Weird issue with corexy

Posted by emielvs

|

Weird issue with corexy September 07, 2018 12:39PM |

Registered: 8 years ago Posts: 5 |

Hi Guys,

I'm converting my crappy leapfrog creatr to a corexy machine

to a corexy machine .

.

But I'm having a really strange issue with it. The same as this YouTube video: [www.youtube.com]

I don't know how he fixed it what do you guys think?

Thanks

I'm converting my crappy leapfrog creatr

to a corexy machine

to a corexy machine .

.But I'm having a really strange issue with it. The same as this YouTube video: [www.youtube.com]

I don't know how he fixed it what do you guys think?

Thanks

|

Re: Weird issue with corexy September 07, 2018 03:36PM |

Registered: 11 years ago Posts: 5,780 |

Do you have the same size pulleys on both motors?

Are you sure?

Are the X and Y steps/mm set the same in the firmware? Are they set differently in a config over ride file somewhere?

Edited 2 time(s). Last edit at 09/07/2018 03:49PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Are you sure?

Are the X and Y steps/mm set the same in the firmware? Are they set differently in a config over ride file somewhere?

Edited 2 time(s). Last edit at 09/07/2018 03:49PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Weird issue with corexy September 07, 2018 03:47PM |

Registered: 7 years ago Posts: 363 |

|

Re: Weird issue with corexy September 08, 2018 04:51AM |

Registered: 8 years ago Posts: 5 |

Yes I counted the 2 pulley's in the back twice. they have 16 tootrh

I'm running the printer with a re-arm(smoothieware on it) with a ramps converted to 24V and on the X&Y i have TMC2100 stepper drivers (In spreadcycle). Attached my config files en config override.

