Newbie looking for some setup guidance...

Posted by ampapa

|

Re: Newbie looking for some setup guidance... November 28, 2017 08:09AM |

Registered: 10 years ago Posts: 14,672 |

Most people use a Z probe to establish where Z=0 is prior to printing. A few people don't use a Z probe, but have a Z min endstop switch (i.e. a switch that triggers when the nozzle is close to touching the bed). If you only use a Z max endstop switch, I suspect you may have a problem with differential thermal expansion of your frame (probably aluminium) and your leadscrews (some type of steel), which will change the number of motor steps you need to go from endstop triggered at max Z to Z=0.

Edited 1 time(s). Last edit at 11/28/2017 08:10AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 11/28/2017 08:10AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Newbie looking for some setup guidance... November 28, 2017 02:15PM |

Registered: 7 years ago Posts: 128 |

Bare with me as I try to understand fully... So, currently I have 1 switch at the top of the Z axis. In this scenario, when I home the machine the switch is below the hot end and the Z axis is essentially set to Zero when it touches the switch.

If I move the switch to be above the hot end obviously the hot end will bury into the bed before it zero's.

So, I see 2 options then for homing the Z axis to the hot end.

- move the switch in accordance with the hot end so that the hot end just touches the bed and then lock the switch in to place.

- use a Z probe on the hot end

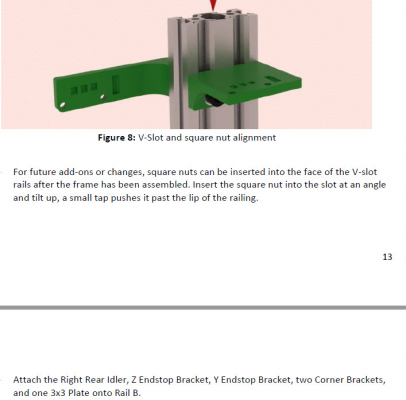

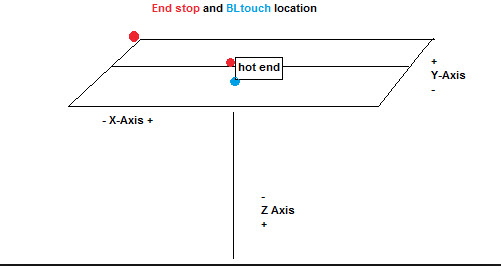

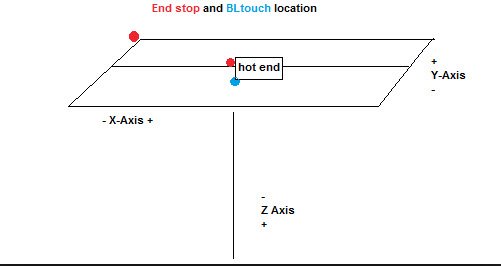

If that is the case, if using a Z probe, what is the purpose of the Z end stop at the top of the Z axis as shown in the image below on the left?

Using a Z Probe on the hot end I would think is the only solution?

If I move the switch to be above the hot end obviously the hot end will bury into the bed before it zero's.

So, I see 2 options then for homing the Z axis to the hot end.

- move the switch in accordance with the hot end so that the hot end just touches the bed and then lock the switch in to place.

- use a Z probe on the hot end

If that is the case, if using a Z probe, what is the purpose of the Z end stop at the top of the Z axis as shown in the image below on the left?

Using a Z Probe on the hot end I would think is the only solution?

|

Re: Newbie looking for some setup guidance... November 28, 2017 05:43PM |

Registered: 10 years ago Posts: 14,672 |

You can set up a Z min homing switch so that it triggers when the nozzle is close to the bed but not touching (e.g. 1mm off) and configure the firmware to know what the height is when the switch is triggered. But many people use just a Z probe, and no Z homing switches at all.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Newbie looking for some setup guidance... November 28, 2017 08:55PM |

Registered: 7 years ago Posts: 128 |

|

Re: Newbie looking for some setup guidance... November 29, 2017 02:49AM |

Registered: 10 years ago Posts: 14,672 |

Quote

ampapa

Anyone have suggestions for a compatible probe for the Duet?

