yet another corexy needs your review please

Posted by Ernest1122

|

yet another corexy needs your review please March 01, 2019 06:33AM |

Registered: 5 years ago Posts: 25 |

Yeah this is another CoreXY build hoping to get your valuable review.

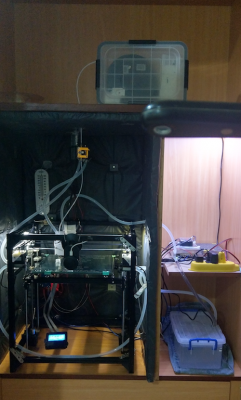

I've built and run my CoreXY from china kit for a few months, put it in empty closet as enclosure (PLA parts distorted), tried 10mm carbon fiber rods to reduce x axis weight (not easy to find proper clearance of the plastic bearing), attached 40x40mm water-cooling pads to steppers to prevent overheating (not bad), and eventually I realized I need a more reliable machine if I want go further.

Thank a lot to many previous discussions, especially digital dentist's blog gave so much insights. Here I list my thoughts, pics and some questions, hope to be reviewed before ordering parts. I'm not an native English speaker so please just point out if anything not precise.

Goal

- Multi-material capability including TPU, ABS, PETG and PC which prints can be used in my car or engine bay.

- Prefer precession > durability > speed > power consumption

- Waste less time on upgrading/adjusting the printer, spend more time on designing real useful parts

- 300x300x300 print size or larger

Frame

- 30x30 extrusion frame

- 6061 5mm plate as XY plane

- All steppers will be outside of the frame.

- Put power, control board, filament, water pump/tank above the frame. Water hoses and filament tube go into the enclosure from top.

Transmission

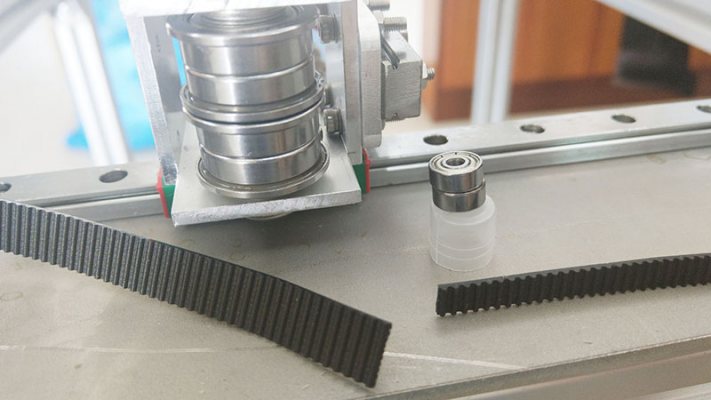

- Genuine HIWIN MGN12H and 400mm rails

- 2GT 10mm belt and stacked F608zz as idler with no other support. I think the 8mm bolt/nut/washer combination should be rigid enough to prevent tilting.

- Belt tensioner with M3 screw pushing XY stepper mount backward.

- Z axis is moved by two 1204 ball screws which driven by single belt. The Rino worm drive + belt-suspended solution is too expensive.

Bed & Extruder

- 24V power + SSR + thin aluminum heating plate + boro glass for easily retrieving the print. Sometimes the print sticks too well and I want to be gentle to the bed and linear rail so I gave up the neat tooling plate solution.

- Direct extrude with NEMA17 20mm short stepper with Titan Aqua water cooling extruder to resist 80c ~ 100c chamber temperature.

After two weeks of study and design, these are some points I can't make decision with...

- since the CTE (coefficient of thermal expansion) of two metals are different and the linear rail and aluminum plate are locked together, will they bend if the air temperature raises to 80c ~ 100c when printing polycarbonate?

- any experience of replacing the 6061 X base plate with 5mm or even 8mm carbon fiber plate? I'm still not that comfortable with dentist's design which leaves one end of the x axis rail supported by a linear block. I googled that the CTE of carbon fiber are about 1/10 of aluminum, 1/5 of steel, which should be good enough under high temperature. Also 5~8mm thickness of CF should resist twisting or bending.

- is there better way to mount MGN12 rail (m3 bolts) onto the 3030 extrusion (m4 T-nut)? although one more aluminum plate between the rail and extrusion will do but it seems too long to be rigid enough. Choose other brands of linear rail with m4 bolt?

- is it worth that expense to choose IKO/THK than HIWIN?

Needs your valuable comments, thank you!

