Moving Gantry CoreXY Printer

Posted by gmedlicott

|

Moving Gantry CoreXY Printer February 18, 2019 06:40PM |

Registered: 5 years ago Posts: 71 |

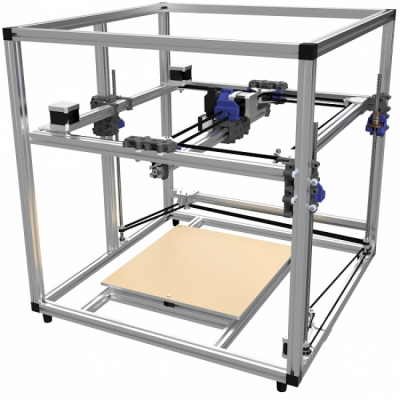

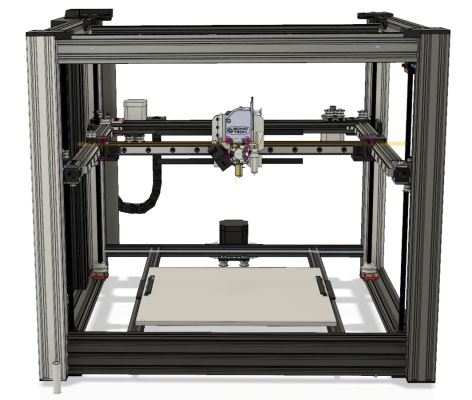

Inspired by the Voron II (and Railcore II), I've designed a moving gantry CoreXY 3D printer. I'm using my own custom carriages that ride on the 2020 extrusions.

The gantry is supported by three vertical rails, with adjustment to keep the gantry in plane on two of the three rails. Initially it will be powered by one Z motor for simplicity. The end goal is a Railcore II type three Z motor auto bed (or gantry in this case) leveling.

The reasoning for a moving gantry vs. bed is this is intended to be scalable to larger units (i.e. 1 meter plus X or Y), where the bed starts to get heavy.

More detail can be found here:

www.exoslide.com/blog/moving-gantry-3D-printer-design

I'll post the CAD files and DXF file for the sheet-metal to the above site once I build one to see if it works!

The gantry is supported by three vertical rails, with adjustment to keep the gantry in plane on two of the three rails. Initially it will be powered by one Z motor for simplicity. The end goal is a Railcore II type three Z motor auto bed (or gantry in this case) leveling.

The reasoning for a moving gantry vs. bed is this is intended to be scalable to larger units (i.e. 1 meter plus X or Y), where the bed starts to get heavy.

More detail can be found here:

www.exoslide.com/blog/moving-gantry-3D-printer-design

I'll post the CAD files and DXF file for the sheet-metal to the above site once I build one to see if it works!

|

Re: Moving Gantry CoreXY Printer February 19, 2019 07:51AM |

Registered: 6 years ago Posts: 1,007 |

|

Re: Moving Gantry CoreXY Printer February 20, 2019 01:23AM |

Registered: 5 years ago Posts: 8 |

|

Re: Moving Gantry CoreXY Printer February 20, 2019 03:16AM |

Registered: 6 years ago Posts: 1,007 |

Even more screwed. Who will dare a 5 leadscrews ?

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Moving Gantry CoreXY Printer February 20, 2019 06:40AM |

Registered: 5 years ago Posts: 23 |

IMHO, the first link also has the belts wrongly set, belts that should be paralel to movement are not...

|

Re: Moving Gantry CoreXY Printer February 20, 2019 09:37AM |

Registered: 11 years ago Posts: 5,780 |

Hey, thanks! I've added this one to my collection of bad corexy builds.

