Accelerations / Jerk Speeds for Thingverse 1001065 Build?

Posted by WesBrooks

|

Accelerations / Jerk Speeds for Thingverse 1001065 Build? September 05, 2017 04:44AM |

Registered: 9 years ago Posts: 383 |

Hello,

I'm wondering what settings people are using so I know roughly what ball park figures to aim for/start from on the axis tuning.

My setup is:

Duet 0.6

Stepper Motors from Ormerod 2 - JK42HS34-1334A

24V stepper drive voltage

E3D Titan Extruder

E3D V6 hot end

Z-axis is two steppers wired in series.

Thanks.

Edited 1 time(s). Last edit at 09/05/2017 04:44AM by WesBrooks.

I'm wondering what settings people are using so I know roughly what ball park figures to aim for/start from on the axis tuning.

My setup is:

Duet 0.6

Stepper Motors from Ormerod 2 - JK42HS34-1334A

24V stepper drive voltage

E3D Titan Extruder

E3D V6 hot end

Z-axis is two steppers wired in series.

Thanks.

Edited 1 time(s). Last edit at 09/05/2017 04:44AM by WesBrooks.

|

Re: Accelerations / Jerk Speeds for Thingverse 1001065 Build? September 05, 2017 09:35AM |

Registered: 9 years ago Posts: 383 |

These are the settings I've got in at the moment. I'm running a no heat test run with honeycomb core fill and it seems to be fine. I would like to push this to find the limits at some point but thing the lack of diagonal bracing on the frame will quickly result in a shaky thing!

M566 X900 Y900 Z30 E300 ; Set maximum instantaneous speed changes (mm/min)

M203 X9000 Y9000 Z600 E3000 ; Set maximum speeds (mm/min)

M201 X800 Y800 Z250 E1000 ; Set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

M566 X900 Y900 Z30 E300 ; Set maximum instantaneous speed changes (mm/min)

M203 X9000 Y9000 Z600 E3000 ; Set maximum speeds (mm/min)

M201 X800 Y800 Z250 E1000 ; Set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

|

Re: Accelerations / Jerk Speeds for Thingverse 1001065 Build? September 06, 2017 03:21AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Accelerations / Jerk Speeds for Thingverse 1001065 Build? September 06, 2017 03:33AM |

Registered: 9 years ago Posts: 383 |

Point well made! I'm learning as I go here.

Ringing being the wobble after a direction change of the head creating visible artefacts/wobble on the outer walls?

My current tactic was to find the missed steps level and drop 10-20% to create a safety margin before running live trials after everything has arrived. I'm not running polymer at the moment just running dry stress tests. Once building I would then look at tuning it further for an acceptable balance between unwanted artefacts and speed. I take it it is significantly lower then? I've noted my machine does wobble a bit, but the desk it's on isn't rigid, and appreciate that this is only an issue if the nozzle is moving relative to the elevator which will only be apparent when I start building things.

Ringing being the wobble after a direction change of the head creating visible artefacts/wobble on the outer walls?

My current tactic was to find the missed steps level and drop 10-20% to create a safety margin before running live trials after everything has arrived. I'm not running polymer at the moment just running dry stress tests. Once building I would then look at tuning it further for an acceptable balance between unwanted artefacts and speed. I take it it is significantly lower then? I've noted my machine does wobble a bit, but the desk it's on isn't rigid, and appreciate that this is only an issue if the nozzle is moving relative to the elevator which will only be apparent when I start building things.

|

Re: Accelerations / Jerk Speeds for Thingverse 1001065 Build? September 06, 2017 11:18AM |

Registered: 8 years ago Posts: 5,232 |

Yes, ringing/ghosting is the artefacts you get after direction changes.

How much ringing is acceptable is a subjective thing, but usually you aim for least possible at max. extruder speed ( which is often another limiting factor )

Dry testing is a good idea, it keeps you motivated to make the D-Bot reach these numbers with decent print quality too.

