Corners on round shapes

Posted by Schild0r

|

Corners on round shapes July 15, 2018 08:00AM |

Registered: 7 years ago Posts: 126 |

Hey there,

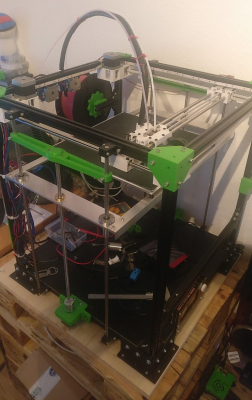

I built a CoreXY after the design of Jand1122 (https://github.com/jand1122/RepRap-XY) into an Flsun Cube

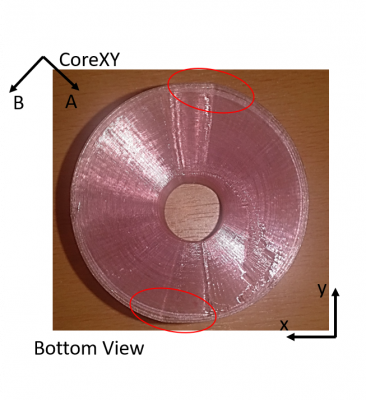

But unfortunately when I print some shapes I get a strange behavior which I tried to point out in this picture

I am doing this with some filament I only use for calibration stuff and so on so excuse the color... You see that I get "corners" where it stitches the Perimeters Ends.

Also it seems to print a straight line there at the end where it should be round. This happens on the sections of the circlethat are parallel to the x-Axis but I can not measure any reverse play or backlash.

G-Code is all fine and round

Any tips how I could fix that I am becoming desperate on this...

Thanks for any help

I built a CoreXY after the design of Jand1122 (https://github.com/jand1122/RepRap-XY) into an Flsun Cube

But unfortunately when I print some shapes I get a strange behavior which I tried to point out in this picture

I am doing this with some filament I only use for calibration stuff and so on so excuse the color... You see that I get "corners" where it stitches the Perimeters Ends.

Also it seems to print a straight line there at the end where it should be round. This happens on the sections of the circlethat are parallel to the x-Axis but I can not measure any reverse play or backlash.

G-Code is all fine and round

Any tips how I could fix that I am becoming desperate on this...

Thanks for any help

|

Re: Corners on round shapes July 15, 2018 08:57AM |

Registered: 11 years ago Posts: 5,780 |

What acceleration, jerk, speeds, motor currents are you using?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Corners on round shapes July 15, 2018 09:27AM |

Registered: 7 years ago Posts: 126 |

Quote

What acceleration, jerk, speeds, motor currents are you using?

#define DEFAULT_ACCELERATION 1000

#define DEFAULT_RETRACT_ACCELERATION 2500

#define DEFAULT_TRAVEL_ACCELERATION 1500

#define DEFAULT_XJERK 9.0

#define DEFAULT_YJERK 9.0

Quite high motor current of 1.4A on MKS LV8729 drivers

|

Re: Corners on round shapes July 15, 2018 01:34PM |

Registered: 11 years ago Posts: 5,780 |

You may be seeing the result of flexing in the guide rails, or play in the bearings or both.

Are you printing at high speeds?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Are you printing at high speeds?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Corners on round shapes July 15, 2018 09:18PM |

Registered: 5 years ago Posts: 30 |

|

Re: Corners on round shapes July 16, 2018 12:27AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Corners on round shapes July 16, 2018 07:37AM |

Registered: 7 years ago Posts: 126 |

Sorry for my late reply

I would consider the x Axis more stable than y becaus of the two directly connected rods which are also a little shorter

As I said there is no play as far as I can tell. Belts are very tight but I don't think it is strong enough to bend these rods which I got directly from IGUS (so they should be high quality)

I also think this is a mechanical problem but I don't know what exactly causes this

-> No I am printing at about 50-60mm/sQuote

Are you printing at high speeds?