I am amazed at how many people put so much effort and $ into making otherwise solid printers without understanding how the corexy mechanism works. One would think that people would wonder why, after building one of these abominations, the belt tensions change every time they move the extruder carriage. You'd think that would set off some alarms, but I guess not because they keep posting bad designs on the web.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Moving Gantry CoreXY Printer February 20, 2019 11:45AM |

Registered: 6 years ago Posts: 1,007 |

|

Re: Moving Gantry CoreXY Printer February 20, 2019 12:34PM |

Registered: 5 years ago Posts: 71 |

Thanks for the links. All three use four Z screws to control the gantry, similar to the Voron II. On mine, the one mid-placed Z screw I use is possible because the carriage and bracket arrangement is quite stiff. But since I can't guarantee the perpendicular gantry extrusion carrying the XY motors is 100% parallel to the bed, the opposing two Z screws have adjustment on them (dovetail adjusters) to keep the gantry in plane. The bed also has one of the three mounts adjustable to keep it parallel to gantry.

The Z-adjustments and the Z belt arrangement for the single Z motor may be as difficult to get working right as three Z motors with Duet control (e.g. Railcore II). I'll build the former first, then have a go a the Duet option.

Edited 2 time(s). Last edit at 02/20/2019 12:37PM by gmedlicott.

|

Re: Moving Gantry CoreXY Printer February 20, 2019 06:37PM |

Registered: 11 years ago Posts: 1,049 |

|

Re: Moving Gantry CoreXY Printer February 20, 2019 08:13PM |

Registered: 5 years ago Posts: 71 |

Quote

cozmicray

EcoSlide?

What is it?

Where?

Cost?

ExoSlide, not EcoSlide (Exo like outer skeleton). Hopefully I don't have a typo somewhere!

They are modular linear slides for aluminum extrusions.

Stay tuned, I'll have product details available shortly (though not in this thread, I'll keep it CoreXY related)

|

Re: Moving Gantry CoreXY Printer February 21, 2019 01:42AM |

Registered: 10 years ago Posts: 14,672 |

Are you certain that your gantry will be rigid enough to need only 3 leadscrews to support it and not 4?

The Duet can level 4 leadscrews (assuming there is a little flexibility in the gantry) as well as 3.

Edited 1 time(s). Last edit at 02/21/2019 01:42AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

The Duet can level 4 leadscrews (assuming there is a little flexibility in the gantry) as well as 3.

Edited 1 time(s). Last edit at 02/21/2019 01:42AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Moving Gantry CoreXY Printer February 21, 2019 02:17AM |

Registered: 6 years ago Posts: 1,007 |

Indeed, flexibility, you need it. Anyway ....

What makes the ExoSlide different from regular wheel carriages ? The fact they are modular and can be assembled ? How do you adjust the "play", by the two long screws one can see ?

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

What makes the ExoSlide different from regular wheel carriages ? The fact they are modular and can be assembled ? How do you adjust the "play", by the two long screws one can see ?

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Moving Gantry CoreXY Printer February 21, 2019 03:55PM |

Registered: 5 years ago Posts: 71 |

Quote

dc42

Are you certain that your gantry will be rigid enough to need only 3 leadscrews to support it and not 4?

The Duet can level 4 leadscrews (assuming there is a little flexibility in the gantry) as well as 3.

It was sufficiently stiff (for reasonable spans) in the testing of a carriage with a cross bar.

Stiffness of the mounting scheme is one of the advantages of the slides coupled with the brackets.

If the X (or Y) span is too long, I might go with 4 Z supports.

Modular Linear Slides for Aluminum Extrusions [www.exoslide.com]

|

Re: Moving Gantry CoreXY Printer February 21, 2019 04:02PM |

Registered: 5 years ago Posts: 71 |

Quote

MKSA

What makes the ExoSlide different from regular wheel carriages ? The fact they are modular and can be assembled ? How do you adjust the "play", by the two long screws one can see ?

Many differences; a proper release is coming very soon!

Lots can already be teased out from the main page photo and the last blog post. Preload adjustment is by the small m3 screws nested near each other (in the assembly).

