Single leadscrew non-cantilevered bed: possible?

Posted by EgonVLC

|

Single leadscrew non-cantilevered bed: possible? February 20, 2019 04:15AM |

Registered: 5 years ago Posts: 23 |

|

Re: Single leadscrew non-cantilevered bed: possible? February 20, 2019 04:43AM |

Registered: 6 years ago Posts: 1,007 |

You could with wires and pulleys, shown some place here but more complicated to make and adjust than to add a second leadscrew or belts instead.

Read the thread here, to save time, dismiss anything that has more than two leadscrews and two guides.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

Read the thread here, to save time, dismiss anything that has more than two leadscrews and two guides.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Single leadscrew non-cantilevered bed: possible? February 20, 2019 05:11AM |

Registered: 5 years ago Posts: 23 |

My design intent has two guides and two leadscrews, but I've had problems in the past with pulleys not perfectly concentric in leadscrews and leadscrew bending due to belt tension. That's why I tought about a single leadscrew.

Having a second thought, if I mount the motor centered under the bed, with the leadscrew "looking down", I could use just that one, but the printer height should acomodate that double z height... But it's not practical nor elegant, and I don't really know even if it would work.

Having a second thought, if I mount the motor centered under the bed, with the leadscrew "looking down", I could use just that one, but the printer height should acomodate that double z height... But it's not practical nor elegant, and I don't really know even if it would work.

|

Re: Single leadscrew non-cantilevered bed: possible? February 20, 2019 10:06AM |

Registered: 11 years ago Posts: 5,780 |

How would you make a noncantilevered bed using only one lead screw to lift it?

Using two lead screws on opposite sides of the bed would also be cantilevered, but the length of the cantilever would be shorter.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Using two lead screws on opposite sides of the bed would also be cantilevered, but the length of the cantilever would be shorter.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Single leadscrew non-cantilevered bed: possible? February 20, 2019 10:51AM |

Registered: 5 years ago Posts: 23 |

Quote

the_digital_dentist

How would you make a noncantilevered bed using only one lead screw to lift it?

Using two lead screws on opposite sides of the bed would also be cantilevered, but the length of the cantilever would be shorter.

So the cantilever concept is about the flexibility of the bed structure itself? If overconstraining movement wasn't a problem, and in an ideal word with perfect linear guides, would a design with 4 guides (one in each corner) or even 6 guides still have the problems associated with cantilevered designs if it only used one screw to lift the whole structure?

|

Re: Single leadscrew non-cantilevered bed: possible? February 20, 2019 11:33AM |

Registered: 11 years ago Posts: 5,780 |

No, cantilever is about supporting a structure at one end and letting the rest float in the air. see: [en.wikipedia.org]

Here's a 3D printer (a CubeX Duo) with a cantilevered bed:

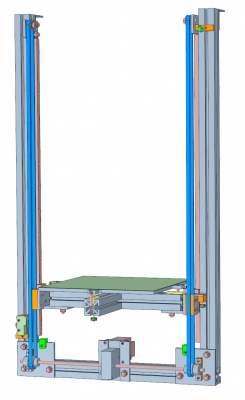

Here's a Z axis design that is also cantilevered, but since it is lifted on two sides, the cantilevers are much shorter.

The problem with cantilevered beds is that they tend to bounce due to frame motion caused by the XY stage moving around. The CubeX Duo speed was limited because of the bouncing of the free end of the bed. In the second example (my printer) bouncing doesn't seem to be a problem.

Z axis linear guides do not provide vertical support (at least they aren't supposed to). They are there to provide guidance in the direction of travel. If you use more guides than necessary to provide guidance you create problems. The motion is supposed to be smooth, but misalignment of guides and flex in the bed structure will result in "walking" (tilting back and forth as the bed moves) or binding. Aligning and keeping multiple guides parallel to each other can be very difficult.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Here's a 3D printer (a CubeX Duo) with a cantilevered bed:

Here's a Z axis design that is also cantilevered, but since it is lifted on two sides, the cantilevers are much shorter.

The problem with cantilevered beds is that they tend to bounce due to frame motion caused by the XY stage moving around. The CubeX Duo speed was limited because of the bouncing of the free end of the bed. In the second example (my printer) bouncing doesn't seem to be a problem.

