Varriable belt tention

Posted by ArcherThompson

|

Varriable belt tention April 17, 2018 11:41PM |

Registered: 6 years ago Posts: 5 |

Ok so I have A homemade core xy build and I noticed today that when moving in the y direction one of my belts became very very tight at the other end. The other belt doesnt do this. I am sure it wasnt doing this before or it was it has gotten way way worse because ive printing on it for 3 weeks and then today its completly not working.. It is like a spectrum so when the x gantry is all the back towards the motors the belt is the perfect length, when its on the opposite side it is about 15-16 mm to short (when detached of course otherwise it just stops). Nothing apperent on the frame has changed and I can not wrap my head around what would cause it to do this.

|

Re: Varriable belt tention April 18, 2018 03:45AM |

Registered: 8 years ago Posts: 5,232 |

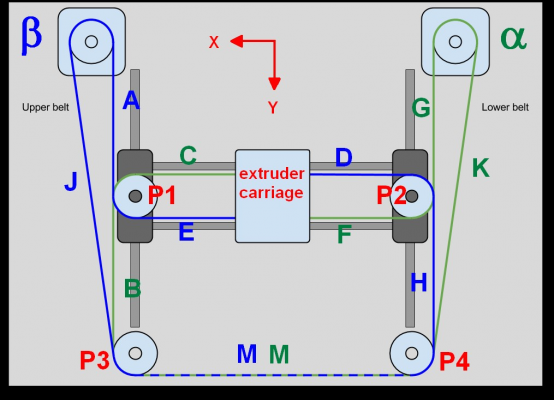

Digital Dentist has a nice picture posted recently, where the relevant sections of the belt (A-H ) are shown that has_to_be parallel to the axis'. Otherwise the belt tension varies, just as you described. Maybe one of your idler shafts got bent?

Edited 2 time(s). Last edit at 04/18/2018 03:47AM by o_lampe.

Edited 2 time(s). Last edit at 04/18/2018 03:47AM by o_lampe.

|

Re: Varriable belt tention April 18, 2018 07:57AM |

Registered: 11 years ago Posts: 5,780 |

In that image, belt segments labeled A-H have to be parallel to the guide rails. If they are not, the tension will vary with the position of the extruder carriage and prints will be distorted, especially as you get away from the center of the range of motion. Segments J, K, and M do not have to be parallel to the guide rails. It sounds like you have a severe case of non parallel belts...

This is what the belts should look like:

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

This is what the belts should look like:

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Varriable belt tention April 18, 2018 08:30AM |

Registered: 6 years ago Posts: 5 |

|

Re: Varriable belt tention April 18, 2018 11:33AM |

Registered: 6 years ago Posts: 5 |

|

Re: Varriable belt tention April 18, 2018 06:33PM |

Registered: 11 years ago Posts: 5,780 |

|

Re: Varriable belt tention April 18, 2018 08:56PM |

Registered: 6 years ago Posts: 5 |

|

Re: Varriable belt tention April 18, 2018 09:31PM |

Registered: 10 years ago Posts: 770 |

|

Re: Varriable belt tention April 18, 2018 11:38PM |

Registered: 11 years ago Posts: 5,780 |

Yeah, I'd say you definitely need to fix that. Don't feel bad. It's a common mistake, and I'd bet money that you won't repeat it in your next printer. And there will be a next one...

One more suggestion: don't feed filament from a spool with the axis oriented vertically. You're asking for problems. When the filament on a newish spool springs off the flanges and drops in a pile at the bottom of the spool holder (or the bottom flange of the spool), it's liable to tie itself into knots. If you orient the spool with its axis horizontal, there's less of a tendency to do that. Better still is to add some rollers that rest against the edges of the spools flanges and prevent the uncoiling. Finally, always handle the filament spools carefully. Never let the free end of the filament loose. When you take it off the printer, keep it under control at all times and feed it through the holes in the edge of the flange so it can't uncoil.

I've had good results from these two spool holder designs, but there are many other, equally effective designs if you look around thingiverse and youmagine.

[drmrehorst.blogspot.com]

[www.youmagine.com]

One final bit of advice, since you are new to all this... Youmagine and Thingiverse are like the rest of the internet. Anyone can publish anything they want to. As a result there are a lot of bad designs, some of which are unprintable (with current technology). Until you get some CAD chops, stick with designs that have photos of printed parts. If there are no photos either by the original author or by someone else in the "I printed this" section, it's best to keep looking. Sometimes those designs, even if unprintable can serve as inspiration for your own designs.

Edited 1 time(s). Last edit at 04/19/2018 12:20AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

One more suggestion: don't feed filament from a spool with the axis oriented vertically. You're asking for problems. When the filament on a newish spool springs off the flanges and drops in a pile at the bottom of the spool holder (or the bottom flange of the spool), it's liable to tie itself into knots. If you orient the spool with its axis horizontal, there's less of a tendency to do that. Better still is to add some rollers that rest against the edges of the spools flanges and prevent the uncoiling. Finally, always handle the filament spools carefully. Never let the free end of the filament loose. When you take it off the printer, keep it under control at all times and feed it through the holes in the edge of the flange so it can't uncoil.

