Very Large Cable Driven CoreXY Mechanism

Posted by the_digital_dentist

|

Re: Very Large Cable Driven CoreXY Mechanism September 03, 2018 03:35AM |

Registered: 6 years ago Posts: 1,007 |

Quote

the_digital_dentist

I'm planning on using fixed red and blue LEDs because I don't want changing colors and flashing lights to distract attention from the patterns in the sand.

My calculations indicate that a single 50 lb bag of baking soda should cover the table to 1/2" deep. I'll be picking the stuff up at Harbor Freight Tools tomorrow if they have any in stock. I have a 25% off coupon, so $30 will buy the bag.

Please show your calculation

Nice machine BTW, and no need for kids anymore to enjoy drawings on sand !

Edited 1 time(s). Last edit at 09/03/2018 03:37AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Very Large Cable Driven CoreXY Mechanism September 04, 2018 11:06PM |

Registered: 11 years ago Posts: 5,780 |

It turns out, about 25 lbs of media is sufficient: [vimeo.com]

I need to optimize depth and speed/acceleration.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I need to optimize depth and speed/acceleration.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Very Large Cable Driven CoreXY Mechanism September 05, 2018 01:11AM |

Registered: 7 years ago Posts: 249 |

|

Re: Very Large Cable Driven CoreXY Mechanism September 05, 2018 02:45AM |

Admin Registered: 16 years ago Posts: 13,886 |

... I was thinking of an "inverted" design in the style of e-paper.

The table is then a flat box, filled with a tinted fluid and floating white plastic microspheres.

If all the particles are spread evenly under the top plate, it looks bright.

Now a moving ball underneath (maybe floating too?) will plow through the microspheres, push them aside and leave a dark (or coloured, if other dye than black) trail ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

The table is then a flat box, filled with a tinted fluid and floating white plastic microspheres.

If all the particles are spread evenly under the top plate, it looks bright.

Now a moving ball underneath (maybe floating too?) will plow through the microspheres, push them aside and leave a dark (or coloured, if other dye than black) trail ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Very Large Cable Driven CoreXY Mechanism September 07, 2018 11:36PM |

Registered: 11 years ago Posts: 5,780 |

I generated some patterns today and did some speed and acceleration testing. I was very pleasantly surprised to find that the whole thing works fine at acceleration of 1000 mm/sec^2 and speed of 500 mm/sec:

[vimeo.com]

[vimeo.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

[vimeo.com]

[vimeo.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Very Large Cable Driven CoreXY Mechanism September 08, 2018 02:41AM |

Registered: 8 years ago Posts: 5,232 |

It really looks great!

What causes the pauses at the corners? Is jerk setting too low or does the magnet move but it takes a while for the ball to follow? ( square mag/round ball issue we discussed earlier )

edit: I didn't watch the first test... video before, but the pulsing movement seems to be related to unfocussed mag-forces?

Edited 1 time(s). Last edit at 09/08/2018 03:03AM by o_lampe.

What causes the pauses at the corners? Is jerk setting too low or does the magnet move but it takes a while for the ball to follow? ( square mag/round ball issue we discussed earlier )

edit: I didn't watch the first test... video before, but the pulsing movement seems to be related to unfocussed mag-forces?

Edited 1 time(s). Last edit at 09/08/2018 03:03AM by o_lampe.

|

Re: Very Large Cable Driven CoreXY Mechanism September 08, 2018 08:27AM |

Registered: 11 years ago Posts: 5,780 |

I don't think the shape of the magnet is affecting the motion. I'm pretty sure I set the junction deviation to zero so the ball stops at the end of every straight segment. When I ran the ball on the table without sand at 200 mm/sec with acceleration turned up the magnet would lose the ball on direction changes. I think that was due to the ball's momentum. That's when I turned the junction deviation to zero to counter that. With the sand providing damping to the motion, the momentum should be less of a problem, so I can probably turn the junction deviation up a bit.

I think the jerky motion at low speed is related to the resistance the sand presents to the ball. At low speed, the sand behaves like a thick liquid and presents a large resistance to motion. When I watch the ball moving at high speeds there is a wave in the sand ahead of the ball where the sand is thrown forward and to the sides. I think the churning that is going on in front of the ball reduces the resistance to the motion. Sort of like the opposite of a classic non Newtonian fluid. At higher speeds, the sand, once started moving out of the ball's way, pushes sand in front of it and essentially "liquefies" it so the resistance to the motion is lower and the ball moves more smoothly. I think.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I think the jerky motion at low speed is related to the resistance the sand presents to the ball. At low speed, the sand behaves like a thick liquid and presents a large resistance to motion. When I watch the ball moving at high speeds there is a wave in the sand ahead of the ball where the sand is thrown forward and to the sides. I think the churning that is going on in front of the ball reduces the resistance to the motion. Sort of like the opposite of a classic non Newtonian fluid. At higher speeds, the sand, once started moving out of the ball's way, pushes sand in front of it and essentially "liquefies" it so the resistance to the motion is lower and the ball moves more smoothly. I think.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Very Large Cable Driven CoreXY Mechanism September 10, 2018 09:08PM |

