Building Core XY dual extruder from scratch

Posted by ______BlackCat13

|

Building Core XY dual extruder from scratch July 23, 2018 07:46AM |

Registered: 5 years ago Posts: 7 |

Hello all,

Im in the process of designing and building a core XY 3d printer.

Frame: 500mm 2020 alum extrusion w T slot Cube.

XY: will be on 3 Mgn 12 rails 2 for Y and 1 for X. Im hoping to use a 2020 alum extrusion for the X support bar. Would I need a smooth rod aswell or is this straight enough?

Am thinking of printing the x and y carriages. The motor mounts aswell unless you believe an aluminum one is better.

Z: want to put it on rails but i am very undecided as to how.

Z CARRIAGE: Im thinking of 4 2020 alum extrusions in a square and some sort of mounts for the lifting mechanism.

Bed : thinking of 400 x 400 bed.

Board: smoothieboard mks sbase v1.3 w wifi and tft LCD

Psu: unsure

Planning on using normal switch endstops and maybe auto level sensor if possible.

Main issue: live in sweden and finding reasonably priced parts is a hassle, dont know many EU vendors.

Thanks in advance for help and tips

Edited 1 time(s). Last edit at 07/23/2018 09:18AM by ______BlackCat13.

Im in the process of designing and building a core XY 3d printer.

Frame: 500mm 2020 alum extrusion w T slot Cube.

XY: will be on 3 Mgn 12 rails 2 for Y and 1 for X. Im hoping to use a 2020 alum extrusion for the X support bar. Would I need a smooth rod aswell or is this straight enough?

Am thinking of printing the x and y carriages. The motor mounts aswell unless you believe an aluminum one is better.

Z: want to put it on rails but i am very undecided as to how.

Z CARRIAGE: Im thinking of 4 2020 alum extrusions in a square and some sort of mounts for the lifting mechanism.

Bed : thinking of 400 x 400 bed.

Board: smoothieboard mks sbase v1.3 w wifi and tft LCD

Psu: unsure

Planning on using normal switch endstops and maybe auto level sensor if possible.

Main issue: live in sweden and finding reasonably priced parts is a hassle, dont know many EU vendors.

Thanks in advance for help and tips

Edited 1 time(s). Last edit at 07/23/2018 09:18AM by ______BlackCat13.

|

Re: Building Core XY dual extruder from scratch July 23, 2018 11:19AM |

Registered: 5 years ago Posts: 155 |

Welcome to this forum!

I am building a corexy from scratch also.

The best introduction to mechanical aspects I know is this blog with sub-blogs, it's a very good starting point to understand:

[drmrehorst.blogspot.com]

Mark Rehorst is the_digital_dentist here.

The blogs explains reasons for specific construction requirements, like xy frame, bed construction etc.

For a big printer as you plan, a good stability to support the required masses, belt tensions etc. will be important.

Edited 1 time(s). Last edit at 07/23/2018 11:20AM by JoergS5.

I am building a corexy from scratch also.

The best introduction to mechanical aspects I know is this blog with sub-blogs, it's a very good starting point to understand:

[drmrehorst.blogspot.com]

Mark Rehorst is the_digital_dentist here.

The blogs explains reasons for specific construction requirements, like xy frame, bed construction etc.

For a big printer as you plan, a good stability to support the required masses, belt tensions etc. will be important.

Edited 1 time(s). Last edit at 07/23/2018 11:20AM by JoergS5.

|

Re: Building Core XY dual extruder from scratch July 24, 2018 05:49PM |

Registered: 5 years ago Posts: 7 |

|

Re: Building Core XY dual extruder from scratch July 24, 2018 07:12PM |

Registered: 11 years ago Posts: 5,780 |

Here's the source for the Rino: [www.ebay.com]

I made one attempt at a low cost worm gear drive. The results weren't great. The print's Z axis quality is a direct function of the quality of the gears, especially the worm gear. The Rino uses very high quality gears that would probably cost more to buy than buying a Rino.

