A problem about printing a circle

Posted by ttgiegi

|

A problem about printing a circle May 19, 2019 10:06PM |

Registered: 4 years ago Posts: 29 |

Hello guys!

I'm a freshman of designing a 3d printer.I'm really interested in a printer work with wheels so It took me one month to design a corexy.But i have a strange problem that confused me for a long time.When it is printing a square or something else everything is good but when i try to print a circle It will change into a oval.This problem is not obvious when the circle is big enough for example a circle with 20mm diameter,but the thickness is not even and the outside surface is not smooth enough,I can see that surface is consisted of many lines.I don't think this was caused by the gcode file because it's normal when i use the other machine.I have tried many ways but seemed useless.I really need your help.Looking forward to your reply abuot any suggestions,thank you.

I'm a freshman of designing a 3d printer.I'm really interested in a printer work with wheels so It took me one month to design a corexy.But i have a strange problem that confused me for a long time.When it is printing a square or something else everything is good but when i try to print a circle It will change into a oval.This problem is not obvious when the circle is big enough for example a circle with 20mm diameter,but the thickness is not even and the outside surface is not smooth enough,I can see that surface is consisted of many lines.I don't think this was caused by the gcode file because it's normal when i use the other machine.I have tried many ways but seemed useless.I really need your help.Looking forward to your reply abuot any suggestions,thank you.

|

Re: A problem about printing a circle May 19, 2019 10:43PM |

Registered: 11 years ago Posts: 5,780 |

Are steps/mm set to same value for both A and B motors?

Are belts parallel to guide rails?

Is the X axis perpendicular to the Y axis?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Are belts parallel to guide rails?

Is the X axis perpendicular to the Y axis?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: A problem about printing a circle May 20, 2019 12:20AM |

Registered: 4 years ago Posts: 29 |

|

Re: A problem about printing a circle May 20, 2019 12:42AM |

Registered: 4 years ago Posts: 29 |

|

Re: A problem about printing a circle May 20, 2019 07:17AM |

Registered: 11 years ago Posts: 5,780 |

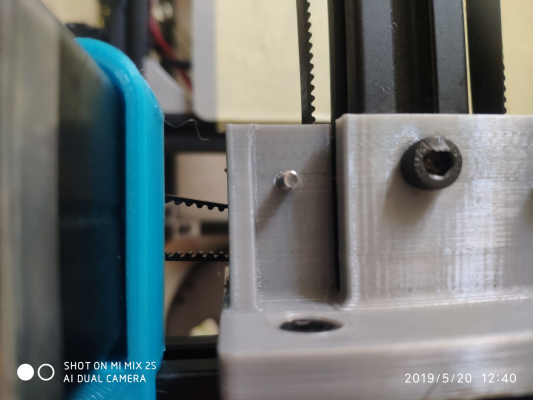

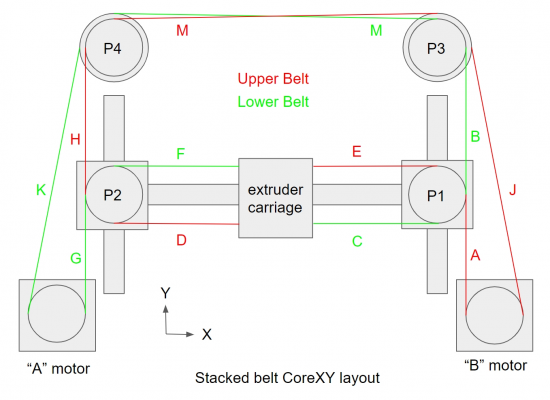

Yes, that's a problem. Belt segments A-H have to be parallel to the guide rails or geometry will be distorted, especially as the print gets away from the center of the bed.

See: [drmrehorst.blogspot.com]

Gaps between the lines on the first layer means that the extrusion is set too low, the nozzle is too high off the bed, or the bed isn't flat, or the mesh compensation (if you have it) isn't working, or some combo of those.

Trying to print small circles very fast often results in odd geometry. How fast are you printing? Acceleration?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

See: [drmrehorst.blogspot.com]

Gaps between the lines on the first layer means that the extrusion is set too low, the nozzle is too high off the bed, or the bed isn't flat, or the mesh compensation (if you have it) isn't working, or some combo of those.

