CoreXY or Ultimaker gantry

Posted by karl0508

|

CoreXY or Ultimaker gantry June 20, 2018 05:09AM |

Registered: 6 years ago Posts: 8 |

Hi Guys

I currently have a Prusa I3 clone, i love it, i use a bowden extruder and use it for PLA and PETG

I would now like to make a CoreXY machine of my own design, however because i have not got any experience with a CoreXY machine i would like some opinions.

I plan on having a 150×150×150mm build area.

So my biggest question is what are the advantage of the CoreXY vs the ultimaker gantry?

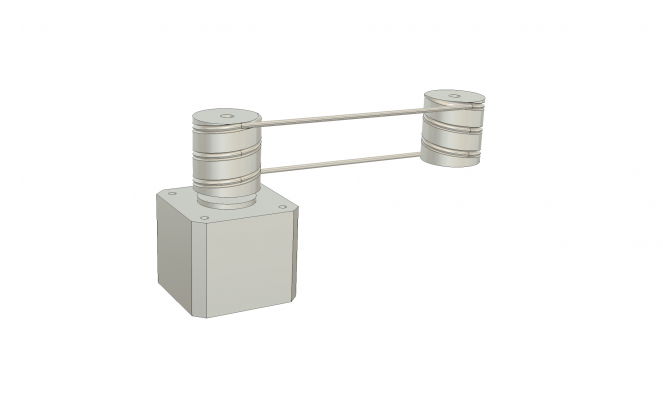

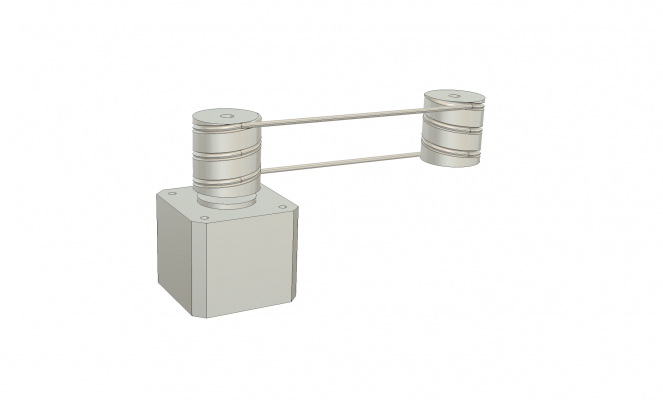

I have attached an image of the concept i had started, please not i have 2 X gantries in the model, this is only to make sure the hotend can move all the way to the correct build area

I currently have a Prusa I3 clone, i love it, i use a bowden extruder and use it for PLA and PETG

I would now like to make a CoreXY machine of my own design, however because i have not got any experience with a CoreXY machine i would like some opinions.

I plan on having a 150×150×150mm build area.

So my biggest question is what are the advantage of the CoreXY vs the ultimaker gantry?

I have attached an image of the concept i had started, please not i have 2 X gantries in the model, this is only to make sure the hotend can move all the way to the correct build area

|

Re: CoreXY or Ultimaker gantry June 21, 2018 01:32AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: CoreXY or Ultimaker gantry June 21, 2018 12:53PM |

Registered: 6 years ago Posts: 8 |

|

Re: CoreXY or Ultimaker gantry June 21, 2018 05:28PM |

Registered: 5 years ago Posts: 30 |

|

Re: CoreXY or Ultimaker gantry June 21, 2018 05:36PM |

Registered: 6 years ago Posts: 8 |

|

Re: CoreXY or Ultimaker gantry June 21, 2018 06:27PM |

Registered: 10 years ago Posts: 43 |

|

Re: CoreXY or Ultimaker gantry June 21, 2018 09:21PM |

Registered: 5 years ago Posts: 30 |

|

Re: CoreXY or Ultimaker gantry June 22, 2018 02:26AM |

Registered: 6 years ago Posts: 8 |

Perhaps a corexy machine like dice but using Fireline, would allow you go put idlers closer together, reduce the size of the XY joiner.

Anything to reduce foot print, i could also look to make a single printable plate that all the mechanism mounts to.

Sort of like the original CoreXY steel plate

Anything to reduce foot print, i could also look to make a single printable plate that all the mechanism mounts to.

Sort of like the original CoreXY steel plate

|

Re: CoreXY or Ultimaker gantry June 22, 2018 02:56AM |

Registered: 10 years ago Posts: 43 |

|

Re: CoreXY or Ultimaker gantry June 22, 2018 03:02AM |

Registered: 6 years ago Posts: 8 |

Could do what E3D have done and use an extra idler to bring the belts together.

The problem i always have with small printers is because we still use Nema 17 the mechanics still have to be so large, nema 14 would be better as they would take less percentage away from the print area.

Suppose thats one of the advantages of ultimaker gantry as you can mount the motors is such a way you don't have that as an issue

The problem i always have with small printers is because we still use Nema 17 the mechanics still have to be so large, nema 14 would be better as they would take less percentage away from the print area.

