My 3d printer (work in progress)

Posted by DocRaptor

|

My 3d printer (work in progress) May 06, 2018 08:41PM |

Registered: 6 years ago Posts: 51 |

Hi everyone,

I currently design and building my own 3d printer from scratch. The first fews tries failed with the x and y axes. I tried the ultimaker-style, but leveling linear guides was nearly imposible (and first I tried it with leadscrew [one linearguide per axis replaced with leadsrews]). So I try now the h-bot design, but I wait for a few printed parts to be printed (I don't have my own printer, so this is my first 3d printer). But I thought I upload the files for the printer. The chassis for the printer is made out of 4mm din a4 plywood. I will upload photos as soon as possible. There are no mounts for the xy steppermotors because I work on them for the moment. But maybe you can reuse parts of the current design for your printer design and maybe i have succses this time and it works.

Everything is done in openscad.

I currently design and building my own 3d printer from scratch. The first fews tries failed with the x and y axes. I tried the ultimaker-style, but leveling linear guides was nearly imposible (and first I tried it with leadscrew [one linearguide per axis replaced with leadsrews]). So I try now the h-bot design, but I wait for a few printed parts to be printed (I don't have my own printer, so this is my first 3d printer). But I thought I upload the files for the printer. The chassis for the printer is made out of 4mm din a4 plywood. I will upload photos as soon as possible. There are no mounts for the xy steppermotors because I work on them for the moment. But maybe you can reuse parts of the current design for your printer design and maybe i have succses this time and it works.

Everything is done in openscad.

|

Re: My 3d printer (work in progress) May 08, 2018 01:07PM |

Registered: 8 years ago Posts: 120 |

|

Re: My 3d printer (work in progress) May 08, 2018 04:30PM |

Registered: 6 years ago Posts: 51 |

Quote

MatthewHall

Pictures please?

Im still waiting for the printed parts to arive. I should get the things today, but unfortunately the guy who print the parts for me on his printer forgett the parts at home. I hope I get them tomorrow, so I can mount everything toghether and to make photos.

Edited 2 time(s). Last edit at 05/08/2018 04:34PM by DocRaptor.

|

Re: My 3d printer (work in progress) May 09, 2018 02:49PM |

Registered: 6 years ago Posts: 51 |

I got the last parts.

Pictures of mounting the y-axis and the chassis. Unfortunately a piece broke, but fortunately I got the option to print the piece by somebody in a short time.

Pictures of mounting the y-axis and the chassis. Unfortunately a piece broke, but fortunately I got the option to print the piece by somebody in a short time.

|

Re: My 3d printer (work in progress) May 10, 2018 01:52AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: My 3d printer (work in progress) May 10, 2018 05:27AM |

Registered: 6 years ago Posts: 51 |

Quote

o_lampe

Only one part broke? IMHO, they look horrible...I hope you didn't pay too much? Are they made from ABS? Then you can use Acetone to treat them and repair.

The first thing, you should print on your own printer are replacement parts.

These are made out of PLA. And I didn't pay much for them. The grey parts are printed with an anet a6, but the owner of it is (still) waiting for his prusa i3 mk3 to arrive. And the printer which printed the blue part printed a rubber material before (and a lot of other materials. It has nearly 10000 hours on the counter).

After I calibrate it I will print improved parts because I found a few smaller design flaws

|

Re: My 3d printer (work in progress) May 12, 2018 03:08AM |

Registered: 6 years ago Posts: 1,007 |

|

Re: My 3d printer (work in progress) May 12, 2018 07:44AM |

Registered: 6 years ago Posts: 51 |

|

Re: My 3d printer (work in progress) May 12, 2018 07:51AM |

Registered: 6 years ago Posts: 51 |

Now the z-axis (this is an older assambly more as an Mockup, but I worked ok so I reuse it).

|

Re: My 3d printer (work in progress) May 12, 2018 10:29AM |

Registered: 6 years ago Posts: 51 |

More mounting. I forgot to let the pulleymount be printed, but some 1,5mm aluminum works in this case, too. It also works a mountingbracket for nema 23 stepper motors (Why Nema 23? I had them lying around).