Trying to print small circles very fast often results in odd geometry. How fast are you printing? Acceleration?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: A problem about printing a circle May 20, 2019 11:02AM |

Registered: 10 years ago Posts: 14,672 |

What Gcode are you using to generate the circle? In a CNC application it should be a single G2 or G3 command. If that is what you are doing, then it's up to your firmware what size segments it uses to approximate the circle. What firmware are you using.

Circles in 3D print models are almost always represented as line segments anyway. The program that generates the STL file sets the segment size.

If small circles are turned into ovals, this typically indicates that there is backlash on one of the axes.

Edited 3 time(s). Last edit at 05/20/2019 11:07AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Circles in 3D print models are almost always represented as line segments anyway. The program that generates the STL file sets the segment size.

If small circles are turned into ovals, this typically indicates that there is backlash on one of the axes.

Edited 3 time(s). Last edit at 05/20/2019 11:07AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: A problem about printing a circle May 20, 2019 11:50AM |

Registered: 4 years ago Posts: 29 |

|

Re: A problem about printing a circle May 20, 2019 11:58AM |

Registered: 4 years ago Posts: 29 |

The firmware of my printer is Marlin.I download it from github.The software is cura 4.0.0.I don't think it was caused by the gcode file because this file works well on the other printer.It may caused by the angel between belts and guide rails.I'm trying to change the parts to solve this problem.

|

Re: A problem about printing a circle May 20, 2019 12:22PM |

Registered: 7 years ago Posts: 363 |

I was going to suggest you try to print a larger circle at very slow, normal, and fast speeds each to see if the level of distortion changes.

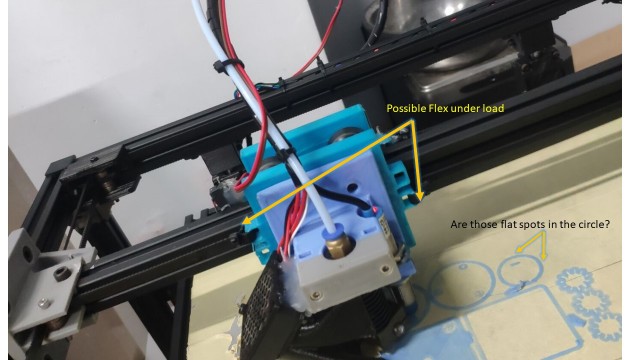

I noticed a couple of possible weaknesses in your design that may allow for flex when the moving mass changes direction that could be contributing to your out of round circles. The belt geometry is another possible cause as TDD pointed out above.

This one is much less likely a cultprit but still worth investigating when you've addressed the other items of note (belt geometry and the belt mounting points on your carriage)

You could try printing slower and possibly reducing the tension on your belts some to see if you can get more accurate circles, but I would find and correct the cause as those are only bandaid options and you'll just keep running into other odd issues while printing.

On another note, I've found that the black delrin v-wheels tend to wear unevenly and develop flat spots causing undesireable artifacts in your print, you may want to consider upgrading to the clear polycarbonate wheels, they are much more durable. Another consideration is that your belts are pulling tension laterally on those wheels. You may find it better for long term use to reorient your y-axis wheel carriages by 90 degrees although that's going to require you to redesign several printed parts to execute.

I noticed a couple of possible weaknesses in your design that may allow for flex when the moving mass changes direction that could be contributing to your out of round circles. The belt geometry is another possible cause as TDD pointed out above.

This one is much less likely a cultprit but still worth investigating when you've addressed the other items of note (belt geometry and the belt mounting points on your carriage)

You could try printing slower and possibly reducing the tension on your belts some to see if you can get more accurate circles, but I would find and correct the cause as those are only bandaid options and you'll just keep running into other odd issues while printing.