The guide rails don't keep anything level. They guide motion in the vertical direction. One rail guides the vertical motion, prevents tilting, but allows rotation around the rail. A second rail stops that rotation. In theory, that's all you need. Adding additional rails increases the chances of the mechanism binding, and makes alignment harder. End supported guide rails tend to flex which can lead to the bed bouncing, especially if it is cantilevered. Linear guides that are fully supported have much less of that problem, but if you're going to use a cantilever, three lifters, with two linear guides is probably optimal. If you're using belts to do the lifting, round guide rails should be fine because the belts don't produce any lateral forces that would tend to move the bed and wreck print Z axis quality. End supported rails are more likely to flex and allow lateral movement of the bed that will affect Z axis quality of prints.

The lifters (screws or belts) determine the amount of vertical motion and are the things that keep the bed level. If you use multiple motors, they will get out of sync. You have to have some strategy for dealing with that- usually autoleveling. Or you can couple all the lifters with rods or belts driven by a single motor, and they won't ever get out of sync. If the mechanism is properly aligned, you should not need anti backlash nuts on Z axis screws. Gravity will keep the screws and nuts in contact at all times regardless of the direction of motion. If you use 3 or 4 guide rails and the mechanism is not aligned well, it can cause backlash and walking in the Z axis motion.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I made one attempt at a low cost worm gear drive. The results weren't great. The print's Z axis quality is a direct function of the quality of the gears, especially the worm gear. The Rino uses very high quality gears that would probably cost more to buy than buying a Rino.

The guide rails don't keep anything level. They guide motion in the vertical direction. One rail guides the vertical motion, prevents tilting, but allows rotation around the rail. A second rail stops that rotation. In theory, that's all you need. Adding additional rails increases the chances of the mechanism binding, and makes alignment harder. End supported guide rails tend to flex which can lead to the bed bouncing, especially if it is cantilevered. Linear guides that are fully supported have much less of that problem, but if you're going to use a cantilever, three lifters, with two linear guides is probably optimal. If you're using belts to do the lifting, round guide rails should be fine because the belts don't produce any lateral forces that would tend to move the bed and wreck print Z axis quality. End supported rails are more likely to flex and allow lateral movement of the bed that will affect Z axis quality of prints.

The lifters (screws or belts) determine the amount of vertical motion and are the things that keep the bed level. If you use multiple motors, they will get out of sync. You have to have some strategy for dealing with that- usually autoleveling. Or you can couple all the lifters with rods or belts driven by a single motor, and they won't ever get out of sync. If the mechanism is properly aligned, you should not need anti backlash nuts on Z axis screws. Gravity will keep the screws and nuts in contact at all times regardless of the direction of motion. If you use 3 or 4 guide rails and the mechanism is not aligned well, it can cause backlash and walking in the Z axis motion.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Building Core XY dual extruder from scratch July 25, 2018 04:00AM |

Registered: 5 years ago Posts: 7 |

I dont like the canti levered design, was thinking of 2 mid mounted rails holding the bed with E shaped supports or maybe a whole piece printed but heat I would think is an issue.

I wanted a. Rod per corner so the bed wouldnt tilt but if you think that 2 rails can keep it tilt free im down for that.

That rino is god awful expensive but I guess if theres no other alternative for sale which bewilders me I'll have to go for it.

Any ideas on nema17 motors for my titan aero extruders? Or are they all just as quiet/negligible. Im looking at a printed holder I found on thingiverse.

[www.thingiverse.com]

What things can I get away with printed. I have yet to print in ABS but can try and if not I have a buddy that works at an industrial 3d printing co and can print stuff for me w the good stuff.

I wanted a. Rod per corner so the bed wouldnt tilt but if you think that 2 rails can keep it tilt free im down for that.

That rino is god awful expensive but I guess if theres no other alternative for sale which bewilders me I'll have to go for it.

Any ideas on nema17 motors for my titan aero extruders? Or are they all just as quiet/negligible. Im looking at a printed holder I found on thingiverse.

