Zasquatch's CoreXY Design/Build

Posted by Zasquatch

|

Re: Zasquatch's CoreXY Design/Build November 16, 2017 02:22PM |

Registered: 11 years ago Posts: 5,780 |

If the bed is 600 x 550 mm, it is going to expand a lot when heated. You might want to consider what happens to/at the leveling screws when that happens.

I didn't care too much for glass when it was on my first printer. These days I like PEI- prints stick and are relatively easy to remove when the time comes. No glue, no hairspray...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I didn't care too much for glass when it was on my first printer. These days I like PEI- prints stick and are relatively easy to remove when the time comes. No glue, no hairspray...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Zasquatch's CoreXY Design/Build November 16, 2017 06:23PM |

Registered: 10 years ago Posts: 14,672 |

The main advantages of using a glass bed plate are that you can put it in the freezer if the print won't release easily, and you can swap plates to allow you to start a new print before the bed has cooled down after finishing the previous one. However, when the bed is as large as yours will be, neither of those really applies. Therefore, if you use tooling plate for the heat spreader, then you may as well stick your chosen bed surface (PEI, polycarbonate etc.) directly on the heat spreader.

If you choose to use glass, I suggest 4mm float glass from your local glazing supplier.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

If you choose to use glass, I suggest 4mm float glass from your local glazing supplier.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Zasquatch's CoreXY Design/Build November 16, 2017 07:13PM |

Registered: 6 years ago Posts: 54 |

Quote

the_digital_dentist

If the bed is 600 x 550 mm, it is going to expand a lot when heated. You might want to consider what happens to/at the leveling screws when that happens.

I didn't care too much for glass when it was on my first printer. These days I like PEI- prints stick and are relatively easy to remove when the time comes. No glue, no hairspray...

If my calculations are correct elongation should only be about 1.5mm... which should be manageable along that span.

Do you use a PEI sheet 3m taped direct to your Al build plate? I’ve had mixed results with PEI on my other printer, not very flat and not as sticky as many claim. Bad supplier maybe?

|

Re: Zasquatch's CoreXY Design/Build November 16, 2017 07:15PM |

Registered: 6 years ago Posts: 54 |

Quote

dc42

The main advantages of using a glass bed plate are that you can put it in the freezer if the print won't release easily, and you can swap plates to allow you to start a new print before the bed has cooled down after finishing the previous one. However, when the bed is as large as yours will be, neither of those really applies. Therefore, if you use tooling plate for the heat spreader, then you may as well stick your chosen bed surface (PEI, polycarbonate etc.) directly on the heat spreader.

If you choose to use glass, I suggest 4mm float glass from your local glazing supplier.

What do you use? My original plan was to stick a sheet of build-tak right to the mic6, but someone suggested I still use glass. That allows for flexibility if a certain material doesn’t like build tak ( or whatever else) and you can just swap the glass.

|

Re: Zasquatch's CoreXY Design/Build November 16, 2017 11:38PM |

Registered: 11 years ago Posts: 5,780 |

When the heated bed plate expands it will push laterally against the leveling screws. 1.5 mm is a lot of movement considering the leveling screws are anchored in the bed support that isn't heated. Something is going to have to flex or the bed is going to drop, pushed down by the slope of the flat-head leveling screws. That's why I used the kinematic mount in UMMD. It doesn't create any lateral forces on the leveling screws. The bed is free to expand, tilt and pivot on the spherical head screws, and go up and down with the screw head, but it can't move any other way. It seems to be working perfectly.

If the printer is heated to print ABS, the frame will heat up and the Y axis guide rails will move apart. Since the X axis guide rail is steel, it won't expand nearly as much as the Y axis rails will try to move, so it will create very large side-loading on the Y axis bearing blocks, possibly enough to cause the mechanism to bind. That's why I used an extra bearing block on the X axis rail. It allows the Y axis rails to move apart without creating the large side loads. The only side loads on the Y axis bearing blocks/rails are created by the belt tension, well within the rating of the Y axis linear guides.