You've build it from the book with v-slot rollers etc? I've built mine with linear rails and also rotated the gantry 90° to make it shorter/lighter. ( 300x200 bed )

How much ringing is acceptable is a subjective thing, but usually you aim for least possible at max. extruder speed ( which is often another limiting factor )

Dry testing is a good idea, it keeps you motivated to make the D-Bot reach these numbers with decent print quality too.

You've build it from the book with v-slot rollers etc? I've built mine with linear rails and also rotated the gantry 90° to make it shorter/lighter. ( 300x200 bed )

|

Re: Accelerations / Jerk Speeds for Thingverse 1001065 Build? September 07, 2017 05:45AM |

Registered: 9 years ago Posts: 383 |

By the book, but 300mm x 300mm. This machine is supposed to be an early demonstration of an expandable format as far as build volume is concerned.

This came about because some people at HQ (different site, different country) are interested in the technology at work, and despite often saying it's not ideal for their intended application they still want to have a go to see what it's like. I took advantage of this and proposed I rebuild the Ormerod 2 I bought as a technology demonstrator in 2014 to something more suitable for building the prototypes / test samples they are interested in on the understanding that the rest of the R&D team here could use it for there own purposes too. Essentially they were struggling to find people who were willing to work with odd ball materials and struggling more to get those people to build things in a reasonable time frame. I'm the lucky one here as I love tinkering with things like this and you can take as much room to play with settings/hardware/electronics/firmware as you like to tweak the system to suit your own needs.

There are holes I could pick in the design but they'd be unfair as I'm not building to the same brief/intent as the original designer. Likewise I didn't want to design my own unit just yet for a couple of reasons; #1 I'd like to be sure the things I'm 'fixing' are definitely causing part quality issues. #2 If I have difficulties in the build or set up (not unlike this canvassing on accelerations) I'd like to be reasonably close to a standard set up to give me a reasonable chance of coming across more who have had similar issues until I'm more self-sufficient.

All that said I'd be surprised if the wobbling of the frame doesn't cause artefacts on the parts. There's a visible shake on the machine at the moment that I could probably dial out with either lower jerk or acceleration settings. I'm going to move from my current test build to something simpler - a solid cube - and use that as a starting point. I'll also plot the effect of changing speeds/accelerations/jerk to the overall build rate. For example I'll make sure I'm not trying to push speed when the increase in speed gives marginal increases in build rate due to low accelerations / short vectors.

Planned changes are:

1) Print bracket for z-probe from Ormerod 2.

2) Print motor pulley covers.

3) Print cable supports to take strain off the connectors onto the duet.

4) Fit cable chains and or supports.

Maybe changes:

1) Limit switches on both extremes of travel for each axis and set machine up for stop build on switch trigger - would be a fault anyway. Better still would be encoder feedback from the steppers, but that is not commonly supported and having gone that far servo motors may be a better choice.

2) Covers to reduce/control airflows.

My knee jerk gut instincts on design changes would be;

1) Design a square nut caddy to slide in to the frame to hold the bastard nuts still while you try and bolt things on! ;-)

2) Three screws (with independent motor drive), moving the existing to to the outside rear of the frame near the wheels and the third to the front centre with additional railing. That'd stop any tenancy to pivot about the castors when changing elevator direction.

3) More bracing on the sides of the machine and where possible other than where the screws from 2) sit. I'd think long and hard about the viability of removing or limiting the use of the printed corner brackets at this point.

Edited 1 time(s). Last edit at 09/07/2017 05:47AM by WesBrooks.

This came about because some people at HQ (different site, different country) are interested in the technology at work, and despite often saying it's not ideal for their intended application they still want to have a go to see what it's like. I took advantage of this and proposed I rebuild the Ormerod 2 I bought as a technology demonstrator in 2014 to something more suitable for building the prototypes / test samples they are interested in on the understanding that the rest of the R&D team here could use it for there own purposes too. Essentially they were struggling to find people who were willing to work with odd ball materials and struggling more to get those people to build things in a reasonable time frame. I'm the lucky one here as I love tinkering with things like this and you can take as much room to play with settings/hardware/electronics/firmware as you like to tweak the system to suit your own needs.