On another note, I've found that the black delrin v-wheels tend to wear unevenly and develop flat spots causing undesireable artifacts in your print, you may want to consider upgrading to the clear polycarbonate wheels, they are much more durable. Another consideration is that your belts are pulling tension laterally on those wheels. You may find it better for long term use to reorient your y-axis wheel carriages by 90 degrees although that's going to require you to redesign several printed parts to execute.

|

Re: A problem about printing a circle May 20, 2019 12:34PM |

Registered: 11 years ago Posts: 5,780 |

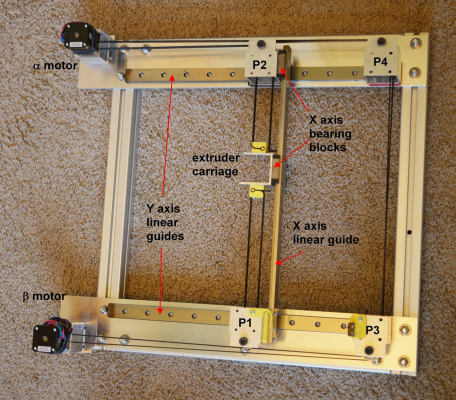

It might be a good idea to post pictures of the whole printer...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: A problem about printing a circle May 20, 2019 12:58PM |

Registered: 7 years ago Posts: 363 |

|

Re: A problem about printing a circle May 20, 2019 10:24PM |

Registered: 4 years ago Posts: 29 |

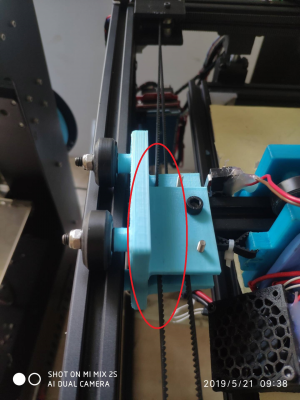

The grey carriages of y axis is a little bit loose with y guide rail I printed a new y carriage and I think it will be better.And Just as you said the outside surface of my wheels are made of POM material and the abrasion is eyeable maybe I will upgrade it in the future.About redesign the y carriage,you mean let the axis of the wheels perpendicular to the xoy flat surface?The flat spots you pointed out in the picture is outside the circle.I have uploaded more pictures of my printer.

|

Re: A problem about printing a circle May 20, 2019 10:26PM |

Registered: 4 years ago Posts: 29 |

|

Re: A problem about printing a circle May 20, 2019 10:29PM |

Registered: 4 years ago Posts: 29 |

more picture

Attachments:

open | download - _1782568257_IMG_20190521_093843_1558402723000_xg_0.jpg (155.4 KB)

open | download - _1786262341_IMG_20190521_093847_1558402727000_xg_0.jpg (159.6 KB)

open | download - _1808426845_IMG_20190521_093850_1558402730000_xg_0.jpg (132.8 KB)

open | download - _1813044450_IMG_20190521_093855_1558402735000_xg_0.jpg (147.5 KB)

open | download - _-1742182525_IMG_20190521_093900_1558402740000_xg_0.jpg (152.2 KB)

open | download - _-1737564920_IMG_20190521_093905_1558402745000_xg_0.jpg (136.7 KB)

open | download - _-1734794357_IMG_20190521_093908_1558402748000_xg_0.jpg (133.7 KB)

open | download - _-1706165206_IMG_20190521_093918_1558402758000_xg_0.jpg (155.7 KB)

open | download - _-1683077181_IMG_20190521_093922_1558402762000_xg_0.jpg (224.8 KB)

open | download - _-1647983383_IMG_20190521_093939_1558402779000_xg_0.jpg (175.3 KB)

open | download - _1782568257_IMG_20190521_093843_1558402723000_xg_0.jpg (155.4 KB)

open | download - _1786262341_IMG_20190521_093847_1558402727000_xg_0.jpg (159.6 KB)

open | download - _1808426845_IMG_20190521_093850_1558402730000_xg_0.jpg (132.8 KB)

open | download - _1813044450_IMG_20190521_093855_1558402735000_xg_0.jpg (147.5 KB)

open | download - _-1742182525_IMG_20190521_093900_1558402740000_xg_0.jpg (152.2 KB)

open | download - _-1737564920_IMG_20190521_093905_1558402745000_xg_0.jpg (136.7 KB)

open | download - _-1734794357_IMG_20190521_093908_1558402748000_xg_0.jpg (133.7 KB)

open | download - _-1706165206_IMG_20190521_093918_1558402758000_xg_0.jpg (155.7 KB)

open | download - _-1683077181_IMG_20190521_093922_1558402762000_xg_0.jpg (224.8 KB)

open | download - _-1647983383_IMG_20190521_093939_1558402779000_xg_0.jpg (175.3 KB)

|

Re: A problem about printing a circle May 20, 2019 10:30PM |

Registered: 4 years ago Posts: 29 |

|

Re: A problem about printing a circle May 20, 2019 11:38PM |

Registered: 6 years ago Posts: 134 |

Based on this picture tension of the belt, belt length and geometry of the gantry changes as Y carriage approaches idlers side. The belt should go free without "corners" from the motor to idlers. It may not be parallel to Y-axis but free from bending at Y carriage.

