CoreXY, fixed bed

Posted by McZ

|

CoreXY, fixed bed May 12, 2017 05:02AM |

Registered: 6 years ago Posts: 2 |

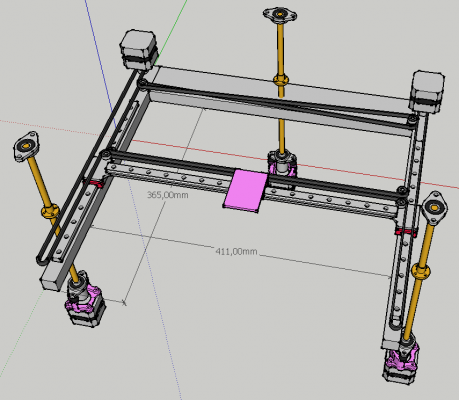

Any issues with my idea of a CoreXY design with fixed bed?

using 2x300mm MGN12 rails for Y and 1x400mm MGN12 rail for X. And then there is 20x20 T-Slot extrusion holding the Y rails and they are fixed together with a 20x60 T-Slot in the back.

I have 3 lead screws for the z-axis (200-300mm) and I am planning to use one stepper for each screw, to get the bed leveling like the Sparkcube v1.1 XL.

Will the open front gantry design flex to much?

using 2x300mm MGN12 rails for Y and 1x400mm MGN12 rail for X. And then there is 20x20 T-Slot extrusion holding the Y rails and they are fixed together with a 20x60 T-Slot in the back.

I have 3 lead screws for the z-axis (200-300mm) and I am planning to use one stepper for each screw, to get the bed leveling like the Sparkcube v1.1 XL.

Will the open front gantry design flex to much?

|

Re: CoreXY, fixed bed May 12, 2017 06:08AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: CoreXY, fixed bed May 12, 2017 09:03AM |

Registered: 9 years ago Posts: 251 |

|

Re: CoreXY, fixed bed May 12, 2017 10:52AM |

Registered: 11 years ago Posts: 5,780 |

The biggest problem with lifting the XY mechanism is that it has a lot of moving mass that gets thrown around at print speed. You'll need some pretty solid bearings and rails to prevent the whole thing from wobbling. Then there's all the cables. I suppose you could attach the electronics to the part being lifted and then only the power cable would have to move, but figuring out where to put that stuff could get tricky.

Edited 1 time(s). Last edit at 05/12/2017 10:57AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Edited 1 time(s). Last edit at 05/12/2017 10:57AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: CoreXY, fixed bed May 12, 2017 11:41AM |

Registered: 7 years ago Posts: 249 |

With linear guides, the front won't flex, as the gantry provides more than enough bracing.

Plus, your "U" frame will also add to the rigidity. Though I would have a concern of the "U" arms flexing up and down.

Adding triangle shaped gussets under the "U" arms, with their points forward and a tall flat back plate, will help minimize vertical deflection.

How are you guiding the Z axis? It will need to be able to handle the moving masses of the gantry and X carriage without allowing shake.

Surprised DD didn't jump your case about using 3 independent Z motors, rather than one large stepper belted to the screws... meh

Plus, your "U" frame will also add to the rigidity. Though I would have a concern of the "U" arms flexing up and down.

Adding triangle shaped gussets under the "U" arms, with their points forward and a tall flat back plate, will help minimize vertical deflection.

How are you guiding the Z axis? It will need to be able to handle the moving masses of the gantry and X carriage without allowing shake.

Surprised DD didn't jump your case about using 3 independent Z motors, rather than one large stepper belted to the screws... meh

|

Re: CoreXY, fixed bed May 12, 2017 01:03PM |

Registered: 11 years ago Posts: 5,780 |

You didn't watch the video- the motors are independently controlled to level the bed at the start of each print. That requires 3 motor drivers, 3 motors, and 3 cables instead of one of each, and a power supply to accommodate them, and if you do it right, 3 limit switches, so it isn't economically justified. The extruder carriage is carrying the extra weight of the bed sensor all the time, even though it's only needed at the start of the print, and it needs another cable.

Leveling the bed serves only two purposes - to get the first layer to stick, and to add one more feature for the printer's marketing literature. Having to relevel the bed with every print is a sign of poor printer construction, which goes hand in hand with poor print quality and/or reliability. If the printer doesn't need to be releveled with each print but has autoleveling anyway, you're going to pay a much higher price for the printer because it has all that unnecessary hardware.

One motor, one driver, and a looped belt with pulleys would be cheaper, more reliable, and easier to troubleshoot, but a lot of people in the 3D printing world seem to like to create complex solutions to nonexistent problems, or problems that are better solved in simpler ways. If they had put the money for all the motors and drivers, etc., into improving the machine's structure, not only would the first layer stick, but the print quality would improve, and the machine would be more reliable and easier to fix when the time comes.

Have doubts about decreased reliability? Look how many posts there are from people with i3 type machines that have 2 Z motors (usually driven by one driver) complaining about not being able to level their print beds, and discovering that the X axis has tilted so far that the z axis is binding, or related problems. Now imagine what throwing a third motor into that scenario is likely to do.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Leveling the bed serves only two purposes - to get the first layer to stick, and to add one more feature for the printer's marketing literature. Having to relevel the bed with every print is a sign of poor printer construction, which goes hand in hand with poor print quality and/or reliability. If the printer doesn't need to be releveled with each print but has autoleveling anyway, you're going to pay a much higher price for the printer because it has all that unnecessary hardware.

One motor, one driver, and a looped belt with pulleys would be cheaper, more reliable, and easier to troubleshoot, but a lot of people in the 3D printing world seem to like to create complex solutions to nonexistent problems, or problems that are better solved in simpler ways. If they had put the money for all the motors and drivers, etc., into improving the machine's structure, not only would the first layer stick, but the print quality would improve, and the machine would be more reliable and easier to fix when the time comes.

Have doubts about decreased reliability? Look how many posts there are from people with i3 type machines that have 2 Z motors (usually driven by one driver) complaining about not being able to level their print beds, and discovering that the X axis has tilted so far that the z axis is binding, or related problems. Now imagine what throwing a third motor into that scenario is likely to do.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: CoreXY, fixed bed May 14, 2017 12:05PM |

Registered: 6 years ago Posts: 2 |

Thanks for all answers

My plan was to start with a belt for the three z-axis. Then later "upgrade" to 3 independet steppers for autoleveling. But like the_digital_dentist says, it is better to build a rigid frame.

If I fix my current XY gantry to a 20x20mm T-slot cube frame, will it be strong enough with the u-shape I have? I like the open front for accessibility.

Anyone using Dibond? the aluminium sandwich stuff? Was thinking of a Dibond back panel and bottom panel, above z-steppers.

My plan was to start with a belt for the three z-axis. Then later "upgrade" to 3 independet steppers for autoleveling. But like the_digital_dentist says, it is better to build a rigid frame.

If I fix my current XY gantry to a 20x20mm T-slot cube frame, will it be strong enough with the u-shape I have? I like the open front for accessibility.

Anyone using Dibond? the aluminium sandwich stuff? Was thinking of a Dibond back panel and bottom panel, above z-steppers.

|

Re: CoreXY, fixed bed May 15, 2017 03:55AM |

Registered: 8 years ago Posts: 5,232 |

Sorry, only registered users may post in this forum.