|

Re: New printer design with new 'twist' for XY on Z March 05, 2018 07:52PM |

Registered: 6 years ago Posts: 207 |

Quote

the_digital_dentist

Quote

klcjr89

In the reliable case of using three synchronized ballscrews with one stepper motor, would you recommend the fourth corner being a 25mm ground linear shaft?

I would not recommend that configuration at all. Screws provide motive force. Guide rails provide guidance. One round guide rail allows the bed to go up and down along the axis of the rail, and allows it to rotate around the rail. You need a second rail to prevent the rotation. 3 screws and 2 guide rails should do the job. I would not try to use screws or guide rails as structural elements.

I know you like the way your design looks, but it isn't very good mechanically. I think you have to decide if you want your printer to look nice or perform well. If you want both you may have to explore options that allow for more than 4 vertical elements.

Thank you. Would you say, I could use three 1505 ballscrews that are allowed to have the ballnut turn in a loose fit bushing (lift XY plate from the bottom), and two 20mm linear shafts for constrainment? So that would make my design have five columns instead of four, which is okay.

Edited 2 time(s). Last edit at 03/05/2018 07:56PM by klcjr89.

|

Re: New printer design with new 'twist' for XY on Z March 06, 2018 12:45AM |

Registered: 7 years ago Posts: 51 |

|

Re: New printer design with new 'twist' for XY on Z March 06, 2018 12:47AM |

Registered: 6 years ago Posts: 207 |

Quote

Vigilant

I do think the idea is good, but it doesn't address abnd resolve the number 1 problem with Z axis which is z banding.

It should if the bushings the ballnuts rotate within have a clearance inner diameter. Example: if the OD of the ballnut was 40mm, choose a 41mm ID or comparable bushing.

Edited 1 time(s). Last edit at 03/06/2018 12:47AM by klcjr89.

|

Re: New printer design with new 'twist' for XY on Z March 06, 2018 01:05AM |

Registered: 7 years ago Posts: 51 |

Quote

klcjr89

Quote

Vigilant

I do think the idea is good, but it doesn't address abnd resolve the number 1 problem with Z axis which is z banding.

It should if the bushings the ballnuts rotate within have a clearance inner diameter. Example: if the OD of the ballnut was 40mm, choose a 41mm ID or comparable bushing.

I'll believe it when I see the print result and how the layers align with each other.

|

Re: New printer design with new 'twist' for XY on Z March 06, 2018 01:08AM |

Registered: 6 years ago Posts: 207 |

Quote

Vigilant

Quote

klcjr89

Quote

Vigilant

I do think the idea is good, but it doesn't address abnd resolve the number 1 problem with Z axis which is z banding.

It should if the bushings the ballnuts rotate within have a clearance inner diameter. Example: if the OD of the ballnut was 40mm, choose a 41mm ID or comparable bushing.

I'll believe it when I see the print result and how the layers align with each other.

That won't happen until this thread can decide on the proper way about implementing this design as to not waste a grand.

|

Re: New printer design with new 'twist' for XY on Z March 06, 2018 01:14AM |

Registered: 11 years ago Posts: 5,780 |

You are planning on turning the nuts with the motors on the moving platform. Belts will loop around the motor pulleys and the nuts. Even if you use a "loose" bushing to hold the nuts to allow for unstraight screws, the belt tension is going to keep the nut pulled to one side (torward the motor). If the screw deviates from straight, it will still pull the moving platform to the side by pulling on the belt which will pull the motor which will pull the platform. It won't have the effect you want.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: New printer design with new 'twist' for XY on Z March 06, 2018 01:15AM |

Registered: 6 years ago Posts: 207 |

Quote

the_digital_dentist

You are planning on turning the nuts with the motors on the moving platform. Belts will loop around the motor pulleys and the nuts. Even if you use a "loose" bushing to hold the nuts to allow for unstraight screws, the belt tension is going to keep the nut pulled to one side (torward the motor). If the screw deviates from straight, it will still pull the moving platform to the side by pulling on the belt which will pull the motor which will pull the platform. It won't have the effect you want.