|

Re: A problem about printing a circle May 21, 2019 12:11AM |

Registered: 4 years ago Posts: 29 |

|

Re: A problem about printing a circle May 21, 2019 06:25AM |

Registered: 7 years ago Posts: 363 |

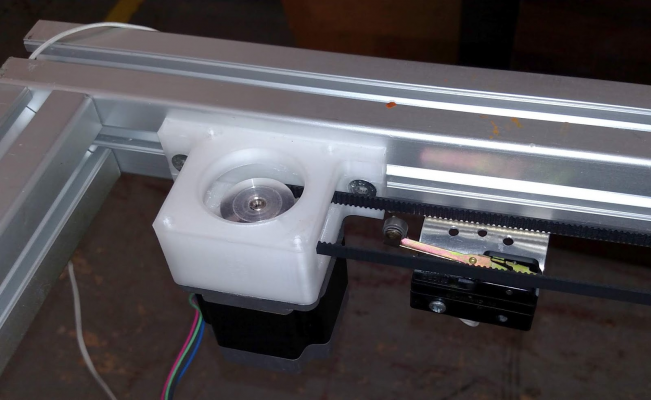

1. How do you adjust tension on your belts?

2. Have you verified your x-axis gantry is perfectly perpendicular to the y-axis rails?

Once you tension your belts, some of your plastic parts may flex and act like a spring. When your printer is printing circles this will present as flat spots at the 4 points where motors will change direction, because it changes the force applied to the 'spring'. This will also show up as really crazy looking smaller circles because the spring is flexing and dampening precise motion as the tension on your belts is not constant.

I hope I've articulated that well enough.

Also, what I was talking about with the orientation of your y-axis carriages is your wheels would work better if they are running on the sides of your v-slot profile instead of along the top an bottom grooves. Your current setup really applies all the load to just one side of the wheel.

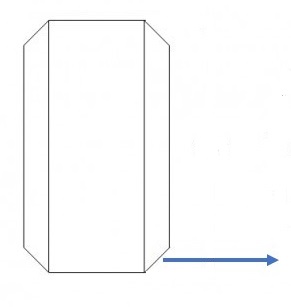

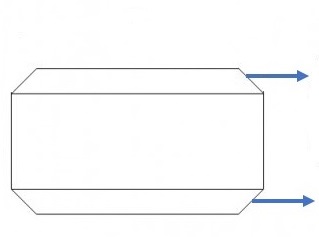

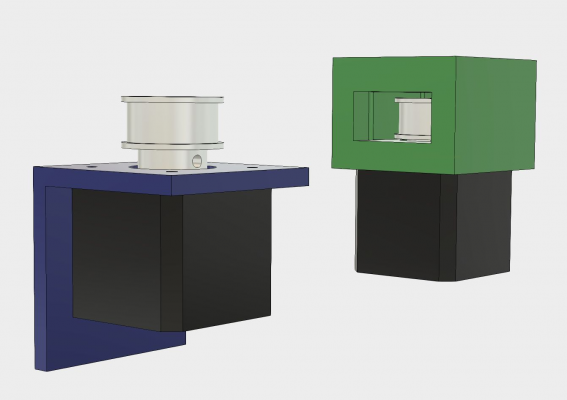

Your setup now:

What I propose:

Edited 1 time(s). Last edit at 05/21/2019 06:59AM by obelisk79.

2. Have you verified your x-axis gantry is perfectly perpendicular to the y-axis rails?

Once you tension your belts, some of your plastic parts may flex and act like a spring. When your printer is printing circles this will present as flat spots at the 4 points where motors will change direction, because it changes the force applied to the 'spring'. This will also show up as really crazy looking smaller circles because the spring is flexing and dampening precise motion as the tension on your belts is not constant.

I hope I've articulated that well enough.