Attachments:

open | download - 1.JPG (404.5 KB)

open | download - 2.JPG (442 KB)

open | download - 3.JPG (490.9 KB)

open | download - 4.JPG (416 KB)

open | download - 5.JPG (460.2 KB)

open | download - 6.JPG (549 KB)

open | download - 7.JPG (417.3 KB)

open | download - 8.JPG (379.7 KB)

open | download - 9.JPG (520.4 KB)

open | download - 10.JPG (425 KB)

open | download - 1.JPG (404.5 KB)

open | download - 2.JPG (442 KB)

open | download - 3.JPG (490.9 KB)

open | download - 4.JPG (416 KB)

open | download - 5.JPG (460.2 KB)

open | download - 6.JPG (549 KB)

open | download - 7.JPG (417.3 KB)

open | download - 8.JPG (379.7 KB)

open | download - 9.JPG (520.4 KB)

open | download - 10.JPG (425 KB)

|

Re: My 3d printer (work in progress) May 12, 2018 10:32AM |

Registered: 6 years ago Posts: 51 |

|

Re: My 3d printer (work in progress) May 13, 2018 09:18AM |

Registered: 11 years ago Posts: 5,780 |

A few random comments...

The motor mounts, X axis pulley mounts , and far corner pulley mounts are going to flex inward as soon as you tension the belts. Motor and pulley mounts need to be "beefy" to resist the forces applied by the belts.

The X axis pulleys should have flanges.

NEMA-23 motors are going to be loud, especially mounted on large plywood resonators.

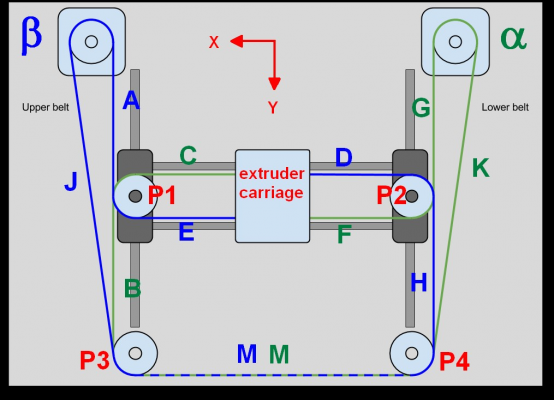

The belt paths don't look right. The variable length segments must be parallel to their guide rails. In the diagram below, segments labeled A-H must be parallel to the guide rails. If they are not, belt tension will vary with extruder carriage position, and more importantly, the steps/mm in X and Y will vary with extruder carriage position and prints will be distorted as a result. It looks like your segments C-F are not parallel to the X axis, even once tension is applied.

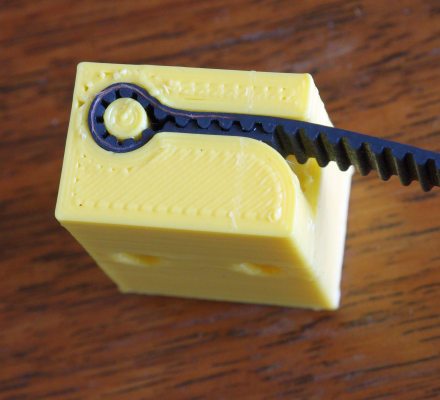

Belt clamps can be made self-locking by folding the toothed side of the belt back on itself, like this:

I suspect the very long, very thin metal hot-end mount is going to flex while printing which will spoil print quality.

No bearings on the far corner pulleys? No Z axis bearings?

In general, the Z axis screw shouldn't need an antibacklash nut. The Z axis, like other axes, should move smoothly in both directions if properly aligned. Gravity will keep the nut in contact with the screw threads at all times, whether the Z axis is moving up or down. Anti backlash nuts are needed in horizontal motion systems where you don't have gravity providing a continuous load.

Edited 2 time(s). Last edit at 05/13/2018 09:29AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

The motor mounts, X axis pulley mounts , and far corner pulley mounts are going to flex inward as soon as you tension the belts. Motor and pulley mounts need to be "beefy" to resist the forces applied by the belts.

The X axis pulleys should have flanges.