I use 0.7 mm PEI taped down on the cast tooling plate bed. The thickness seems well-controlled so it's flat enough to print edge to edge on my 300x300 bed plate. I've checked a few different sources and found that the PEI should expand about double the aluminum expansion, yet it stays flat and attached to the bed plate. I'm not sure what's happening there, but it works fine on two machines I have built. I don't know what to tell you about the PEI you used. I get Ultem 1000 via amazon and everything sticks.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

If the printer is heated to print ABS, the frame will heat up and the Y axis guide rails will move apart. Since the X axis guide rail is steel, it won't expand nearly as much as the Y axis rails will try to move, so it will create very large side-loading on the Y axis bearing blocks, possibly enough to cause the mechanism to bind. That's why I used an extra bearing block on the X axis rail. It allows the Y axis rails to move apart without creating the large side loads. The only side loads on the Y axis bearing blocks/rails are created by the belt tension, well within the rating of the Y axis linear guides.

I use 0.7 mm PEI taped down on the cast tooling plate bed. The thickness seems well-controlled so it's flat enough to print edge to edge on my 300x300 bed plate. I've checked a few different sources and found that the PEI should expand about double the aluminum expansion, yet it stays flat and attached to the bed plate. I'm not sure what's happening there, but it works fine on two machines I have built. I don't know what to tell you about the PEI you used. I get Ultem 1000 via amazon and everything sticks.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Zasquatch's CoreXY Design/Build November 17, 2017 03:32AM |

Registered: 10 years ago Posts: 14,672 |

Quote

Zasquatch

Quote

dc42

The main advantages of using a glass bed plate are that you can put it in the freezer if the print won't release easily, and you can swap plates to allow you to start a new print before the bed has cooled down after finishing the previous one. However, when the bed is as large as yours will be, neither of those really applies. Therefore, if you use tooling plate for the heat spreader, then you may as well stick your chosen bed surface (PEI, polycarbonate etc.) directly on the heat spreader.

If you choose to use glass, I suggest 4mm float glass from your local glazing supplier.

What do you use? My original plan was to stick a sheet of build-tak right to the mic6, but someone suggested I still use glass. That allows for flexibility if a certain material doesn’t like build tak ( or whatever else) and you can just swap the glass.

Yes, swapping the glass gives you flexibility, but it is obviously less easy to do on a large printer.

The 200 x 215mm bed on my Cartesian printer uses 3mm float glass. I print PLA directly on it with no coating, I just wipe it with a paper towel moistened with distilled malt vinegar between prints. My delta has a 330mm diameter bed. I have two 4mm float glass beds for it, one with PEI on top and one with PrintBite.

Float glass is usually very flat, but 1 piece of about 8 that I bought was bent and had to be thrown away. So check it against a straight edge such as a steel rule. 3mm glass is mostly used for greenhouses, so it may be made to a lower standard than 4mm glass. Tempered glass is best avoided because the tempering process often bends the glass a little.

Glass doesn't conduct heat very well, so expect a temperature drop of around 5C across it at the temperatures used with PLA, and about 10C at the higher temperatures used when printing ABS.

Edited 1 time(s). Last edit at 11/17/2017 03:38AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Zasquatch's CoreXY Design/Build November 17, 2017 09:18PM |