Also, what I was talking about with the orientation of your y-axis carriages is your wheels would work better if they are running on the sides of your v-slot profile instead of along the top an bottom grooves. Your current setup really applies all the load to just one side of the wheel.

Your setup now:

What I propose:

Edited 1 time(s). Last edit at 05/21/2019 06:59AM by obelisk79.

|

Re: A problem about printing a circle May 21, 2019 07:00AM |

Registered: 11 years ago Posts: 5,780 |

I second piper3d's comment. The belt should not be bending- something is interfering with it.

Someone else pointed out that your Y axis wheels are standing vertically and the belt tension is going to be pulling them inward, side-loading the wheels and possibly causing the plastic holding them to flex. I think they'd be better if the wheels were horizontal and the far side had a plate for the bolts to go through (like the extruder carriage) so the carriage would be less likely to flex. I know it will be big and ugly, but that's what using wheels on t-slot looks like.

I can't really see the whole thing but the motor mounting plates look very thin and flexible.

I don't see any flanges on your pulleys, and there appears to be some belt dust on one photo of the extruder carriage. With nothing to guide the belts and flexy pulley and motor mounts, I think you'll have problems.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Someone else pointed out that your Y axis wheels are standing vertically and the belt tension is going to be pulling them inward, side-loading the wheels and possibly causing the plastic holding them to flex. I think they'd be better if the wheels were horizontal and the far side had a plate for the bolts to go through (like the extruder carriage) so the carriage would be less likely to flex. I know it will be big and ugly, but that's what using wheels on t-slot looks like.

I can't really see the whole thing but the motor mounting plates look very thin and flexible.

I don't see any flanges on your pulleys, and there appears to be some belt dust on one photo of the extruder carriage. With nothing to guide the belts and flexy pulley and motor mounts, I think you'll have problems.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: A problem about printing a circle May 21, 2019 07:15AM |

Registered: 7 years ago Posts: 363 |

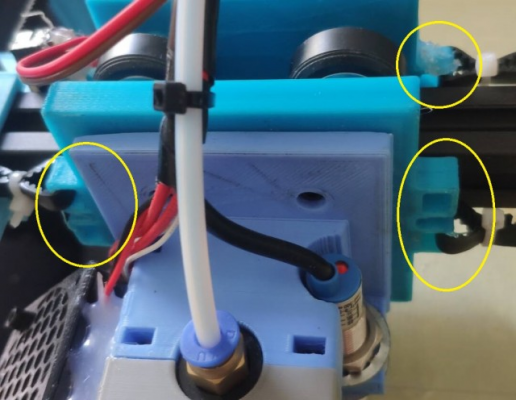

The points I circled look like weak points where the plastic could flex

Also I agree, your motor mounts look like they could allow for the plastic to flex.

Flex is the enemy.

Edited 1 time(s). Last edit at 05/21/2019 07:15AM by obelisk79.

Also I agree, your motor mounts look like they could allow for the plastic to flex.

Flex is the enemy.

Edited 1 time(s). Last edit at 05/21/2019 07:15AM by obelisk79.

|

Re: A problem about printing a circle May 21, 2019 09:08AM |

Registered: 4 years ago Posts: 29 |

First question I adjust the length of belts to change the strength on them and I'm considering about to add a spring to increase tension but It will make the x distance of travel smaller than now.Second whrn I set y guide rail Iused a levelling instrument to make sure the beging and the end of each guide rail is standard and to make sure both of them on the same flat surface.For x axis I used similar way to adjust.Now I don't have a good way to make those plastic parts be stable after I tension the belts.There have already been some strengthening rid near some weak points on y carriage.Maybe use ABS or some more powerful material to print these parts is a good idea?

And about the placement mode of all of the wheels,I have thought about carefully about your suggestion.I think you are right the way I'm useing now will make the wheels abrade on the one side.I will change it in the second version of my printer.Thank you so much about your suggestions!They are helpful.

And about the placement mode of all of the wheels,I have thought about carefully about your suggestion.I think you are right the way I'm useing now will make the wheels abrade on the one side.I will change it in the second version of my printer.Thank you so much about your suggestions!They are helpful.

|

Re: A problem about printing a circle May 21, 2019 10:15AM |

Registered: 7 years ago Posts: 363 |

Do not add a spring to your belt paths that will create more problems. You want no spring effect in your belts at all. If the plastic pieces that hold your belt in place are too weak and flex or stretch if will act like a spring and cause print problems. You motor mounts, and the loops you zip-tie your belts to look like areas that allow for flex, you need a stronger design.