NEMA-23 motors are going to be loud, especially mounted on large plywood resonators.

The belt paths don't look right. The variable length segments must be parallel to their guide rails. In the diagram below, segments labeled A-H must be parallel to the guide rails. If they are not, belt tension will vary with extruder carriage position, and more importantly, the steps/mm in X and Y will vary with extruder carriage position and prints will be distorted as a result. It looks like your segments C-F are not parallel to the X axis, even once tension is applied.

Belt clamps can be made self-locking by folding the toothed side of the belt back on itself, like this:

I suspect the very long, very thin metal hot-end mount is going to flex while printing which will spoil print quality.

No bearings on the far corner pulleys? No Z axis bearings?

In general, the Z axis screw shouldn't need an antibacklash nut. The Z axis, like other axes, should move smoothly in both directions if properly aligned. Gravity will keep the nut in contact with the screw threads at all times, whether the Z axis is moving up or down. Anti backlash nuts are needed in horizontal motion systems where you don't have gravity providing a continuous load.

Edited 2 time(s). Last edit at 05/13/2018 09:29AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My 3d printer (work in progress) May 13, 2018 12:42PM |

Registered: 6 years ago Posts: 51 |

I know there are some designflaws, but at least its not a complet desaster like my previous designs I talked about. I use the Nema 23 motors now because I had them liyng around for years and the next design I work on will have Nema 17 motors. This printer will getting after setting up the electronics better pulley-mounts, hotend-mounts and better motor-mounts, so that the belts are correct. The next version will get corner-pices with integrated pulley-mounts and axis-mounts, corner-pices with integrated motor-mounts and axis-mounts and many other things.So its not end of the line.

|

Re: My 3d printer (work in progress) May 15, 2018 10:43AM |

Registered: 8 years ago Posts: 338 |

|

Re: My 3d printer (work in progress) May 15, 2018 02:42PM |

Registered: 11 years ago Posts: 1,049 |

Are the design requirements:

Not to be based on any proven design

Use only hardware that is handy

Print should not be visible when printing (hole cut in plywood - would not make it much more flimsy)

Bed leveling next to impossible

Do not use bolts or screws of the proper length?

Do not cut bolts / screws to proper length?

Do not use lock washers or stop nuts

Drywall screw thru plywood not too good (point sticking out will make you bleed) --- why not bolt and nut?

Z Axis extreme cantalever

Drywall screws holding Z axis bracket?

Tubes as Z axis guides -- how will they ever be straight -- perhaps outside should be polished for bearings

Z-Axis bearings what are they

7mm plywood (not even 7 layer Baltic) has to be constructed like furniture to be strong and orthagonal (right angles)

It may print --- but NOT well / consistant

Perhaps a look at designs at Open Builds

[openbuilds.com]

Not to be based on any proven design

Use only hardware that is handy

Print should not be visible when printing (hole cut in plywood - would not make it much more flimsy)

Bed leveling next to impossible

Do not use bolts or screws of the proper length?

Do not cut bolts / screws to proper length?

Do not use lock washers or stop nuts

Drywall screw thru plywood not too good (point sticking out will make you bleed) --- why not bolt and nut?

Z Axis extreme cantalever

Drywall screws holding Z axis bracket?

Tubes as Z axis guides -- how will they ever be straight -- perhaps outside should be polished for bearings

Z-Axis bearings what are they

7mm plywood (not even 7 layer Baltic) has to be constructed like furniture to be strong and orthagonal (right angles)

It may print --- but NOT well / consistant

Perhaps a look at designs at Open Builds

[openbuilds.com]

|

Re: My 3d printer (work in progress) May 15, 2018 04:07PM |

Registered: 8 years ago Posts: 338 |

|

Re: My 3d printer (work in progress) May 15, 2018 04:13PM |

Registered: 8 years ago Posts: 338 |

|

Re: My 3d printer (work in progress) May 16, 2018 01:50AM |

Registered: 6 years ago Posts: 1,007 |

|

Re: My 3d printer (work in progress) May 16, 2018 04:57AM |

Registered: 6 years ago Posts: 51 |

Quote

cozmicray

Are the design requirements:

Not to be based on any proven design

Use only hardware that is handy

Print should not be visible when printing (hole cut in plywood - would not make it much more flimsy)

Bed leveling next to impossible

Do not use bolts or screws of the proper length?

