My CoreXY is completed, finally!

Posted by Ernest1122

|

My CoreXY is completed, finally! April 01, 2019 11:09PM |

Registered: 5 years ago Posts: 25 |

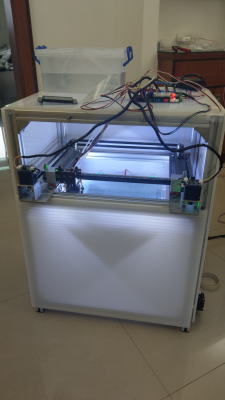

The front panel is a peice of transparent acrylic.

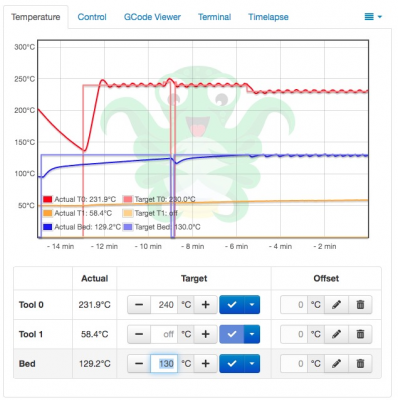

Interestingly, the bed heater can heat the chamber up to 60c without help of the chamber heater, but the chamber heater can do at most 55c and takes longer time.

3DTouch will be fried in the chamber and recover after cooldown. I don't think a genuine BLTouch will survive either.

Edited 2 time(s). Last edit at 04/03/2019 10:52AM by Ernest1122.

SecKit, all-metal linear rail CoreXY kit

[seckit3dp.design]

|

Re: My CoreXY is completed, finally! April 01, 2019 11:50PM |

Registered: 5 years ago Posts: 25 |

The yellow line (tool 1) is chamber temperature. Bed heater is ON, chamber heater is OFF. The thermistor is placed at top of the chamber.

Edited 1 time(s). Last edit at 04/01/2019 11:51PM by Ernest1122.

SecKit, all-metal linear rail CoreXY kit

[seckit3dp.design]

|

Re: My CoreXY is completed, finally! April 03, 2019 09:37AM |

Registered: 5 years ago Posts: 20 |

|

Re: My CoreXY is completed, finally! April 03, 2019 10:11AM |

Registered: 11 years ago Posts: 5,780 |

That looks pretty good- I like the way the lighting shows through the white side panels.

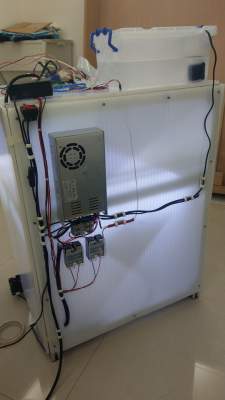

I think the side panels would work better as thermal insulators if you taped the edges to prevent air flow through them. You may also have problems with insects taking up residence if you leave them open, especially with the inside of the printer lit up. In my printer the panels are inside the t-slots in the frame which prevents most air flow and keeps bugs out, but I probably should have taped them anyway.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I think the side panels would work better as thermal insulators if you taped the edges to prevent air flow through them. You may also have problems with insects taking up residence if you leave them open, especially with the inside of the printer lit up. In my printer the panels are inside the t-slots in the frame which prevents most air flow and keeps bugs out, but I probably should have taped them anyway.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: My CoreXY is completed, finally! April 03, 2019 10:39AM |

Registered: 5 years ago Posts: 25 |

Quote

the_digital_dentist

That looks pretty good- I like the way the lighting shows through the white side panels.

I think the side panels would work better as thermal insulators if you taped the edges to prevent air flow through them. You may also have problems with insects taking up residence if you leave them open, especially with the inside of the printer lit up. In my printer the panels are inside the t-slots in the frame which prevents most air flow and keeps bugs out, but I probably should have taped them anyway.

The triangle shadow is a surprise and becomes a logo.

Yeh I use EVA stripes and lock panels with t-nuts. Another convenient way is soft magnetic stripes, but they affect the servo control board a lot since they are hall effect sensors. I'll consult my vendor and then decide to use servos or pure steppers.

Put panels on and the chamber temperature raises to 60C easily. I'll consider to remove the active heater too.

Insects!? hmm.... XD

SecKit, all-metal linear rail CoreXY kit

[seckit3dp.design]

|

Re: My CoreXY is completed, finally! April 03, 2019 10:41AM |

Registered: 5 years ago Posts: 25 |

Quote

tabana

It looks great, well done.

Can you post more photos? I would like to see connection between X and Y axis. Also the bed leveling system. Maybe some finished prints if you have?

Please check my Instagram in the signature. Just ignore those hairly, failed support, they won't affect the final print. lol

SecKit, all-metal linear rail CoreXY kit

[seckit3dp.design]

Sorry, only registered users may post in this forum.