Making sure belts are parallel

Posted by MadsRC

|

Making sure belts are parallel December 15, 2018 04:46PM |

Registered: 5 years ago Posts: 7 |

After using my Ender 3 for some time, and after reading the_digital_dentist's blog series on the UMMD, I've decided to start my own project for a printer that has, atleast, a 500x500 build area.

Been reading and studying for the last few months, and got a design in my head. Also tried a few ideas in Fusion 360. The issue that I keep running into is I'm not 100% sure how I can ensure

that my belts are parallel.

I'm planning on using GT2 9mm belts, 20-teeth GT2 pulleys, F608zz and F6902ZZ bearings as idlers.

It's been atleast 15years since I touched any CAD software or did any mechanical engineering, and my math is... Let's just say it ain't my day job!

My guess is that for the belt to run parallel between a GT2 pulley and an idler, the top of the pulley teeth should be in-line/parallel to the surface of the idler?

Please correct me if I'm wrong!

Been reading and studying for the last few months, and got a design in my head. Also tried a few ideas in Fusion 360. The issue that I keep running into is I'm not 100% sure how I can ensure

that my belts are parallel.

I'm planning on using GT2 9mm belts, 20-teeth GT2 pulleys, F608zz and F6902ZZ bearings as idlers.

It's been atleast 15years since I touched any CAD software or did any mechanical engineering, and my math is... Let's just say it ain't my day job!

My guess is that for the belt to run parallel between a GT2 pulley and an idler, the top of the pulley teeth should be in-line/parallel to the surface of the idler?

Please correct me if I'm wrong!

|

Re: Making sure belts are parallel December 15, 2018 08:55PM |

Registered: 6 years ago Posts: 134 |

|

Re: Making sure belts are parallel December 16, 2018 05:01AM |

Registered: 5 years ago Posts: 7 |

Rereading my question, I see that I see that the actual question isn't really obvious. That's what you get for posting late at night!

You seem to have caught the gist of my question. If the belt is 1.2 mm thick, the surface of the smooth idler would have to be 1.2 mm from the bottom (and not the top of the teeth) of the pulley teeth, right?

You seem to have caught the gist of my question. If the belt is 1.2 mm thick, the surface of the smooth idler would have to be 1.2 mm from the bottom (and not the top of the teeth) of the pulley teeth, right?

|

Re: Making sure belts are parallel December 16, 2018 06:38AM |

Registered: 5 years ago Posts: 7 |

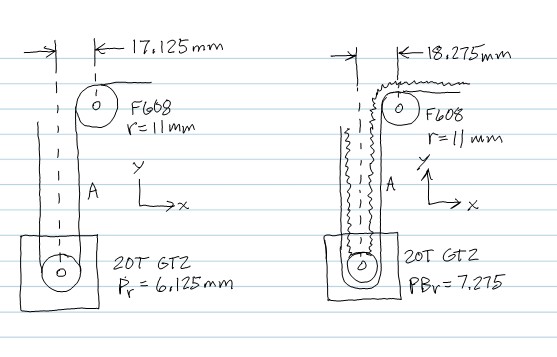

Had another go at it today, and the attached PNG is what, somehow, makes sense in my head.

For reference, I used table 12 on page 17 here to get the PD (12.73) and the OD (12.22) of a 20T GT2 pulley, and the tech drawing here for the belt dimensions.

The linked PDF also had the following quote, which helped me understand it a bit better:

Also, the idler's I'm referring to consists of 2 F608ZZ bearings with a OD of 22.

Given that data, my assumptions is that if the belts teeth needs to be in contact with the idler, and stay perpendicular, the idler center would have to be 5.64 mm below the pulley (Which is the rightmost circle on my drawing).

If the belts back would need to be in contact with the idler, the center of the idler would have to be 17.74 mm above the pulley (Which is the leftmost circle on my drawing).

Is my assumptions correct? I'm aware that the measurements is different if 2 idlers are involved and no pulley, but I'm confident that if the above assumptions is correct, figuring that out should be a no-brainer...

For reference, I used table 12 on page 17 here to get the PD (12.73) and the OD (12.22) of a 20T GT2 pulley, and the tech drawing here for the belt dimensions.

The linked PDF also had the following quote, which helped me understand it a bit better:

Quote

The reinforcing

cord centerline will coincide with the pulley pitch diameter while the belt is in contact with the pulley. At

the same time, the outside diameter of the pulley will be in contact with the bottom of the belt tooth.

Also, the idler's I'm referring to consists of 2 F608ZZ bearings with a OD of 22.

Given that data, my assumptions is that if the belts teeth needs to be in contact with the idler, and stay perpendicular, the idler center would have to be 5.64 mm below the pulley (Which is the rightmost circle on my drawing).

If the belts back would need to be in contact with the idler, the center of the idler would have to be 17.74 mm above the pulley (Which is the leftmost circle on my drawing).