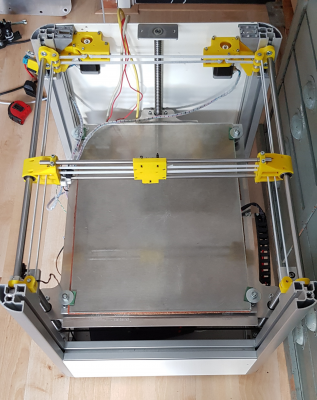

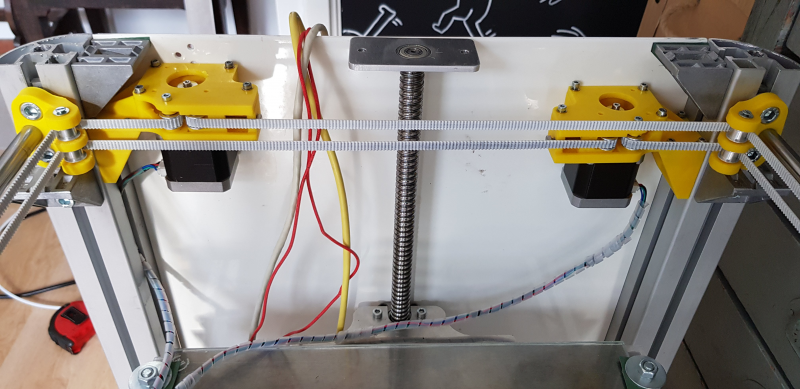

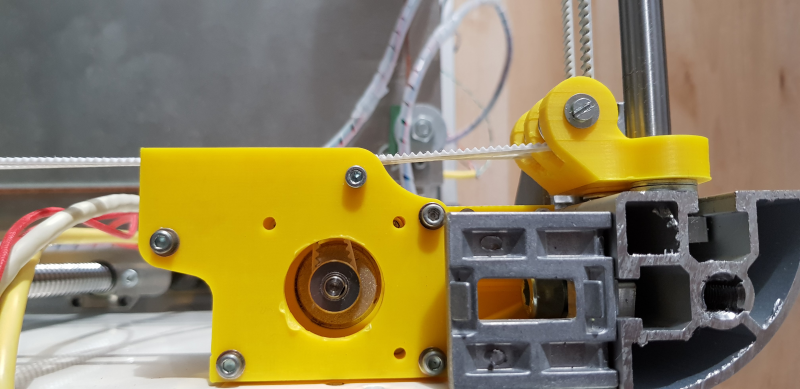

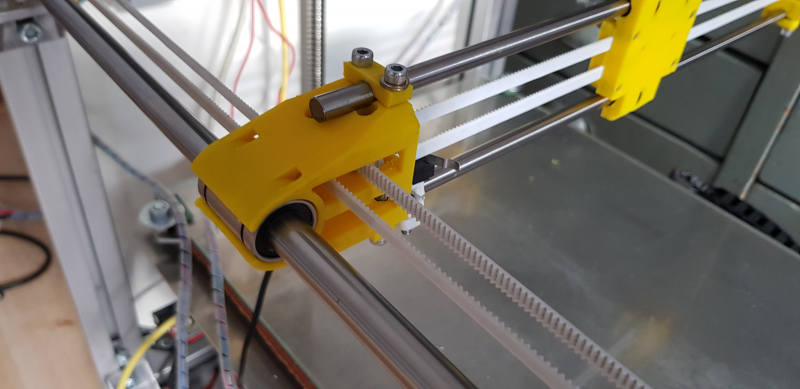

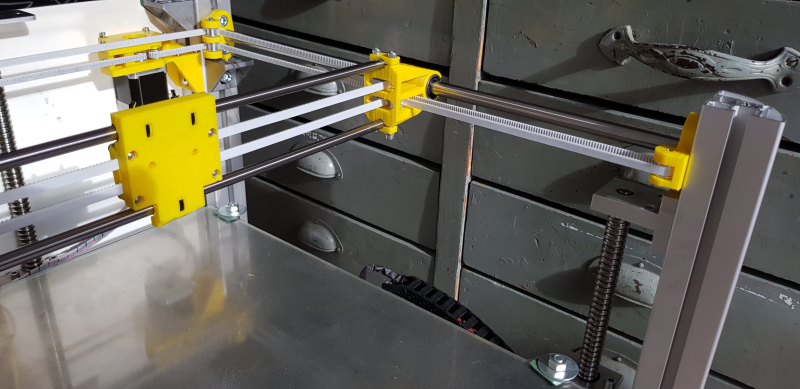

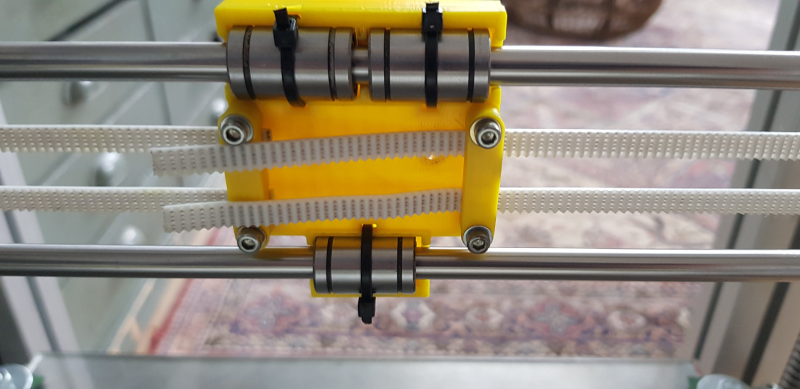

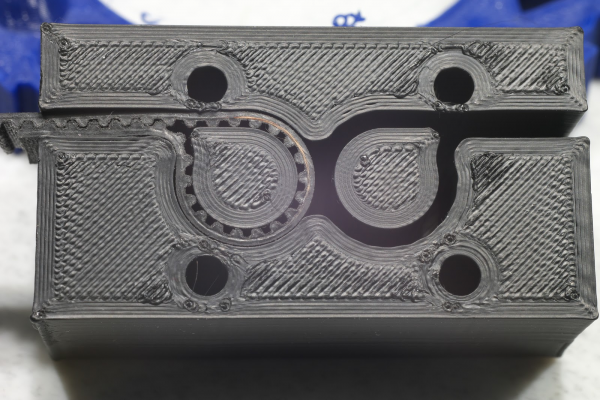

And hereby some images of my printer.

My previous design was running the same (Re-arm, 24V, TMC2100 etc) and was running fine. So I'm suspecting it's in the cartesian system.

