XY mystery May 07, 2017 01:14AM |

Registered: 10 years ago Posts: 211 |

|

Re: Core XY mystery May 07, 2017 02:26PM |

Registered: 10 years ago Posts: 211 |

So I took the suggestion of tgmorris, and printed a rectangle, 20x40x80, with the orientation 45 degrees to the edge of the bed.

Also, I checked the bed level as Mogal suggested, it is not level, but that is not the point, table is most likely not level, any, the bubble did not appear to move during the entire movement of the z, I also checked moving the z the entire 260, and there was no movement.

If there were stepper issues, I would have expected to see the short or long side of the rectangle (or both) not align properly. But, this is not the case, It is perfect in that the layers align on all 4 sides, no evidence of skipping and measures 20x40x80 within .1mm on all sides.

Using my square, and I have tried 3 different ones, they all indicate it is not square on the base vs the vertical. The same as the triangles before, the item is leaning to the right, about 1 degree. I measure about .8mm lean over this 80mm tall rectangle.

So I believe it is Z is not aligned properly. I was really intent on finding the culprit, but have not been able to. I again put the bed to z0. I then take an extrusion and place on the left vertical extrusions, at the same height z0, I measure from the extrusion to the bed, at the front and the rear, then I drop the z to 80 do the same measurement. It is within .1mm in all places. So yes it is possible by frame and my z rods are both not 90 degrees to the bed and that is where this monster is hiding. Hmmmmm at this point I am trying to decide

All of the below is based on looking at the cube from the front;

1) move bottom of z rods to right 1.5mm see if it changes

2) move top of z rods to left 1.5mm see if it changes

3 move bottom of z right 1mm and top of z left 1mm see if it changes

????? I am not sure but I believe the movement of the z rods is going to be the only way to fix. Again previously I have already moved the bottom of z rods 1.5 mm to the right and there was no change. Possibly I need to move farther ???

For what it is worth here are measurements of z rods distance from inside of outer extrusion to closest side of z rod

Left Rod Top Left Rod Bottom Right Rod Top Right Rod Bottom

87.6mm 88.8mm 87.0 86.3

Based on the above, the left rod already appears to be slanted top to bottom from left to right by 1.2 mm

the right rod appears to be slanted from top to bottom from right to left by .7mm

Now maybe this is what digital dentist and olampe have suggested is wrong? And they are probably right, but why then when I measure the extrusion to the bed on the side at z0 and z80, do I not see this movement?

So maybe

4) just move right rod bottom so that it is at 88.2 the same relative slant as the left rod?

So many variables not sure which way to go with it.

Any advice welcome

Thanks

Also, I checked the bed level as Mogal suggested, it is not level, but that is not the point, table is most likely not level, any, the bubble did not appear to move during the entire movement of the z, I also checked moving the z the entire 260, and there was no movement.

If there were stepper issues, I would have expected to see the short or long side of the rectangle (or both) not align properly. But, this is not the case, It is perfect in that the layers align on all 4 sides, no evidence of skipping and measures 20x40x80 within .1mm on all sides.

Using my square, and I have tried 3 different ones, they all indicate it is not square on the base vs the vertical. The same as the triangles before, the item is leaning to the right, about 1 degree. I measure about .8mm lean over this 80mm tall rectangle.

So I believe it is Z is not aligned properly. I was really intent on finding the culprit, but have not been able to. I again put the bed to z0. I then take an extrusion and place on the left vertical extrusions, at the same height z0, I measure from the extrusion to the bed, at the front and the rear, then I drop the z to 80 do the same measurement. It is within .1mm in all places. So yes it is possible by frame and my z rods are both not 90 degrees to the bed and that is where this monster is hiding. Hmmmmm at this point I am trying to decide

All of the below is based on looking at the cube from the front;

1) move bottom of z rods to right 1.5mm see if it changes

2) move top of z rods to left 1.5mm see if it changes

3 move bottom of z right 1mm and top of z left 1mm see if it changes

????? I am not sure but I believe the movement of the z rods is going to be the only way to fix. Again previously I have already moved the bottom of z rods 1.5 mm to the right and there was no change. Possibly I need to move farther ???