Registered: 6 years ago Posts: 54 |

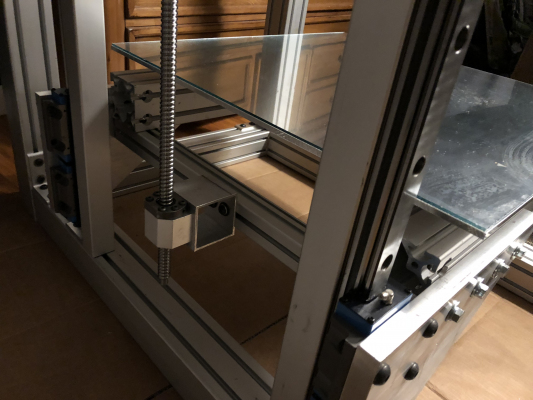

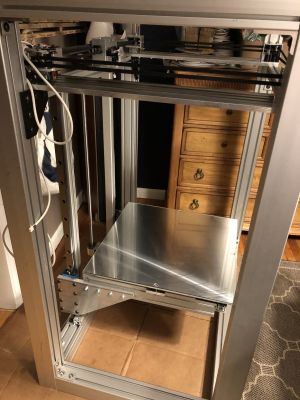

More progress... discovered a downside of using a ballscrew on a heavy z-stage is that it wants to fall to the ground when no load is on the screw. I think that’s a good sign that everything is aligned but yet another consideration to think about...I will make a bump stop at the bottom extent for sure.

Edited 1 time(s). Last edit at 11/19/2017 05:21PM by Zasquatch.

Edited 1 time(s). Last edit at 11/19/2017 05:21PM by Zasquatch.

|

Re: Zasquatch's CoreXY Design/Build November 20, 2017 08:32PM |

Registered: 6 years ago Posts: 54 |

Well,as many of you probably predicted, the z-axis test failed... z axis is too damn heavy for the little NEMA17 stepper motor (83.6 oz-in)... assuming my firmware settings were correct.

Options I see on the table are:

Get a planetary geared stepper

Create counterweight system

I see the benefits of a counterweight ... looking for some opinions

Edited 2 time(s). Last edit at 11/20/2017 08:50PM by Zasquatch.

Options I see on the table are:

Get a planetary geared stepper

Create counterweight system

I see the benefits of a counterweight ... looking for some opinions

Edited 2 time(s). Last edit at 11/20/2017 08:50PM by Zasquatch.

|

Re: Zasquatch's CoreXY Design/Build November 21, 2017 02:25AM |

Registered: 7 years ago Posts: 249 |

|

Re: Zasquatch's CoreXY Design/Build November 21, 2017 05:30AM |

Registered: 6 years ago Posts: 54 |

Quote

prot0typ1cal

Seems there's room for a NEMA23, though using a worm drive gear box will also end any dropping worries.

What about planetary gears? Would those also prevent dropping?

I plan on rigging up a quick counterweight with a kettle-bell to see how the system reacts.

Edited 2 time(s). Last edit at 11/21/2017 05:31AM by Zasquatch.

|

Re: Zasquatch's CoreXY Design/Build November 21, 2017 08:02AM |

Registered: 11 years ago Posts: 5,780 |

The motor's detent torque will be multiplied by the gear ratio. If you know the holding torque required to stop the screw from turning when it is loaded with a print, select a gear ratio that brings the detent torque of the motor up to that value and the bed won't move when power is cut.

Or use a worm gear reducer...(but not all worm gear drives are going to do the job)

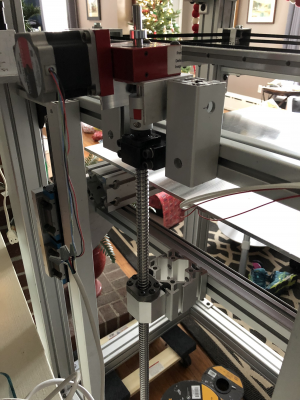

Is that a thrust bearing up at the motor mount end of the screw?

Edited 2 time(s). Last edit at 11/21/2017 08:08AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Or use a worm gear reducer...(but not all worm gear drives are going to do the job)

Is that a thrust bearing up at the motor mount end of the screw?

Edited 2 time(s). Last edit at 11/21/2017 08:08AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Zasquatch's CoreXY Design/Build November 21, 2017 10:49AM |

Registered: 6 years ago Posts: 54 |

If I go big stepper I’m thinking this will probably do the trick:

[www.omc-stepperonline.com]

Assuming a 5.6 oz-in detent torque, with a 10:1 ratio that should be more than plenty to keep the bed raised with power off.