Suppose thats one of the advantages of ultimaker gantry as you can mount the motors is such a way you don't have that as an issue

|

Re: CoreXY or Ultimaker gantry June 22, 2018 04:42AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: CoreXY or Ultimaker gantry June 22, 2018 04:44AM |

Registered: 6 years ago Posts: 8 |

Quote

o_lampe

Quote

adambrum

I would keep away from fireline especially on a small printer, the line tends to walk on the drive pulley which alter the length

I posted a 'crossed' version of line pulleys, which eliminates the length-issue.

Could you please share me a link? this would allow the lines to be closer than 13 mm which the belts have as a gap, this would reduce overall foot print

|

Re: CoreXY or Ultimaker gantry June 23, 2018 03:06AM |

Registered: 8 years ago Posts: 5,232 |

It starts on page 2 of this thread, but it's worth reading it from the beginning:

replace belts with FireLine

replace belts with FireLine

|

Re: CoreXY or Ultimaker gantry June 23, 2018 11:25AM |

Registered: 11 years ago Posts: 5,780 |

An observation about pulleys used with cable: in all the drawings the cable is coming off the pulleys at an angle and it seems you're relying on the pulley to find its position to wrap on the pulley by using the already wrapped cable as a guide, and it always occurs at and angle to the desired motion- the cable is not parallel to the guide rail.

Is there some reason you don't put "threads" in the pulleys to guide the cable straight? If one pulley is left hand threaded and the other is right hand threaded the cable will come off and go onto the pulleys parallel to the guide rail and there will be no danger of the cable getting crossed and feeding at any other angle. Such pulleys would be printable, except that they may not hold up well under the forces applied by the tension on the cable. They would not be hard to turn on a lathe. Something like this:

I think this technique was used in cable driven plotters for years.

Or maybe I'm misunderstanding what is being described...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Is there some reason you don't put "threads" in the pulleys to guide the cable straight? If one pulley is left hand threaded and the other is right hand threaded the cable will come off and go onto the pulleys parallel to the guide rail and there will be no danger of the cable getting crossed and feeding at any other angle. Such pulleys would be printable, except that they may not hold up well under the forces applied by the tension on the cable. They would not be hard to turn on a lathe. Something like this:

I think this technique was used in cable driven plotters for years.

Or maybe I'm misunderstanding what is being described...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: CoreXY or Ultimaker gantry June 23, 2018 10:13PM |

Registered: 11 years ago Posts: 939 |

I did something similar years ago.

[3dprinterhell.blogspot.com]

It works fine, but IMO it’s just not worth the effort, belts and pulleys just aren’t that expensive anymore.

I’ve built both corexy and ultimaker style gantries, I prefer the latter, but if the corexy design is sufficiently rigid they work fine as well. In fact my current project is a corexy design.

___________________________________________________________________________

My blog [3dprinterhell.blogspot.com]

[3dprinterhell.blogspot.com]

It works fine, but IMO it’s just not worth the effort, belts and pulleys just aren’t that expensive anymore.

I’ve built both corexy and ultimaker style gantries, I prefer the latter, but if the corexy design is sufficiently rigid they work fine as well. In fact my current project is a corexy design.

___________________________________________________________________________

My blog [3dprinterhell.blogspot.com]

|

Re: CoreXY or Ultimaker gantry June 24, 2018 01:27AM |

Registered: 8 years ago Posts: 5,232 |

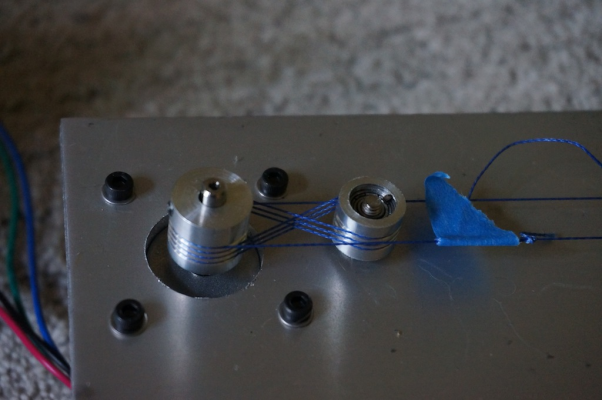

The cable runs parallel, that's right, but it also wanders up/down the pulley. ( a lot more than without thread )

In my setup you can see that one cable runs parallel to the rail too and only needs 4.2mm pulley length for 20cm travel. ( 0.5mm cable )

The angle of the returning cable is pretty steep, but it spools up nice and reliable. I tested a honeycomb-savey gcode file at 200% speed without issues.

|

Re: CoreXY or Ultimaker gantry June 24, 2018 10:01AM |

Registered: 11 years ago Posts: 5,780 |

Ah! I see it now.

polygonhell- how is the pulley arranged at the far end- the line on the drive end is coming off and going onto the drive pulley at two vertical levels. Do you set the far-end pulley groove at the same level as the top or bottom of the drive end? Isn't the cable rubbing against the offset drive pulley all the time?

