Building a custom CoreXY

Posted by OutcastZeroOne

|

Building a custom CoreXY July 02, 2017 12:12PM |

Registered: 6 years ago Posts: 36 |

This is to be a build log for a custom machine I am making.

Parts list so far:

24v 15amp power supply

NEMA 17 motors

V6 clone hotend

DUET board

13"x13" build plate

400mm rods and screw drives

custom made Zesty Nimble extruder

power monitor for seeing power usage

12864 LCD

Rasberry PI with 7" touch screen, though may change this

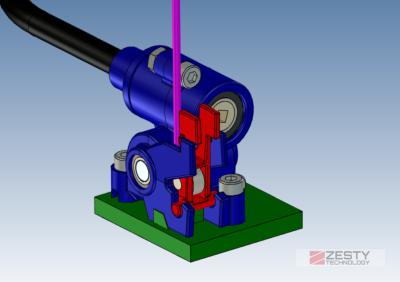

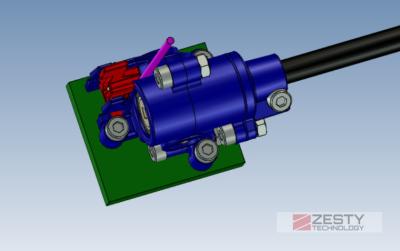

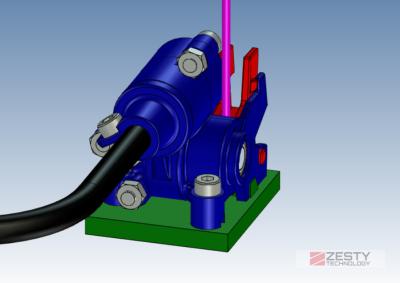

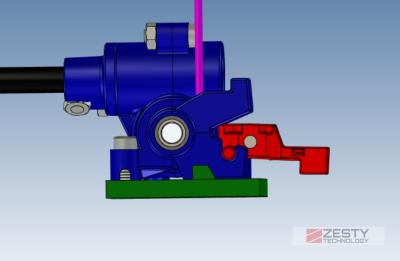

So, I have been working on a custom CoreXY machine. Have a large 13”x13” build plate and have been slowly gathering parts to put this together.I was wanting to keep it as confined to the inside of the frame of the machine. Original plan was to use a bowden but then I found the Zesty Nimble. After talking with Brian and Lykle I asked them if it was possible to make one that had its drive cable come in from the side. Within a day they had drawn up plans for a unit, here it is, the Sidewinder! (working title).

For those of you who don’t know what the Nimble system is, its a cable driven extruder. It gives you all the lightness of a bowden setup, but without the backlash of bound material in the tube. The guys have been hard at work testing out the new design and I should be the proud owner of the first of these new units. For anyone else doing a CoreXY they will also have the unit up for sale soon! Soon as I get mine up and running Ill be sure to show you all what it can do!

Plan for now is to make the frame from 1" birch plywood. Laying out everything best as I can for most efficient thermal layout. Electronics down low, build area up top. Once i get all the parts I should start building the fram fairly quickly. Just dont want to build something only to find something needed more room.

Edited 1 time(s). Last edit at 07/02/2017 12:17PM by OutcastZeroOne.

Parts list so far:

24v 15amp power supply

NEMA 17 motors

V6 clone hotend

DUET board

13"x13" build plate

400mm rods and screw drives

custom made Zesty Nimble extruder

power monitor for seeing power usage

12864 LCD

Rasberry PI with 7" touch screen, though may change this

So, I have been working on a custom CoreXY machine. Have a large 13”x13” build plate and have been slowly gathering parts to put this together.I was wanting to keep it as confined to the inside of the frame of the machine. Original plan was to use a bowden but then I found the Zesty Nimble. After talking with Brian and Lykle I asked them if it was possible to make one that had its drive cable come in from the side. Within a day they had drawn up plans for a unit, here it is, the Sidewinder! (working title).