For motor mounts try searching thingiverse, I personally didn't see any standout designs, but I'm sure there are some to save you time on designing one. Or, just buy inexpensive metal ones, they will be more rigid. Like these: [www.amazon.com]

Also, before you do anything else, your belt geometry needs to be fixed as pointed out multiple times here.

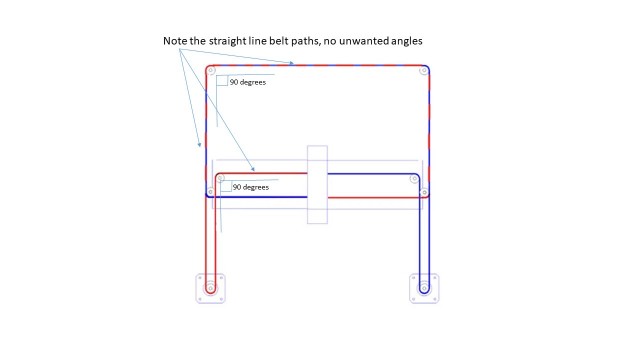

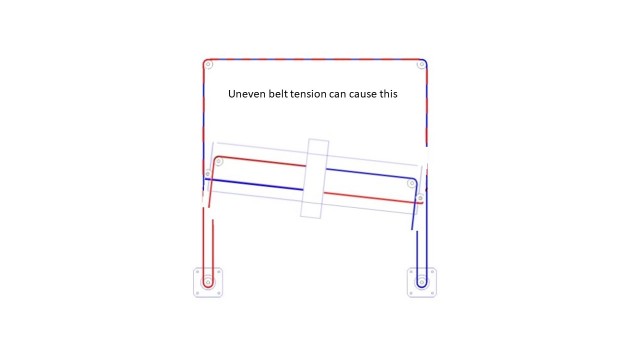

Good:

Bad:

For motor mounts try searching thingiverse, I personally didn't see any standout designs, but I'm sure there are some to save you time on designing one. Or, just buy inexpensive metal ones, they will be more rigid. Like these: [www.amazon.com]

Also, before you do anything else, your belt geometry needs to be fixed as pointed out multiple times here.

Good:

Bad:

|

Re: A problem about printing a circle May 21, 2019 11:31AM |

Registered: 11 years ago Posts: 5,780 |

No! Don't add springs. The belts, motors, and flexible pulley and motor mounts are springs. Adding more springs won't improve anything. You want to remove springs by making parts less flexible.

Making stronger, more rigid plastic parts means making them thicker. For example, which of the motor mounts pictured below is more likely to flex when belt tension is applied?

I'd worry less about flex and more about belt alignment parallel to the guide rails where the belts attach to the extruder carriage. The zip tie technique is very sloppy and doesn't guarantee the position of the belt.

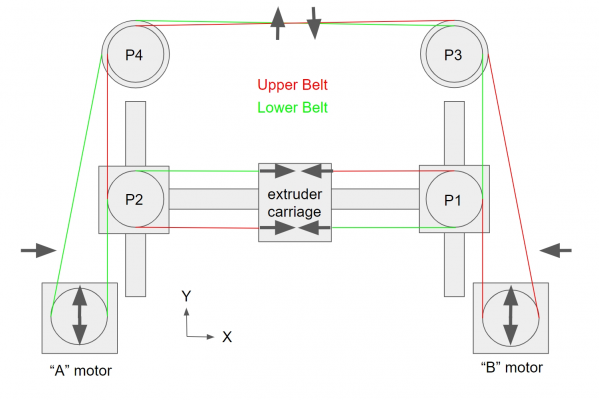

Belt tension can be adjusted in any place indicated by the arrows below:

Making the adjustments at the motor mounts allows for take-up of several mm of belt length, making it easy to mount the belts because they can be put on loose and then tightened as needed. Other positions for adjusters only allow a couple mm of take-up.

See: [drmrehorst.blogspot.com]

Edited 2 time(s). Last edit at 05/21/2019 11:39AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Making stronger, more rigid plastic parts means making them thicker. For example, which of the motor mounts pictured below is more likely to flex when belt tension is applied?