Still plan on looking into counterweights, I think the benefits would be multiple.

[www.omc-stepperonline.com]

Assuming a 5.6 oz-in detent torque, with a 10:1 ratio that should be more than plenty to keep the bed raised with power off.

Still plan on looking into counterweights, I think the benefits would be multiple.

|

Re: Zasquatch's CoreXY Design/Build November 21, 2017 11:28AM |

Registered: 11 years ago Posts: 5,780 |

If your current 83.6 oz-in motor isn't enough to lift the bed, why would 56 oz-in (motor detent torque x gear ratio) be enough to stop it from falling?

Counterweights are OK but it's hard to make them look decent. Your printer is a work of functional art. It would be a shame to spoil it with cables and weights hanging all over the place.

Edited 2 time(s). Last edit at 11/21/2017 11:34AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Counterweights are OK but it's hard to make them look decent. Your printer is a work of functional art. It would be a shame to spoil it with cables and weights hanging all over the place.

Edited 2 time(s). Last edit at 11/21/2017 11:34AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Zasquatch's CoreXY Design/Build November 21, 2017 11:44AM |

Registered: 6 years ago Posts: 54 |

Quote

the_digital_dentist

If your current 83.6 oz-in motor isn't enough to lift the bed, why would 56 oz-in (motor detent torque x gear ratio) be enough to stop it from falling?

Friction!

I’ve been using this calculator because I’m lazy. I validated its results for one case months ago and haven’t since so perhaps it’s time for another check.

[www.daycounter.com]

I tallied up my weights and my complete z assembly weighs.... ready for it..... ~80 lbs.

I think I need to realign things to make sure I’m not introducing too much unnecessary friction. Otherwise it looks like the motor just can’t push that kind of load. Wishful thinking going with an inexpensive NEMA 17.

I have some ideas of how to make a counterweight look acceptable, but it will be more work.......

Edited 2 time(s). Last edit at 11/21/2017 01:17PM by Zasquatch.

|

Re: Zasquatch's CoreXY Design/Build November 21, 2017 01:11PM |

Registered: 6 years ago Posts: 54 |

Quote

the_digital_dentist

The motor's detent torque will be multiplied by the gear ratio. If you know the holding torque required to stop the screw from turning when it is loaded with a print, select a gear ratio that brings the detent torque of the motor up to that value and the bed won't move when power is cut.

Or use a worm gear reducer...(but not all worm gear drives are going to do the job)

Is that a thrust bearing up at the motor mount end of the screw?

Sort of, the BK12 block has two 7001 ball bearings seated in it, which allow for a pretty significant axial load.

|

Re: Zasquatch's CoreXY Design/Build November 21, 2017 01:43PM |

Registered: 7 years ago Posts: 249 |

|

Re: Zasquatch's CoreXY Design/Build November 21, 2017 02:09PM |

Registered: 6 years ago Posts: 54 |

Quote

prot0typ1cal

BTW, the open box Z nut mount should be turned 90 degrees, so the openings are top and bottom, not side to side...

Yeah..... I was waiting for someone to pick up on that. I am looking through a buddy’s scrap bin for something stronger, but at a minimum plan to rotate 90

|

Re: Zasquatch's CoreXY Design/Build November 21, 2017 02:41PM |

Registered: 11 years ago Posts: 5,780 |

Quote

Zasquatch

Quote

the_digital_dentist

If your current 83.6 oz-in motor isn't enough to lift the bed, why would 56 oz-in (motor detent torque x gear ratio) be enough to stop it from falling?

Friction!