For those of you who don’t know what the Nimble system is, its a cable driven extruder. It gives you all the lightness of a bowden setup, but without the backlash of bound material in the tube. The guys have been hard at work testing out the new design and I should be the proud owner of the first of these new units. For anyone else doing a CoreXY they will also have the unit up for sale soon! Soon as I get mine up and running Ill be sure to show you all what it can do!

Plan for now is to make the frame from 1" birch plywood. Laying out everything best as I can for most efficient thermal layout. Electronics down low, build area up top. Once i get all the parts I should start building the fram fairly quickly. Just dont want to build something only to find something needed more room.

Edited 1 time(s). Last edit at 07/02/2017 12:17PM by OutcastZeroOne.

|

Re: Building a custom CoreXY July 02, 2017 05:02PM |

Registered: 8 years ago Posts: 601 |

I saw this in there recent newsletter. It is an interesting idea but unfortunately it doesn't address the issue that the filament must also enter from the top. On brittle filaments especially you might find that the bend radius allowed by the filament is not too dissimilar to that of the drive cable. If so the drive cable may as well be routed with the filament path.

Also, the bend in the drive cable may not be enough to utilise the full area in a coreXY, for example if the cable exited at the back, the gantry may not move to the maximum of X and Y or the extra drag of the cable may cause missed steps. Most cable chains have a wide arc that slightly snakes around the gantry, or use a tight U so that space is maximised.

This design may still be useful for head clearance on some Cartesian machines. A slight rejig of my gantry gave an extra 30mm of Z height... This might give me another 20mm.

Edited 2 time(s). Last edit at 07/03/2017 01:36AM by Origamib.

Also, the bend in the drive cable may not be enough to utilise the full area in a coreXY, for example if the cable exited at the back, the gantry may not move to the maximum of X and Y or the extra drag of the cable may cause missed steps. Most cable chains have a wide arc that slightly snakes around the gantry, or use a tight U so that space is maximised.

This design may still be useful for head clearance on some Cartesian machines. A slight rejig of my gantry gave an extra 30mm of Z height... This might give me another 20mm.

Edited 2 time(s). Last edit at 07/03/2017 01:36AM by Origamib.

|

Re: Building a custom CoreXY July 02, 2017 05:35PM |

Registered: 11 years ago Posts: 1,049 |

As said by old sage Digital Dentist

work from inside out

13 x 13 build plate? Is there a 13 x 13 heater in your parts?

a 13 x 13 aluminum tooling plate?

some linear rails and slides also on BOM?

1" birch ply? -- must be outside US --- 7 ply birch plywood rare / expensive?

How will you square and fasten your birch ply sides?

Inserts or the hardware used to put together furniture may be good?

[www.wwhardware.com]

Good luck with lumber frame?

work from inside out

13 x 13 build plate? Is there a 13 x 13 heater in your parts?

a 13 x 13 aluminum tooling plate?

some linear rails and slides also on BOM?

1" birch ply? -- must be outside US --- 7 ply birch plywood rare / expensive?

How will you square and fasten your birch ply sides?

Inserts or the hardware used to put together furniture may be good?

[www.wwhardware.com]

Good luck with lumber frame?

|

Re: Building a custom CoreXY July 02, 2017 11:07PM |

Registered: 7 years ago Posts: 249 |

|

Re: Building a custom CoreXY July 03, 2017 01:43AM |

Registered: 8 years ago Posts: 312 |

Good points Origamib,

I looked at how I could lower the filament as well, but in the end it needs to be vertical by the time it enters that hot end.

Using an Aero style hot end will lower that point, but the issue remains.

(btw, I found old PLA to be the most brittle filament, you know anything more brittle?)

And as to the print area, yes, it all depends on how the drive cable and other wires are routed. So, again, agree.

The main thing is that it gives a choice, it is simply another option for an extruder that might work for somebody. That the ultimate usefulness is limited, I have no doubt, it might just be the perfect fit for Outcast. We will see.