Edited 2 time(s). Last edit at 03/01/2019 06:44AM by Ernest1122.

I've built and run my CoreXY from china kit for a few months, put it in empty closet as enclosure (PLA parts distorted), tried 10mm carbon fiber rods to reduce x axis weight (not easy to find proper clearance of the plastic bearing), attached 40x40mm water-cooling pads to steppers to prevent overheating (not bad), and eventually I realized I need a more reliable machine if I want go further.

Thank a lot to many previous discussions, especially digital dentist's blog gave so much insights. Here I list my thoughts, pics and some questions, hope to be reviewed before ordering parts. I'm not an native English speaker so please just point out if anything not precise.

Goal

- Multi-material capability including TPU, ABS, PETG and PC which prints can be used in my car or engine bay.

- Prefer precession > durability > speed > power consumption

- Waste less time on upgrading/adjusting the printer, spend more time on designing real useful parts

- 300x300x300 print size or larger

Frame

- 30x30 extrusion frame

- 6061 5mm plate as XY plane

- All steppers will be outside of the frame.

- Put power, control board, filament, water pump/tank above the frame. Water hoses and filament tube go into the enclosure from top.

Transmission

- Genuine HIWIN MGN12H and 400mm rails

- 2GT 10mm belt and stacked F608zz as idler with no other support. I think the 8mm bolt/nut/washer combination should be rigid enough to prevent tilting.

- Belt tensioner with M3 screw pushing XY stepper mount backward.

- Z axis is moved by two 1204 ball screws which driven by single belt. The Rino worm drive + belt-suspended solution is too expensive.

Bed & Extruder

- 24V power + SSR + thin aluminum heating plate + boro glass for easily retrieving the print. Sometimes the print sticks too well and I want to be gentle to the bed and linear rail so I gave up the neat tooling plate solution.

- Direct extrude with NEMA17 20mm short stepper with Titan Aqua water cooling extruder to resist 80c ~ 100c chamber temperature.

After two weeks of study and design, these are some points I can't make decision with...

- since the CTE (coefficient of thermal expansion) of two metals are different and the linear rail and aluminum plate are locked together, will they bend if the air temperature raises to 80c ~ 100c when printing polycarbonate?

- any experience of replacing the 6061 X base plate with 5mm or even 8mm carbon fiber plate? I'm still not that comfortable with dentist's design which leaves one end of the x axis rail supported by a linear block. I googled that the CTE of carbon fiber are about 1/10 of aluminum, 1/5 of steel, which should be good enough under high temperature. Also 5~8mm thickness of CF should resist twisting or bending.

- is there better way to mount MGN12 rail (m3 bolts) onto the 3030 extrusion (m4 T-nut)? although one more aluminum plate between the rail and extrusion will do but it seems too long to be rigid enough. Choose other brands of linear rail with m4 bolt?

- is it worth that expense to choose IKO/THK than HIWIN?

Needs your valuable comments, thank you!

Edited 2 time(s). Last edit at 03/01/2019 06:44AM by Ernest1122.

|

Re: yet another corexy needs your review please March 01, 2019 08:56AM |

Registered: 8 years ago Posts: 1,671 |

|

Re: yet another corexy needs your review please March 01, 2019 09:27AM |

Registered: 5 years ago Posts: 25 |

|

Re: yet another corexy needs your review please March 01, 2019 10:16AM |

Registered: 11 years ago Posts: 5,780 |

Will your extruder motor operate at that high temperature? Do you have belts that are spec'd to operate at that high a temperature? I would not trust any no-spec belts or motors to last at that temperature.

Will CF composite and linear guides hold up at that high temperature?

CF composite has anisotropic thermal expansion characteristics that depend on the direction of lay of the fibers and the stacking of the layers. If someone quotes a CTE number, they also have to quote the direction.

When the printer's frame heats up, it will expand and the Y axis rails are going to move apart. You have to do something in the X axis to allow for that expansion or the mechanism is going to bind. That is why I used an extra bearing block on the X axis rail.

I would not use a DC powered heater for a bed that large. I did that in SoM and finally/recently replaced it with a higher powered AC line powered heater. It doesn't require a high current power supply or cable and heats up MUCH faster. The SSR that switches power to it doesn't need a heat sink.

How will you heat the enclosure? What kind of insulation will you use to keep the heat in the enclosure? I have a 500W heater in my 420 liter enclosure and it takes about 20 minutes to get the enclosure up to 50C for printing ABS (with the bed heater running at 100C).

