Poor Man's Digital Dentist Core XY build

Posted by Qdeathstar

|

Re: Poor Man's Digital Dentist Core XY build June 05, 2017 03:56PM |

Registered: 8 years ago Posts: 338 |

No particular reason. I had them for my delta printer as at one point I was considering installing them as an upgrade on the delta. Never got around to it (working in the delta was kind of pain because the electronics are in a small compartment on the bottom), so in they go. I got two more but I think I am going to use an inductive sensor for the z endstop.

Worked well on my i3..

[www.googleadservices.com]

Worked well on my i3..

[www.googleadservices.com]

|

Re: Poor Man's Digital Dentist Core XY build June 21, 2017 11:45PM |

Registered: 8 years ago Posts: 338 |

Some minor updates

I managed to mock up a cable carrier. I'm not sure if this one will have enough room to carry all the cables i need, but i bought multiple sizes so once i move into the wiring phase i'll make my decision.

One of the biggest changes is that i decided to go with 3" L bracket for a more roomier feel. It doesn't cost me any y space, but it might cost me some x space. I'm not 100% sure this is the final design but for the moment i like it. It allows me to mount my extruder and hotend right to the aluminum. For the extruder i am planning to use the Zesty Nimble which is a worm gear extruder and then a cyclops/chimera for the hotend. Initially i wanted to with two v6's... but with the chimera i can still get most of the larger nozzle sizes... and i already have a water-cooled cyclops in my delta. I might add watercooling to this printer too if needed, but i think with the wide open space for airflow under the hotend mount and the big hunk of alumninum, i might not need it. I'm only going to 50c in the enclosure.

I also changed how i routed the belts. I made basically a larger version of what was done on The Digital Dentist's corexy Z axis. It consists of a back plate, a center plate, and a front plate. The belts run through and are sandwiched together with six m3 screws. I have a peice of belt facing the opposite direction in each "tray" to help hold the belts. I'm not sure how this will work over time, but it seems like i got the belts a lot tighter using this method. In order to tighten the belts, i made the ends long so they fit all the way through the plates, then inserted a peice of belt along side the drive belt and pulled it though until everything was tight. Seems to work, but we will see how well everything handles being tugged on my motors soon.

I also started work on the z-drive. Nothing too crazy here... looks like it will work. Finally decided to invest in a nice set of metric taps, which made tapping the mounting holes a lot easier.

Edited 1 time(s). Last edit at 06/22/2017 12:03AM by Qdeathstar.

I managed to mock up a cable carrier. I'm not sure if this one will have enough room to carry all the cables i need, but i bought multiple sizes so once i move into the wiring phase i'll make my decision.

One of the biggest changes is that i decided to go with 3" L bracket for a more roomier feel. It doesn't cost me any y space, but it might cost me some x space. I'm not 100% sure this is the final design but for the moment i like it. It allows me to mount my extruder and hotend right to the aluminum. For the extruder i am planning to use the Zesty Nimble which is a worm gear extruder and then a cyclops/chimera for the hotend. Initially i wanted to with two v6's... but with the chimera i can still get most of the larger nozzle sizes... and i already have a water-cooled cyclops in my delta. I might add watercooling to this printer too if needed, but i think with the wide open space for airflow under the hotend mount and the big hunk of alumninum, i might not need it. I'm only going to 50c in the enclosure.

I also changed how i routed the belts. I made basically a larger version of what was done on The Digital Dentist's corexy Z axis. It consists of a back plate, a center plate, and a front plate. The belts run through and are sandwiched together with six m3 screws. I have a peice of belt facing the opposite direction in each "tray" to help hold the belts. I'm not sure how this will work over time, but it seems like i got the belts a lot tighter using this method. In order to tighten the belts, i made the ends long so they fit all the way through the plates, then inserted a peice of belt along side the drive belt and pulled it though until everything was tight. Seems to work, but we will see how well everything handles being tugged on my motors soon.

