The Janky-XY printer

Posted by obelisk79

The Janky-XY printer  August 22, 2018 11:28AM |

Registered: 7 years ago Posts: 363 |

Sharing some photos of my WIP build. I've been able to get pretty reliable quality out of design so far but there are still a few quirks left to work through along with a few part design improvements I am contemplating. Please feel free to critique. I could use the constructive criticism.

Re: The Janky-XY printer  August 22, 2018 11:36AM |

Registered: 7 years ago Posts: 363 |

Re: The Janky-XY printer  August 23, 2018 01:38AM |

Registered: 8 years ago Posts: 5,232 |

Re: The Janky-XY printer  August 23, 2018 02:44AM |

Registered: 9 years ago Posts: 31 |

Re: The Janky-XY printer  August 23, 2018 06:45AM |

Registered: 7 years ago Posts: 363 |

I did have excessive z wobble at first using just the lead screws, I later added a better guide zwobble is minimal but not completely eliminated.

Edited 1 time(s). Last edit at 08/23/2018 06:52AM by obelisk79.

Edited 1 time(s). Last edit at 08/23/2018 06:52AM by obelisk79.

Re: The Janky-XY printer  August 23, 2018 05:54PM |

Registered: 7 years ago Posts: 363 |

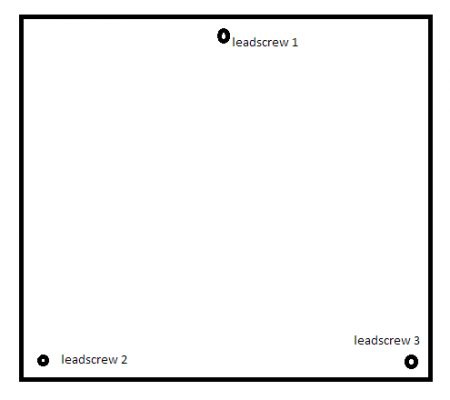

I think I'm just going to add a third leadscrew to the z-belt loop and that should give me adequate stability to eliminate all z-wobble, then I can eliminate the 2020 z-guide. Thoughts?

Edited 1 time(s). Last edit at 08/23/2018 05:56PM by obelisk79.

Edited 1 time(s). Last edit at 08/23/2018 05:56PM by obelisk79.

Re: The Janky-XY printer  August 23, 2018 09:09PM |

Registered: 5 years ago Posts: 16 |

Re: The Janky-XY printer  August 24, 2018 12:23AM |

Registered: 8 years ago Posts: 5,232 |

Re: The Janky-XY printer  August 24, 2018 01:33AM |

Registered: 7 years ago Posts: 363 |

Re: The Janky-XY printer  August 24, 2018 09:16AM |

Registered: 6 years ago Posts: 1,007 |

Quote

o_lampe

Using the leadscrews as Z-guides too is a bit unusual. The print doesn't show any signs of wobble yet, but maybe after some hours of printing?

It works. BUT the lead screws must be straight, of sufficient diam and no play in the bearings and nuts. I use two TR8 lead screws on my modified Geetech Prusa Al (in fact, the only thing left from Geetech is the Al frame), X gantry.

These Tr8 are not the best, yet wobble is unnoticeable.

Good 12mm, 16mm TR lead screws and of course ball screws would be perfect.

Properly made with 3 suitable lead screws no problem.

Failure for sure if the set up is not properly done, overconstrained, ....

It is what I will do if I decide to build a CoreXY or Ultimaker like printer.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

Re: The Janky-XY printer  August 24, 2018 10:10AM |

Registered: 7 years ago Posts: 363 |

Re: The Janky-XY printer  August 24, 2018 01:46PM |

Registered: 5 years ago Posts: 71 |

Three lead-screws will ensure the bed doesn't wobble in the Z-direction but won't help the X and Y wobble much if your bed / print is heavy.

To limit X and Y bed movement, two uprights are needed. Adding a second 2020 on the opposite side of your current one would work, as long as it is very close to parallel to prevent binding. To also limit binding, you could remove the top bearings from the lead screws, though this is more of an issue if you have a very stiff bed plate, and yours being MDF looks like it will have enough play. My Folger FT5 had that issue.

An example of the above scheme is the Fusion3 F306 which had three lead screws and two lateral support members.

Giles

To limit X and Y bed movement, two uprights are needed. Adding a second 2020 on the opposite side of your current one would work, as long as it is very close to parallel to prevent binding. To also limit binding, you could remove the top bearings from the lead screws, though this is more of an issue if you have a very stiff bed plate, and yours being MDF looks like it will have enough play. My Folger FT5 had that issue.