Do not cut bolts / screws to proper length?

Do not use lock washers or stop nuts

I wanted to take a picture of the bed leveling system with springs and knurled nuts (like most printer have), where the printbed sits (a mirror. These were cheap in 15cmx15cm for 12 peaces in my local hardware store), but I forget to put the sd card in to the camera (genius).

With the bolt and screw and a few other things: Most of the stuf I used is stuff I have liyng around.

With the print being not visible: I have no proper saw and the saws (electric) my father have, well he say: 5cm is a small tolerance.

Quote

Qdeathstar

How do you plan to drive the steppers, do you already have drivers?

I currently wiring all the stuff to a ramps 1.4 with A4988 stepper drivers.

Edited 1 time(s). Last edit at 05/16/2018 05:00AM by DocRaptor.

|

Re: My 3d printer (work in progress) May 16, 2018 07:34AM |

Registered: 8 years ago Posts: 338 |

|

Re: My 3d printer (work in progress) May 16, 2018 08:42AM |

Registered: 6 years ago Posts: 1,007 |

|

Re: My 3d printer (work in progress) May 16, 2018 09:01AM |

Registered: 6 years ago Posts: 51 |

|

Re: My 3d printer (work in progress) May 16, 2018 09:19AM |

Registered: 11 years ago Posts: 5,780 |

You can run NEMA-23 motors using the A4988 drivers. As long as you keep the current down to a level that doesn't overheat the drivers the motors will run and probably deliver as much torque/speed as you need. I did it for a couple years in SoM when it used A/R. Right now the X and Z axes are NEMA-23 motors driven by the drivers on the SmoothieBoard.

Edited 1 time(s). Last edit at 05/17/2018 09:31AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Edited 1 time(s). Last edit at 05/17/2018 09:31AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My 3d printer (work in progress) May 17, 2018 08:41AM |

Registered: 6 years ago Posts: 51 |

|

Re: My 3d printer (work in progress) May 20, 2018 04:23PM |

Registered: 6 years ago Posts: 51 |

I made my first testprint (and abort it). There a few problems, but these things I hope can be fixed with adjust the software and some other things. The Extruder push to much and is rubing on the fillament and there is no fan in the moment, I have to mount one. I but I hope to solve them.

|

Re: My 3d printer (work in progress) May 21, 2018 01:06AM |

Registered: 6 years ago Posts: 60 |

|

Re: My 3d printer (work in progress) May 21, 2018 04:50AM |

Registered: 6 years ago Posts: 51 |

|

Re: My 3d printer (work in progress) May 21, 2018 11:03AM |

Registered: 6 years ago Posts: 63 |

|

Re: My 3d printer (work in progress) May 21, 2018 05:58PM |

Registered: 10 years ago Posts: 14,672 |

Quote

warbunniex

You should go for some bigfoot drivers. youll be able to handle much higher current. though i would suggest a cooling fan for the drivers.

Or use Duet electronics, which has the TMC2660 high-current drivers on-board. The Duet doesn't normally need a cooling fan unless you set the motor currents above 2.0A.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: My 3d printer (work in progress) May 28, 2018 06:29PM |

Registered: 6 years ago Posts: 51 |

After some calibration I got it working. The prints, well let us say they aren't the best, but I can work with them. I started to print some mounts for 8mm aluminum tube profiles. These parts will mount to the axis mounts to reinforce the printer. I upload this part. Also I upload some of the files of new parts for version 2 of the printer. This includes: Axis mounts with integrated 8mm tube profiles mounts for reinforcing, corected belt pulley mounts with offset for 4x8x3 mm ball bearings to be used as pulleymounts, axis bearing and linear guide mount in the version for 12mm bushing and 10mm bushing, stronger mounting points for 4x8x3 mm ball bearings to be used as return pulleys, and corner pices for the bottom under the printer with integrated 8mm tube profiles mounts for reinforcing, which also provides mounting points for a controllpanel and an ac socket.

Sorry, only registered users may post in this forum.