I'm running the printer with a re-arm(smoothieware on it) with a ramps converted to 24V and on the X&Y i have TMC2100 stepper drivers (In spreadcycle). Attached my config files en config override.

And hereby some images of my printer.

My previous design was running the same (Re-arm, 24V, TMC2100 etc) and was running fine. So I'm suspecting it's in the cartesian system.

|

Re: Weird issue with corexy September 08, 2018 08:11AM |

Registered: 11 years ago Posts: 5,780 |

I like the way you routed the belts and the tensioning using the adjustable pulleys in the motor mounts. Very nice, except that it's an awful lot of pulleys for the motors to have to bend those belts around. It looks like you're using steel core belts. I suspect the pulleys are too small and that will lead to the steel cables inside the belts breaking. Then the belts will stretch in the areas where the cables are broken and that will cause all sorts of mysterious problems with print quality. Maybe the cores are already broken?

The config file and the over-ride file look fine (I just looked at them for the stuff that controls the motion- there could be other problems). The config file used to have a parameter that controlled the pulse duration to the stepper divers, but they seem to have taken that out. I wonder if there is some problem with the pulses being too short for the external drivers/cables to them.

I'm not a big fan of config-overrides. I'd suggest putting whatever is in there into the main config file and deleting the over-ride file, once you have all the settings worked out.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

The config file and the over-ride file look fine (I just looked at them for the stuff that controls the motion- there could be other problems). The config file used to have a parameter that controlled the pulse duration to the stepper divers, but they seem to have taken that out. I wonder if there is some problem with the pulses being too short for the external drivers/cables to them.

I'm not a big fan of config-overrides. I'd suggest putting whatever is in there into the main config file and deleting the over-ride file, once you have all the settings worked out.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Weird issue with corexy September 08, 2018 02:38PM |

Registered: 8 years ago Posts: 5 |

Quote

the_digital_dentist

I like the way you routed the belts and the tensioning using the adjustable pulleys in the motor mounts. Very nice, except that it's an awful lot of pulleys for the motors to have to bend those belts around. It looks like you're using steel core belts. I suspect the pulleys are too small and that will lead to the steel cables inside the belts breaking. Then the belts will stretch in the areas where the cables are broken and that will cause all sorts of mysterious problems with print quality. Maybe the cores are already broken?

The config file and the over-ride file look fine (I just looked at them for the stuff that controls the motion- there could be other problems). The config file used to have a parameter that controlled the pulse duration to the stepper divers, but they seem to have taken that out. I wonder if there is some problem with the pulses being too short for the external drivers/cables to them.

I'm not a big fan of config-overrides. I'd suggest putting whatever is in there into the main config file and deleting the over-ride file, once you have all the settings worked out.

Aah damn indeed on some places the steel core was already broken! Changed it to my old gt2.5 belts and it works!!!

Thanks for your help

Thanks for your help

So now waiting on a my new GT2 belts, finishing the design and then it will be on thingiverse and youmagine

If someone has any feedback on the design to improve your more than welcome to share with me

|

Re: Weird issue with corexy September 08, 2018 09:06PM |

Registered: 6 years ago Posts: 134 |

This is a very nice looking design. Congratulations on fixing your problem.

Few notes:

- On X you are not using X rods to fight belt tension so Y rods are getting bend force to fight belts. You may engage X rods to resist bending forces.

- Location of the X endstop may be changed to increase X printable room. Now you are subtracting the size of endstop sensor from X dimension.

- Belt tensioning mechanism may be improved if you will create a separate fixture for each belt.

- If you will move motors closer to the vertical extrusion you may not need one of the idlers, and use corner idler instead of the second idler on the motor mount and still use almost al curvature of the pulley.

Overall nice work.

Few notes:

- On X you are not using X rods to fight belt tension so Y rods are getting bend force to fight belts. You may engage X rods to resist bending forces.

- Location of the X endstop may be changed to increase X printable room. Now you are subtracting the size of endstop sensor from X dimension.

- Belt tensioning mechanism may be improved if you will create a separate fixture for each belt.

- If you will move motors closer to the vertical extrusion you may not need one of the idlers, and use corner idler instead of the second idler on the motor mount and still use almost al curvature of the pulley.