But oh, it was such fun to design it and get a working model out so fast!

Lykle

________________________________________________

Co-creator of the Zesty Nimble, worlds lightest Direct Drive extruder.

[zesty.tech]

I looked at how I could lower the filament as well, but in the end it needs to be vertical by the time it enters that hot end.

Using an Aero style hot end will lower that point, but the issue remains.

(btw, I found old PLA to be the most brittle filament, you know anything more brittle?)

And as to the print area, yes, it all depends on how the drive cable and other wires are routed. So, again, agree.

The main thing is that it gives a choice, it is simply another option for an extruder that might work for somebody. That the ultimate usefulness is limited, I have no doubt, it might just be the perfect fit for Outcast. We will see.

But oh, it was such fun to design it and get a working model out so fast!

Lykle

________________________________________________

Co-creator of the Zesty Nimble, worlds lightest Direct Drive extruder.

[zesty.tech]

|

Re: Building a custom CoreXY July 03, 2017 08:12AM |

Registered: 8 years ago Posts: 601 |

Quote

Lykle

Good points Origamib,

I looked at how I could lower the filament as well, but in the end it needs to be vertical by the time it enters that hot end.

Using an Aero style hot end will lower that point, but the issue remains.

(btw, I found old PLA to be the most brittle filament, you know anything more brittle?)

And as to the print area, yes, it all depends on how the drive cable and other wires are routed. So, again, agree.

The main thing is that it gives a choice, it is simply another option for an extruder that might work for somebody. That the ultimate usefulness is limited, I have no doubt, it might just be the perfect fit for Outcast. We will see.

But oh, it was such fun to design it and get a working model out so fast!

The options are nice to have I would agree. I think it's usefulness will be on standard Cartesian machines (prusa style perhaps) where the drive cable could exit out the back, rather then take up valuable Z height.

I think the answer to the filament issue lies with the hotend and developing a 90 degree meltzone. I believe this should not affect retractions but will likely require a totally new heatblock and nozzle system.

Colorfabb carbon fibre and other filled filaments are very brittle in my experience.

|

Re: Building a custom CoreXY July 03, 2017 03:03PM |

Registered: 8 years ago Posts: 776 |

Quote

OutcastZeroOne

custom made Zesty Nimble extruder

niiiice. looked at the zesty nimble, it seems extremely good: compact, light-weight. i am a huge fan of mutley3d's flex3drive concept, which is engineered the same way. 40:1 worm drive which is specificallly made of a material that has lubrication infused into the plastic (instead of 30:1 gearing of an unspecified type made of unspecified material) and an automotive grade flexible driveshaft. how i know the things that i do about the fllex3drive is because i went to meet jason in the UK and talked with him for several hours.

here's the thing: zesty is extremely short on technical specs. they go into a lot of promotional aspects about how clever the shape is, but make absolutely no mention whatsoever about really critical things like the materials specification of the gears and the flexible driveshaft. i also note that there appears to be no outer casing on the flexible shaft (no closeup photos so it's hard to tell). this has me concerned.

so whilst i know that the flexible drive concept is a huge leap over both bowden and direct drive, zesty's lack of critical information should prompt you to be asking questions before committing to their products. if it was a properly open design there would be no problem. you could analyse the design and parts.

|

Re: Building a custom CoreXY July 03, 2017 05:35PM |

Registered: 8 years ago Posts: 338 |

I thought I had read they liscened the product from direct3drive (or something, there was an argument over ethics on the kickstarter page but mutley3D never addressed it) and its not like flexible drive shafts are particularly special. It does have an outer jacket. However I do agree they should be more open about the specs, particularly in the measurements department... they won't release any of the models so if a part breaks (it's just sls nylon) your pretty much f*cked... and the breach looks extremely susceptible to fatigue breakage. the gears are off the shelf made from nylon.. they added a dribble of lubricant.

Edited 1 time(s). Last edit at 07/03/2017 05:56PM by Qdeathstar.

