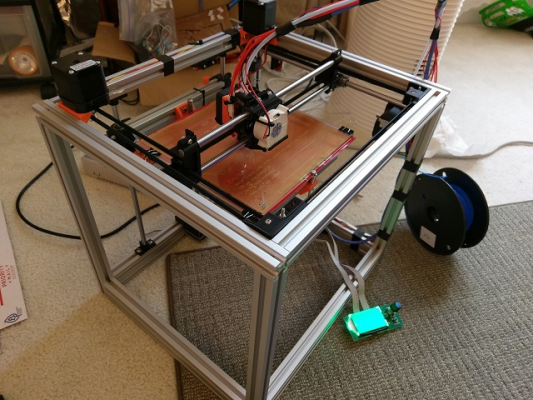

FuseBox2 Printer

Posted by AlexY

|

FuseBox2 Printer July 12, 2017 09:57PM |

Registered: 8 years ago Posts: 166 |

After 2 years of printing with my FuseBox, I've been working on a successor design. Predictably named the FuseBox2, it takes the low-price and accessibility of the original and makes improvements upon reliability, quality, and speed.

Here's an album of the build: http://imgur.com/a/Kdmro

Github repo: [github.com] // Thingiverse page: [www.thingiverse.com]

Key improvements include a much more rigid 2020/2040 frame, vertical gantry for easier hotend removal, improved cooling duct that doesn't focus air on the heater block, and more robust endstop mounts.

Overall I'm pretty happy with the way the printer's turning out. I still need to mount the LCD, PSU, and cord socket as well as do some more fine tuning to the firmware/slicer settings.

Here's an album of the build: http://imgur.com/a/Kdmro

Github repo: [github.com] // Thingiverse page: [www.thingiverse.com]

Key improvements include a much more rigid 2020/2040 frame, vertical gantry for easier hotend removal, improved cooling duct that doesn't focus air on the heater block, and more robust endstop mounts.

Overall I'm pretty happy with the way the printer's turning out. I still need to mount the LCD, PSU, and cord socket as well as do some more fine tuning to the firmware/slicer settings.

|

Re: FuseBox2 Printer July 14, 2017 09:29AM |

Registered: 7 years ago Posts: 270 |

Looks good, though the gantry must be pretty heavy - how quickly (in minutes) did you print that 3DBenchy? How did you join profiles together w/o the corner brackets? I also see you've switched from horizontal to vertical X axis. Do you like the new arrangement better? I think horizontal should be more precise because you can control slop in the horizontal plane where it counts.

|

Re: FuseBox2 Printer July 14, 2017 01:53PM |

Registered: 8 years ago Posts: 166 |

The gantry should be a similar weight - there's a bit more ducting for the fans, but the plastic doesn't weigh much compared to the metal parts (in my case it's probably lighter because I used an E3DV6 instead of a Lite6).

The vertical axis has several benefits - it serves to improve hotend cooling, increase y movement range, and make the hotend easier to remove - so far it doesn't seem to be less precise since ringing does appear to be more controlled. I did reinforce the x-ends in the design afterwards, though the prototype doesn't have those installed and seems ok.

I joined the extrusions by drilling and tapping - each extrusion has its ends tapped and screwed down for a super rigid frame (see http://forums.reprap.org/read.php?177,601562).. It's both cheaper and likely stronger than the corner brackets.

Biggest issue right now is probably a minor amount of z artifacts - that may be due to the cheap bearings that I bought.

The vertical axis has several benefits - it serves to improve hotend cooling, increase y movement range, and make the hotend easier to remove - so far it doesn't seem to be less precise since ringing does appear to be more controlled. I did reinforce the x-ends in the design afterwards, though the prototype doesn't have those installed and seems ok.

I joined the extrusions by drilling and tapping - each extrusion has its ends tapped and screwed down for a super rigid frame (see http://forums.reprap.org/read.php?177,601562).. It's both cheaper and likely stronger than the corner brackets.

Biggest issue right now is probably a minor amount of z artifacts - that may be due to the cheap bearings that I bought.

|

Re: FuseBox2 Printer July 16, 2017 11:18PM |

Registered: 8 years ago Posts: 166 |

I somehow ended up fixing the printer's banding issues by pushing the leadscrew all the way down into the flex coupler - effectively making the motor to leadscrew connection rigid.

Here's a before/after pic:

Print quality's looking great now!

Here's a before/after pic:

Print quality's looking great now!

|

Re: FuseBox2 Printer July 17, 2017 01:31AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: FuseBox2 Printer July 17, 2017 05:23AM |

Registered: 8 years ago Posts: 601 |

|

Re: FuseBox2 Printer July 17, 2017 03:11PM |

Registered: 8 years ago Posts: 166 |

|

Re: FuseBox2 Printer July 18, 2017 02:05AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: FuseBox2 Printer July 18, 2017 02:12AM |

Registered: 8 years ago Posts: 5,232 |

Quote

Origamib

Quote

o_lampe

I have placed a 4.5mm steelball between stepper shaft and leadscrew. That way the z-compression is "0" but the coupler can still flex.

That's a good idea, any pictures of the quality or banding (or lack of)?

I could show you some perfect prints

, but only a before_after comparison would make sense. But I haven't made any pics without the balls inserted.

, but only a before_after comparison would make sense. But I haven't made any pics without the balls inserted.

|

Re: FuseBox2 Printer July 18, 2017 12:08PM |

Registered: 9 years ago Posts: 251 |

|

Re: FuseBox2 Printer July 18, 2017 12:23PM |

Registered: 8 years ago Posts: 601 |

|

Re: FuseBox2 Printer July 18, 2017 01:14PM |

Registered: 8 years ago Posts: 166 |

Yeah, mostly simplicity and reduced cost. The 2020 makes it a lot more rigid than the previous revision, and for a 200mm bed size a cantilevered bed is adequate.

I went for smooth rods mainly because they were more accessible - linear guides are a bit harder to find and can be a lot more expensive. A hybrid version with a linear guide only for the x gantry would be interesting, providing the benefit of reduced gantry weight without increasing cost too much.

I went for smooth rods mainly because they were more accessible - linear guides are a bit harder to find and can be a lot more expensive. A hybrid version with a linear guide only for the x gantry would be interesting, providing the benefit of reduced gantry weight without increasing cost too much.

|

Re: FuseBox2 Printer July 18, 2017 01:17PM |

Registered: 8 years ago Posts: 166 |

|

Re: FuseBox2 Printer July 19, 2017 10:45AM |

Registered: 7 years ago Posts: 270 |

|

Re: FuseBox2 Printer July 19, 2017 01:26PM |

Registered: 8 years ago Posts: 5,232 |

|

Re: FuseBox2 Printer July 19, 2017 07:14PM |

Registered: 8 years ago Posts: 166 |

Sorry, only registered users may post in this forum.