I'm getting ready to build a large corexy mechanism for a sand table and was thinking of trying cable drive. This is just what I need, I think.

Edited 1 time(s). Last edit at 06/24/2018 10:03AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

polygonhell- how is the pulley arranged at the far end- the line on the drive end is coming off and going onto the drive pulley at two vertical levels. Do you set the far-end pulley groove at the same level as the top or bottom of the drive end? Isn't the cable rubbing against the offset drive pulley all the time?

I'm getting ready to build a large corexy mechanism for a sand table and was thinking of trying cable drive. This is just what I need, I think.

Edited 1 time(s). Last edit at 06/24/2018 10:03AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: CoreXY or Ultimaker gantry June 24, 2018 11:19AM |

Registered: 11 years ago Posts: 939 |

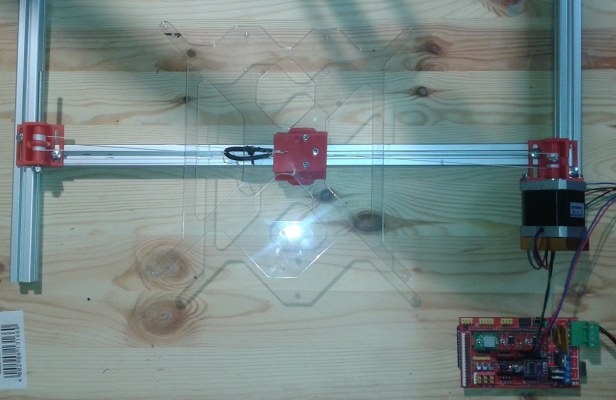

It’s arrranged so the side that needs to be parallel for linear motion is.

I used v-groove pulleys, the angles are negligible for any reasonably sized axis.

The bigger issue is the angles between the grooves in the 2 drive pulleys, once the line is tensioned, you can hear the line as it comes in and out of the grooves.

It worked fine and it’s trivial to machine.

This might give you a better idea how the entire thing worked

[m.youtube.com]

I never really used the mechanism in anything other than proof of concepts, my concern would be that unlike with belts where there is effective registration on every tooth line could accumulate error. I did run tests over days, and couldn’t measure significant errror so maybe i’m just overthinking it.

The original tantilus mechanism effectively fixes the line, so it can’t accumulate error, but it was a pain to tension, and the drive angle varied with motion, it really didn’t matter because of the small print size.

Back when I made it a lot of people were playing with line instead of belt, there were a lot of Kosel variants using line, you simply couldn’t buy cheap belt and pulleys.

I’ve built a lot of printers, and I just reached the point of it’s not worth saving a few dollars for a potentially significant mechanical compromise.

On the original topic, the reason I prefer ultimaker style gantries over CoreXY, is if you don’t Align them properly they just don’t work. When I first played with CoreXY reasonably priced linear rails were unobtainable, and they really need a degree of rigidity in design that’s not easily obtained with rods and bearings.

Edited 2 time(s). Last edit at 06/24/2018 11:36AM by Polygonhell.

___________________________________________________________________________

My blog [3dprinterhell.blogspot.com]

I used v-groove pulleys, the angles are negligible for any reasonably sized axis.

The bigger issue is the angles between the grooves in the 2 drive pulleys, once the line is tensioned, you can hear the line as it comes in and out of the grooves.

It worked fine and it’s trivial to machine.

This might give you a better idea how the entire thing worked

[m.youtube.com]

I never really used the mechanism in anything other than proof of concepts, my concern would be that unlike with belts where there is effective registration on every tooth line could accumulate error. I did run tests over days, and couldn’t measure significant errror so maybe i’m just overthinking it.

The original tantilus mechanism effectively fixes the line, so it can’t accumulate error, but it was a pain to tension, and the drive angle varied with motion, it really didn’t matter because of the small print size.

Back when I made it a lot of people were playing with line instead of belt, there were a lot of Kosel variants using line, you simply couldn’t buy cheap belt and pulleys.

I’ve built a lot of printers, and I just reached the point of it’s not worth saving a few dollars for a potentially significant mechanical compromise.

On the original topic, the reason I prefer ultimaker style gantries over CoreXY, is if you don’t Align them properly they just don’t work. When I first played with CoreXY reasonably priced linear rails were unobtainable, and they really need a degree of rigidity in design that’s not easily obtained with rods and bearings.

Edited 2 time(s). Last edit at 06/24/2018 11:36AM by Polygonhell.

___________________________________________________________________________

My blog [3dprinterhell.blogspot.com]

|

Re: CoreXY or Ultimaker gantry June 25, 2018 02:29AM |

Registered: 6 years ago Posts: 8 |

Sorry, only registered users may post in this forum.