Edited 1 time(s). Last edit at 07/03/2017 05:56PM by Qdeathstar.

|

Re: Building a custom CoreXY July 04, 2017 01:44AM |

Registered: 8 years ago Posts: 312 |

Hi guys,

@lckl Thanks for the compliment. Worked hard to get it compact.

Just a quick mention of a couple of facts.

We have published the POM used in the gears, can't find it now but will get back to you on that. Was back in the Kickstarter days.

Everything in the Nimble is designed by me, working with Brian. The only off the shelf components are the bearings and the nuts and bolts. The hob, the gears, the shell, it is all my own work. We own the moulds and the special tools made to be able to make the hob. Of course the drive cable is automotive quality, it is almost the only industry these specific cables are used in. As to measurements, all the Nimbles have mockups in the Thingiverse page. And spare parts will be available soon, nobody has needed any yet, despite the heavy use we see.

Lykle

@lckl Thanks for the compliment. Worked hard to get it compact.

Just a quick mention of a couple of facts.

We have published the POM used in the gears, can't find it now but will get back to you on that. Was back in the Kickstarter days.

Everything in the Nimble is designed by me, working with Brian. The only off the shelf components are the bearings and the nuts and bolts. The hob, the gears, the shell, it is all my own work. We own the moulds and the special tools made to be able to make the hob. Of course the drive cable is automotive quality, it is almost the only industry these specific cables are used in. As to measurements, all the Nimbles have mockups in the Thingiverse page. And spare parts will be available soon, nobody has needed any yet, despite the heavy use we see.

Lykle

|

Re: Building a custom CoreXY July 04, 2017 01:44AM |

Registered: 8 years ago Posts: 312 |

Hi guys,

@lckl Thanks for the compliment. Worked hard to get it compact.

Just a quick mention of a couple of facts.

We have published the POM used in the gears, can't find it now but will get back to you on that. Was back in the Kickstarter days.

Everything in the Nimble is designed by me, working with Brian. The only off the shelf components are the bearings and the nuts and bolts. The hob, the gears, the shell, it is all my own work. We own the moulds and the special tools made to be able to make the hob. Of course the drive cable is automotive quality, it is almost the only industry these specific cables are used in. As to measurements, all the Nimbles have mockups in the Thingiverse page. And spare parts will be available soon, nobody has needed any yet, despite the heavy use we see.

Lykle

@lckl Thanks for the compliment. Worked hard to get it compact.

Just a quick mention of a couple of facts.

We have published the POM used in the gears, can't find it now but will get back to you on that. Was back in the Kickstarter days.

Everything in the Nimble is designed by me, working with Brian. The only off the shelf components are the bearings and the nuts and bolts. The hob, the gears, the shell, it is all my own work. We own the moulds and the special tools made to be able to make the hob. Of course the drive cable is automotive quality, it is almost the only industry these specific cables are used in. As to measurements, all the Nimbles have mockups in the Thingiverse page. And spare parts will be available soon, nobody has needed any yet, despite the heavy use we see.

Lykle

|

Re: Building a custom CoreXY July 04, 2017 10:52AM |

Registered: 8 years ago Posts: 338 |

|

Re: Building a custom CoreXY July 04, 2017 11:54AM |

Registered: 8 years ago Posts: 601 |

Quote

lkcl

here's the thing: zesty is extremely short on technical specs. they go into a lot of promotional aspects about how clever the shape is, but make absolutely no mention whatsoever about really critical things like the materials specification of the gears and the flexible driveshaft. i also note that there appears to be no outer casing on the flexible shaft (no closeup photos so it's hard to tell). this has me concerned.Quote

OutcastZeroOne

custom made Zesty Nimble extruder

so whilst i know that the flexible drive concept is a huge leap over both bowden and direct drive, zesty's lack of critical information should prompt you to be asking questions before committing to their products. if it was a properly open design there would be no problem. you could analyse the design and parts.