[www.thingiverse.com]

What things can I get away with printed. I have yet to print in ABS but can try and if not I have a buddy that works at an industrial 3d printing co and can print stuff for me w the good stuff.

|

Re: Building Core XY dual extruder from scratch July 25, 2018 04:11AM |

Registered: 5 years ago Posts: 7 |

|

Re: Building Core XY dual extruder from scratch July 25, 2018 07:50AM |

Registered: 11 years ago Posts: 5,780 |

Using 3 or 4 guide rails can be made to work, but aligning them will be difficult. If they aren't aligned perfectly, the bed will walk (tilt back and forth) as it moves up and down. As I said, the rails aren't there to prevent tilting, they are there to guide the vertical motion and prevent lateral motion. The lifters are what prevents tilting. The most stable lifting is done using 3 lifters- think of it like a 3 legged stool. The bed sitting on 3 lifters is stable at every position, which is also why you should use 3 leveling screws, not 4.

You're planning to use 20 mm t-slot for the 500x500 mm frame. I think it's going to be much too flexible. I wouldn't attempt to make anything that large with less than 40x40 mm t-slot. You're going to be throwing two extruders and the entire X axis back and forth at print speed at the top of the machine. The whole thing is going to wobble unless you attach rigid side panels or print very slowly.

A warning about thingiverse- there's a lot of poor designs that are essentially unprintable. The printed extruder mount design you linked doesn't look very good to me. I can't relate the photos to the printed part design, and the design looks typically thin and flexible. Look at the thin little discs that protrude from the design. What are those for and how are you going to print them, and how strong will they be if you manage to break away the support material they will need without breaking them off? If you want a printed part that is going to work/last, you have to design it like it's plastic, not steel. Plastic gets strength and rigidity from bulk.

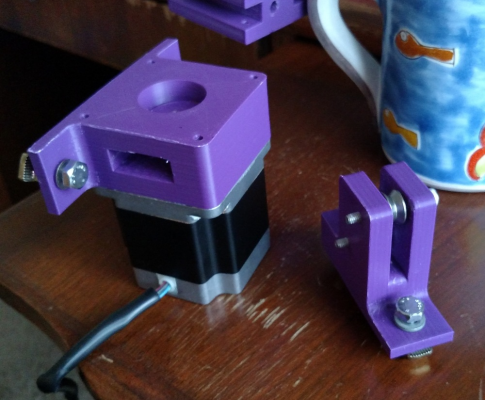

Here are a couple parts I recently printed for a project- it's for a sand table using a cable driven coreXY mechanism. There will be tension on the cables, so the parts are designed with that in mind, and printed in an orientation that provides greatest strength - i.e. the tension on the cables is parallel to the print layers, and isn't trying to pull them apart. I don't want the parts to break or distort, so I bulk them up. They don't look like folded sheet steel or cast metal because they're made of plastic.

PLA is a toy material. It's fine for Yoda heads and tugboats and not much else. If you anticipate ever trying to print ABS in your printer, or ever transporting the printer in a car, don't put PLA in it. PLA softens and distorts at low temperatures, like in a hot car or a warm, enclosed 3D printer. PLA filament absorbs moisture from the air if you leave it sitting out, and becomes brittle. So do PLA prints. It is best to avoid printed parts altogether, but if you have to use printed parts, ABS or PC are much better choices than PLA, and it's best to limit their use to situations where the applied forces compress or are parallel to the print layers.

I'm not sure what you mean about a long rod and gears and a NEMA-17 motor. A NEMA-17 motor should have sufficient torque to lift a 400x400 bed and support structure if it is geared down sufficiently. If you take a look at the link in my previous post about the DIY printed worm drive you'll see that a 40 mm long NEMA-17 motor had no problems lifting the bed in my printer. The thing that was a problem was the quality of the gears. Imperfections in the worm gear show up in the Z axis of the prints and repeat every time the worm makes one revolution, 2 mm in Z in my case. The reason for using a worm gear over other gear reduction mechanisms is that a worm gear can be irreversible. The Rino is not guaranteed to be irreversible by the manufacturer under all loads (this is because of the pitch of the gears, the friction, and the maximum load the part is designed to handle), but under the relatively light load of lifting a print bed and print, it is irreversible. That means the weight of the load won't cause the motor to turn, so when power is cut, the bed stays put.

