Introducing myself and some cuestions about bed design in CoreXY

Posted by EgonVLC

|

Introducing myself and some cuestions about bed design in CoreXY February 12, 2019 07:33AM |

Registered: 5 years ago Posts: 23 |

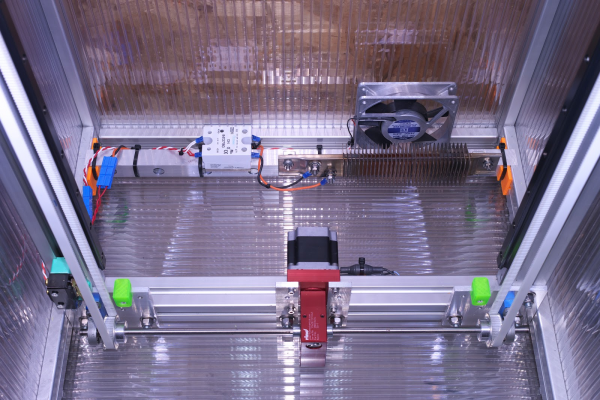

First of all, let me introduce myself, as this is my very first post here! I'm an electrical engineer and software engineer from Spain, but I really like all kind of tecnical challenges. My 3D printing adventures began almost 2 years ago, with a Tevo Tarantula (I said I like challenges, didn't I...?). It kind of printed ok-ish after assembly, but it had an awful lot of limitations. As any unexperienced thingiverser out there, I printed all "improvements" I found, sometimes for the better, sometimes... not, but I learned A LOT in the process. Thing is that some months ago I completely redesigned my printer, up to the point it was no longer a Tarantula anymore: I made a sturdy bolted 2020 structure, dual 12mm smooth rod bed support, linear guide X and double linear guide and double leadcrew Z, almost everything bolted metal or metal supported. I've managed to get a very good quality and layer registration up to 0.08mm layer height, so 0.2mm printing is near flawless. But the speed is not so great, moving a heavy bed at more than 60mm/s (and 30mm/s perimeters) shows more ringing that I'd like, and I have to keep acceleration below 1000mm/s. So be it called the "3DEgon 1". Now I'm aiming to an all new config for "3DEgon 2", and CoreXY is the architecture I gravitated to.

The issue I had the hardest time with was Z axis. The original Tarantula had a single leadscrew cantilevered X gantry with wheels on T-Slot, 4 wheels each side. It never worked really good, tried custom 4 and 3 wheeled gantries, more/less tension in the wheels, dual leadscrew, oldham couplers... Nothing worked to get good quality, so for my redisgn I aimed to dual linear guide and holy cow, that thing was a game changer! Once aligned, it was ultra-smooth but also ultra stable and had no play at all. Regarding the motor, my first design was a two-leadscrew with single motor and closed belt. And the problems began. My leadscrews weren't chinese, but from a german store, www.motedis.de, 400mm TR8x1.5, with nuts. I set it up, but the result was not so good: I had some mild Z wobble.

The reason was multiple: the pulleys were not perfectly concentric in the leadscews, one of the leadscrews was slighty bent, the belt was bowing lightly the leadscrews, and the less tension, the less wobbling, but the less tension, the less precission too, so was a no-no. I finally ditched the leadscrews, and bought 2 motors with integrated TR8x2 leadscrews, then connected them in series. It works flawlessly, but now I live with the fear of desync. I can daily print over more than a month without releveling the bed, but I don't feel comfortable with the chance of desyncing. I suppose the it works so well because I have quite a heavy X gantry (dual extruder chimera with extruders mounted in a 2020 gantry) and everytime the power goes of both motors go to the lower fullstep, but who knows...