Registered: 7 years ago Posts: 249 |

|

Re: Very Large Cable Driven CoreXY Mechanism September 11, 2018 09:05AM |

Registered: 11 years ago Posts: 5,780 |

When one pattern overwrites another there are always some remnants of the previous pattern remaining that lend some extra character to the current pattern. Even if you see the same pattern repeated multiple times, it will usually look different each time because the pattern before it was probably different. I put the sequences together in a pseudo random way- I generated a bunch of patterns (tedious), then strung them together so that where one pattern ends, the next one starts (also tedious). Most of it looks pretty good, but there are some patterns that just don't work well in sequence together.

I do have some "wipes" made by spiraling the ball, or running it in a zigzag pattern like the first layer of a 3D print, but they always leave lines in the background. I run a wipe every 10 or 12 patterns. I left the machine running overnight and found that the sequence on the SD card runs for over 24 hours. I also found that when you let the machine run that long it tends to push the sand out to the perimeter of the table, though that may be controllable by running approximately equal numbers of patterns that spiral inward and outward. Today's project is to make a tool to spread the sand back out evenly. I'm thinking of a comb that is manually dragged through the sand a few times. The comb will be the width of the table and have discs on the ends that will set the depth of the sand.

I've noticed that with patterns that bring the lines close together, the large ball and relatively coarse sand I'm using tends to wipe out the lines completely. I might be able to get it to erase to a smooth surface by simply running parallel lines close together.

Edited 1 time(s). Last edit at 09/11/2018 09:12AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I do have some "wipes" made by spiraling the ball, or running it in a zigzag pattern like the first layer of a 3D print, but they always leave lines in the background. I run a wipe every 10 or 12 patterns. I left the machine running overnight and found that the sequence on the SD card runs for over 24 hours. I also found that when you let the machine run that long it tends to push the sand out to the perimeter of the table, though that may be controllable by running approximately equal numbers of patterns that spiral inward and outward. Today's project is to make a tool to spread the sand back out evenly. I'm thinking of a comb that is manually dragged through the sand a few times. The comb will be the width of the table and have discs on the ends that will set the depth of the sand.

I've noticed that with patterns that bring the lines close together, the large ball and relatively coarse sand I'm using tends to wipe out the lines completely. I might be able to get it to erase to a smooth surface by simply running parallel lines close together.

Edited 1 time(s). Last edit at 09/11/2018 09:12AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Very Large Cable Driven CoreXY Mechanism September 11, 2018 10:07AM |

Registered: 6 years ago Posts: 134 |

|

Re: Very Large Cable Driven CoreXY Mechanism September 11, 2018 11:07AM |

Registered: 11 years ago Posts: 5,780 |

I may add ball changing- that's super easy- just a few gcode commands to drop one ball and pick up another...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Very Large Cable Driven CoreXY Mechanism September 17, 2018 01:51PM |

Registered: 11 years ago Posts: 5,780 |

My very large corexy mechanism now has stacked belts. Too much wear on the belts with the single level and twists. I also installed some red and blue LED strips to light it up, powered via buck converters that allow me to adjust the relative brightness of the lights. It is now running pretty well and I'm moving on to try some other pattern generating ideas.

[vimeo.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

[vimeo.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Very Large Cable Driven CoreXY Mechanism September 18, 2018 12:40AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Very Large Cable Driven CoreXY Mechanism September 18, 2018 09:11AM |

Registered: 11 years ago Posts: 5,780 |

I think NEMA-17 motors would work, and probably quieter too. I don't think the load is very large- the mechanism moves easily, and the magnet manages to hang onto the ball even as it is dragged through the sand, so it can't be too much of a load. The moving masses are pretty low, too. When I get a couple spare NEMA-17 motors I'll try it out.