Edited 1 time(s). Last edit at 03/01/2019 02:21PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Will CF composite and linear guides hold up at that high temperature?

CF composite has anisotropic thermal expansion characteristics that depend on the direction of lay of the fibers and the stacking of the layers. If someone quotes a CTE number, they also have to quote the direction.

When the printer's frame heats up, it will expand and the Y axis rails are going to move apart. You have to do something in the X axis to allow for that expansion or the mechanism is going to bind. That is why I used an extra bearing block on the X axis rail.

I would not use a DC powered heater for a bed that large. I did that in SoM and finally/recently replaced it with a higher powered AC line powered heater. It doesn't require a high current power supply or cable and heats up MUCH faster. The SSR that switches power to it doesn't need a heat sink.

How will you heat the enclosure? What kind of insulation will you use to keep the heat in the enclosure? I have a 500W heater in my 420 liter enclosure and it takes about 20 minutes to get the enclosure up to 50C for printing ABS (with the bed heater running at 100C).

Edited 1 time(s). Last edit at 03/01/2019 02:21PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: yet another corexy needs your review please March 01, 2019 11:29AM |

Registered: 6 years ago Posts: 1,007 |

|

Re: yet another corexy needs your review please March 01, 2019 01:25PM |

Registered: 5 years ago Posts: 71 |

Looks good!

One note on the stacked idlers, they should to be different diameters (i.e. the idler with the belt running directly to the motor pulley should be larger), otherwise the belts can rub when the carriage moves to the end-stop by the idlers.

Modular Linear Slides for Aluminum Extrusions [www.exoslide.com]

One note on the stacked idlers, they should to be different diameters (i.e. the idler with the belt running directly to the motor pulley should be larger), otherwise the belts can rub when the carriage moves to the end-stop by the idlers.

Modular Linear Slides for Aluminum Extrusions [www.exoslide.com]

|

Re: yet another corexy needs your review please March 02, 2019 02:59AM |

Registered: 7 years ago Posts: 249 |

You could move the AB motors down on the base, outside the enclosure, by using vertical shafts to the pulleys. Yes, more bearings.

Plus water cool the hot end and direct drive extruder motor for longer life/better control.

Laminating another piece of steel under the aluminum plate, that's under the linear guide rail, may reduce the bow/warp from the difference in the CTE.

Or just use stainless plate. Half the thickness gives the same strength as aluminum, though will weigh about 30% more. But the CTE is much lower.

Good tool steel will be about the same strength as aluminum by weight, only 1/3rd the size, with roughly half the CTE.

FIR heaters might work better than forced air in your application, though SPA/hot tub forced air heaters are also a good option.

Benefit of Far Infrared heaters they mainly heat objects that absorb IR radiation, like opaque plastics. The emmiters themselves stay cool. Aluminum also reflects IR really well. Steel not so much.

Glass will reflect FIR, AKA the greenhouse effect. From what I know, Polycarbonate and plexiglass are better insulators for recirculating hot air boxes.

One thing I learned from building my own printer from extrusions is that it's better to through bolt than use corner brackets. That's why the center core of extrusions are conveniently near a tap drill size.

Now I do both, bolt and metal bracket. 3d printed brackets just seem to spontaneously fail, except the SLS and SLA variety.

Last thing to consider is servos over steppers, to prevent layer shifts and failed prints due to collisions/hick-ups.

Not gonna talk Z axis, run with whatever make you feel good.

Plus water cool the hot end and direct drive extruder motor for longer life/better control.

Laminating another piece of steel under the aluminum plate, that's under the linear guide rail, may reduce the bow/warp from the difference in the CTE.

Or just use stainless plate. Half the thickness gives the same strength as aluminum, though will weigh about 30% more. But the CTE is much lower.

Good tool steel will be about the same strength as aluminum by weight, only 1/3rd the size, with roughly half the CTE.

FIR heaters might work better than forced air in your application, though SPA/hot tub forced air heaters are also a good option.

Benefit of Far Infrared heaters they mainly heat objects that absorb IR radiation, like opaque plastics. The emmiters themselves stay cool. Aluminum also reflects IR really well. Steel not so much.

Glass will reflect FIR, AKA the greenhouse effect. From what I know, Polycarbonate and plexiglass are better insulators for recirculating hot air boxes.

One thing I learned from building my own printer from extrusions is that it's better to through bolt than use corner brackets. That's why the center core of extrusions are conveniently near a tap drill size.