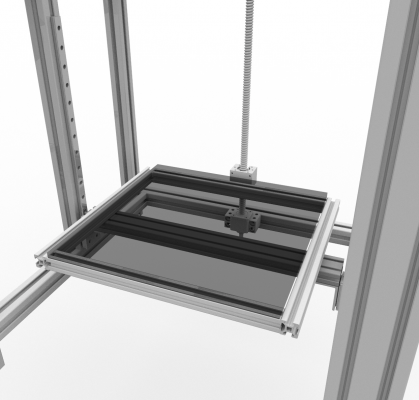

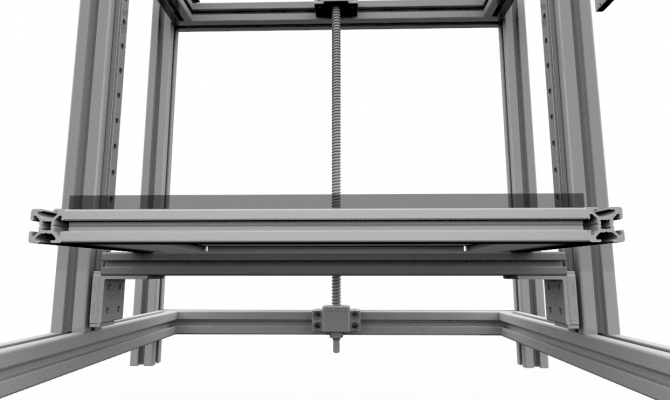

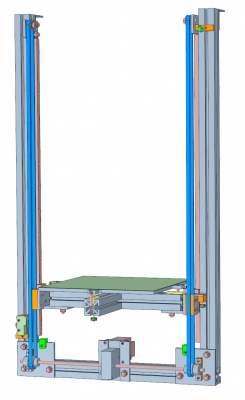

So, right now, I wonder which approach should be better for my new CoreXY bed motion. I plan it to be 300x300mm size, and I'd really like to keep a single Z motor, and I definitely want to use linear guides (my experience with unsupported smooth rods, even at 12mm, is that I cannot stop them vibrating when the bed moves a large span, and the Y wall texture is not as perfect as X texture). So my first idea is something like 2 linear guides, each one at the middle of bed's left and right sides, and a single 1204 ballscrew in the middle back side. Do u thing it would be stable enough? Should I try a 3 ballscrew setup with a closed belt?

Thank in advance for your thoughts!

Edited 2 time(s). Last edit at 02/12/2019 10:29AM by EgonVLC.

The issue I had the hardest time with was Z axis. The original Tarantula had a single leadscrew cantilevered X gantry with wheels on T-Slot, 4 wheels each side. It never worked really good, tried custom 4 and 3 wheeled gantries, more/less tension in the wheels, dual leadscrew, oldham couplers... Nothing worked to get good quality, so for my redisgn I aimed to dual linear guide and holy cow, that thing was a game changer! Once aligned, it was ultra-smooth but also ultra stable and had no play at all. Regarding the motor, my first design was a two-leadscrew with single motor and closed belt. And the problems began. My leadscrews weren't chinese, but from a german store, www.motedis.de, 400mm TR8x1.5, with nuts. I set it up, but the result was not so good: I had some mild Z wobble.

The reason was multiple: the pulleys were not perfectly concentric in the leadscews, one of the leadscrews was slighty bent, the belt was bowing lightly the leadscrews, and the less tension, the less wobbling, but the less tension, the less precission too, so was a no-no. I finally ditched the leadscrews, and bought 2 motors with integrated TR8x2 leadscrews, then connected them in series. It works flawlessly, but now I live with the fear of desync. I can daily print over more than a month without releveling the bed, but I don't feel comfortable with the chance of desyncing. I suppose the it works so well because I have quite a heavy X gantry (dual extruder chimera with extruders mounted in a 2020 gantry) and everytime the power goes of both motors go to the lower fullstep, but who knows...

So, right now, I wonder which approach should be better for my new CoreXY bed motion. I plan it to be 300x300mm size, and I'd really like to keep a single Z motor, and I definitely want to use linear guides (my experience with unsupported smooth rods, even at 12mm, is that I cannot stop them vibrating when the bed moves a large span, and the Y wall texture is not as perfect as X texture). So my first idea is something like 2 linear guides, each one at the middle of bed's left and right sides, and a single 1204 ballscrew in the middle back side. Do u thing it would be stable enough? Should I try a 3 ballscrew setup with a closed belt?

Thank in advance for your thoughts!

Edited 2 time(s). Last edit at 02/12/2019 10:29AM by EgonVLC.

|

Re: Introducing myself and some cuestions about ned design in CoreXY February 12, 2019 08:48AM |

Registered: 5 years ago Posts: 23 |

|

Re: Introducing myself and some cuestions about bed design in CoreXY February 12, 2019 11:53AM |

Registered: 11 years ago Posts: 5,780 |

One screw located far from the linear guides might be a problem because the spacing between the screw and the bearing blocks acts as a lever to tilt the bed. That will cause the bed to rock on the bearing blocks as the bed moves up and down. Lifting should be done as close to the bearing blocks as possible. If you want to use one motor only, use two screws located next to the bearing blocks and belt it all together.

I used 2 belts to lift Z...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I used 2 belts to lift Z...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Introducing myself and some cuestions about bed design in CoreXY February 12, 2019 02:35PM |

Registered: 5 years ago Posts: 23 |

Quote

the_digital_dentist

One screw located far from the linear guides might be a problem because the spacing between the screw and the bearing blocks acts as a lever to tilt the bed. That will cause the bed to rock on the bearing blocks as the bed moves up and down. Lifting should be done as close to the bearing blocks as possible. If you want to use one motor only, use two screws located next to the bearing blocks and belt it all together.

That's just what I was afraid of... I will complete de design and perform a complete request for comments. Do you think that a third linear guide + ballscrew is worth it? Or it will overconstrain bed movement a bit too much? And what about leadscrew vs ballscrew? Do you think is worth it? I chose ball screws instead leadscrew because of my bad experience with leadscrews and pulleys...