For what it is worth here are measurements of z rods distance from inside of outer extrusion to closest side of z rod

Left Rod Top Left Rod Bottom Right Rod Top Right Rod Bottom

87.6mm 88.8mm 87.0 86.3

Based on the above, the left rod already appears to be slanted top to bottom from left to right by 1.2 mm

the right rod appears to be slanted from top to bottom from right to left by .7mm

Now maybe this is what digital dentist and olampe have suggested is wrong? And they are probably right, but why then when I measure the extrusion to the bed on the side at z0 and z80, do I not see this movement?

So maybe

4) just move right rod bottom so that it is at 88.2 the same relative slant as the left rod?

So many variables not sure which way to go with it.

Any advice welcome

Thanks

|

Re: Core XY mystery May 07, 2017 04:56PM |

Registered: 10 years ago Posts: 211 |

Some further information. I printed one triangle in front of each z rod. They still are not exactly square, but the error is much less. It appears they are only slanted by about .2mm, hard to measure. Both appear to be equal in the slanting. So the condition is worse as you move away from the z rods.

So I am still stuck on what is the fix, if it is the bed twist or the z rods not at a right angle to the bed or z rods not parallel.

So I am still stuck on what is the fix, if it is the bed twist or the z rods not at a right angle to the bed or z rods not parallel.

|

Re: Core XY mystery May 07, 2017 09:39PM |

Registered: 10 years ago Posts: 211 |

|

Re: Core XY mystery May 09, 2017 03:32PM |

Registered: 7 years ago Posts: 45 |

|

Re: Core XY mystery May 09, 2017 07:22PM |

Registered: 10 years ago Posts: 211 |

Thanks tgmorris

I am making some adjustments now. I did not see how the plumb bob would work here, because the bed and the xy plane are not necessarily level, they are in the same plane, but not level, but the plumb bob was to ensure the belt is 90 degrees to a level plane. So I modified the idea a bit, I am using a square and a level on the square, allowing me to measure the belt to the same "level" as the bed, if you see what I mean.

I will post back later.

I really kind of believe that probably most people who built hypercubes (maybe other printers), have not ensured their objects like the triangle are printing at 90 degrees, imho. For Yoda's and slinkys it probably does not matter, the error was minor .8mm over 80mm, so maybe I am just being too critical, but I want to try to get it right.

I am making some adjustments now. I did not see how the plumb bob would work here, because the bed and the xy plane are not necessarily level, they are in the same plane, but not level, but the plumb bob was to ensure the belt is 90 degrees to a level plane. So I modified the idea a bit, I am using a square and a level on the square, allowing me to measure the belt to the same "level" as the bed, if you see what I mean.

I will post back later.

I really kind of believe that probably most people who built hypercubes (maybe other printers), have not ensured their objects like the triangle are printing at 90 degrees, imho. For Yoda's and slinkys it probably does not matter, the error was minor .8mm over 80mm, so maybe I am just being too critical, but I want to try to get it right.

|

Re: Core XY mystery May 09, 2017 09:52PM |

Registered: 10 years ago Posts: 211 |

Well, I moved the front Belt, the upper bearing mount, 4mm to the left, trying to make it perpendicular to the bed, as best I could with a square and level. I now have improvement. The 80mm tall triangle, now has 1/2, .4mm lean to the right, vs the .8mm of lean I previously had. This is now better. Not sure if I will continue to play with it, or just accept it as is.

|

Re: Core XY mystery May 10, 2017 05:53PM |

Registered: 7 years ago Posts: 13 |

Glad you are making progress. I think the various suggestions about leveling/plum bobs/... are spot on. I would level the table it sits on with shims and then do what others have suggested. For my prusa i3 derivative printer I built, I built a table for it to sit on and put levelers on each leg. If I move the table, the first thing I do it level it - a 5 minute job. Having a flat, level surface has made squaring up the printer really easy using squares, levels and plum bobs.

|

Re: Core XY mystery May 28, 2017 06:25PM |

Registered: 8 years ago Posts: 3,525 |

Might be entirely irrelevant but I had a perplexing leaning object problem on a delta and it turned out to be related to a belt that was failing and stretching at a certain height. Probably not the cause but belts are cheap and need replacing occasionally anyway. Took me 3 weeks and the forum 5 pages before we finally worked it out.

Edited 1 time(s). Last edit at 05/28/2017 06:25PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Edited 1 time(s). Last edit at 05/28/2017 06:25PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Core XY mystery May 29, 2017 02:18PM |

Registered: 8 years ago Posts: 622 |

Sorry, only registered users may post in this forum.