Now I do both, bolt and metal bracket. 3d printed brackets just seem to spontaneously fail, except the SLS and SLA variety.

Last thing to consider is servos over steppers, to prevent layer shifts and failed prints due to collisions/hick-ups.

Not gonna talk Z axis, run with whatever make you feel good.

|

Re: yet another corexy needs your review please March 02, 2019 03:54AM |

Registered: 5 years ago Posts: 25 |

Thank you all for so much input and pushing me think further about the temperature, another day of non-stop survey!

I set the goal of 80c~100c chamber temperature based on googled info, but there are also others said 50c~60c chamber is enough for small PC parts. Large PC prints may still shear apart at that temp.

I think I should lower my expectation to print small PC parts in at most 70c chamber after some more study as listed below.

For passive heated chamber (by bed and extruder) the chamber reaches 35c~40c which is the same with my experience, active heating will be a must if high temperature is required. I think AC powered PTC heater (self-regulated temp, safe, no fire hazard) + air mixer fan + GPIO relay + OctoPi temp plugin will be a proper solution.

[www.ptc-heater.com.tw]

Enclosure panel can be 1.5~2mm PC plate (120c, transparent), 8mm double layer PC plate (semi transparent) or 5cm rock wool plate (650c, fire proof, noise reduction, opaque).

According to HIWIN spec, high temperature mainly affect the age of plastic parts in a linear block. They provide some constants (< 1.0) to be multiplied with estimated age if temp is over 100c. Also to prevent the extruder carriage from wobbling, I'll choose HIWIN linear block with preload grade Z0, not ZF (with clearance).

[www.hiwin.tw]

Branded belt like Gates operate between -54°C to +85°C.

[industrialbeltdrives.com]

I hope the water cooled Titan Aqua extruder removes heat fast enough in a 70c chamber, but still need experiment to verify. When I was running my current machine all inside a rock wool isolated enclosure at 600mm/s, the steppers were fried and under-extruded. Later I attached water cooling pads behind the steppers and they're running well. Since the new machine steppers are outside I think only extruder stepper needs to be water cooled.

For the end stops, originally I plan to use Hall effect sensors. But considering the temp will affect magnets I'll change to optical ones.

I'm sold to use another linear block at one end of X axis. According to the calculation: CTE of commercial grade carbon fiber varies from -1 ~ 8 uin/in-F (-1.8 ~ 14.4 um/m-C) depend on the direction and other factor. Naively assume 7 um/m-C for 45 degree weaving pattern, under 500mm X axis and 50c temp span from 20c to 70c, there will be 7x50x500=175um=0.175mm expansion at X direction, which is unacceptable.

Annealing (another thermal cycle to release internal stress of material) will get some more strength of the print

[www.reddit.com]

On the other hand, all above lead me to think how large build size do I really need? Will it be a hobbyist project or engineering project? Technical challenges and costs raises exponentially with build size. My current machine is 300mm cubic but most of my needs are small functional parts like accessory mounts, holders, gadgets, etc. I can't imagine a single large thing I have to print, an air filter box or wind screen for motorcycle? maybe 200mm cubic will be enough for me. What are you large prints?

Edited 2 time(s). Last edit at 03/02/2019 03:59AM by Ernest1122.

I set the goal of 80c~100c chamber temperature based on googled info, but there are also others said 50c~60c chamber is enough for small PC parts. Large PC prints may still shear apart at that temp.

I think I should lower my expectation to print small PC parts in at most 70c chamber after some more study as listed below.

For passive heated chamber (by bed and extruder) the chamber reaches 35c~40c which is the same with my experience, active heating will be a must if high temperature is required. I think AC powered PTC heater (self-regulated temp, safe, no fire hazard) + air mixer fan + GPIO relay + OctoPi temp plugin will be a proper solution.

[www.ptc-heater.com.tw]

Enclosure panel can be 1.5~2mm PC plate (120c, transparent), 8mm double layer PC plate (semi transparent) or 5cm rock wool plate (650c, fire proof, noise reduction, opaque).

According to HIWIN spec, high temperature mainly affect the age of plastic parts in a linear block. They provide some constants (< 1.0) to be multiplied with estimated age if temp is over 100c. Also to prevent the extruder carriage from wobbling, I'll choose HIWIN linear block with preload grade Z0, not ZF (with clearance).

[www.hiwin.tw]

Branded belt like Gates operate between -54°C to +85°C.