This was exactly the explanation I was needing, and I was able to visualize it. Thank you!

Edited 3 time(s). Last edit at 03/06/2018 01:47AM by klcjr89.

|

Re: New printer design with new 'twist' for XY on Z March 06, 2018 02:16AM |

Registered: 8 years ago Posts: 5,232 |

Quote

If the ballnut's OD is 40mm, I could solve this with just using a 42mm ID bushing, correct?

Not really, how would you deal with the belt tension? The stepper would have to "swim" too.

Sorry, DD already explained it much better than me.

The thread exploded over night, but I'd like to add another question:

What's the reason to have rotating ballnuts, instead of rotating screws?

With semi-fixed nuts and the belt around the screws, you could mount the stepper(s) to the ground.

Edited 1 time(s). Last edit at 03/06/2018 02:39AM by o_lampe.

|

Re: New printer design with new 'twist' for XY on Z March 06, 2018 02:39AM |

Registered: 6 years ago Posts: 207 |

|

Re: New printer design with new 'twist' for XY on Z March 06, 2018 10:24AM |

Registered: 6 years ago Posts: 1,007 |

This thread reminds me of this one: [forums.reprap.org]

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: New printer design with new 'twist' for XY on Z March 06, 2018 11:02AM |

Registered: 6 years ago Posts: 1,007 |

Quote

691175002

....

As I mentioned before, using ballscrews as linear guides is discouraged, but the datasheets make it seem pretty plausible. Its entirely possible that screws might be smoother than the Chinese LMU parts. [imgur.com]

Quote

the_digital_dentist

... I would not try to use screws or guide rails as structural elements.

....

Ball lead screws are perfectly suitable to be used as guides considering a 3D printer is NOT an accurate machine despite the use and abuse of "micron" in all the discussions. Even good TR lead screws are OK provided you custom fit the nuts to have close to no play and backlash.

BUT you have to take care of the possible misalignment and of course thermal expansion. For a Z mvt, one nut must be locked in X,Y, the second in X or Y, the third free in X and Y. (isostatism as used in DD three points bed support) You have to size them accordingly too.

I modified my Prusa Z in that sense and it is OK despite using just TR8. No wobble, just some minute ripple in sharp direction change.

Of course they are unsuitable to be used as structural elements ( "frame") like in this proposal which condemns it.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: New printer design with new 'twist' for XY on Z March 06, 2018 11:37AM |

Registered: 6 years ago Posts: 207 |

Quote

MKSA

Of course they are unsuitable to be used as structural elements ( "frame") like in this proposal which condemns it.

I wouldn't think of them as all that structural when the top and side plates go on to enclose the machine, other than to support the weight of the XY platform.

Or were you referring to using the TR8 leadscrews as the frame and I misquoted you?

Edited 2 time(s). Last edit at 03/06/2018 11:41AM by klcjr89.

|

Re: New printer design with new 'twist' for XY on Z March 06, 2018 01:13PM |

Registered: 6 years ago Posts: 1,007 |

Quote

klcjr89

Quote

MKSA

Of course they are unsuitable to be used as structural elements ( "frame") like in this proposal which condemns it.

I wouldn't think of them as all that structural when the top and side plates go on to enclose the machine, other than to support the weight of the XY platform.

Or were you referring to using the TR8 leadscrews as the frame and I misquoted you?

The way you use the ball screws, they are part of the structure, the frame. Can be seen in the rendering and you wrote it initially.

If you "attach" them to a frame as advised, then we are back to a more classic approach, still with plenty of issues some described above.

Edited 1 time(s). Last edit at 03/06/2018 01:20PM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: New printer design with new 'twist' for XY on Z March 06, 2018 01:23PM |

Registered: 6 years ago Posts: 207 |

Quote

MKSA

The way you use the ball screws, they are part of the structure, the frame. Can be seen in the rendering and you wrote it initially.