Z axis linear guides do not provide vertical support (at least they aren't supposed to). They are there to provide guidance in the direction of travel. If you use more guides than necessary to provide guidance you create problems. The motion is supposed to be smooth, but misalignment of guides and flex in the bed structure will result in "walking" (tilting back and forth as the bed moves) or binding. Aligning and keeping multiple guides parallel to each other can be very difficult.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Single leadscrew non-cantilevered bed: possible? February 21, 2019 10:24AM |

Registered: 11 years ago Posts: 335 |

Quote

EgonVLC

Having a second thought, if I mount the motor centered under the bed, with the leadscrew "looking down", I could use just that one, but the printer height should accommodate that double z height... But it's not practical nor elegant, and I don't really know even if it would work.

Stratasys does something like that but it is certainly wasteful unless you need an airtight heated chamber.

|

Re: Single leadscrew non-cantilevered bed: possible? February 21, 2019 01:27PM |

Registered: 6 years ago Posts: 134 |

|

Re: Single leadscrew non-cantilevered bed: possible? February 21, 2019 04:37PM |

Registered: 11 years ago Posts: 5,780 |

Oh yeah! Scissor lift is interesting but a problem to build. Every joint in the scissor, and flex in the levers or arms contributes to slop in the movement of the platform. I saw a build by a guy in New Zealand (?) a few years ago that used something else- not a scissor but a hinged platform whose name I can't recall. I don't know how well it worked, but I haven't seen another one like it, so maybe not so well.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Single leadscrew non-cantilevered bed: possible? February 21, 2019 04:48PM |

Registered: 5 years ago Posts: 71 |

You mean the Bartolobot 3DX, as posted on Toms 3d forum?

https://discuss.toms3d.org/3d-printers-f13/show-your-printer-s-t37-s50.html

https://discuss.toms3d.org/3d-printers-f13/show-your-printer-s-t37-s50.html

|

Re: Single leadscrew non-cantilevered bed: possible? February 22, 2019 12:35AM |

Registered: 11 years ago Posts: 5,780 |

Not that one. The machine was built by a grad student, and had a weird plastic bubble for an enclosure.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Single leadscrew non-cantilevered bed: possible? February 22, 2019 03:57PM |

Registered: 11 years ago Posts: 1,049 |

|

Re: Single leadscrew non-cantilevered bed: possible? February 22, 2019 05:49PM |

Registered: 11 years ago Posts: 5,780 |

It was a Sarrus linkage. It had same-size top and bottom plates with hinges on all 4 edges between the two plates. I don't know how the screw was arranged.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Single leadscrew non-cantilevered bed: possible? February 22, 2019 11:43PM |

Registered: 6 years ago Posts: 207 |

Quote

the_digital_dentist

It was a Sarrus linkage. It had same-size top and bottom plates with hinges on all 4 edges between the two plates. I don't know how the screw was arranged.

This is the printer you're referring to: [www.youtube.com]

|

Re: Single leadscrew non-cantilevered bed: possible? February 23, 2019 01:13AM |

Registered: 11 years ago Posts: 5,780 |

|

Re: Single leadscrew non-cantilevered bed: possible? February 27, 2019 11:16AM |

Registered: 11 years ago Posts: 250 |

My build sports a cantilever bed, but with spectra line supports.

I'm getting good prints, and had no issues with sagging, bouncing or Repeatability.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

I'm getting good prints, and had no issues with sagging, bouncing or Repeatability.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Single leadscrew non-cantilevered bed: possible? February 27, 2019 11:39PM |

Registered: 8 years ago Posts: 1,671 |

|

Re: Single leadscrew non-cantilevered bed: possible? March 26, 2019 05:12PM |

Registered: 6 years ago Posts: 11 |

Quote

EgonVLC

...

Having a second thought, if I mount the motor centered under the bed, with the leadscrew "looking down", I could use just that one, but the printer height should acomodate that double z height... But it's not practical nor elegant, and I don't really know even if it would work.

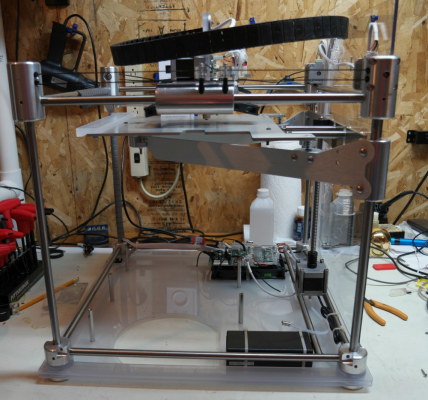

I did this and it actually works pretty well. But you need to mount it on a tall stand or bore a hole in the top of your bench. It's mounted on a base w/ a hole & 100mm of leadscrew peeking out so II drilled a hole in my countertop. I made the piece with the Z nut so it was snug on the Z but could float to self locate on the X & Y . It's secured to the bottom of my plywood base w/ 3 large screws in oversize holes plus big washers.