[industrialbeltdrives.com]

I hope the water cooled Titan Aqua extruder removes heat fast enough in a 70c chamber, but still need experiment to verify. When I was running my current machine all inside a rock wool isolated enclosure at 600mm/s, the steppers were fried and under-extruded. Later I attached water cooling pads behind the steppers and they're running well. Since the new machine steppers are outside I think only extruder stepper needs to be water cooled.

For the end stops, originally I plan to use Hall effect sensors. But considering the temp will affect magnets I'll change to optical ones.

I'm sold to use another linear block at one end of X axis. According to the calculation: CTE of commercial grade carbon fiber varies from -1 ~ 8 uin/in-F (-1.8 ~ 14.4 um/m-C) depend on the direction and other factor. Naively assume 7 um/m-C for 45 degree weaving pattern, under 500mm X axis and 50c temp span from 20c to 70c, there will be 7x50x500=175um=0.175mm expansion at X direction, which is unacceptable.

Annealing (another thermal cycle to release internal stress of material) will get some more strength of the print

[www.reddit.com]

On the other hand, all above lead me to think how large build size do I really need? Will it be a hobbyist project or engineering project? Technical challenges and costs raises exponentially with build size. My current machine is 300mm cubic but most of my needs are small functional parts like accessory mounts, holders, gadgets, etc. I can't imagine a single large thing I have to print, an air filter box or wind screen for motorcycle? maybe 200mm cubic will be enough for me. What are you large prints?

Edited 2 time(s). Last edit at 03/02/2019 03:59AM by Ernest1122.

|

Re: yet another corexy needs your review please March 02, 2019 04:18AM |

Registered: 5 years ago Posts: 25 |

Quote

prot0typ1cal

FIR heaters might work better than forced air in your application, though SPA/hot tub forced air heaters are also a good option.

Benefit of Far Infrared heaters they mainly heat objects that absorb IR radiation, like opaque plastics. The emmiters themselves stay cool. Aluminum also reflects IR really well. Steel not so much.

Glass will reflect FIR, AKA the greenhouse effect. From what I know, Polycarbonate and plexiglass are better insulators for recirculating hot air boxes.

I'm sold with the 304 laser cut steel plate! will 2mm be enough?

FIR heater looks interesting. but how to measure the temperature of prints, since air is not that hot? will 100% solid infill be heated uniformly?

If to use water cooling, it's better to just cool steppers near similar heights. small water pump may got problem producing enough pressure as shown in my picture above.

Some painted corner brackets affect orthogonality. i spent hours grinding off those low quality paint finish.

|

Re: yet another corexy needs your review please March 02, 2019 03:42PM |

Registered: 7 years ago Posts: 249 |

The taller the section, the better for X. Height, not width, is more important for beams. L shapes will help for higher accels/decels in the Y.

Under the Y rails, I'd go thick enough to thread the M3 used to secure the rail. Non-moving so weight will help there to dampen vibrations.

Yea, FIR would require a IR camera to regulate. Though just a hand held IR laser temp sensor will be enough to set the emmiters once. Being "too hot" for CF or PC doesn't seem to be an issue.

Water cooling is its own animal. Most computer CPU/GPU solutions will work fine for motors.

You will need a custom block and separate system for the extruder. Though, you could use the return line off the transition heat sink onto the extruder motor, as the temps will be low enough.

Thermoelectric coolers (TEC) are another option. As one side is cool, the other side is hot. Cools your components and heats the chamber at the same time. To be safe, each would need a thermocouple/thermister.

Under the Y rails, I'd go thick enough to thread the M3 used to secure the rail. Non-moving so weight will help there to dampen vibrations.

Yea, FIR would require a IR camera to regulate. Though just a hand held IR laser temp sensor will be enough to set the emmiters once. Being "too hot" for CF or PC doesn't seem to be an issue.

Water cooling is its own animal. Most computer CPU/GPU solutions will work fine for motors.

You will need a custom block and separate system for the extruder. Though, you could use the return line off the transition heat sink onto the extruder motor, as the temps will be low enough.

Thermoelectric coolers (TEC) are another option. As one side is cool, the other side is hot. Cools your components and heats the chamber at the same time. To be safe, each would need a thermocouple/thermister.

|

Re: yet another corexy needs your review please March 02, 2019 07:35PM |

Registered: 5 years ago Posts: 25 |

china laser cutting shop qouted me less than 30usd for my two 3mm 304 steel y plates. for now i think they are thick enough to resist vibration/twist. i'll give a try once my design is settled down, plz stop me if i'm naieve.

yes, in my current machine i connect xy steppers, extruder stepper, bowder extruder, and psu in series and they work very well, although these 11mm silicone hoses look like a mess and add some weight to the extruder. ha.

as for the active chamber heater, thanks for so many options, it's kind of difficult to decide. i think i'll go PTC heater + OctoPi for auto temp control and cost reason.