I've had good results from these two spool holder designs, but there are many other, equally effective designs if you look around thingiverse and youmagine.

[drmrehorst.blogspot.com]

[www.youmagine.com]

One final bit of advice, since you are new to all this... Youmagine and Thingiverse are like the rest of the internet. Anyone can publish anything they want to. As a result there are a lot of bad designs, some of which are unprintable (with current technology). Until you get some CAD chops, stick with designs that have photos of printed parts. If there are no photos either by the original author or by someone else in the "I printed this" section, it's best to keep looking. Sometimes those designs, even if unprintable can serve as inspiration for your own designs.

Edited 1 time(s). Last edit at 04/19/2018 12:20AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Varriable belt tention April 19, 2018 07:31AM |

Registered: 11 years ago Posts: 5,780 |

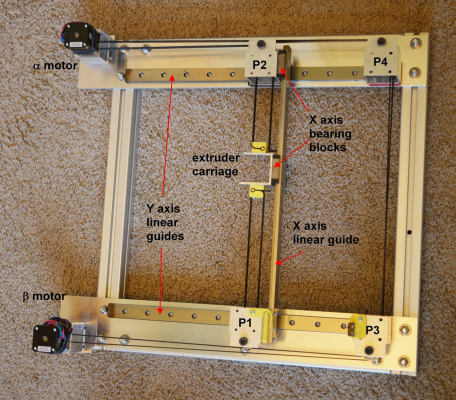

Closer look at the photos of the belt attachment to the extruder carriage finds that the attachment point on the carriage is at a lower Z altitude than the pulley that is feeding it, meaning the belt is twisting. That's going to cause all sorts of problems, too. Belts are intended to operate on flat pulleys that are all in-line vertically. Your design should have an upper belt and a lower belt, and the two must stay at the same altitude from one end of the belt to the other -both ends anchor at the extruder carriage, but on opposite sides of the carriage. Also, you're trying to anchor the belts on those skinny little posts on the extruder carriage which will certainly flex and most likely snap off when you properly tension the belts, once you get the belt paths sorted out.

This is the belt clamp I used in UMMD to illustrate a better method. Self locking designs like mine (fold the belt so the teeth engage in a narrow slot), or zip ties work OK too, but you have to design the clamp with accurately located slots to keep the C, D, E, and F belt segments parallel to the X axis guide rail(s), and with proper vertical spacing to prevent twisting the belts. That means you have to consider the pulley diameters and the belt thicknesses when figuring out how to space the slots on the clamps or the pulley positions on the ends of the X axis. This is where learning to use CAD software can really help- you make models of the parts you're using and get them positioned for proper belt paths in CAD, then make measurements from the CAD file to locate where to drill holes, or print parts with slots in the real world.

The physical limits of motion of the machine depend on the spacing between the X and Y axis guide rails. You have the X axis rails spaced far apart and the Y axis rails relatively close together. That's great for using longer bearings and that minimizes play in the extruder carriage, but severely limits range of motion, and possible print X and Y dimensions. You can stack the pulleys on the ends of the X axis which will allow you to move the X axis rails closer together and get greater range of motion in Y, however, you're using a printed plastic extruder carriage which will probably flex unless you beef up the design a lot for stacked pulleys.

Don't let the belt run against the Z axis lead screw. The oil/grease on the screw will destroy the belt (and interferes with the smooth motion of the belt for XY positioning). You can cut the lead screw using a cut-off wheel on a dremel tool or grinder.

Edited 2 time(s). Last edit at 04/19/2018 11:56AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

This is the belt clamp I used in UMMD to illustrate a better method. Self locking designs like mine (fold the belt so the teeth engage in a narrow slot), or zip ties work OK too, but you have to design the clamp with accurately located slots to keep the C, D, E, and F belt segments parallel to the X axis guide rail(s), and with proper vertical spacing to prevent twisting the belts. That means you have to consider the pulley diameters and the belt thicknesses when figuring out how to space the slots on the clamps or the pulley positions on the ends of the X axis. This is where learning to use CAD software can really help- you make models of the parts you're using and get them positioned for proper belt paths in CAD, then make measurements from the CAD file to locate where to drill holes, or print parts with slots in the real world.

The physical limits of motion of the machine depend on the spacing between the X and Y axis guide rails. You have the X axis rails spaced far apart and the Y axis rails relatively close together. That's great for using longer bearings and that minimizes play in the extruder carriage, but severely limits range of motion, and possible print X and Y dimensions. You can stack the pulleys on the ends of the X axis which will allow you to move the X axis rails closer together and get greater range of motion in Y, however, you're using a printed plastic extruder carriage which will probably flex unless you beef up the design a lot for stacked pulleys.

Don't let the belt run against the Z axis lead screw. The oil/grease on the screw will destroy the belt (and interferes with the smooth motion of the belt for XY positioning). You can cut the lead screw using a cut-off wheel on a dremel tool or grinder.

Edited 2 time(s). Last edit at 04/19/2018 11:56AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Varriable belt tention April 19, 2018 11:00AM |

Registered: 6 years ago Posts: 5 |

Sorry, only registered users may post in this forum.