I was looking at either, LJ18A3-8-Z/BX or LJ12A3-4-Z-BX...

See [duet3d.com] and [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Newbie looking for some setup guidance... November 29, 2017 09:15PM |

Registered: 7 years ago Posts: 128 |

|

Re: Newbie looking for some setup guidance... December 09, 2017 03:31PM |

Registered: 7 years ago Posts: 128 |

Making some progress today but having some problems zeroing my Z axis... my Z axis hits the end stop and reverses direction but never attempts to touch off the end stop a second time?

Original

Shouldn't it go 350+ then 2.5- then 10+?

ampapa,

Original

G91 ; Relative positioning G1 Z350 S1 F300 ; Move Z down until the switch triggers G1 Z-2.5 F150 G1 Z10 S1 F150 ; Move Z down until the switch triggers G90 ; Back to absolute positioning G92 Z10 ; Tell the firmware where we are

Shouldn't it go 350+ then 2.5- then 10+?

ampapa,

|

Re: Newbie looking for some setup guidance... December 09, 2017 04:22PM |

Registered: 11 years ago Posts: 5,780 |

You told it to drop 350 from whatever the starting point or until it hit the switch, then go up 2.5, then drop 10, or hit the switch. Then you're telling it the absolute coordinate is Z=10, but it seems to me it's going to leave the bed near the bottom of the Z axis.

Is there some reason you don't put the switch at Z=0 and then just use a normal homing command to zero the bed?

The firmware should be set to turn the motor toward the home switch when a home command is executed. Then, when the switch is triggered, you set the Z ordinate- Z=0 if the home switch is at the physical top of the Z axis near the extruder, or Z=300 or 350 or whatever it is if the switch is near the bottom of the Z axis.

The "normal" way to set up a switch for that is to bolt the switch to the printer's frame and have a screw on the bed/moving assembly that bumps the switch. Fine adjustments to the Z=0 position are made by turning the screw.

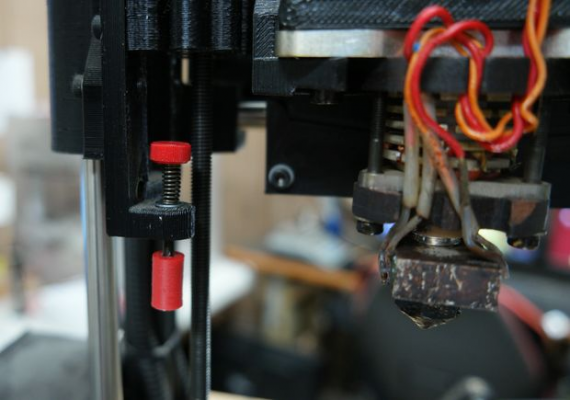

Here's an example from a Taz printer - the screw moves up and down with the X axis and bumps a switch that is mounted on the printer's frame. Turning the screw sets the Z=0 position. Part of what makes this a poor design is that one turn of the screw moves the nozzle 700 um (0.7 mm pitch screw), so fine adjustments can be tricky:

Here's the Z=0 switch on my CoreXY printer:

UMMD Z=0 switch

In this design, the cam bumps the switch that is bolted to the frame. The cam moves up and down with the bed, and allows for very fine adjustment of the Z=0 position (1 turn of the screw moves the Z=0 point by about 100 um).

You could mount the switch on the moving part, such as the bed or even on the extruder carriage, but then you have to run wires to a moving part and deal with the complications that frequent flexing may create. The switch is usually mounted on the frame so the wiring doesn't have to move. If you don't want the Z=0 switch to actually put the bed at the nozzle for fear of damage, offset it a few mm and then use a Z offset in your slicer or in the firmware. Triggering the switch close to the extruder in Z is more precise than triggering it at the physical bottom of the Z axis and then moving the bed up to the nozzle by 300 mm or so. It's also quieter and much faster than running the bed down and up at the start of every print, and reduces mechanical wear on the Z axis components.