Edited 1 time(s). Last edit at 03/03/2019 11:59AM by Ernest1122.

yes, in my current machine i connect xy steppers, extruder stepper, bowder extruder, and psu in series and they work very well, although these 11mm silicone hoses look like a mess and add some weight to the extruder. ha.

as for the active chamber heater, thanks for so many options, it's kind of difficult to decide. i think i'll go PTC heater + OctoPi for auto temp control and cost reason.

Edited 1 time(s). Last edit at 03/03/2019 11:59AM by Ernest1122.

|

Re: yet another corexy needs your review please March 02, 2019 08:21PM |

Registered: 5 years ago Posts: 23 |

|

Re: yet another corexy needs your review please March 02, 2019 08:52PM |

Registered: 5 years ago Posts: 25 |

Quote

EgonVLC

Could you please share the link of the cutting service?

it's one of the tens of matel processing shops in taobao.com. i havent use it, i mentioed it just based on the price they offered.

[m.tb.cn]

taobao is china's ebay. chinese ppl do all 2b or 2c business online. i mean ALL. western ppl usually use aliexpress because of language. i live in taiwan so easier for me to access these materials/products/services. if language is not a problem, choose wisely based on their china style review system, you'll find qualified enough products.

|

Re: yet another corexy needs your review please March 03, 2019 02:54AM |

Registered: 6 years ago Posts: 1,007 |

Quote

Ernest1122

....

Annealing (another thermal cycle to release internal stress of material) will get some more strength of the print

[www.reddit.com]

...

For extra strength I anneal PETG parts with a heatgun. I think it doesn't just relieve stress but increase the layer bond (mainly of the "skin"). Layer bond is the main weakness of printed parts.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: yet another corexy needs your review please March 03, 2019 02:17PM |

Registered: 5 years ago Posts: 25 |

Quote

MKSA

For extra strength I anneal PETG parts with a heatgun. I think it doesn't just relieve stress but increase the layer bond (mainly of the "skin"). Layer bond is the main weakness of printed parts.

i found this oven with 25cm^3 chamber, up to 300c and cost about 60usd (w/o shipping). maybe you can have a try.

[detail.tmall.com]

|

Re: yet another corexy needs your review please March 03, 2019 02:33PM |

Registered: 6 years ago Posts: 1,007 |

Quote

Ernest1122

Quote

MKSA

For extra strength I anneal PETG parts with a heatgun. I think it doesn't just relieve stress but increase the layer bond (mainly of the "skin"). Layer bond is the main weakness of printed parts.

i found this oven with 25cm^3 chamber, up to 300c and cost about 60usd (w/o shipping). maybe you can have a try.

[detail.tmall.com]

In lieu of the kitchen oven, I prefer to use a heatgun with T° adj; as I noticed that just heating the surface to glass point is enough to strengthen the part without having it deform.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: yet another corexy needs your review please March 03, 2019 02:49PM |

Registered: 5 years ago Posts: 25 |

|

Re: yet another corexy needs your review please March 04, 2019 03:34AM |

Registered: 5 years ago Posts: 23 |

Quote

Ernest1122

Quote

EgonVLC

Could you please share the link of the cutting service?

it's one of the tens of matel processing shops in taobao.com. i havent use it, i mentioed it just based on the price they offered.

[m.tb.cn]

taobao is china's ebay. chinese ppl do all 2b or 2c business online. i mean ALL. western ppl usually use aliexpress because of language. i live in taiwan so easier for me to access these materials/products/services. if language is not a problem, choose wisely based on their china style review system, you'll find qualified enough products.