Is my assumptions correct? I'm aware that the measurements is different if 2 idlers are involved and no pulley, but I'm confident that if the above assumptions is correct, figuring that out should be a no-brainer...

|

Re: Making sure belts are parallel December 16, 2018 06:53AM |

Registered: 11 years ago Posts: 5,780 |

Pitch diameter is where the cords run inside the belt, not where the back of the belt will be. The back of the belt is the reference for checking parallelism with the guide rails because the back of the belt, not the cords in the belt's core, will be riding on one of the pulleys. If you're using the same layout I used in UMMD, the only place where this matters is in positioning the motor mounts in the X direction to ensure that belt segments A and G are parallel to the Y axis guide rails. All the rest of the pulleys' axles can simply be positioned along lines parallel to the guide rails and the belts will end up parallel to the rails between those pulleys.

Edited 2 time(s). Last edit at 12/16/2018 07:00AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Edited 2 time(s). Last edit at 12/16/2018 07:00AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Making sure belts are parallel December 16, 2018 01:03PM |

Registered: 6 years ago Posts: 134 |

|

Re: Making sure belts are parallel December 16, 2018 01:49PM |

Registered: 5 years ago Posts: 7 |

That makes sense (Had to make a small ad-hoc CAD drawing to verify it, but it seems to work) - Though that formula only works when the belt is oriented so that the back is in contact with the idler, I'll see if I can't figure out the formula for when the belt is oriented so that the teeth is in contact with the idler.

|

Re: Making sure belts are parallel December 16, 2018 01:55PM |

Registered: 5 years ago Posts: 7 |

@the_digital_dentist: Thanks man, I'm trying to use the same overall layout, though I'd like for the motors to be inside the enclosure. The note about only having to worry about the motor placement is gold... That seems to be the only place where the 2 adjacent idlers isn't of the same size and thus can't just be aligned using the center point (If that makes sense?)

I'm having troubles following your drawing though... Pr of 6.125 is identical to piper3d's 13.5 mm diameter for a motor pulley with a GT2 belt wrapped around, but labeling it Pr makes me thing you mean the pitch radius (and thus Pitch diameter) - Is that correct? What about PBr then (Which stands for?)

Edited 1 time(s). Last edit at 12/16/2018 01:56PM by MadsRC.

I'm having troubles following your drawing though... Pr of 6.125 is identical to piper3d's 13.5 mm diameter for a motor pulley with a GT2 belt wrapped around, but labeling it Pr makes me thing you mean the pitch radius (and thus Pitch diameter) - Is that correct? What about PBr then (Which stands for?)

Edited 1 time(s). Last edit at 12/16/2018 01:56PM by MadsRC.

|

Re: Making sure belts are parallel December 16, 2018 02:39PM |

Registered: 5 years ago Posts: 7 |

Quote

piper3d

@MadsRC very simple way of finding the distance between the idler and motor pulley: wrap a gt2 belt around your motor pulley and measure outer diameter with the belt for me it is 13.5mm, measure the diameter of the toothless idler for me it is 11.9mm. (13.5+11.9)/2=12.7mm

Using a 2mm GT2 belt and a 20T pulley? That GT2 belt should be 1.38mm thick, 0.75 of those "lost" to the teeth of the pulley, leaving 0.63 mm - A 20T pulley having a diameter of 12.22 and adding the 0.63 from the belt should give you a total diameter of 12.85 - Or am I missing something... If we change the 20T pulley for a 21T pulley, your numbers match, so that might be it?

|

Re: Making sure belts are parallel December 16, 2018 03:17PM |

Registered: 6 years ago Posts: 134 |

I am measuring outer diameter of pulley with belt making it "actual" measurement not a "theoretical" calculation  . 13.5mm is actual outer diameter of my 20 teeth motor pulley with 10mm gt2 belt on a live 3d printer.

. 13.5mm is actual outer diameter of my 20 teeth motor pulley with 10mm gt2 belt on a live 3d printer.

. 13.5mm is actual outer diameter of my 20 teeth motor pulley with 10mm gt2 belt on a live 3d printer.

. 13.5mm is actual outer diameter of my 20 teeth motor pulley with 10mm gt2 belt on a live 3d printer.|

Re: Making sure belts are parallel December 16, 2018 03:33PM |

Registered: 5 years ago Posts: 7 |

That is fascinating... I can't really expect you to take your printer apart and have you count the teeth on that pulley, or measure the thickness of the belt, to satisfy my curiosity (Though, it is tempting...)

I guess that's a fine example of how theory and practice often differ...

Thank you to the both of you, I think I might have figured it out. Now, all I need to do is draw it and I'll try to order some parts for it!

I guess that's a fine example of how theory and practice often differ...

Thank you to the both of you, I think I might have figured it out. Now, all I need to do is draw it and I'll try to order some parts for it!

Sorry, only registered users may post in this forum.