I'd worry less about flex and more about belt alignment parallel to the guide rails where the belts attach to the extruder carriage. The zip tie technique is very sloppy and doesn't guarantee the position of the belt.

Belt tension can be adjusted in any place indicated by the arrows below:

Making the adjustments at the motor mounts allows for take-up of several mm of belt length, making it easy to mount the belts because they can be put on loose and then tightened as needed. Other positions for adjusters only allow a couple mm of take-up.

See: [drmrehorst.blogspot.com]

Edited 2 time(s). Last edit at 05/21/2019 11:39AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: A problem about printing a circle May 21, 2019 11:53AM |

Registered: 4 years ago Posts: 29 |

I changed the part and make the belt be parallel to the y guide rail(at least from my own angel of view) About the placement mode of the wheels after you both talked about this problem I think about It carefully and I agree with your idea the mode I'm useing now will abrade only one side and If the printer is used for a long time some trouble there gonna be.Anyway it's my first time to design a machine there will must be many questions need to be fixed.Your suggestion are helpful.

|

Re: A problem about printing a circle May 21, 2019 11:59AM |

Registered: 4 years ago Posts: 29 |

|

Re: A problem about printing a circle May 21, 2019 12:14PM |

Registered: 4 years ago Posts: 29 |

For my motor mounts their thickness are both 8mm I think it's enough to hold the moters.Useing a metallic mount is a good idea they are cheap and reliable.And now the belts looks good when the carriage is very close to the max position.

Edited 2 time(s). Last edit at 05/21/2019 12:36PM by ttgiegi.

Edited 2 time(s). Last edit at 05/21/2019 12:36PM by ttgiegi.

|

Re: A problem about printing a circle May 21, 2019 12:25PM |

Registered: 11 years ago Posts: 5,780 |

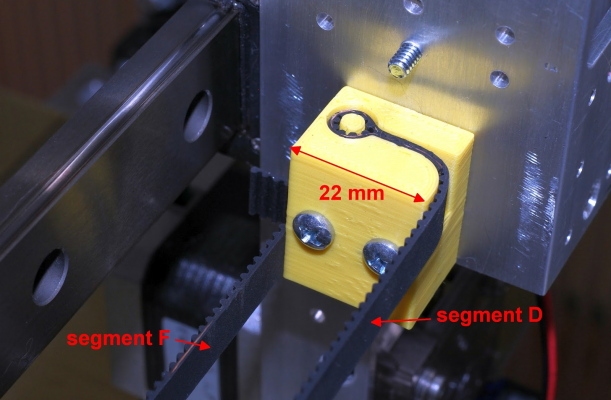

You need something that fixes the positions of the belts parallel to the X axis guide rail(s). Just looping the belt back on itself and securing it with a zip tie doesn't do that.

This is what I did in my corexy printer:

Note that the belt's positions are fixed, exactly 22 mm apart by the width of the clamp which matches the pulley diameter, and both belts are held parallel to the X axis guide rail:

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

This is what I did in my corexy printer:

Note that the belt's positions are fixed, exactly 22 mm apart by the width of the clamp which matches the pulley diameter, and both belts are held parallel to the X axis guide rail:

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: A problem about printing a circle May 21, 2019 12:31PM |

Registered: 4 years ago Posts: 29 |

|

Re: A problem about printing a circle May 21, 2019 12:47PM |

Registered: 4 years ago Posts: 29 |

|

Re: A problem about printing a circle May 21, 2019 01:05PM |

Registered: 11 years ago Posts: 5,780 |

Yes, adding wheels to push against the belts in those places would work. However, all your belt routing and motor positions are within the frame of the printer. You can use that to easily make positionable motor mounts like I did in my corexy sand table:

The motor mount has a tang that fits into the t-slot to keep it oriented, and uses t-nuts to lock it in position. You just install the belt, slide the motor mount back until the belt is tight, then tighten the screws. You only need to be able to move the motor 5mm or so to adjust the tension, so it doesn't have to use up all your Y axis space.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

The motor mount has a tang that fits into the t-slot to keep it oriented, and uses t-nuts to lock it in position. You just install the belt, slide the motor mount back until the belt is tight, then tighten the screws. You only need to be able to move the motor 5mm or so to adjust the tension, so it doesn't have to use up all your Y axis space.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.