If you "attach" them to a frame as advised, then we are back to a more classic approach, still with plenty of issues some described above.

The printer needs an enclosure regardless, so it will have top and side plates. I think the print should be stationary like a delta and the reason for this design being created. Having the XY on a Mic-6 plate will guarantee they are on the same plane; just need to make sure the Z movement doesn't screw up anything.

Would love to solve these issues aesthetically

Edited 1 time(s). Last edit at 03/06/2018 01:24PM by klcjr89.

|

Re: New printer design with new 'twist' for XY on Z March 06, 2018 03:48PM |

Registered: 6 years ago Posts: 1,007 |

Quote

klcjr89

Quote

MKSA

The way you use the ball screws, they are part of the structure, the frame. Can be seen in the rendering and you wrote it initially.

If you "attach" them to a frame as advised, then we are back to a more classic approach, still with plenty of issues some described above.

The printer needs an enclosure regardless, so it will have top and side plates. I think the print should be stationary like a delta and the reason for this design being created. Having the XY on a Mic-6 plate will guarantee they are on the same plane; just need to make sure the Z movement doesn't screw up anything.

Would love to solve these issues aesthetically

To move the bed versus moving the whole XY gantry plus print head etc has already been discussed on this forum. Same plane guarantee ? Why ? So, document and justify why you think so.

Note the comparison with the Delta is irrelevant.

Same for aesthetic. See above, DD comments about youtube etc.... Functionality must prevail.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: New printer design with new 'twist' for XY on Z March 06, 2018 05:24PM |

Registered: 6 years ago Posts: 207 |

Quote

MKSA

Quote

klcjr89

Quote

MKSA

The way you use the ball screws, they are part of the structure, the frame. Can be seen in the rendering and you wrote it initially.

If you "attach" them to a frame as advised, then we are back to a more classic approach, still with plenty of issues some described above.

The printer needs an enclosure regardless, so it will have top and side plates. I think the print should be stationary like a delta and the reason for this design being created. Having the XY on a Mic-6 plate will guarantee they are on the same plane; just need to make sure the Z movement doesn't screw up anything.

Would love to solve these issues aesthetically

To move the bed versus moving the whole XY gantry plus print head etc has already been discussed on this forum. Same plane guarantee ? Why ? So, document and justify why you think so.

Note the comparison with the Delta is irrelevant.

Same for aesthetic. See above, DD comments about youtube etc.... Functionality must prevail.

Having the XY on a mic-6 plate is much better than using V slot which isn’t great when you do the measurements on a surface plate.

|

Re: New printer design with new 'twist' for XY on Z March 07, 2018 02:50AM |

Registered: 6 years ago Posts: 1,007 |

Quote

klcjr89

Having the XY on a mic-6 plate is much better than using V slot which isn’t great when you do the measurements on a surface plate.

V slots where ? What measurement ?

How rigid is your mic -6 plate with a big hole in the center ? Will it even still be flat when you have mounted everything ?

How about completing your built to give a clear picture.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: New printer design with new 'twist' for XY on Z March 07, 2018 12:31PM |

Registered: 6 years ago Posts: 207 |

Quote

MKSA

Quote

klcjr89

Having the XY on a mic-6 plate is much better than using V slot which isn’t great when you do the measurements on a surface plate.

V slots where ? What measurement ?

How rigid is your mic -6 plate with a big hole in the center ? Will it even still be flat when you have mounted everything ?

How about completing your built to give a clear picture.

I am not sure how to calculate the mic-6 plate's deflection when the center square section of it is cut out.