I also started work on the z-drive. Nothing too crazy here... looks like it will work. Finally decided to invest in a nice set of metric taps, which made tapping the mounting holes a lot easier.

Edited 1 time(s). Last edit at 06/22/2017 12:03AM by Qdeathstar.

|

Re: Poor Man's Digital Dentist Core XY build June 22, 2017 07:56AM |

Registered: 11 years ago Posts: 5,780 |

|

Re: Poor Man's Digital Dentist Core XY build June 25, 2017 10:14AM |

Registered: 8 years ago Posts: 338 |

I am starting to get to the point where i need to plan how to to mount my bed to the printer. The easiest way seems to use screws and springs at three points like a prusa i3. However, that isn't the path many have chose. I see little balls placed under the bed. What are they? How do you secur the bed to the round balls? How to you machine the aluminum plate so that the bottom of it is round? Would a drill bit be enough? Maybe a burring drill bit.

I saw how The Digital Dentist did it, but that seemed to require a mill.... trying to figure out how i can do this with just a drill press.

Edited 1 time(s). Last edit at 06/25/2017 10:18AM by Qdeathstar.

I saw how The Digital Dentist did it, but that seemed to require a mill.... trying to figure out how i can do this with just a drill press.

Edited 1 time(s). Last edit at 06/25/2017 10:18AM by Qdeathstar.

|

Re: Poor Man's Digital Dentist Core XY build June 28, 2017 02:13PM |

Registered: 8 years ago Posts: 601 |

Quote

Qdeathstar

I am starting to get to the point where i need to plan how to to mount my bed to the printer. The easiest way seems to use screws and springs at three points like a prusa i3. However, that isn't the path many have chose. I see little balls placed under the bed. What are they? How do you secur the bed to the round balls? How to you machine the aluminum plate so that the bottom of it is round? Would a drill bit be enough? Maybe a burring drill bit.

I saw how The Digital Dentist did it, but that seemed to require a mill.... trying to figure out how i can do this with just a drill press.

Invest in a sliding clamp... It's possible to do very accurate work on a drill press, just make sure your drill is securely mounted and the bit is centered. Securely mount piece to be cut, line it up and take it slow. If it is off, recenter before you reach desired depth. make the groove using a countersink drill bit. Using sliding clamp allows you to easily move the piece whilst cutting to achieve desired result.

Amazon - sliding clamp

|

Re: Poor Man's Digital Dentist Core XY build July 08, 2017 08:35AM |

Registered: 8 years ago Posts: 338 |

|

Re: Poor Man's Digital Dentist Core XY build July 08, 2017 10:04AM |

Registered: 11 years ago Posts: 5,780 |

ATP-5 is a 5083 alloy with high magnesium content. This pdf on the properties of 5083 says it isn't for use above 65C, but it's saying that in reference to corrosion. I'm not sure that makes any difference when using it for the bed heater in a 3D printer, which is normally operated in a pretty benign environment. If you live near the ocean it might be better to use MIC6.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Poor Man's Digital Dentist Core XY build July 08, 2017 05:35PM |

Registered: 11 years ago Posts: 335 |

My printer is 100% ATP-6. [3.bp.blogspot.com]

Note that if you are ordering from Midwest Steel the bottom of the plates will be mangled by forklift marks. I'm not sure if other suppliers also have that issue.

Stress cracking is more of an issue for ships and bridges. A print bed has virtually no load so there really isn't any chance of mechanical failure.

Note that if you are ordering from Midwest Steel the bottom of the plates will be mangled by forklift marks. I'm not sure if other suppliers also have that issue.

Stress cracking is more of an issue for ships and bridges. A print bed has virtually no load so there really isn't any chance of mechanical failure.

|

Re: Poor Man's Digital Dentist Core XY build July 08, 2017 09:22PM |

Registered: 8 years ago Posts: 338 |

|

Re: Poor Man's Digital Dentist Core XY build July 09, 2017 07:19PM |

Registered: 8 years ago Posts: 338 |

Another round of updates. I have figured out the z axis belt tensioning.