This is a very good point on technical specs... What is the working bend radius of the drive cable? Is function inhibited after a certain amount? These are important points for enclosing a printer, and how well a sidewinder nimble would work in a CoreXY application.

|

Re: Building a custom CoreXY July 04, 2017 12:13PM |

Registered: 8 years ago Posts: 312 |

Yep, you are right.

In this case it is a lot more important than in a Delta where the bend radius is almost always shaped by the sleeve well within the safety margins.

But this is a work in progress, it is not a product yet, it is still under development and it will be changed before we add it as a product.

as for tech details. I am sure we have mentioned it a few times and I am pretty sure we wrote it on the site.

I will do some digging. Minimum bend radius is 75 mm by the way.

On a different note, I now have the latest prototype and as soon as a printer is free I will put it on there and start testing it. This one has had some big design changes and I already see that I will need to modify the breech block a little bit. The trick is to do it in such a way that the filament path is still completely enclosed when the breech is closed.

Always onwards and upwards.

ps, I will dig up where we posted the tech details and I will add them to the site, where needed.

In this case it is a lot more important than in a Delta where the bend radius is almost always shaped by the sleeve well within the safety margins.

But this is a work in progress, it is not a product yet, it is still under development and it will be changed before we add it as a product.

as for tech details. I am sure we have mentioned it a few times and I am pretty sure we wrote it on the site.

I will do some digging. Minimum bend radius is 75 mm by the way.

On a different note, I now have the latest prototype and as soon as a printer is free I will put it on there and start testing it. This one has had some big design changes and I already see that I will need to modify the breech block a little bit. The trick is to do it in such a way that the filament path is still completely enclosed when the breech is closed.

Always onwards and upwards.

ps, I will dig up where we posted the tech details and I will add them to the site, where needed.

|

Re: Building a custom CoreXY July 05, 2017 09:59PM |

Registered: 6 years ago Posts: 36 |

wow, for what is to be a build log, this has seemed to have turned into a bash rant.

1. Wood is strong, I work with wood all the time. Having been in the car stereo industry for the past 11+ years I work with wood all the time to build rock solid sub boxes from MDF to birch ply depending on the application. If you think otherwise then you either dont have much wood working skill or have only used poor quality materials. Making things square is really simple, you measure. Im doing 1" because it is overkill :p and Im getting furnature grade material, not the stuff construction crews slap on a building. Wood can be very clean and turn out very nice. And yes, I live in America

2. Yes, i have 8mm linear rails and bearings for movement, excuse me for not listing every single part.

3. Yes, its a 13x13 heated bed, they do make those. The design will allow for easy swapping and upgrade of parts as needed.

4. I dont use cheap filament. I have yet to get a single roll of ABS that had any issue. Everything I do will be exposed to the weather in some form or another, and do not use PLA for that reason since, as even Dremal states in the description of their machine "PLA is in a constant state of decomposition". It being vegetable base, it is designed to decompose.

5. there will also be a filtration system on the machine to deal with fumes from ABS. the frame will also be enclosed to retain a more stable enviroment. Throwing around the idea of also including a thermostat driven fan to regulate temperature inside.

6.The bend radius of the drive cable and filament are being taken into consideration with the build. Until I have the unit in hand, I am not doing any construction so that I can see all parts in hand and build accordingly.

Here I was hoping for comments of encouragement, instead half are bashing "youre an idiot for doing that"

1. Wood is strong, I work with wood all the time. Having been in the car stereo industry for the past 11+ years I work with wood all the time to build rock solid sub boxes from MDF to birch ply depending on the application. If you think otherwise then you either dont have much wood working skill or have only used poor quality materials. Making things square is really simple, you measure. Im doing 1" because it is overkill :p and Im getting furnature grade material, not the stuff construction crews slap on a building. Wood can be very clean and turn out very nice. And yes, I live in America

2. Yes, i have 8mm linear rails and bearings for movement, excuse me for not listing every single part.

3. Yes, its a 13x13 heated bed, they do make those. The design will allow for easy swapping and upgrade of parts as needed.