Modular Linear Slides for Aluminum Extrusions [www.exoslide.com]

|

Re: Moving Gantry CoreXY Printer July 24, 2019 01:29AM |

Registered: 5 years ago Posts: 71 |

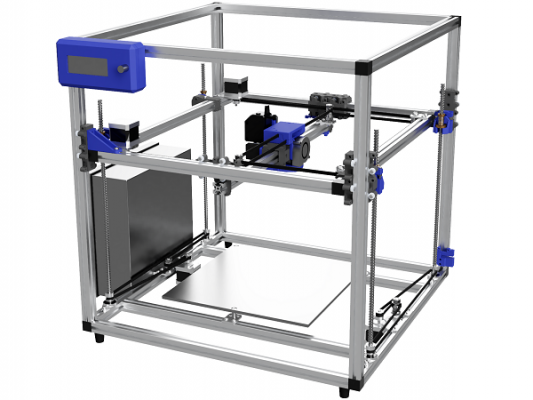

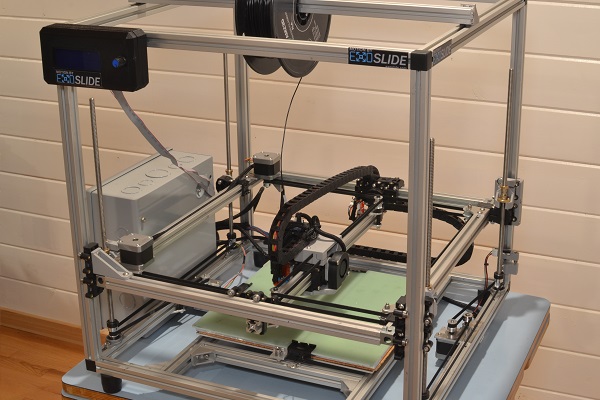

The CAD models are now complete for this printer! DC42 was correct in a previous post, the design required four T8 lead screws to be stiff enough. The final model looks like this:

All the 3D printable part models (in blue) are found here (If anyone wants the Fusion 360 files, PM me):

https://exoslide.com/exocube-printer

Right now its running on Marlin 1.1.9 on a board with 5 drivers. I would like to move a board with 6 drivers (or ideally 7) for auto gantry leveling.

If you have any questions, ask away!

Edited 2 time(s). Last edit at 07/24/2019 01:53AM by gmedlicott.

Modular Linear Slides for Aluminum Extrusions [www.exoslide.com]

All the 3D printable part models (in blue) are found here (If anyone wants the Fusion 360 files, PM me):

https://exoslide.com/exocube-printer

Right now its running on Marlin 1.1.9 on a board with 5 drivers. I would like to move a board with 6 drivers (or ideally 7) for auto gantry leveling.

If you have any questions, ask away!

Edited 2 time(s). Last edit at 07/24/2019 01:53AM by gmedlicott.

Modular Linear Slides for Aluminum Extrusions [www.exoslide.com]

|

Re: Moving Gantry CoreXY Printer July 24, 2019 02:05AM |

Registered: 10 years ago Posts: 14,672 |

Quote

gmedlicott

Right now its running on Marlin 1.1.9 on a board with 5 drivers. I would like to move a board with 6 drivers (or ideally 7) for auto gantry leveling.

Duet Maestro with daughter board provides 7 drivers (TMC2224, similar to TMC2208)

Duet WiFi or Duet Ethernet plus DueX2 provides 7 TMC2660 drivers, or 10 using DueX5 instead of DueX2.

All run RepRapFirmware which supports 2, 3 and 4 leadscrew true bed levelling as standard.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Moving Gantry CoreXY Printer July 24, 2019 02:19AM |

Registered: 6 years ago Posts: 134 |

You want to look at Klipper. with 1 additional 8 bit board and RPI you will have 10 stepper drivers, with 1 more board 15. So you can run 4 Z motors to auto-level and several more left for tool changer and a robotic arm to remove printed parts (this is optionalQuote

gmedlicott

Right now its running on Marlin 1.1.9 on a board with 5 drivers. I would like to move a board with 6 drivers (or ideally 7) for auto gantry leveling.