As you can see the bottom belt enters a printed block and then exits back out the bottom. I used another piece of belt along size to make sure it doesn't slip out. On the top, i have a screw and captive nut that pushes down on a block to pull the belt tight. I designed the part with some grooves so that it can't pop out. I didn't really have enough room for a belt along side the main belt where it exits (its there but only three teeth) so i zip-tied the belt together up top to stop it from slipping. It did not slip before i zip-tied it however. Over at it works

These are the things the belt pushes against. I put a bolt on the top where the other bolt pushes into this piece so that the plastic doesn't get worn or give as much. The little slot was for an alternate idea that didn't go anywhere . I was going to slide in a small washer and have the main screw hit that and feed through the plastic piece. This way is simpler and works.

. I was going to slide in a small washer and have the main screw hit that and feed through the plastic piece. This way is simpler and works.

Due to several factors i will need to redesign the hot end mount, as well as the x-rail. I am not happy with it ATM because it costs me too much y-space (3" almost) and i also need to be able to move it down about three inches. I think i will get another wider rail for the x axis and mount it in a more similar way to The Digital Dentists original design. In the end i may not go with the nimble because it creates about the same amount of problems as it solves. I bought it when i was committed to sticking with my Delta... was hoping i could repurpose it for the corexy but the drive cable will make an enclosure harder to design.

Figuring out the z-axis was so far the hardest part of the printer. I eventually settled on this set up. I had an extra 8mm rod, so cut it to length and mounted it to the top of the printer as you see. The pulley slides on the rod without a bearing. Its not the best, but i think for my purpose it will be OK. If not they do have some 5mm id 8mm od bearings. I can then get some 5mm rod and mount it in a similar way, with the bearing in-between the rod and pulley. Im up for other ideas as well.

I got the bed mount ready. The three black screws will be 50mm flat head screws that will be fed through the mic6 bed, with a spring, to allow me to level the bed. The aluminum blocks are tapped and there is a 6mm hole drilled through the extrusions to allow the screw to pass cleanly through without interference. I may need to beef this up, apparently the plate weighs 10 lbs!

Coming along.

Edited 2 time(s). Last edit at 07/09/2017 07:21PM by Qdeathstar.

As you can see the bottom belt enters a printed block and then exits back out the bottom. I used another piece of belt along size to make sure it doesn't slip out. On the top, i have a screw and captive nut that pushes down on a block to pull the belt tight. I designed the part with some grooves so that it can't pop out. I didn't really have enough room for a belt along side the main belt where it exits (its there but only three teeth) so i zip-tied the belt together up top to stop it from slipping. It did not slip before i zip-tied it however. Over at it works

These are the things the belt pushes against. I put a bolt on the top where the other bolt pushes into this piece so that the plastic doesn't get worn or give as much. The little slot was for an alternate idea that didn't go anywhere

. I was going to slide in a small washer and have the main screw hit that and feed through the plastic piece. This way is simpler and works.

. I was going to slide in a small washer and have the main screw hit that and feed through the plastic piece. This way is simpler and works.Due to several factors i will need to redesign the hot end mount, as well as the x-rail. I am not happy with it ATM because it costs me too much y-space (3" almost) and i also need to be able to move it down about three inches. I think i will get another wider rail for the x axis and mount it in a more similar way to The Digital Dentists original design. In the end i may not go with the nimble because it creates about the same amount of problems as it solves. I bought it when i was committed to sticking with my Delta... was hoping i could repurpose it for the corexy but the drive cable will make an enclosure harder to design.

Figuring out the z-axis was so far the hardest part of the printer. I eventually settled on this set up. I had an extra 8mm rod, so cut it to length and mounted it to the top of the printer as you see. The pulley slides on the rod without a bearing. Its not the best, but i think for my purpose it will be OK. If not they do have some 5mm id 8mm od bearings. I can then get some 5mm rod and mount it in a similar way, with the bearing in-between the rod and pulley. Im up for other ideas as well.