The motor voltage rating has nothing to do with the power supply voltage used in the printer. In general, you want low voltage rated motors- look for steppers rated for 2-3V, 1-2A. It is normal to operate stepper motors from power supplies that are rated up to about 10x the rated voltage of the motor. Also, in general, you will get best performance if you use low voltage motors and use a 24V power supply for the printer.

Edited 3 time(s). Last edit at 07/25/2018 09:43AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

You're planning to use 20 mm t-slot for the 500x500 mm frame. I think it's going to be much too flexible. I wouldn't attempt to make anything that large with less than 40x40 mm t-slot. You're going to be throwing two extruders and the entire X axis back and forth at print speed at the top of the machine. The whole thing is going to wobble unless you attach rigid side panels or print very slowly.

A warning about thingiverse- there's a lot of poor designs that are essentially unprintable. The printed extruder mount design you linked doesn't look very good to me. I can't relate the photos to the printed part design, and the design looks typically thin and flexible. Look at the thin little discs that protrude from the design. What are those for and how are you going to print them, and how strong will they be if you manage to break away the support material they will need without breaking them off? If you want a printed part that is going to work/last, you have to design it like it's plastic, not steel. Plastic gets strength and rigidity from bulk.

Here are a couple parts I recently printed for a project- it's for a sand table using a cable driven coreXY mechanism. There will be tension on the cables, so the parts are designed with that in mind, and printed in an orientation that provides greatest strength - i.e. the tension on the cables is parallel to the print layers, and isn't trying to pull them apart. I don't want the parts to break or distort, so I bulk them up. They don't look like folded sheet steel or cast metal because they're made of plastic.

PLA is a toy material. It's fine for Yoda heads and tugboats and not much else. If you anticipate ever trying to print ABS in your printer, or ever transporting the printer in a car, don't put PLA in it. PLA softens and distorts at low temperatures, like in a hot car or a warm, enclosed 3D printer. PLA filament absorbs moisture from the air if you leave it sitting out, and becomes brittle. So do PLA prints. It is best to avoid printed parts altogether, but if you have to use printed parts, ABS or PC are much better choices than PLA, and it's best to limit their use to situations where the applied forces compress or are parallel to the print layers.

I'm not sure what you mean about a long rod and gears and a NEMA-17 motor. A NEMA-17 motor should have sufficient torque to lift a 400x400 bed and support structure if it is geared down sufficiently. If you take a look at the link in my previous post about the DIY printed worm drive you'll see that a 40 mm long NEMA-17 motor had no problems lifting the bed in my printer. The thing that was a problem was the quality of the gears. Imperfections in the worm gear show up in the Z axis of the prints and repeat every time the worm makes one revolution, 2 mm in Z in my case. The reason for using a worm gear over other gear reduction mechanisms is that a worm gear can be irreversible. The Rino is not guaranteed to be irreversible by the manufacturer under all loads (this is because of the pitch of the gears, the friction, and the maximum load the part is designed to handle), but under the relatively light load of lifting a print bed and print, it is irreversible. That means the weight of the load won't cause the motor to turn, so when power is cut, the bed stays put.

The motor voltage rating has nothing to do with the power supply voltage used in the printer. In general, you want low voltage rated motors- look for steppers rated for 2-3V, 1-2A. It is normal to operate stepper motors from power supplies that are rated up to about 10x the rated voltage of the motor. Also, in general, you will get best performance if you use low voltage motors and use a 24V power supply for the printer.

Edited 3 time(s). Last edit at 07/25/2018 09:43AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Building Core XY dual extruder from scratch July 26, 2018 02:07AM |

Registered: 5 years ago Posts: 155 |

Thanks a lot you for sharing a lot of your experience about building a 3d printer. If I'd seen your blog earlier, I might not have a department store at home today

I agree that thingiverse has very good, but very bad designs also. To value it, I often check the Makes and Comments of the thing and whether the author has designed other things also.