My printer has a Zmax switch as well as a Z=0 switch. The Zmax switch is there to protect against driving the Z axis too far- the drive has a lot of torque and it may do some damage if the Z axis attempts to keep moving beyond the physical bottom of the machine. The Zmax switch stops the motion about 0.5 mm above the green TPU bumper.

Edited 6 time(s). Last edit at 12/09/2017 04:45PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Is there some reason you don't put the switch at Z=0 and then just use a normal homing command to zero the bed?

The firmware should be set to turn the motor toward the home switch when a home command is executed. Then, when the switch is triggered, you set the Z ordinate- Z=0 if the home switch is at the physical top of the Z axis near the extruder, or Z=300 or 350 or whatever it is if the switch is near the bottom of the Z axis.

The "normal" way to set up a switch for that is to bolt the switch to the printer's frame and have a screw on the bed/moving assembly that bumps the switch. Fine adjustments to the Z=0 position are made by turning the screw.

Here's an example from a Taz printer - the screw moves up and down with the X axis and bumps a switch that is mounted on the printer's frame. Turning the screw sets the Z=0 position. Part of what makes this a poor design is that one turn of the screw moves the nozzle 700 um (0.7 mm pitch screw), so fine adjustments can be tricky:

Here's the Z=0 switch on my CoreXY printer:

UMMD Z=0 switch

In this design, the cam bumps the switch that is bolted to the frame. The cam moves up and down with the bed, and allows for very fine adjustment of the Z=0 position (1 turn of the screw moves the Z=0 point by about 100 um).

You could mount the switch on the moving part, such as the bed or even on the extruder carriage, but then you have to run wires to a moving part and deal with the complications that frequent flexing may create. The switch is usually mounted on the frame so the wiring doesn't have to move. If you don't want the Z=0 switch to actually put the bed at the nozzle for fear of damage, offset it a few mm and then use a Z offset in your slicer or in the firmware. Triggering the switch close to the extruder in Z is more precise than triggering it at the physical bottom of the Z axis and then moving the bed up to the nozzle by 300 mm or so. It's also quieter and much faster than running the bed down and up at the start of every print, and reduces mechanical wear on the Z axis components.

My printer has a Zmax switch as well as a Z=0 switch. The Zmax switch is there to protect against driving the Z axis too far- the drive has a lot of torque and it may do some damage if the Z axis attempts to keep moving beyond the physical bottom of the machine. The Zmax switch stops the motion about 0.5 mm above the green TPU bumper.

Edited 6 time(s). Last edit at 12/09/2017 04:45PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Newbie looking for some setup guidance... December 09, 2017 07:22PM |

Registered: 7 years ago Posts: 128 |

Quote

the_digital_dentist

You told it to drop 350 from whatever the starting point or until it hit the switch, then go up 2.5, then drop 10, or hit the switch. Then you're telling it the absolute coordinate is Z=10, but it seems to me it's going to leave the bed near the bottom of the Z axis.

Is there some reason you don't put the switch at Z=0 and then just use a normal homing command to zero the bed?

The firmware should be set to turn the motor toward the home switch when a home command is executed. Then, when the switch is triggered, you set the Z ordinate- Z=0 if the home switch is at the physical top of the Z axis near the extruder, or Z=300 or 350 or whatever it is if the switch is near the bottom of the Z axis.

My current Z axis home switch is located at the top of the axis so that should be Z=0 for me if I'm not mistaken.

When running the command G1 Z350 S1 F300 what happens when it hits the switch, should it just stop? If I took all the other commands out is that what would happen?

G91 ; Relative positioning G1 Z350 S1 F300 ; Move Z up until the switch triggers

Slightly modified...

G91 ; Relative positioning G1 Z350 S1 F300 ; Move Z up until the switch triggers G1 Z-2.5 F150 ; Move Z down towards the table/bottom G1 Z10 S1 F150 ; Move Z up until the switch triggers G90 ; Back to absolute positioning G92 Z0 ; Tell the firmware where we are. Will this effectively set my Zmax?