I got the bed mount ready. The three black screws will be 50mm flat head screws that will be fed through the mic6 bed, with a spring, to allow me to level the bed. The aluminum blocks are tapped and there is a 6mm hole drilled through the extrusions to allow the screw to pass cleanly through without interference. I may need to beef this up, apparently the plate weighs 10 lbs!

Coming along.

Edited 2 time(s). Last edit at 07/09/2017 07:21PM by Qdeathstar.

|

Re: Poor Man's Digital Dentist Core XY build July 10, 2017 02:52AM |

Registered: 8 years ago Posts: 5,232 |

Have you considered "Cam-followers" for the z-axis idler?

They have a smooth surface, but maybe you can integrate them in a ( printed ) pulley?

They have a smooth surface, but maybe you can integrate them in a ( printed ) pulley?

|

Re: Poor Man's Digital Dentist Core XY build July 10, 2017 07:06AM |

Registered: 11 years ago Posts: 5,780 |

The problem with putting the leveling screws into a block of metal is that you have to tap the hole for the screw's threads. That immediately makes it possible for the screw to wobble in the hole. The only way to lock it and prevent wobble is to add nuts to put tension on the screws, which complicates the leveling process- every time you tighten the nut, your leveling adjustment goes out so you have to go back and forth a few times to get it right. One of the reasons I used teflon blocks is that I could use undersized holes and drive the leveling screws in knowing that there would be zero play in the screw. Of course, it won't matter if you're going to use autoleveling. All you have to do is lock the bed down and you're good to go.

I know a lot of people use printed pulleys, but I'd rather use the smooth surface of a bearing (or cam follower). When you're trying to build a high precision/accuracy mechanism, the last place you want 3D printed parts is driving the belt. Think about what happens if the hole is slightly off center, or the overall shape is out of round, or the teeth aren't spaced perfectly (and a printed part will have all of these problems to some degree). 3D printers can't print with the sort of accuracy you get from the smooth metal surface of a bearing or the machined teeth of a metal pulley.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I know a lot of people use printed pulleys, but I'd rather use the smooth surface of a bearing (or cam follower). When you're trying to build a high precision/accuracy mechanism, the last place you want 3D printed parts is driving the belt. Think about what happens if the hole is slightly off center, or the overall shape is out of round, or the teeth aren't spaced perfectly (and a printed part will have all of these problems to some degree). 3D printers can't print with the sort of accuracy you get from the smooth metal surface of a bearing or the machined teeth of a metal pulley.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Poor Man's Digital Dentist Core XY build July 10, 2017 07:59AM |

Registered: 8 years ago Posts: 338 |

|

Re: Poor Man's Digital Dentist Core XY build July 10, 2017 10:05AM |

Registered: 11 years ago Posts: 5,780 |

Springs can't supply nearly enough tension to prevent the screws from wobbling in the holes. Teflon tape is soft and will get pushed out of contact areas and into gaps, which is why plumbers use it for sealing pipes.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Poor Man's Digital Dentist Core XY build July 10, 2017 11:35AM |

Registered: 8 years ago Posts: 338 |

|

Re: Poor Man's Digital Dentist Core XY build July 10, 2017 01:26PM |

Registered: 11 years ago Posts: 5,780 |

I used stacked F608zz bearings for the top pulleys. No teeth.

If the leveling screws go into 10-15 mm of teflon, they will be very stable. Look up the drill size for tapping threads that matches the size of screw that you're going to use. Drill that size hole, and then just drive the screws into the teflon without tapping.

Edited 1 time(s). Last edit at 07/10/2017 01:28PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

If the leveling screws go into 10-15 mm of teflon, they will be very stable. Look up the drill size for tapping threads that matches the size of screw that you're going to use. Drill that size hole, and then just drive the screws into the teflon without tapping.