There are holes I could pick in the design but they'd be unfair as I'm not building to the same brief/intent as the original designer. Likewise I didn't want to design my own unit just yet for a couple of reasons; #1 I'd like to be sure the things I'm 'fixing' are definitely causing part quality issues. #2 If I have difficulties in the build or set up (not unlike this canvassing on accelerations) I'd like to be reasonably close to a standard set up to give me a reasonable chance of coming across more who have had similar issues until I'm more self-sufficient.

All that said I'd be surprised if the wobbling of the frame doesn't cause artefacts on the parts. There's a visible shake on the machine at the moment that I could probably dial out with either lower jerk or acceleration settings. I'm going to move from my current test build to something simpler - a solid cube - and use that as a starting point. I'll also plot the effect of changing speeds/accelerations/jerk to the overall build rate. For example I'll make sure I'm not trying to push speed when the increase in speed gives marginal increases in build rate due to low accelerations / short vectors.

Planned changes are:

1) Print bracket for z-probe from Ormerod 2.

2) Print motor pulley covers.

3) Print cable supports to take strain off the connectors onto the duet.

4) Fit cable chains and or supports.

Maybe changes:

1) Limit switches on both extremes of travel for each axis and set machine up for stop build on switch trigger - would be a fault anyway. Better still would be encoder feedback from the steppers, but that is not commonly supported and having gone that far servo motors may be a better choice.

2) Covers to reduce/control airflows.

My knee jerk gut instincts on design changes would be;

1) Design a square nut caddy to slide in to the frame to hold the bastard nuts still while you try and bolt things on! ;-)

2) Three screws (with independent motor drive), moving the existing to to the outside rear of the frame near the wheels and the third to the front centre with additional railing. That'd stop any tenancy to pivot about the castors when changing elevator direction.

3) More bracing on the sides of the machine and where possible other than where the screws from 2) sit. I'd think long and hard about the viability of removing or limiting the use of the printed corner brackets at this point.

Edited 1 time(s). Last edit at 09/07/2017 05:47AM by WesBrooks.

|

Re: Accelerations / Jerk Speeds for Thingverse 1001065 Build? September 07, 2017 11:35AM |

Registered: 8 years ago Posts: 5,232 |

To hold the nuts in place, i simply used cigarette filters.

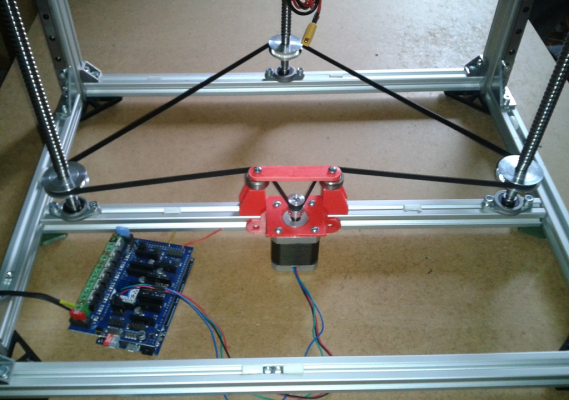

IMHO three motors for the screws is overkill, although I heard you can do bed levelling with it. Here's my closed belt version:

I didn't spend much time with printed corner brackets and got some aluminum brackets. Some smaller and some bigger ( where suitable ).

Now my frame is solid and I had to crossbrace the table instead

Edited 1 time(s). Last edit at 09/07/2017 11:38AM by o_lampe.

IMHO three motors for the screws is overkill, although I heard you can do bed levelling with it. Here's my closed belt version:

I didn't spend much time with printed corner brackets and got some aluminum brackets. Some smaller and some bigger ( where suitable ).

Now my frame is solid and I had to crossbrace the table instead

Edited 1 time(s). Last edit at 09/07/2017 11:38AM by o_lampe.

Sorry, only registered users may post in this forum.