Edited 1 time(s). Last edit at 03/07/2018 12:32PM by klcjr89.

|

Re: New printer design with new 'twist' for XY on Z March 07, 2018 11:36PM |

Registered: 7 years ago Posts: 28 |

As far as I understand the cut aluminium plate as X/Y frame is mainly to keep YY symmetrical and angled, as that's the direction of the plates rigidity. The thickness to surface ratio I've seen till now look like they would twist in the Z direction. Now, a cut stone slab, that should assure a flat plane  (I'm only half kidding, a granite frame printer would be something)

(I'm only half kidding, a granite frame printer would be something)

(I'm only half kidding, a granite frame printer would be something)

(I'm only half kidding, a granite frame printer would be something)

|

Re: New printer design with new 'twist' for XY on Z March 08, 2018 03:31AM |

Registered: 6 years ago Posts: 1,007 |

Quote

orea

Now, a cut stone slab, that should assure a flat plane(I'm only half kidding, a granite frame printer would be something)

This is not kidding at all.

I have suggested that and plan it for the bed (1cm thick 25by25). Easy to find in graveyard(just use the side without the lettering

For the printer base, I looked to use a 40cm concrete slab but settled for a 4cm kitchen top, good enough, a bit lighter and better looking.

Edited 1 time(s). Last edit at 03/08/2018 03:32AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: New printer design with new 'twist' for XY on Z March 08, 2018 08:12AM |

Registered: 8 years ago Posts: 120 |

Quote

klcjr89

Quote

691175002

I edited my post with a few more details. The side-loads on a 3d printer might be small, but you are still looking at maybe 200-400g of acceleration depending on the speed and extruder being used.

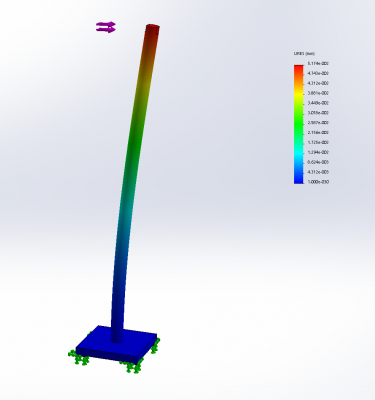

If you put that load on the very end of a 500mm rod that is only being held by a tiny section on one end it will still bend quite a bit. For example here is an extremely rough FEA where I modeled the whole assembly as a solid block of steel and it moves 0.05mm when 200g of force is applied. Its not awful, but the simulation is probably 2-4 times more rigid than your actual build will be and that kind of deflection will be visible.

The bigger problem IMO is that if you leave the rods unsupported and someone bumps into them you are essentially applying half a meter of leverage to a very small hole in a piece of cast aluminum. I'd guess 2Kg at the top of the rod could permanently damage the alignment of the printer.

Again, not awful, but not really something I'd want to risk.

Your post and edited post are helpful! When you mentioned the 22mm diameter leadscrew as 'doing almost nothing', do you mean that it's just oversized for no purpose other than visually matching the size of the linear shafts?

Would it be possible to lift the XY plate with only one ballscrew and not using my diagonal approach?

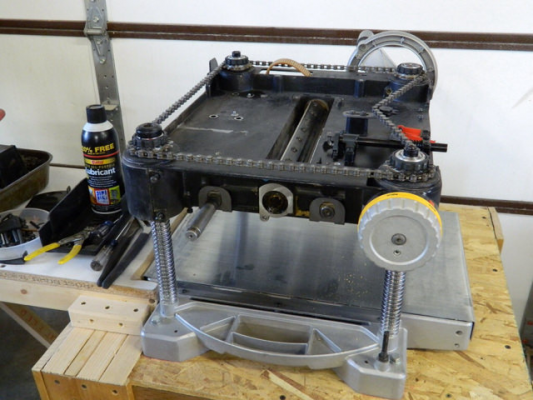

In the wood planer I mentioned, it actually uses 4 leadscrews as the posts and uses a closed loop chain to wrap around all four leadnuts:

Ohhh... you are using large leadscrews. Those should be more than enough to ensure the stability of the printer. Remember, when copying the design you need to copy all of it.

|

Re: New printer design with new 'twist' for XY on Z March 08, 2018 11:24AM |

Registered: 6 years ago Posts: 207 |

Quote

MatthewHall

Quote

klcjr89

Quote

691175002

I edited my post with a few more details. The side-loads on a 3d printer might be small, but you are still looking at maybe 200-400g of acceleration depending on the speed and extruder being used.