Edited 1 time(s). Last edit at 07/10/2017 01:28PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Poor Man's Digital Dentist Core XY build July 10, 2017 03:37PM |

Registered: 8 years ago Posts: 338 |

|

Re: Poor Man's Digital Dentist Core XY build July 10, 2017 06:18PM |

Registered: 11 years ago Posts: 5,780 |

That's insane.

1"x 3.2"x12" $37: [www.ebay.com]

30mm dia x 100mm long $17: [www.aliexpress.com]

Or check your local plastics suppliers for cut-offs. I recently bought 3 pieces of teflon about 15 x 20 x 75 mm for $7 at my local Midland Plastics shop.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

1"x 3.2"x12" $37: [www.ebay.com]

30mm dia x 100mm long $17: [www.aliexpress.com]

Or check your local plastics suppliers for cut-offs. I recently bought 3 pieces of teflon about 15 x 20 x 75 mm for $7 at my local Midland Plastics shop.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Poor Man's Digital Dentist Core XY build July 10, 2017 07:25PM |

Registered: 8 years ago Posts: 338 |

|

Re: Poor Man's Digital Dentist Core XY build July 11, 2017 01:44AM |

Registered: 11 years ago Posts: 5,780 |

I have some random pieces of Torlon I can send to you if you PM your address to me. Torlon won't mind the heat, but it's a little difficult to work with.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Poor Man's Digital Dentist Core XY build July 11, 2017 08:21AM |

Registered: 8 years ago Posts: 338 |

|

Re: Poor Man's Digital Dentist Core XY build July 14, 2017 02:38PM |

Registered: 8 years ago Posts: 338 |

Well, I've been wanting a milling machine for a little while now, and I finally talked myself into making an investment that will never pay for itself. Not a Bridgeport but I think it will suit my needs for long while. Mmm Chinesium. Grizzly g0672 with dro added. I did look for used Bridgeport first, but all of them in the $2500 price range were rust buckets... plus, a Bridgeport weighs 2500lbs... this is s more manageable but still significant 760 lbs (plus 250 for the base)

This is going to delay my printer project for a while

This is going to delay my printer project for a while

|

Re: Poor Man's Digital Dentist Core XY build July 14, 2017 04:56PM |

Registered: 6 years ago Posts: 48 |

I found this on amazon: [www.amazon.com]Quote

Qdeathstar

Grizzly g0672

Are you sure its a milling machine?

Edited 1 time(s). Last edit at 07/14/2017 04:56PM by DerEchteLanger.

|

Re: Poor Man's Digital Dentist Core XY build July 14, 2017 05:27PM |

Registered: 8 years ago Posts: 338 |

|

Re: Poor Man's Digital Dentist Core XY build July 14, 2017 07:20PM |

Registered: 7 years ago Posts: 249 |

|

Re: Poor Man's Digital Dentist Core XY build July 14, 2017 08:52PM |

Registered: 8 years ago Posts: 338 |

|

Re: Poor Man's Digital Dentist Core XY build August 10, 2017 03:40AM |

Registered: 8 years ago Posts: 1,671 |

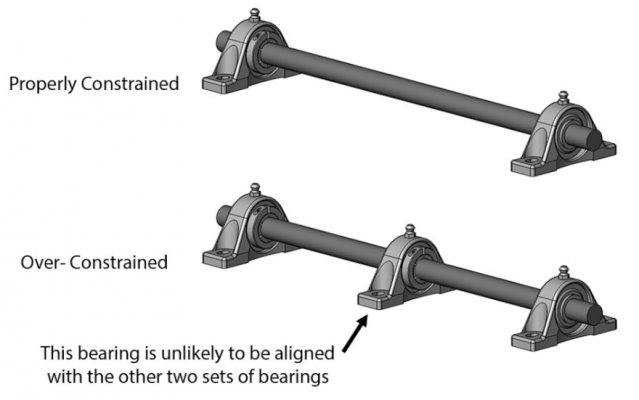

By having the motor in the middle with no couplers does it become over constrained or is it 2 shafts.