I agree that thingiverse has very good, but very bad designs also. To value it, I often check the Makes and Comments of the thing and whether the author has designed other things also.

|

Re: Building Core XY dual extruder from scratch July 26, 2018 08:13AM |

Registered: 5 years ago Posts: 7 |

I have nylon I have been waiting to try out now that my cr 10 s5 has been outfitted with a micro swiss hot end.

My only issue is my printer room is very drafty and the cr 10s bed movement makes it impossible to make an enclosure without it being ridiculously large even had to pull my work desk from the wall as the printer was hitting it.

I'll see about ordering 500mm 2040 alum profiles to reinforce the frame and t slot braces to square up the corners. I do have large acrylic sheets about 550x550 atleast if not 600 im going to use for the sides to enclose it.

My only issue is my printer room is very drafty and the cr 10s bed movement makes it impossible to make an enclosure without it being ridiculously large even had to pull my work desk from the wall as the printer was hitting it.

I'll see about ordering 500mm 2040 alum profiles to reinforce the frame and t slot braces to square up the corners. I do have large acrylic sheets about 550x550 atleast if not 600 im going to use for the sides to enclose it.

|

Re: Building Core XY dual extruder from scratch July 26, 2018 08:15AM |

Registered: 5 years ago Posts: 7 |

Quote

JoergS5

Thanks a lot you for sharing a lot of your experience about building a 3d printer. If I'd seen your blog earlier, I might not have a department store at home today

I agree that thingiverse has very good, but very bad designs also. To value it, I often check the Makes and Comments of the thing and whether the author has designed other things also.

I know about that. Its just been a little hard to find a dual titan aero mount that will work on an mgn 12 rail.

|

Re: Building Core XY dual extruder from scratch July 26, 2018 09:07AM |

Registered: 11 years ago Posts: 5,780 |

It sounds like someone needs to design a good one...

Designing and building a printer from scratch is an excellent excuse to learn CAD modeling as it will save you from a lot of errors, and once you have a printer, you're going to want to do more with it than just download other people's designs from thingiverse. Learning CAD now will let you design the parts you need for the printer and other projects.

Edited 1 time(s). Last edit at 07/26/2018 10:06AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Designing and building a printer from scratch is an excellent excuse to learn CAD modeling as it will save you from a lot of errors, and once you have a printer, you're going to want to do more with it than just download other people's designs from thingiverse. Learning CAD now will let you design the parts you need for the printer and other projects.

Edited 1 time(s). Last edit at 07/26/2018 10:06AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Building Core XY dual extruder from scratch July 27, 2018 08:18AM |

Registered: 11 years ago Posts: 5,780 |

Quote

JoergS5

Thanks a lot you for sharing a lot of your experience about building a 3d printer. If I'd seen your blog earlier, I might not have a department store at home today

Yeah, but now you have parts for other projects....

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Building Core XY dual extruder from scratch August 03, 2018 04:59AM |

Registered: 5 years ago Posts: 7 |

So I have ordered 8 2040 t slot to reinforce the frame and the extruders and motors and some other miscellaneous stuff.

I finally managed to find a flat 400mm+ print bed in the EU.

It is here. [rover.ebay.com]

A question as to the rhino keyed shaft. What size am I supposed to use as diameter and key? I cant find anything on the listing or on your build page only that its 600mm long (in my case I'll be using 500mm.

I finally managed to find a flat 400mm+ print bed in the EU.

It is here. [rover.ebay.com]

A question as to the rhino keyed shaft. What size am I supposed to use as diameter and key? I cant find anything on the listing or on your build page only that its 600mm long (in my case I'll be using 500mm.

|

Re: Building Core XY dual extruder from scratch August 27, 2018 04:54AM |

Registered: 6 years ago Posts: 13 |

I realize this post is several weeks old but thought I'd chime in anyway. The rino uses an 8mm diameter output shaft with a 2mm key. Here's a pdf.

[www.wildbot3d.com]

[www.wildbot3d.com]

Sorry, only registered users may post in this forum.