Realy? How much friction does a planetary gear box add?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Zasquatch's CoreXY Design/Build November 21, 2017 03:03PM |

Registered: 6 years ago Posts: 54 |

Quote

the_digital_dentist

Quote

Zasquatch

Quote

the_digital_dentist

If your current 83.6 oz-in motor isn't enough to lift the bed, why would 56 oz-in (motor detent torque x gear ratio) be enough to stop it from falling?

Friction!

Realy? How much friction does a planetary gear box add?

Sorry I’ll be more clear- to raise the bed the stepper needs to overcome the stack up of system friction forces - from the rails, the ball screw, the shaft mount bearings, any inefficiency due to misalignment, etc. - in addition to the weight of the z-stage.

When the bed is elevated and the motor disabled, the same friction forces act against the bed as it tries to fall. So the detent torque of the motor plus the total system friction force must be greater than the load of the z-stage if you want to prevent dropping.

That being said, if I do go the geared route I want plenty of margin, so the referenced stepper prob is not sufficient.

Edited 1 time(s). Last edit at 11/21/2017 03:04PM by Zasquatch.

|

Re: Zasquatch's CoreXY Design/Build November 22, 2017 05:35AM |

Registered: 6 years ago Posts: 54 |

Quote

the_digital_dentist

Or use a worm gear reducer...(but not all worm gear drives are going to do the job)

Ok after sleeping on it the counterweight solution is no longer appealing to me. Now I need to find a good geared NEMA23...

What do you think about this thing?

[rover.ebay.com]

Most stuff out there seems to be spur or planetary... anyone have a good supplier with options I’m not seeing?

Update: found this on eBay this morning.... seems big but might work? There’s also a listing for a 60:1 model.

[rover.ebay.com]

Edited 4 time(s). Last edit at 11/22/2017 08:51AM by Zasquatch.

|

Re: Zasquatch's CoreXY Design/Build November 22, 2017 09:15AM |

Registered: 11 years ago Posts: 5,780 |

The first one is $109 with shipping, assuming you're in the US.

You can get a Rino 30:1 via ebay for $108 including shipping here: [www.ebay.com]

The Rino is an extremely high quality ($750 new from OnDrives), low backlash part (not that it matters for this application) and has a LOT of torque. This particular model is not guaranteed to be irreversible (related to gear tooth pitch angle, stiction, and forces applied), so it depends on the load applied.

I don't know why that guy's stuff doesn't come up when you search for Rino, or Ondrives, I got to it by chance and found that it does show up in searches for "4th axis sherline".

The combo of 30:1 plus your screw pitch may make the Z axis too slow for you- be sure to calculate the speed limit. The motor torque will probably limit the speed because the motor will be spinning fast if you try to move Z very fast (like 10-20 mm/sec). In my printer, running the motor at 1A, I can get a maximum reliable speed of 20 mm/sec. You might want to contact that seller and ask if he has any lower gear ratio drives.

The second link has no motor, so you'd have a lot of messing around to do...

Edited 1 time(s). Last edit at 11/22/2017 04:15PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

You can get a Rino 30:1 via ebay for $108 including shipping here: [www.ebay.com]

The Rino is an extremely high quality ($750 new from OnDrives), low backlash part (not that it matters for this application) and has a LOT of torque. This particular model is not guaranteed to be irreversible (related to gear tooth pitch angle, stiction, and forces applied), so it depends on the load applied.

I don't know why that guy's stuff doesn't come up when you search for Rino, or Ondrives, I got to it by chance and found that it does show up in searches for "4th axis sherline".

The combo of 30:1 plus your screw pitch may make the Z axis too slow for you- be sure to calculate the speed limit. The motor torque will probably limit the speed because the motor will be spinning fast if you try to move Z very fast (like 10-20 mm/sec). In my printer, running the motor at 1A, I can get a maximum reliable speed of 20 mm/sec. You might want to contact that seller and ask if he has any lower gear ratio drives.

The second link has no motor, so you'd have a lot of messing around to do...