4. I dont use cheap filament. I have yet to get a single roll of ABS that had any issue. Everything I do will be exposed to the weather in some form or another, and do not use PLA for that reason since, as even Dremal states in the description of their machine "PLA is in a constant state of decomposition". It being vegetable base, it is designed to decompose.

5. there will also be a filtration system on the machine to deal with fumes from ABS. the frame will also be enclosed to retain a more stable enviroment. Throwing around the idea of also including a thermostat driven fan to regulate temperature inside.

6.The bend radius of the drive cable and filament are being taken into consideration with the build. Until I have the unit in hand, I am not doing any construction so that I can see all parts in hand and build accordingly.

Here I was hoping for comments of encouragement, instead half are bashing "youre an idiot for doing that"

|

Re: Building a custom CoreXY July 05, 2017 10:43PM |

Registered: 8 years ago Posts: 338 |

I don't think anyone is calling you an idiot.... you are too sensitive. What i saw was someone asking questions and giving you something to consider. Wood expands when it is heated and warps over time... not a good thing when you are talking about a printer which requires preciseness. But if you like working the wood, go for it. That is what reprap is about.

Edited 1 time(s). Last edit at 07/05/2017 10:44PM by Qdeathstar.

Edited 1 time(s). Last edit at 07/05/2017 10:44PM by Qdeathstar.

|

Re: Building a custom CoreXY July 06, 2017 07:12AM |

Registered: 8 years ago Posts: 312 |

|

Re: Building a custom CoreXY July 06, 2017 03:25PM |

Registered: 8 years ago Posts: 601 |

I don't think anyone called you an idiot. It is kind of the standard on these forums to question everything. It isn't an insult, it is just curiosity and debate.

To me, the bend radius is highly important as my designs tend to be compact, and utilise as much space as possible. With the drive cable exiting at 90degrees you may find your machine growing considerably in the XY axis and you may have limitations to print size. Maybe it would make sense to make the printer taller with a standard nimble instead. I look forward to seeing your solution to this.

To me, the bend radius is highly important as my designs tend to be compact, and utilise as much space as possible. With the drive cable exiting at 90degrees you may find your machine growing considerably in the XY axis and you may have limitations to print size. Maybe it would make sense to make the printer taller with a standard nimble instead. I look forward to seeing your solution to this.

|

Re: Building a custom CoreXY July 08, 2017 06:57AM |

Registered: 8 years ago Posts: 776 |

Quote

Lykle

Hi guys,

@lkcl Thanks for the compliment. Worked hard to get it compact.

Just a quick mention of a couple of facts.

We have published the POM used in the gears, can't find it now but will get back to you on that. Was back in the Kickstarter days.

Everything in the Nimble is designed by me, working with Brian. The only off the shelf components are the bearings and the nuts and bolts. The hob, the gears, the shell, it is all my own work.

very cool. mutley3d btw used a special lubricant that can be infused in the actual plastic, so that the injection-molded gears are entirely maintenance-free, meaning that they're self-lubricating. mutley3d thus offers a lifetime-warranty on the gears. i'd recommend investigating that as it would be... unfortunate if the gears wore out.

btw if you provided a "kit" - the full parts (gears, hob, bearings) plus the STL files under an open license (NOT that stupid stupid quotes non-commercial quotes creative commons one) - i would be interested to buy 10 zestys. the reason is: i have 10 printers to put together (starting with a crowd-funding campaign and also a 3D printing farm), but may need to make modifications. as has been demonstrated in this thread, you've made one set of special modifications already: that takes up your time... and then there's another request, and another, and another, and another....

can you satisfy each and every request? i know that mutley3d is pretty overloaded with feature requests, adapter requests and so on: if your product becomes popular the same thing will happen to you. so. would you be interested to nip that in the bud and provide kits (with STL files) instead?

|

Re: Building a custom CoreXY July 08, 2017 07:12AM |

Registered: 8 years ago Posts: 312 |

No, we are developing a few more Nimbles for specific applications, but there is no danger of us getting overloaded.