I'm from Eurpe (Spain), and language is indeed a problem, as shipping cost also is. And makerspaces here are almost non-existent, so access to custom metal pieces is kind of difficult.

|

Re: yet another corexy needs your review please March 04, 2019 04:22AM |

Registered: 5 years ago Posts: 25 |

Quote

EgonVLC

I'm from Eurpe (Spain), and language is indeed a problem, as shipping cost also is. And makerspaces here are almost non-existent, so access to custom metal pieces is kind of difficult.

try aliexpress.com, this is multi-language site for non-chinese ppl. although not all, but many taobao stores are also in aliexpress.com too.

however i think there are definitely local metal processing shops in spain too. send your dwg files and they'll cnc/laser-cut for you. some shops accept hand drawing if parts are simple enough.

|

Re: yet another corexy needs your review please March 04, 2019 04:36AM |

Registered: 5 years ago Posts: 23 |

Quote

Ernest1122

Quote

EgonVLC

I'm from Eurpe (Spain), and language is indeed a problem, as shipping cost also is. And makerspaces here are almost non-existent, so access to custom metal pieces is kind of difficult.

try aliexpress.com, this is multi-language site for non-chinese ppl. although not all, but many taobao stores are also in aliexpress.com too.

however i think there are definitely local metal processing shops in spain too. send your dwg files and they'll cnc/laser-cut for you. some shops accept hand drawing if parts are simple enough.

Local shops are VERY expensive here are they use to require minimum number of pieces, do u have any link?. I've used aliexpress a lot, but didn't know it had that kind of services.