Edited 1 time(s). Last edit at 11/22/2017 04:15PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Zasquatch's CoreXY Design/Build November 22, 2017 09:27AM |

Registered: 6 years ago Posts: 54 |

Oh wow, thank you!! That’s an awesome find.

Another downside is that my layer height won’t align with steps anymore... not sure if that’s a big deal.

If I reduce micro stepping will that help with speed? Can I reduce to 1/4 step (getting me to 4800 steps/mm), but leave on 1/256 interpolation to keep things smooth?

Edited 1 time(s). Last edit at 11/22/2017 10:43AM by Zasquatch.

Another downside is that my layer height won’t align with steps anymore... not sure if that’s a big deal.

If I reduce micro stepping will that help with speed? Can I reduce to 1/4 step (getting me to 4800 steps/mm), but leave on 1/256 interpolation to keep things smooth?

Edited 1 time(s). Last edit at 11/22/2017 10:43AM by Zasquatch.

|

Re: Zasquatch's CoreXY Design/Build November 22, 2017 12:52PM |

Registered: 10 years ago Posts: 14,672 |

Quote

Zasquatch

If I reduce micro stepping will that help with speed? Can I reduce to 1/4 step (getting me to 4800 steps/mm), but leave on 1/256 interpolation to keep things smooth?

Reducing microstepping will only help with speed if the limiting factor is the rate at which the controller can generate steps. Unless you use high microstepping, the limiting factor is likely to be the inductance and back emf of the motor. See [duet3d.com] for the calculations.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Zasquatch's CoreXY Design/Build November 22, 2017 03:56PM |

Registered: 6 years ago Posts: 54 |

|

Re: Zasquatch's CoreXY Design/Build December 01, 2017 08:40AM |

Registered: 6 years ago Posts: 54 |

Have you been able to find any specs for this Vexta stepper? Closest thing I found was this:

[catalog.orientalmotor.com]

I am calculating maximum theoretical speed and really need a torque curve and inductance value to do it right.

[catalog.orientalmotor.com]

I am calculating maximum theoretical speed and really need a torque curve and inductance value to do it right.

|

Re: Zasquatch's CoreXY Design/Build December 09, 2017 10:00AM |

Registered: 6 years ago Posts: 54 |

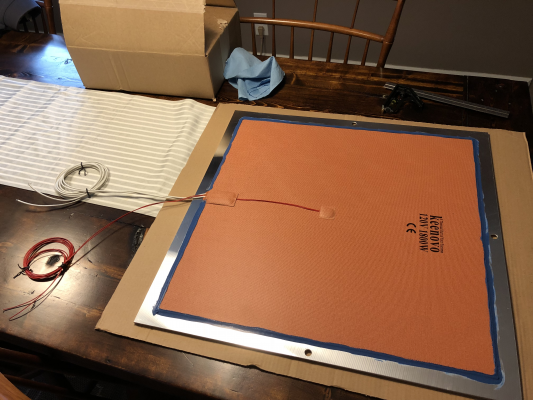

Bed heater came in from China! 550x550 mm. They threw in a good luck ornament too

Edited 1 time(s). Last edit at 12/09/2017 10:00AM by Zasquatch.

Edited 1 time(s). Last edit at 12/09/2017 10:00AM by Zasquatch.

|

Re: Zasquatch's CoreXY Design/Build December 16, 2017 05:43PM |

Registered: 6 years ago Posts: 54 |

Reworked the z axis today, very happy with the results.

|

Re: Zasquatch's CoreXY Design/Build December 31, 2017 10:58AM |

Registered: 8 years ago Posts: 338 |

|

Re: Zasquatch's CoreXY Design/Build June 21, 2019 10:18AM |

Registered: 6 years ago Posts: 54 |

Well it’s been a long time! I have a significant update in the works and will post about it soon. Major house reno put a pause on my 3d printing, but also added a dedicated room for my machines! My printer worked well but had some issues that I am currently designing a update to work out. I’ll be back with more soon!

Sorry, only registered users may post in this forum.