I also realize that this is not the hot end Z0 that has to be accomplished by an offset of some type...

ampapa.

|

Re: Newbie looking for some setup guidance... December 10, 2017 12:26AM |

Registered: 11 years ago Posts: 5,780 |

Z=0 is/should be at/near the physical top of the Z axis, at the level of the extruder nozzle. Z=350 should be at/near the physical bottom of the Z axis. G1 Z 350 should send the bed downward, not upward. That means it will go away from the switch if the switch is at/near the top of the Z axis.

Why aren't you using a G28 command? The G28 command will send the bed toward the switch (if you have set the motor rotation correctly), then, when it bumps the switch, it will back off a few mm and slowly go up to hit the switch again and stop. You don't have to manually write that behavior using multiple G code commands, it's part of the G28 execution.

The first step in setting up the machine is to set the motor rotation directions so that a G28 command sends the extruder and bed toward the limit switches. The limit switches define specific, absolute coordinates, usually, (0,0,0), unless you tell the controller otherwise. G28 XYZ or just G28 should send all three axes toward the limit switches. G28 Z will home just the Z axis. If you send G28 Z and the bed moves away from the switch, the motor is turning the wrong direction. You can reverse the rotation direction of the Z axis motor by reversing the connector (kill the power before unplugging the motor!) or by inverting the direction signal to the Z axis driver in the firmware configuration.

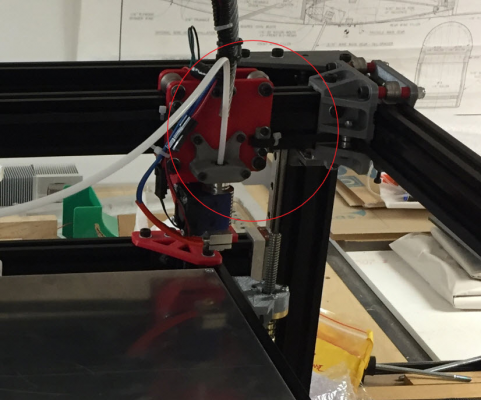

Maybe it would help if you post a photo of the machine and point out the location of the switch, and the thing that bumps the switch.

Take a look at this and see if it helps.

Edited 3 time(s). Last edit at 12/10/2017 01:00AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Why aren't you using a G28 command? The G28 command will send the bed toward the switch (if you have set the motor rotation correctly), then, when it bumps the switch, it will back off a few mm and slowly go up to hit the switch again and stop. You don't have to manually write that behavior using multiple G code commands, it's part of the G28 execution.

The first step in setting up the machine is to set the motor rotation directions so that a G28 command sends the extruder and bed toward the limit switches. The limit switches define specific, absolute coordinates, usually, (0,0,0), unless you tell the controller otherwise. G28 XYZ or just G28 should send all three axes toward the limit switches. G28 Z will home just the Z axis. If you send G28 Z and the bed moves away from the switch, the motor is turning the wrong direction. You can reverse the rotation direction of the Z axis motor by reversing the connector (kill the power before unplugging the motor!) or by inverting the direction signal to the Z axis driver in the firmware configuration.

Maybe it would help if you post a photo of the machine and point out the location of the switch, and the thing that bumps the switch.

Take a look at this and see if it helps.

Edited 3 time(s). Last edit at 12/10/2017 01:00AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Newbie looking for some setup guidance... December 10, 2017 02:43AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Newbie looking for some setup guidance... December 10, 2017 05:58AM |

Registered: 8 years ago Posts: 622 |

Quote

the_digital_dentist

.............................

Why aren't you using a G28 command? The G28 command will send the bed toward the switch (if you have set the motor rotation correctly), then, when it bumps the switch, it will back off a few mm and slowly go up to hit the switch again and stop. You don't have to manually write that behavior using multiple G code commands, it's part of the G28 execution.

The OP is using Duet electronics so G28 simply calls a macro. The macro contains the specific G code commands. G28 with no parameters will call the homeall.g macro. G 28 with an X,Y,Z (any other axis) parameter will run the associated macro i,.e homex.g, homey.g homez.g etc. The default macros usually work well but you can edit them. I think the OP is doing just that.