Overall nice work.

|

Re: Weird issue with corexy September 09, 2018 03:02AM |

Registered: 8 years ago Posts: 5,232 |

Looks good!

I think the clamps for the X-rods could be a bit beefier.

Also the brackets for the idlers look like they could suffer from layer separation one day. Is there a chance to change print orentation?

You could also try to decrease the distance from idler to Y-rod. Even if the printer won't gain print volume: the shorter/the better.

I think the clamps for the X-rods could be a bit beefier.

Also the brackets for the idlers look like they could suffer from layer separation one day. Is there a chance to change print orentation?

You could also try to decrease the distance from idler to Y-rod. Even if the printer won't gain print volume: the shorter/the better.

|

Re: Weird issue with corexy September 11, 2018 12:35PM |

Registered: 5 years ago Posts: 71 |

Nice bracket designs! What material are you printing them from, plain PLA?

I second O_lampe's comment on the layer separation. They would be strongest if printed in the orientation they are mounted. You would also get a tighter tolerance hole to mount the idlers.

What diameter Z lead screws are you using? They look beefy.

Quote

o_lampe

Also the brackets for the idlers look like they could suffer from layer separation one day. Is there a chance to change print orentation?

I second O_lampe's comment on the layer separation. They would be strongest if printed in the orientation they are mounted. You would also get a tighter tolerance hole to mount the idlers.

What diameter Z lead screws are you using? They look beefy.

|

Re: Weird issue with corexy May 06, 2019 06:39AM |

Registered: 4 years ago Posts: 1 |

|

Re: Weird issue with corexy May 06, 2019 08:56AM |

Registered: 11 years ago Posts: 5,780 |

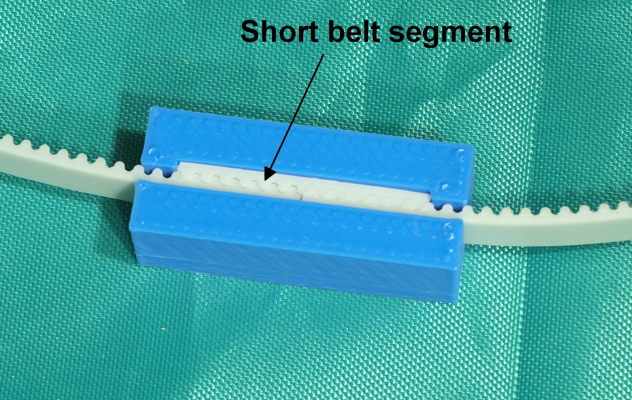

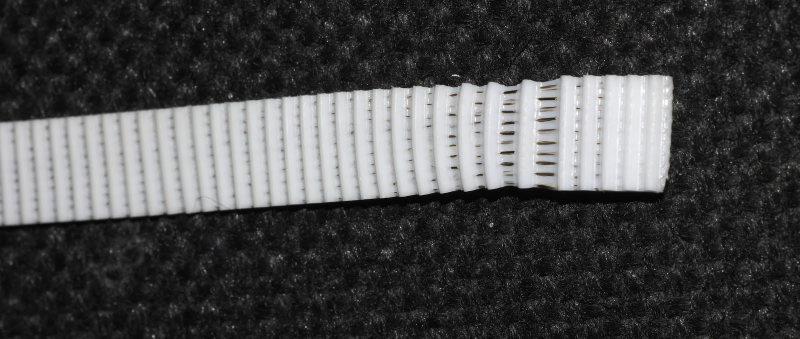

Since we're back to this old thread... I noticed that the belt clamp on the extruder carriage looks disturbingly like one I used in UMMD's Z axis. It failed when the rubber part of the belt stretched over the core wires due to the tension on the belt.

The clamp was like this:

And this is what happened:

The new clamp folds the belt back on itself:

That type of belt clamp has been working without trouble in the XY stage for 2+ years, and in SoM's X axis for at least 5 years.

See: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

The clamp was like this:

And this is what happened:

The new clamp folds the belt back on itself:

That type of belt clamp has been working without trouble in the XY stage for 2+ years, and in SoM's X axis for at least 5 years.