Even found time to design an effector for a competing extruder. (started off as a joke, turned serious fast)

Besides, adapters are easy to design. As long as the base is correct.

And by the way, all the design files for the adapters, adapter bases and groove mount adapter are freely available. A lot of people design their own.

Thank you for your concern, but we are not overloaded. Thanks.

Lykle

________________________________________________

Co-creator of the Zesty Nimble, worlds lightest Direct Drive extruder.

[zesty.tech]

Even found time to design an effector for a competing extruder. (started off as a joke, turned serious fast)

Besides, adapters are easy to design. As long as the base is correct.

And by the way, all the design files for the adapters, adapter bases and groove mount adapter are freely available. A lot of people design their own.

Thank you for your concern, but we are not overloaded. Thanks.

Lykle

________________________________________________

Co-creator of the Zesty Nimble, worlds lightest Direct Drive extruder.

[zesty.tech]

|

Re: Building a custom CoreXY July 08, 2017 07:19AM |

Registered: 8 years ago Posts: 776 |

Quote

Qdeathstar

I don't think anyone is calling you an idiot.... you are too sensitive. What i saw was someone asking questions and giving you something to consider. Wood expands when it is heated and warps over time...

indeed. people working with MDF for 3D printer frames have experienced this, and had to find ways to seal the MDF (paint? varnish? don't know the details). i just had to deal with an issue where i was going to be using a stack of 3mm plywood: i couldn't do it. the reason: each stack could have resulted in a cumulative variation of a whopping 0.5mm under different humidity and temperature. that's on a stack only 21mm high.

OCZ1, the best thing to remember is that this is a community which has people with a heck of a lot of expertise and experience, who would like to share that with others. cumulatively there's a 98% chance that there's going to be someone who's been there, done that, and been burned.... and would very much like it if you didn't have to go through the same pain as they did.

by starting a build log you are also implicitly inviting everyone to comment and are implicitly inviting them to help review and spot any potential flaws before you get yourself into a world of pain and huge expense. now, if you *want* to go through the cost and expense and to make errors of judgement based on lack of experience in this extremely technical area, feel free: that would be your choice. but if you did so, i can say that i would be most sad to see you make such a decision. i love learning from others on here: it saves me a huge amount of time and money.

|

Re: Building a custom CoreXY July 09, 2017 02:35AM |

Registered: 8 years ago Posts: 776 |

Quote

Lykle

All the design files for the adapters, adapter bases and groove mount adapter are freely available.

great! just to reiterate, you missed the question: under what license? (please tell me it's not the stupid non-commercial creative-commons)

also, you missed the other question: can you make kits available so that people can design (or 3D-print) their own cases based on their own requirements.

|

Re: Building a custom CoreXY July 09, 2017 02:41AM |

Registered: 8 years ago Posts: 312 |

|

Re: Building a custom CoreXY July 09, 2017 02:55AM |

Registered: 8 years ago Posts: 776 |

Quote

Lykle

Thingiverse does not allow open license. We picked the least restrictive one.

ok great. so most likely the attribution share-alike one, which will allow commercial use, which is great.

so, to repeat the next question which you missed again: would you be prepared to offer kits (at a reduced price, obviously, as there would neither assembly nor testing costs associated with the kit), so that people may either 3D print their own casework or design their own?

|

Re: Building a custom CoreXY July 09, 2017 03:20AM |

Registered: 8 years ago Posts: 312 |

|

Re: Building a custom CoreXY July 09, 2017 03:58AM |

Registered: 8 years ago Posts: 776 |

Quote

Lykle

We will, in time. Brian is one of the main contributors to Drupal, so we certainly know the value of Open Source.

that's fantastic to hear. i wish there were more businesses like yours that valued open-ness. i'll look out for the kits: if it's available in time i'll be able to consider it for the printer i'm developing (which will be minimum QTY 10 manufactured).