The Duet board will work with CoreXY, Cartesian, Scara, Polar, Idex etc, and the homing command will always be G28 but the behaviour will necessarily differ depending on the machine kinematics. Hence the use of (editable) macros which contain the specific gcode commands for any machine configuration.

|

Re: Newbie looking for some setup guidance... December 10, 2017 08:06AM |

Registered: 7 years ago Posts: 128 |

Here is the location of the Z switch..

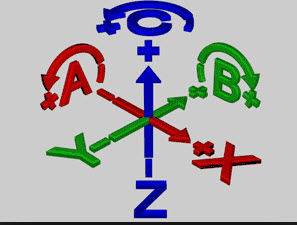

Why is the Z axis backwards from a CNC

I guess I should have paid more attention to the following, my Z axis is backwards.. no wonder why I'm having homing problems.

So, looking at the CoreXY from the front (Z stop back right) home or 0,0,0 will be front left with the bed at the top.

When beginning a print do you always start from 0,0,0 or start in the middle of the build plate like 150,150,0?

Why is the Z axis backwards from a CNC

I guess I should have paid more attention to the following, my Z axis is backwards.. no wonder why I'm having homing problems.

So, looking at the CoreXY from the front (Z stop back right) home or 0,0,0 will be front left with the bed at the top.

When beginning a print do you always start from 0,0,0 or start in the middle of the build plate like 150,150,0?

|

Re: Newbie looking for some setup guidance... December 10, 2017 08:52AM |

Registered: 10 years ago Posts: 14,672 |

Z-0 is when the nozzle is just touching the bed. If the bed moves in the Z axis, that is when the bed is at the top of its travel. If the bed doesn't move in the Z axis but the gantry does, that is when the gantry is at the bottom of its travel. So whether Z=0 is when the moving part of the Z axis is at the top or the bottom of its travel depends on which is moving, the bed or the gantry.

HTH David

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

HTH David

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Newbie looking for some setup guidance... December 10, 2017 09:20AM |

Registered: 11 years ago Posts: 5,780 |

As the bed is lowered during a print, the nozzle deposits plastic higher on the model being printed. That's why Z + is downward in a printer with the bed being lowered in Z. In machines that lift the X axis, including the extruder carriage, Z + is upward. As the nozzle moves upward, it deposits plastic higher on the model being printed.

I saw this posted earlier, so initially I thought he had it figured out,

but the problem description and the picture didn't match.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I saw this posted earlier, so initially I thought he had it figured out,

but the problem description and the picture didn't match.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Newbie looking for some setup guidance... December 10, 2017 09:26AM |

Registered: 7 years ago Posts: 128 |

|

Re: Newbie looking for some setup guidance... December 10, 2017 10:55AM |

Registered: 7 years ago Posts: 128 |

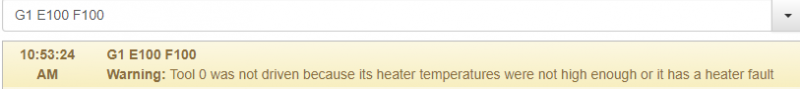

When configuring the extruder and measuring the filament output is it necessary for the printer to be at operating temperature?

Can this be done "offline"?

I guess the real question is should this be done through the hot end as I was going to take measurements with the PTFE tube out of the hot end...

Edited 2 time(s). Last edit at 12/10/2017 06:28PM by ampapa.

Can this be done "offline"?

I guess the real question is should this be done through the hot end as I was going to take measurements with the PTFE tube out of the hot end...

Edited 2 time(s). Last edit at 12/10/2017 06:28PM by ampapa.

|

Re: Newbie looking for some setup guidance... December 10, 2017 12:47PM |

Registered: 10 years ago Posts: 14,672 |

If you are just testing the extruder and not trying to force filament through the nozzle, you can send M302 P1 to enable cold extrusion.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Sorry, only registered users may post in this forum.