See: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Weird issue with corexy April 14, 2020 01:37PM |

Registered: 8 years ago Posts: 5 |

Hi all,

It's been a while but a lot has happened to the "Mod-Frog" and I'm currently working on a new version. Yes, I like experimenting and trying a lot

Since some people have asked for the designs I created a Github for it see: https://github.com/Emielvs/Mod-Frog

These designs we're never made with the focus on sharing them, so they are a bit of a mess but still very useful

The next version will use 10mm CF rods with Hemera direct extruder.

I've printed everything in ABS and the diameter of the leadscrews are 16mm

It's been a while but a lot has happened to the "Mod-Frog" and I'm currently working on a new version. Yes, I like experimenting and trying a lot

Since some people have asked for the designs I created a Github for it see: https://github.com/Emielvs/Mod-Frog

These designs we're never made with the focus on sharing them, so they are a bit of a mess but still very useful

The next version will use 10mm CF rods with Hemera direct extruder.

Quote

gmedlicott

Nice bracket designs! What material are you printing them from, plain PLA?

Quote

o_lampe

Also the brackets for the idlers look like they could suffer from layer separation one day. Is there a chance to change print orentation?

I second O_lampe's comment on the layer separation. They would be strongest if printed in the orientation they are mounted. You would also get a tighter tolerance hole to mount the idlers.

What diameter Z lead screws are you using? They look beefy.

I've printed everything in ABS and the diameter of the leadscrews are 16mm

|

Re: Weird issue with corexy April 14, 2020 02:15PM |

Registered: 11 years ago Posts: 5,780 |

Are those CF rods made for linear guidance? If not, the chances of them working well with randomly selected bushings is poor.

If you must use CF, use the complete assemblies by Igus or their CF tubes that are made for linear guidance (and the companion bushings and mounts). Even at that I wouldn't count on them to be very precise.

You're trying to print at high speed, so you're trying to minimize moving mass. But you're trading the precision of proper linear guides for light weight, which will result in reduced print quality, and you're trying to print fast which will also result in reduced print quality. Moving the mechanism fast with "conventional" parts isn't the problem. Controlling the extrusion, or specifically the liquid plastic after it leaves the nozzle, is the problem. CF, as pretty as it is, doesn't fix that.

Here's my 1.5 kg moving mass corexy printing at 200 mm/sec with acceleration set to 10k

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

If you must use CF, use the complete assemblies by Igus or their CF tubes that are made for linear guidance (and the companion bushings and mounts). Even at that I wouldn't count on them to be very precise.

You're trying to print at high speed, so you're trying to minimize moving mass. But you're trading the precision of proper linear guides for light weight, which will result in reduced print quality, and you're trying to print fast which will also result in reduced print quality. Moving the mechanism fast with "conventional" parts isn't the problem. Controlling the extrusion, or specifically the liquid plastic after it leaves the nozzle, is the problem. CF, as pretty as it is, doesn't fix that.

Here's my 1.5 kg moving mass corexy printing at 200 mm/sec with acceleration set to 10k

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Weird issue with corexy April 15, 2020 03:26AM |

Registered: 8 years ago Posts: 5 |

Thnx for the info!  The high speed isn't the main goal. If I'm printing in between 60mm/s and 80mm/s with nice quality I'm happy!

The high speed isn't the main goal. If I'm printing in between 60mm/s and 80mm/s with nice quality I'm happy!

I've done some reading and testing with cf rods from: HaoZhong and IGUS JSM bushings which are made for CF tubes. With the first design concept, there is barely any play and everything seems to run smoothly. It's takes a lot of adjusting and fine-tuning but that's just patience

[github.com]

The high speed isn't the main goal. If I'm printing in between 60mm/s and 80mm/s with nice quality I'm happy!

The high speed isn't the main goal. If I'm printing in between 60mm/s and 80mm/s with nice quality I'm happy! I've done some reading and testing with cf rods from: HaoZhong and IGUS JSM bushings which are made for CF tubes. With the first design concept, there is barely any play and everything seems to run smoothly. It's takes a lot of adjusting and fine-tuning but that's just patience

[github.com]

Sorry, only registered users may post in this forum.