-> 8mm Rods for both x(410mm length) and y(425mm length)Quote

What diameter and length are you using for the y rods?

I would consider the x Axis more stable than y becaus of the two directly connected rods which are also a little shorter

-> Yep Steel core GT2 but with 24teeth pulleys (~12mm Diameter) and fl624zz bearings (13mm Diameter)Quote

I see white belts. Are you using steel core with a too small pulley diameter?

As I said there is no play as far as I can tell. Belts are very tight but I don't think it is strong enough to bend these rods which I got directly from IGUS (so they should be high quality)

I also think this is a mechanical problem but I don't know what exactly causes this

|

Re: Corners on round shapes July 16, 2018 08:22AM |

Registered: 5 years ago Posts: 30 |

|

Re: Corners on round shapes July 16, 2018 08:50AM |

Registered: 11 years ago Posts: 5,780 |

The straight lines run parallel to the X axis. At that point when you're printing a circle, motion in the Y direction has slowed to a crawl. DRV8825s are known to skip usteps when the speed is low.

Does the machine use DRV8825 drivers?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Does the machine use DRV8825 drivers?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Corners on round shapes July 16, 2018 03:44PM |

Registered: 7 years ago Posts: 126 |

The ones from the bed? No they are fineQuote

boredom.is.me

The lead screws are constrained. Make sure they aren't bent.

Nope as mentioned before I am using the LV8729 nevertheless that might be a point. I will try to snap on the standard polulus again and report back thanks for the hint.Quote

the_digital_dentist

Does the machine use DRV8825 drivers

Unfortunately I can not test this before wednesday evening because I am writing two examina til wednesday

Edited 1 time(s). Last edit at 07/16/2018 03:44PM by Schild0r.

|

Re: Corners on round shapes July 18, 2018 03:49AM |

Registered: 7 years ago Posts: 126 |

|

Re: Corners on round shapes July 18, 2018 03:58AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Corners on round shapes July 18, 2018 11:54AM |

Registered: 7 years ago Posts: 126 |

|

Re: Corners on round shapes July 18, 2018 04:23PM |

Registered: 11 years ago Posts: 5,780 |

The problem with steel core belts in the XY stage is that there are a bunch of pulleys and steel core belts take quite a lot of work just to bend around the pulleys. The ultimate problem with that is that the belts keep flexing back and forth, and if the radius of curvature is too small, the steel core breaks and the belt suddenly gets stretchy at the break site, which causes all sorts of weird behavior in a printer. I haven't found any recommendations on minimum bend radius for steel core belts, but I did see a rule of thumb in a steel cable use note saying that the radius of curvature should be at least 10x the diameter of the cable. The cables in steel core GT2 belt are about 0.5 mm diameter, so by the rule of thumb, a 5 mm bend radius should be OK, but the reality seems like it's too small just based on the effort it takes to bend the belt like that. I was going to try steel core GT2 in the XY stage in my printer, but aborted the install when I realized how much effort it took just to bend the belts around the 22 mm diameter pulleys.

I'm using glass core Gates LL2MR09 belts in my XY stage with 400 step/rev motors, and they perform just fine. My moving mass may be 2-3x your printer's moving mass, so glass core should work fine in your printer.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I'm using glass core Gates LL2MR09 belts in my XY stage with 400 step/rev motors, and they perform just fine. My moving mass may be 2-3x your printer's moving mass, so glass core should work fine in your printer.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Corners on round shapes July 19, 2018 05:52AM |

Registered: 7 years ago Posts: 126 |

Thanks very much for that hint. I will definetly try this but I think I won't get these new belts very quickly...

I am not sure if this solves the problem (because it only appears parallel to the x axis ant not to the y axis)

but I will definetly change the belts. Maybe I will find the cause of this problem when putting on new belts.

I am not sure if this solves the problem (because it only appears parallel to the x axis ant not to the y axis)

but I will definetly change the belts. Maybe I will find the cause of this problem when putting on new belts.

Sorry, only registered users may post in this forum.