An example of the above scheme is the Fusion3 F306 which had three lead screws and two lateral support members.

Giles

Re: The Janky-XY printer  August 24, 2018 06:14PM |

Registered: 5 years ago Posts: 71 |

Re: The Janky-XY printer  August 24, 2018 09:10PM |

Registered: 7 years ago Posts: 363 |

Quote

gmedlicott

Forgot to ask, what is the build volume for your printer? It looks around 1ft cube?

320x300x300mm-ish

I have more volume I can reclaim, Last night I was considering the possibility of routing the belts on the exterior of the extrusions, but I'm not convinced I would like the result of separating the belts along the z-axis anymore than they already are. There are still many other ways to skin that cat however.

Edited 1 time(s). Last edit at 08/24/2018 09:11PM by obelisk79.

Re: The Janky-XY printer  August 25, 2018 06:50AM |

Registered: 6 years ago Posts: 1,007 |

Quote

gmedlicott

Three lead-screws will ensure the bed doesn't wobble in the Z-direction but won't help the X and Y wobble much if your bed / print is heavy.

To limit X and Y bed movement, two uprights are needed. Adding a second 2020 on the opposite side of your current one would work, as long as it is very close to parallel to prevent binding. To also limit binding, you could remove the top bearings from the lead screws, though this is more of an issue if you have a very stiff bed plate, and yours being MDF looks like it will have enough play. My Folger FT5 had that issue.

An example of the above scheme is the Fusion3 F306 which had three lead screws and two lateral support members.

Giles

These printers use the lead screws just for moving,not as guide. So not the configuration discussed here.

Besides they are overconstrained, two quality Z guides and two lead screws ( just to move the bed) would have been enough and simplify the alignment. Luckily these printers have the flexibility and bearings with enough plays to limit binding.

At least they didn't commit the usual mistake of one motor per lead screws.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

Re: The Janky-XY printer  August 25, 2018 02:05PM |

Registered: 5 years ago Posts: 71 |

Quote

MKSA

At least they didn't commit the usual mistake of one motor per lead screws.

Agreed 100%. My Folger FT5 was a nightmare to keep the bed level as the 4 turn lead screws would move when powered off. I changed to a single z-belt like Obelisk79 has in his design here; much better. I see the newer gen FT5 has this also.

Also agreed on the Fusion F306 arrangement using lead screws for z-movement, rods with bearings at each end for X-Y constraint.

If the two rods supported at both ends aren't 100% parallel, then they are over-constrained, unless they rely on flex like you mentioned. I think every builder struggles with the over-constrained issue, I know I did with my second DIY printer, either missing constraints or being over constrained.

Re: The Janky-XY printer  August 25, 2018 06:03PM |

Registered: 10 years ago Posts: 14,672 |

Quote

gmedlicott

Quote

MKSA

At least they didn't commit the usual mistake of one motor per lead screws.

Agreed 100%. My Folger FT5 was a nightmare to keep the bed level as the 4 turn lead screws would move when powered off. I changed to a single z-belt like Obelisk79 has in his design here; much better. I see the newer gen FT5 has this also.

Some firmwares (RepRapFirmware and Repetier) can use the Z probe to check whether the bed is level and adjust the leadscrews independently to make it so. Of course this requires a separate driver per Z motor.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Re: The Janky-XY printer  September 16, 2018 01:25PM |

Registered: 7 years ago Posts: 363 |

I've just about eliminated all variations on my z axis now.

I'm going through and testing the limits of layer height now.

Yesterday I printed this octopus sliced at 50% scale and 0.05mm layer height. Currently I'm printing again this time model scaled to 25% and 0.025mm

I'm going through and testing the limits of layer height now.

Yesterday I printed this octopus sliced at 50% scale and 0.05mm layer height. Currently I'm printing again this time model scaled to 25% and 0.025mm

Re: The Janky-XY printer  September 16, 2018 03:33PM |

Registered: 7 years ago Posts: 363 |

Well, smaller scale so the minor artifacts are slightly more noticeable but I think this turned out quite well.

Re: The Janky-XY printer  September 17, 2018 07:36AM |

Registered: 11 years ago Posts: 5,780 |

Re: The Janky-XY printer  September 17, 2018 01:02PM |

Registered: 7 years ago Posts: 363 |

Sorry, only registered users may post in this forum.