If you put that load on the very end of a 500mm rod that is only being held by a tiny section on one end it will still bend quite a bit. For example here is an extremely rough FEA where I modeled the whole assembly as a solid block of steel and it moves 0.05mm when 200g of force is applied. Its not awful, but the simulation is probably 2-4 times more rigid than your actual build will be and that kind of deflection will be visible.

The bigger problem IMO is that if you leave the rods unsupported and someone bumps into them you are essentially applying half a meter of leverage to a very small hole in a piece of cast aluminum. I'd guess 2Kg at the top of the rod could permanently damage the alignment of the printer.

Again, not awful, but not really something I'd want to risk.

Your post and edited post are helpful! When you mentioned the 22mm diameter leadscrew as 'doing almost nothing', do you mean that it's just oversized for no purpose other than visually matching the size of the linear shafts?

Would it be possible to lift the XY plate with only one ballscrew and not using my diagonal approach?

In the wood planer I mentioned, it actually uses 4 leadscrews as the posts and uses a closed loop chain to wrap around all four leadnuts:

Ohhh... you are using large leadscrews. Those should be more than enough to ensure the stability of the printer. Remember, when copying the design you need to copy all of it.

The large leadscrews were mentioned in my original post (22mm thick) and in my design pic, but sometimes it's hard to tell proportions from a picture. I don't think it's worth copying the small Z height of the planer.

Edited 1 time(s). Last edit at 03/08/2018 11:26AM by klcjr89.

|

Re: New printer design with new 'twist' for XY on Z March 14, 2018 12:46AM |

Registered: 7 years ago Posts: 51 |

Quote

klcjr89

Quote

the_digital_dentist

The planer doesn't have to worry about stacking 200 um layers of plastic on each other with a few 10s of microns accuracy and precision, and its Z movement range is just a few cm.

Is that only info you came to provide here? The planer can mantain a very precise Z depth on a piece of wood with loads of cutting force applied.

In your wood planning machine, if the Z depth deviates by 20 micron it is not visible to the naked eye. In a 3d printer, these deviation causes visible artifacts and surface quality.

Why do you think people are having z banding problems?

|

Re: New printer design with new 'twist' for XY on Z March 14, 2018 12:49AM |

Registered: 6 years ago Posts: 207 |

|

Re: New printer design with new 'twist' for XY on Z March 14, 2018 01:02AM |

Registered: 7 years ago Posts: 51 |

|

Re: New printer design with new 'twist' for XY on Z March 14, 2018 01:07AM |

Registered: 6 years ago Posts: 207 |

Quote

Vigilant

Quote

klcjr89

Quote

Vigilant

Why do you think people are having z banding problems?

Low qualitiy Chinese printers comes to mind at first.

Then do show us that an unguided ball screw can produce nice prints. If you're successful you can start a trend in building printers.

I will attempt it eventually on a printer meant just for experiments, I just have alot of other projects going on.

Edited 1 time(s). Last edit at 03/14/2018 01:07AM by klcjr89.

|

Re: New printer design with new 'twist' for XY on Z March 16, 2018 05:49PM |

Registered: 11 years ago Posts: 1,049 |

The planer only cuts the tiny amount that the blades stick out.

on some planners this is adjustable

--- many fixed at 1/8 " or tuned to the power of the motor and drive system

Leadscrews allow you to plop head down on wood and take the 1/8" cut that blade sticks out

and keep the feeder rollers (if it has them) in contact with wood

NOT a good example for 3D printing

on some planners this is adjustable

--- many fixed at 1/8 " or tuned to the power of the motor and drive system

Leadscrews allow you to plop head down on wood and take the 1/8" cut that blade sticks out

and keep the feeder rollers (if it has them) in contact with wood

NOT a good example for 3D printing

|

Re: New printer design with new 'twist' for XY on Z March 16, 2018 05:51PM |

Registered: 6 years ago Posts: 207 |

Sorry, only registered users may post in this forum.