|

Re: Poor Man's Digital Dentist Core XY build August 10, 2017 07:39AM |

Registered: 11 years ago Posts: 5,780 |

In my printer there is a single long shaft that goes through the disc gear in the worm gear reducer. There are spacers that put the end bearings axes at the same Y level as the shaft, and the holes in the pillow blocks are larger than the screws that hold them down, allowing some slight positional shifting in Z. The motor mount plate holes are also larger than the screws, allowing for some slop in the positioning of the motor. The bearings in the pillow blocks can tilt in the blocks. When I assembled the thing, I tightened down the screws on the pillow blocks first, setting the position of the shaft, then tightened down the motor mount plates. The shaft is keyed, as is the output of the worm drive gear box. There was no obvious misalignment when I assembled it (had there been I would have made a new set of plastic spacers for the pillow blocks).

Putting the motor in the middle of the shaft ensures that the shaft to belt distance is the same on both sides of the motor which means the torsion should be the same on both sides regardless of the print mass. You could put the motor at one end and eliminate one of the pillow blocks, (and the overconstraint) but then you'd have one pulley with effectively zero torsion and the other with 2X the torsion we have with the motor in the middle. It's possible that there is some lateral stress on the shaft due to inaccurate positioning of the pillow blocks, but the shaft will flex (as it will twist), and the output has a LOT more torque than needed to just lift the bed, so it works fine. You can't put the motor in the middle and eliminate one of the pillow blocks because the shaft on the side of the pulley without the pillow block will bend like crazy due to belt tension. That tension will increase with the print mass, so the bending would increase, too.

How would you mount it that would be an improvement over the way I did it? You could put a motor at each pulley, but then you get back to the whole keeping two motors synchronized problem. At some point I'll probably replace the plastic spacers with milled aluminum, but that's low on the priority list. Plastic spacers in compression hold up well.

TLDR: it's only overconstraint if the shaft is ideal and can't flex. But it can and does if necessary. Look at any printer made using 8mm guide rails if you want to see how much an 8mm shaft can flex. They can flex a lot more than slight misalignment in this mechanism asks them to.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Putting the motor in the middle of the shaft ensures that the shaft to belt distance is the same on both sides of the motor which means the torsion should be the same on both sides regardless of the print mass. You could put the motor at one end and eliminate one of the pillow blocks, (and the overconstraint) but then you'd have one pulley with effectively zero torsion and the other with 2X the torsion we have with the motor in the middle. It's possible that there is some lateral stress on the shaft due to inaccurate positioning of the pillow blocks, but the shaft will flex (as it will twist), and the output has a LOT more torque than needed to just lift the bed, so it works fine. You can't put the motor in the middle and eliminate one of the pillow blocks because the shaft on the side of the pulley without the pillow block will bend like crazy due to belt tension. That tension will increase with the print mass, so the bending would increase, too.

How would you mount it that would be an improvement over the way I did it? You could put a motor at each pulley, but then you get back to the whole keeping two motors synchronized problem. At some point I'll probably replace the plastic spacers with milled aluminum, but that's low on the priority list. Plastic spacers in compression hold up well.

TLDR: it's only overconstraint if the shaft is ideal and can't flex. But it can and does if necessary. Look at any printer made using 8mm guide rails if you want to see how much an 8mm shaft can flex. They can flex a lot more than slight misalignment in this mechanism asks them to.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Poor Man's Digital Dentist Core XY build August 10, 2017 07:45AM |

Registered: 8 years ago Posts: 338 |

|

Re: Poor Man's Digital Dentist Core XY build August 10, 2017 12:20PM |

Registered: 8 years ago Posts: 88 |

Quote

Qdeathstar

my mill is sitting at my office waiting to be brought home... then, back to the 3d printer.... Hopefully i get the mill up this weekend

I was faster this year

Sorry, only registered users may post in this forum.