)

)

|

Re: Moving Gantry CoreXY Printer July 24, 2019 11:12PM |

Registered: 5 years ago Posts: 71 |

Quote

dc42

Quote

gmedlicott

Right now its running on Marlin 1.1.9 on a board with 5 drivers. I would like to move a board with 6 drivers (or ideally 7) for auto gantry leveling.

Duet Maestro with daughter board provides 7 drivers (TMC2224, similar to TMC2208)

Duet WiFi or Duet Ethernet plus DueX2 provides 7 TMC2660 drivers, or 10 using DueX5 instead of DueX2.

All run RepRapFirmware which supports 2, 3 and 4 leadscrew true bed levelling as standard.

I have a Maestro lined up to try that I bought at MRRF. I'll proto a PCB to connect the stepper headers to stepsticks (TMC2208, or do I need TCM2224?), unless there is an off the shelf version of this?

Quote

piper3d

Quote

gmedlicott

Right now its running on Marlin 1.1.9 on a board with 5 drivers. I would like to move a board with 6 drivers (or ideally 7) for auto gantry leveling.

You want to look at Klipper. with 1 additional 8 bit board and RPI you will have 10 stepper drivers, with 1 more board 15. So you can run 4 Z motors to auto-level and several more left for tool changer and a robotic arm to remove printed parts (this is optional smiling smiley)

Not really a fan of this approach (bunch of boards), but I've heard Klipper is evolving, so maybe warrants a second look.

|

Re: Moving Gantry CoreXY Printer July 25, 2019 01:28AM |

Registered: 10 years ago Posts: 14,672 |

Yes there is an off-the-shelf daughter board for the Duet Maestro, [www.duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Moving Gantry CoreXY Printer July 25, 2019 01:51AM |

Registered: 5 years ago Posts: 71 |

Excellent! How did I miss that. Cheers!

Edited 1 time(s). Last edit at 07/25/2019 01:51AM by gmedlicott.

|

Re: Moving Gantry CoreXY Printer July 29, 2019 07:28AM |

Registered: 7 years ago Posts: 363 |

That is quite the wall of shame

|

Re: Moving Gantry CoreXY Printer July 29, 2019 08:49AM |

Registered: 11 years ago Posts: 5,780 |

It's intended to be educational. I've seen posts in this and other forums about people being scared to try corexy because they think there's something difficult about it. I suspect the "difficulty" comes from not understanding how to lay out the belt paths for corexy or any other linear motion system. The thing that amazes me is how many bad designs there are that can't possibly work well (maybe they can print small parts near the center of the bed), yet the "designers" think they are good enough that others may want to copy them, so they post the design and BOM on the internet. Then someone builds it, discovers it doesn't work worth a damn, and starts posting about how difficult corexy is...

I don't think I've ever seen anyone position a lead screw out of parallel with a guide rail, but for some reason, people seem to think it's OK to do that with belts.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I don't think I've ever seen anyone position a lead screw out of parallel with a guide rail, but for some reason, people seem to think it's OK to do that with belts.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Moving Gantry CoreXY Printer July 30, 2019 12:27AM |

Registered: 7 years ago Posts: 363 |

Quote

the_digital_dentist

I don't think I've ever seen anyone position a lead screw out of parallel with a guide rail, but for some reason, people seem to think it's OK to do that with belts.

If I had to guess, it's because people think belts give them license to do whatever they want since it's purposely flexible. I instinctively made my belt paths geometrically correct when designing my printer, but I didn't understand why when I initially did so. It just 'made sense' to me back then.

|

Re: Moving Gantry CoreXY Printer July 30, 2019 01:42AM |

Registered: 5 years ago Posts: 71 |

Simple rule of thumb: anything that is moving needs to have belts connected parallel to the direction of travel (e.g. pulleys connected to a XY gantry, a moving bed, etc). Fixed pulleys can have belts going in any direction (within reason), as long as the segment connecting the moving part is parallel to the travel.