You can see that the Z is working OK. I'm new at this and still working all the bugs out of my first design, but so far so good when running PLA.

|

Re: Single leadscrew non-cantilevered bed: possible? March 27, 2019 12:52AM |

Registered: 6 years ago Posts: 207 |

Quote

scoot

Quote

EgonVLC

...

Having a second thought, if I mount the motor centered under the bed, with the leadscrew "looking down", I could use just that one, but the printer height should acomodate that double z height... But it's not practical nor elegant, and I don't really know even if it would work.

I did this and it actually works pretty well. But you need to mount it on a tall stand or bore a hole in the top of your bench. It's mounted on a base w/ a hole & 100mm of leadscrew peeking out so II drilled a hole in my countertop. I made the piece with the Z nut so it was snug on the Z but could float to self locate on the X & Y . It's secured to the bottom of my plywood base w/ 3 large screws in oversize holes plus big washers.

You can see that the Z is working OK. I'm new at this and still working all the bugs out of my first design, but so far so good when running PLA.

It looks like you made a leadscrew-driven quadrap (Ultimaker) style of printer, which is what I wanted to do back in this thread: [reprap.org]

How is the print quality and any issues? How are the speeds and accelerations? Thank you! Your design keeps the motors stationary, which is better and what I planned in the long run.

Edited 2 time(s). Last edit at 03/27/2019 12:57AM by klcjr89.

|

Re: Single leadscrew non-cantilevered bed: possible? March 27, 2019 03:14AM |

Registered: 6 years ago Posts: 11 |

You're right, it is similar to Ultimaker, in fact I 'discovered' the Ultimaker design after I started on this and found I could use an aftermarket print head designed for the Ultimaker. My objectives were to be simple, cheap and portable w/ easy takedown and setup. Minimum number of components with 2 of the 3 supports providing the ways for Z and the leadscrews themselves providing the ways for X & Y. So 3 leadscrew motors, 2 leadscrews, 4 pulleys, 6 bearings, 2 belts, 4 extrusions, 3 support legs, some random hardware, bed plate & bed, hot end, extruder, power supply, controller & screen plus a few printed parts and done. I should start a build thread when I get a little more info on if/how it's still working...

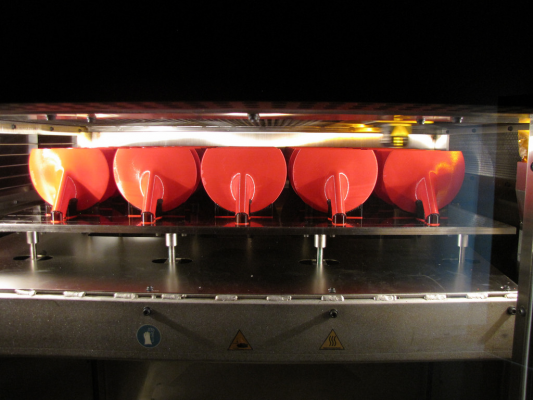

It's early days and I am still tweaking the firmware and alignment to get it working properly. Some failures but some very good prints as well. I did need to slow down the max velocity & acceleration so the motors wouldn't chatter /skip and am still getting my Y dialed in. Here's more pics including the print off contest results between my JGAurora A5(silver), my heavily modified FLSun(orange) and this one(purple). The well tuned old fellows beat the new boy 10% -20% on speed, but I think they came in #2 & #3 in results. This was only the 3rd print it had made.

Back on topic, I think there's a lot to be said for a single, centrally mounted Z motor and this is the only way I could figure out how to get that done. So be it.

Edited 1 time(s). Last edit at 03/27/2019 03:30AM by scoot.

It's early days and I am still tweaking the firmware and alignment to get it working properly. Some failures but some very good prints as well. I did need to slow down the max velocity & acceleration so the motors wouldn't chatter /skip and am still getting my Y dialed in. Here's more pics including the print off contest results between my JGAurora A5(silver), my heavily modified FLSun(orange) and this one(purple). The well tuned old fellows beat the new boy 10% -20% on speed, but I think they came in #2 & #3 in results. This was only the 3rd print it had made.

Back on topic, I think there's a lot to be said for a single, centrally mounted Z motor and this is the only way I could figure out how to get that done. So be it.

Edited 1 time(s). Last edit at 03/27/2019 03:30AM by scoot.

Sorry, only registered users may post in this forum.