|

Re: yet another corexy needs your review please March 04, 2019 04:38AM |

Registered: 5 years ago Posts: 25 |

|

Re: yet another corexy needs your review please March 25, 2019 12:47PM |

Registered: 5 years ago Posts: 25 |

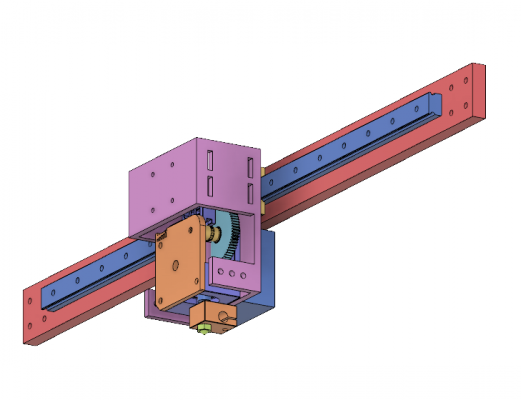

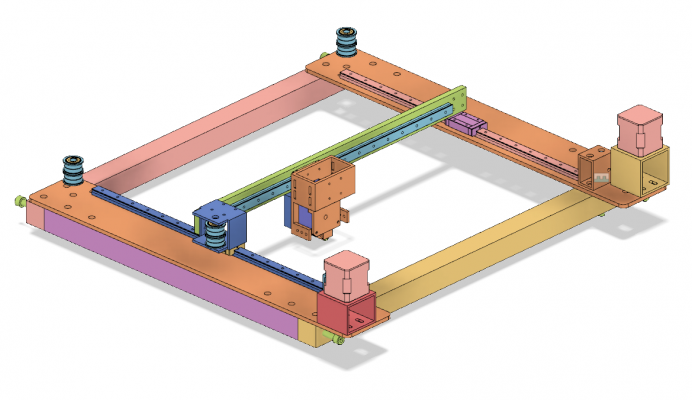

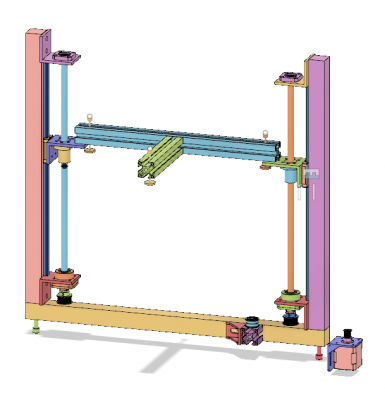

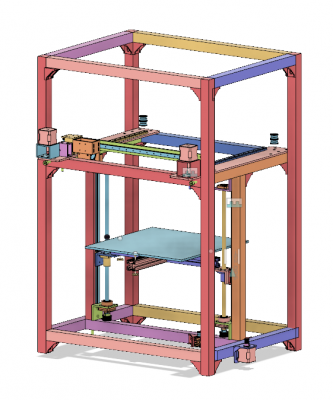

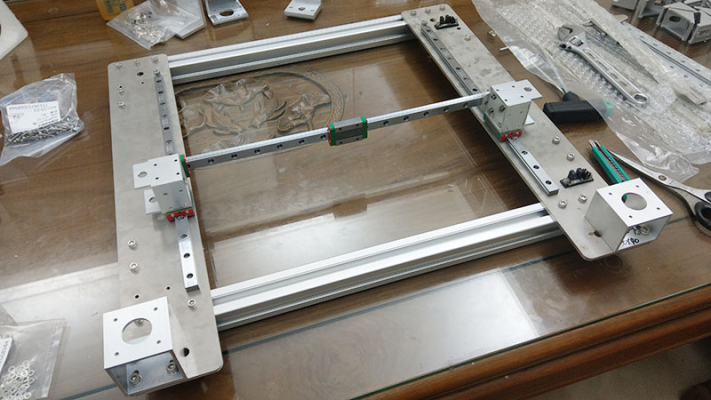

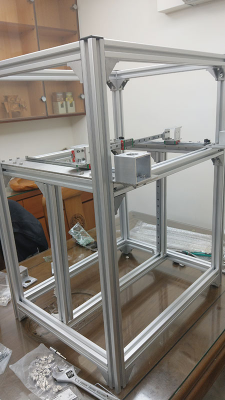

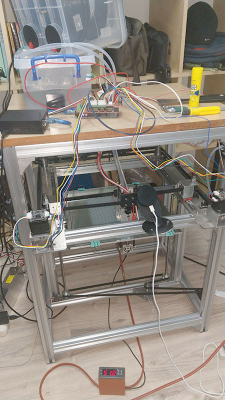

Update some pictures of the assembly in half way. Upon receiving these parts, I immediately realized that my design is totally over-engineering for a 3D printer.

here is a video of test print @ 100mm/s.

hiwin mgn12 linear rail with preload z0.

zf: with light clearance

z0: zero preload, no clearance

z1: 2% dynamic load rating

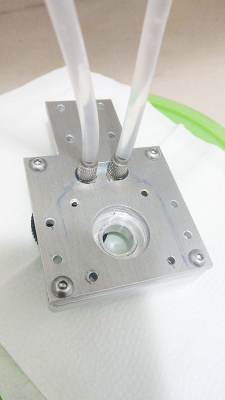

titan aqua attached to the carriage mount. a leaking test lasting for 8 hours has passed.

the extruder looks heavy so the acceleration and jerk values should be lower.

AC heater with 6mm mic-6 tooling plate.

A thinner non-tooling aluminum plate with boro glass is more than enough. A 6mm plate slows down the heating process.

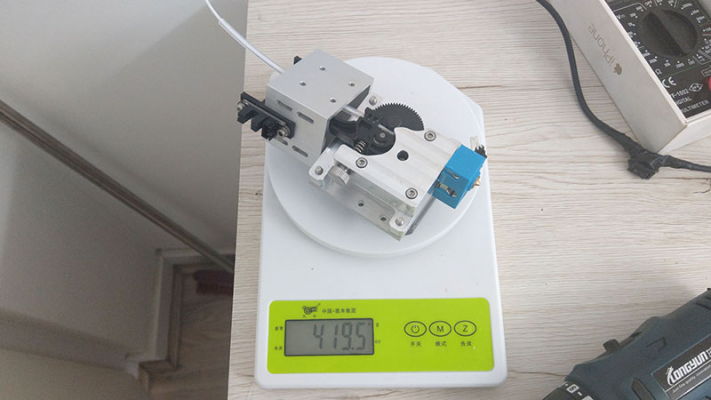

comparing 10mm belt and pulley set with 6mm parts

3030 extrusion + 304 steel plate are far more stronger than the need of a 3D printer.

A test run for 16 hours. Still waiting for my 32-bit board so the original ramps 1.4 is used. The total weight is about 20kg.

Edited 4 time(s). Last edit at 03/26/2019 03:35PM by Ernest1122.

here is a video of test print @ 100mm/s.

hiwin mgn12 linear rail with preload z0.

zf: with light clearance

z0: zero preload, no clearance

z1: 2% dynamic load rating

titan aqua attached to the carriage mount. a leaking test lasting for 8 hours has passed.

the extruder looks heavy so the acceleration and jerk values should be lower.

AC heater with 6mm mic-6 tooling plate.

A thinner non-tooling aluminum plate with boro glass is more than enough. A 6mm plate slows down the heating process.

comparing 10mm belt and pulley set with 6mm parts

3030 extrusion + 304 steel plate are far more stronger than the need of a 3D printer.

A test run for 16 hours. Still waiting for my 32-bit board so the original ramps 1.4 is used. The total weight is about 20kg.

Edited 4 time(s). Last edit at 03/26/2019 03:35PM by Ernest1122.

Sorry, only registered users may post in this forum.