This rule isn't only violated on CoreXY printers, may popular printers have this issue as well, resulting in varying degrees of error in the motion (requested vs actual) due to the belt being the hypotenuse, e.g. Ender 5 X & Y.

Modular Linear Slides for Aluminum Extrusions [www.exoslide.com]

This rule isn't only violated on CoreXY printers, may popular printers have this issue as well, resulting in varying degrees of error in the motion (requested vs actual) due to the belt being the hypotenuse, e.g. Ender 5 X & Y.

Modular Linear Slides for Aluminum Extrusions [www.exoslide.com]

|

Re: Moving Gantry CoreXY Printer July 30, 2019 02:41AM |

Registered: 6 years ago Posts: 1,007 |

|

Re: Moving Gantry CoreXY Printer July 31, 2019 01:47PM |

Registered: 5 years ago Posts: 71 |

Quote

MKSA

@gmedlicott

Can you detail why you now use 4 leadscrews driven by two steppers ?

With four lead screws, the flexible gantry plane is now fully defined. The original plan to keep it simple was to have only one Z motor, with three of the four lead screws having dovetail screw adjusters to level the gantry plane.

The latest design has two Z motors, as with only one motor it exceeded the driver current. In this arrangement, once the opposing rails (the rails attached to the lead screws) are parallel, it acts as a two rod setup much like a Prusa MK3. Two motors also keeps it simple with regards to the control board, as any 5 driver board can be used. Once level, which is easily done by the dovetail adjusters, it works quite well. The only downside is the two motor positions can get out of sync when the machine if off. There are lots of software solutions for this.

A future option as noted above is to have three or four Z motors with auto gantry leveling. This is more expensive from a control board standpoint.

Edited 1 time(s). Last edit at 07/31/2019 01:56PM by gmedlicott.

Modular Linear Slides for Aluminum Extrusions [www.exoslide.com]

|

Re: Moving Gantry CoreXY Printer September 24, 2019 03:34PM |

Registered: 4 years ago Posts: 3 |

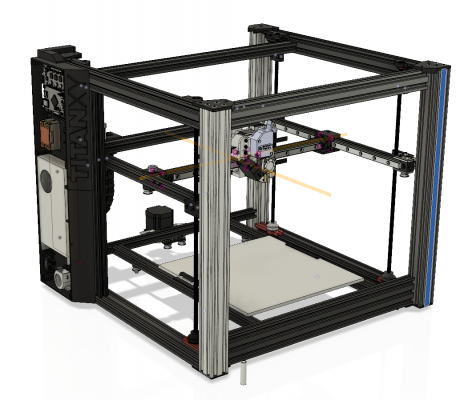

This looks very similar to my Machine I call TitanXY that I made 3 years ago

check this out

[openbuilds.com]

check this out

[openbuilds.com]

|

Re: Moving Gantry CoreXY Printer March 02, 2020 04:13AM |

Registered: 4 years ago Posts: 3 |

|

Re: Moving Gantry CoreXY Printer March 02, 2020 04:25AM |

Registered: 4 years ago Posts: 3 |

|

Re: Moving Gantry CoreXY Printer October 30, 2020 09:33AM |

Registered: 3 years ago Posts: 1 |

Quote

adamfilip

This looks very similar to my Machine I call TitanXY that I made 3 years ago

check this out

[openbuilds.com]

[attachment 112767 titan2.PNG]

[attachment 112768 titan1.PNG]

Hey there! Do you have a cad model of your current setup with linear rails? Followed your Youtube videos

Also, did you mount the gantry in a flexible way?

Also, did you mount the gantry in a flexible way?

Sorry, only registered users may post in this forum.