BTW, you're blog is great like no other, I learned a lot from you!

|

Re: Introducing myself and some cuestions about bed design in CoreXY February 12, 2019 04:16PM |

Registered: 11 years ago Posts: 5,780 |

The two linear guides should be all that's needed for vertical only guidance. If you put two screws next to the two guides (just replacing the belts in my design) it should work fine, or you can put the linear guides near the corners instead of the center of the bed and add a third lead screw to stabilize the cantilevered end of the bed (otherwise it will bounce).

I'd say try it the way you designed it and see what happens. You can always add another lead screw or two as needed.

I don't think there's much advantage to ball screws in this application. The lead will be larger which will require more torque from the motor(s) to lift the load (may not be an issue, depending on the mass being lifted). Ball screws are more likely to let the bed crash to the bottom of the Z axis when power is cut.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I'd say try it the way you designed it and see what happens. You can always add another lead screw or two as needed.

I don't think there's much advantage to ball screws in this application. The lead will be larger which will require more torque from the motor(s) to lift the load (may not be an issue, depending on the mass being lifted). Ball screws are more likely to let the bed crash to the bottom of the Z axis when power is cut.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Introducing myself and some cuestions about bed design in CoreXY February 13, 2019 02:59AM |

Registered: 10 years ago Posts: 14,672 |

You can resync multiple leadscrews automatically if they are driven from separate drivers and you have firmware that supports it. There are two ways of doing it. One is to use the Z probe to measure how out of level the bed is. The other is to use a separate endstop switch for each motor.

Edited 1 time(s). Last edit at 02/13/2019 02:59AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 02/13/2019 02:59AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Introducing myself and some cuestions about bed design in CoreXY February 13, 2019 03:36AM |

Registered: 6 years ago Posts: 1,007 |

Quote

dc42

You can resync multiple leadscrews automatically if they are driven from separate drivers and you have firmware that supports it. There are two ways of doing it. One is to use the Z probe to measure how out of level the bed is. The other is to use a separate endstop switch for each motor.

Yes you can but why correct something latter instead of doing it correct right away ?

Two guides, two lead screws or belts, one motor "et voila". Even simpler than the complex and in fact mechanically unsound "designs" found here and there.

Built properly you don't need "auto leveling". OK, all this is fun programming but not so much fun using it.

Edited 1 time(s). Last edit at 02/13/2019 03:36AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Introducing myself and some cuestions about bed design in CoreXY February 13, 2019 05:54AM |

Registered: 5 years ago Posts: 23 |

Given that my current working machine is not an optimum design (4 screws bed + two motors with leadscrews, Tarantula inheritance...) and I hardly have to relevel it, I want to do it "as right as posible" and forget releveling, so the 2 linear guides + 2 screws is the best choice for me IMHO.

My only left question is about leadscrews and belts. Every single time I've tried to do a leadscrew + belt system, my z layer registration suffers. Don't really know which factor contributes more to it: bent scews, non concentric pulleys on screws, too flexible leadscrews, too much play between leadscrew and nut... I tought that my problems were due to chinesium material, but for my redesign I bough everything at motedis.de (German), and I had even more problems (a not so straight TR8x1.5 leadscrew and nuts with a lot of play).

Right now, with a 2 z motor with integrated leadscrew setup, layer registration is fantastic even with z hop activated, and I don't want to lose that, but I do know that the two z motor setup is going to bite my ass in the future, and that's why I tought about ballscrews, with its machined ends and supports where I hope I can put a puley more realiably.

I also found this: TR16x4mm leadscrew, which should be directly compatible with a ballscrew if I'm not satisifed with the leadscrew. Any thoughts?

Edited 1 time(s). Last edit at 02/13/2019 05:56AM by EgonVLC.

My only left question is about leadscrews and belts. Every single time I've tried to do a leadscrew + belt system, my z layer registration suffers. Don't really know which factor contributes more to it: bent scews, non concentric pulleys on screws, too flexible leadscrews, too much play between leadscrew and nut... I tought that my problems were due to chinesium material, but for my redesign I bough everything at motedis.de (German), and I had even more problems (a not so straight TR8x1.5 leadscrew and nuts with a lot of play).

Right now, with a 2 z motor with integrated leadscrew setup, layer registration is fantastic even with z hop activated, and I don't want to lose that, but I do know that the two z motor setup is going to bite my ass in the future, and that's why I tought about ballscrews, with its machined ends and supports where I hope I can put a puley more realiably.

I also found this: TR16x4mm leadscrew, which should be directly compatible with a ballscrew if I'm not satisifed with the leadscrew. Any thoughts?

Edited 1 time(s). Last edit at 02/13/2019 05:56AM by EgonVLC.

|

Re: Introducing myself and some cuestions about bed design in CoreXY February 13, 2019 06:05AM |

Registered: 5 years ago Posts: 23 |

Sorry, only registered users may post in this forum.