|

Re: Building a custom CoreXY July 09, 2017 01:04PM |

Registered: 8 years ago Posts: 312 |

|

Re: Building a custom CoreXY July 09, 2017 04:53PM |

Registered: 11 years ago Posts: 973 |

ikcl

i think you all out of order trying to guess what mutley used for his gears im sure that does infringe anything they have set up between them with the license agreement, please could you stop using mutleys gears into any comparison to the zesty nimbles please as they not the same. ikcl they dropped the gear ratio to make a smaller gear to make it smaller but have not seen no clean prints from the nimble as such

Edited 1 time(s). Last edit at 07/09/2017 05:34PM by chris33.

Check my rubbish blog for my prusa i3

up and running

[3dimetech.blogspot.co.uk]

i think you all out of order trying to guess what mutley used for his gears im sure that does infringe anything they have set up between them with the license agreement, please could you stop using mutleys gears into any comparison to the zesty nimbles please as they not the same. ikcl they dropped the gear ratio to make a smaller gear to make it smaller but have not seen no clean prints from the nimble as such

Edited 1 time(s). Last edit at 07/09/2017 05:34PM by chris33.

Check my rubbish blog for my prusa i3

up and running

[3dimetech.blogspot.co.uk]

|

Re: Building a custom CoreXY July 09, 2017 05:24PM |

Registered: 8 years ago Posts: 601 |

Quote

chris33

i think you all out of order trying to guess what mutley used for his gears im sure that does infringe anything they have set up between them with the license agreement, please could you stop using mutleys gears into any comparison to the zesty nimbles please as they not the same

I don't have any license agreement with mutley, nor do I have any affiliations with either product so I can talk about it as much as I like. Plastic infused with lubricants was hardly invented by Mutley either. If I invest money into either product (probably a flex3drive if I'm honest ) then I will definitely be drawing comparisons... they are highly similar competing products. It is wrong to ask people to not make these comparisons.

Edited 1 time(s). Last edit at 07/09/2017 05:49PM by Origamib.

|

Re: Building a custom CoreXY July 09, 2017 06:39PM |

Registered: 9 years ago Posts: 425 |

Chris33 - I know you only mean well being an early adopter/beta tester, and strong advocate got Flex3Drive, but can I ask you to try and refrain from defensive posting as some may misunderstand your intended message. The guys above are all cool, its a big world and market. I dont have issue with open discussion as above, and I have to agree with Origamib's comment that people are most welcome to draw comparisons.

Regarding polymers, I use a high end Dupont material which is super tough and super slippery due to having infused lubricant in the material. It is not a first choice material. Arriving at this material took a lot of time effort testing and investigation. To some the polymer might be important, others wont care so long as it works reliably and lasts the test of time. Others simply wont comprehend what may be involved in arriving at a given selection.

As an aside the Flex3Drive drivetrain has a lifetime warranty, including the flexible shafts which are a hi end spec construction. However it is extremely rare that anything gets replaced. Usually it is due to a user error or assembly issue, in which event it will still be replaced under warranty.

Peace.

Flex3Drive.com

Regarding polymers, I use a high end Dupont material which is super tough and super slippery due to having infused lubricant in the material. It is not a first choice material. Arriving at this material took a lot of time effort testing and investigation. To some the polymer might be important, others wont care so long as it works reliably and lasts the test of time. Others simply wont comprehend what may be involved in arriving at a given selection.

As an aside the Flex3Drive drivetrain has a lifetime warranty, including the flexible shafts which are a hi end spec construction. However it is extremely rare that anything gets replaced. Usually it is due to a user error or assembly issue, in which event it will still be replaced under warranty.

Peace.

Flex3Drive.com

|

Re: Building a custom CoreXY July 09, 2017 06:55PM |

Registered: 8 years ago Posts: 338 |

Sorry, only registered users may post in this forum.