I didn't design the mechanism to maximize the printed area- it was mostly designed to be fast/easy to build. I'm looking at a redesign that will use more of the table for the drawings.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I didn't design the mechanism to maximize the printed area- it was mostly designed to be fast/easy to build. I'm looking at a redesign that will use more of the table for the drawings.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Very Large Cable Driven CoreXY Mechanism October 26, 2018 01:57AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Very Large Cable Driven CoreXY Mechanism October 26, 2018 07:15PM |

Registered: 11 years ago Posts: 5,780 |

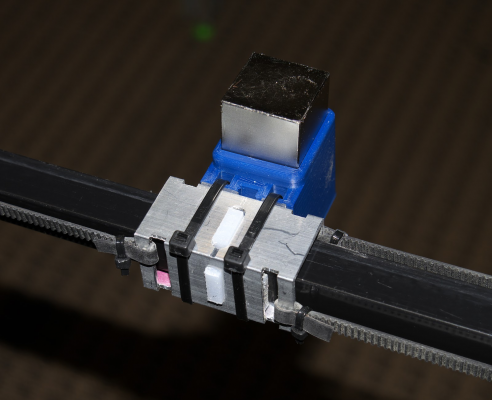

The machine worked fine for the Faire, but close inspection finds that the magnet carriage is wearing out where it rubs against the X axis tube. The tube is powder coated aluminum and it seems that the spring that pushes the magnet against the table is contributing to the wear. The magnet sliding against the table generates very fine wood dust that accumulates on top of the X axis tube and may also be contributing to the wear.

I'm looking at a redesign that will include a UHMW or teflon bearing to reduce wear, as well as sealing the wood with polyurethane, and making a UHMW shoe for the magnet to minimize dust production. Also looking into replacing the NEMA-23 motors with NEMA-17 motors to reduce noise, and maybe putting in a Duet or other controller with TMC high microstepping drivers to further reduce noise. It may be possible to put the magnet directly over the X axis tube instead of off to one side, The tube is 16 mm square and the magnet is a 1" cube, and the frame is 45 mm square t-slot, so I should have barely enough room to do that. I could replace the tube with something a little flatter to gain a little more room to add bearings.

At the Faire I could not get Mike Dubno's RPi firmware running so I just ran from patterns stored on the SD card. I was at the space last night and tried the RPi again and it worked perfectly as soon as I hooked it up. Hmmmm. The RPi talks to the smoothieboard controller via USB.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I'm looking at a redesign that will include a UHMW or teflon bearing to reduce wear, as well as sealing the wood with polyurethane, and making a UHMW shoe for the magnet to minimize dust production. Also looking into replacing the NEMA-23 motors with NEMA-17 motors to reduce noise, and maybe putting in a Duet or other controller with TMC high microstepping drivers to further reduce noise. It may be possible to put the magnet directly over the X axis tube instead of off to one side, The tube is 16 mm square and the magnet is a 1" cube, and the frame is 45 mm square t-slot, so I should have barely enough room to do that. I could replace the tube with something a little flatter to gain a little more room to add bearings.

At the Faire I could not get Mike Dubno's RPi firmware running so I just ran from patterns stored on the SD card. I was at the space last night and tried the RPi again and it worked perfectly as soon as I hooked it up. Hmmmm. The RPi talks to the smoothieboard controller via USB.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Very Large Cable Driven CoreXY Mechanism November 03, 2018 11:50PM |

Registered: 11 years ago Posts: 5,780 |

A new update- I redesigned and fabricated a new magnet carriage with UHMW bearings. Hopefully it won't wear like the ABS did. The new carriage body is a piece of 1" square aluminum tubing with a few slots milled into it to mount the bearings and attach the belts. I was lucky and the belt attachments are almost exactly where they need to be to keep the belts parallel to the X axis guide tube.

[vimeo.com]

Blog post with some deets...

Edited 1 time(s). Last edit at 11/03/2018 11:55PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

[vimeo.com]

Blog post with some deets...

Edited 1 time(s). Last edit at 11/03/2018 11:55PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Very Large Cable Driven CoreXY Mechanism November 09, 2018 02:44PM |

Registered: 11 years ago Posts: 5,780 |

An alternative use for the sand table- entertaining cats...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Very Large Cable Driven CoreXY Mechanism November 12, 2018 02:11AM |

Registered: 6 years ago Posts: 1,007 |

No kidding, I think there is a market for this. Print a mouse to put on the ball.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Very Large Cable Driven CoreXY Mechanism November 12, 2018 01:19PM |

Registered: 5 years ago Posts: 50 |

|

Re: Very Large Cable Driven CoreXY Mechanism November 12, 2018 01:53PM |

Registered: 11 years ago Posts: 5,780 |

Quote

ruyvieira

Could also work as an air hockey robot

I think it's a little too slow for that. The fastest I've been able to run it is about 700 mm/sec. I think it's set to 300 mm/sec in the video.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Very Large Cable Driven CoreXY Mechanism November 12, 2018 04:39PM |

Registered: 5 years ago Posts: 50 |

Quote

the_digital_dentist

Quote

ruyvieira

Could also work as an air hockey robot

I think it's a little too slow for that. The fastest I've been able to run it is about 700 mm/sec. I think it's set to 300 mm/sec in the video.

That's very easy to solve, heh

Just not cheap

Someone else did using a regular Ramps and a webcam for computer vision

Sorry, only registered users may post in this forum.