Why is CoreXY so special?

Posted by dlc60

|

Why is CoreXY so special? July 08, 2019 05:43PM |

Registered: 7 years ago Posts: 619 |

I have seen folks write about CoreXY machines for over a year now and passing over them. So, curiosity has finally gotten the better of me.

I have a 270x260x270 mm Cartesian printer made from 1" aluminum t-slot that is a "traditional" X/Y with Z plane moving bed (The full 300mm extents are not reachable).

Why is CoreXY special? All those long belts at weird angles gives me the shivers with respect to belt wobble and stretch.

What makes this design superior to a traditional (non-bed flinging) Cartesian printer?

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

I have a 270x260x270 mm Cartesian printer made from 1" aluminum t-slot that is a "traditional" X/Y with Z plane moving bed (The full 300mm extents are not reachable).

Why is CoreXY special? All those long belts at weird angles gives me the shivers with respect to belt wobble and stretch.

What makes this design superior to a traditional (non-bed flinging) Cartesian printer?

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Why is CoreXY so special? July 08, 2019 05:47PM |

Registered: 11 years ago Posts: 5,780 |

The X and Y motors are both fixed, so you don't have to throw the X axis motor around or connect a moving cable to it. It's probably no better in terms of performance, but no worse either. CoreXY is pretty easy to build, and once you understand how to configure it, not difficult there, either.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Why is CoreXY so special? July 08, 2019 08:08PM |

Registered: 6 years ago Posts: 134 |

|

Re: Why is CoreXY so special? July 12, 2019 02:08PM |

Registered: 6 years ago Posts: 90 |

As someone who just converted their 500x500x500 Cartesian XY machine to CoreXY I can offer the following...

The only down side so far has been having to perfectly align the drive and idler pulleys but once you figure it out it's pretty easy.

- The design was developed into a usable form by Ilan Moyer at MIT so it can't be all bad

- Lots of folks have experience with it.

- Yes the belt length and angles were a little weird but I got over it after seeing it in action. I have almost 5 meters of 9mm belt but it works fine (using genuine Gates belts).

- I like that I now have only 2 stationary rails to align instead of 4.

- I LOVE that I no longer have a fixed X rail right in front of my face that always seemed to be in my way.

The only down side so far has been having to perfectly align the drive and idler pulleys but once you figure it out it's pretty easy.

|

Re: Why is CoreXY so special? July 12, 2019 02:22PM |

Registered: 11 years ago Posts: 5,780 |

You have to align the drive and idler pulley to keep the belt parallel to the guide rails in any belt driven machine.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Why is CoreXY so special? July 13, 2019 06:14PM |

Registered: 6 years ago Posts: 90 |

Quote

the_digital_dentist

You have to align the drive and idler pulley to keep the belt parallel to the guide rails in any belt driven machine.

Yeah but in my Cartesian, there were 4 sets of 2 and only the 2 in each set had to be aligned together... the drive gear and the far end idler.

Now there are 2 sets of 4 with all 4 in each set having to be in alignment and the 2 in the middle (on each end of the moving gantry) have to be aligned in 2 planes. As I said, it's complicated until you see it in real life then it's pretty easy to get used to.

|

Re: Why is CoreXY so special? July 13, 2019 10:57PM |

Registered: 6 years ago Posts: 134 |

In coreXY, you need to align 4 pairs of idlers/pulleys so the score is the sameQuote

gtj

Quote

the_digital_dentist

You have to align the drive and idler pulley to keep the belt parallel to the guide rails in any belt driven machine.

Yeah but in my Cartesian, there were 4 sets of 2 and only the 2 in each set had to be aligned together... the drive gear and the far end idler.

.

|

Re: Why is CoreXY so special? July 14, 2019 12:43PM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

piper3d

In coreXY, you need to align 4 pairs of idlers/pulleys so the score is the sameQuote

gtj

Quote

the_digital_dentist

You have to align the drive and idler pulley to keep the belt parallel to the guide rails in any belt driven machine.

Yeah but in my Cartesian, there were 4 sets of 2 and only the 2 in each set had to be aligned together... the drive gear and the far end idler.

.

For CoreXY in total 10 pairs of points need to be aligned, quickly doing this from the top of my head. I can show it on a photo if needed.

Edited 1 time(s). Last edit at 07/14/2019 12:43PM by Ohmarinus.

http://www.marinusdebeer.nl/

|

Re: Why is CoreXY so special? July 14, 2019 01:01PM |

Registered: 6 years ago Posts: 134 |

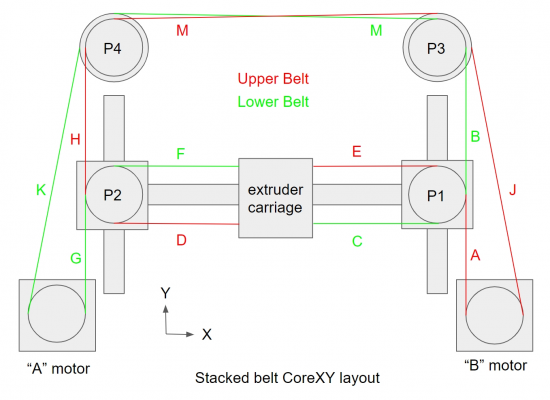

Using @the_digital_dentist picture:

A,B,G,H should be aligned to make square prints rest may not be parallel. Those belt parts each have a pair of idlers/pulleys. (plus F,D,E,C but they have one idler)

A,B,G,H should be aligned to make square prints rest may not be parallel. Those belt parts each have a pair of idlers/pulleys. (plus F,D,E,C but they have one idler)

|

Re: Why is CoreXY so special? July 14, 2019 11:41PM |

Registered: 7 years ago Posts: 619 |

Basically then, it is a Cartesian version of a Delta printer because you don't have to move the X stepper around, which should make it faster, as long as your belts are "stiff" enough to avoid flexing or vibrating too much?

And they look cool.

But with their elaborate belt system, aren't they a bit touchy to "tune"?

Beyond the weight of the end effector possibly allowing higher speeds, is there any real difference between a Core XY and a "regular" Cartesian in terms of performance?

Thanks,

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

And they look cool.

But with their elaborate belt system, aren't they a bit touchy to "tune"?

Beyond the weight of the end effector possibly allowing higher speeds, is there any real difference between a Core XY and a "regular" Cartesian in terms of performance?

Thanks,

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Why is CoreXY so special? July 15, 2019 09:24AM |

Registered: 6 years ago Posts: 90 |

Quote

piper3d

Using @the_digital_dentist picture:

[attachment 112036 beltlayout.jpg]

A,B,G,H should be aligned to make square prints rest may not be parallel. Those belt parts each have a pair of idlers/pulleys. (plus F,D,E,C but they have one idler)

@the_digital_dentist uses stacked pulleys so P1..P4 are actually 2 pulleys on the same shaft. That makes them easier to align but makes shaft assembly a little more complicated because the shafts have to be supported at both ends to properly counter the forces applied. The classic approach (which is what I use) has the pulley's on separate shafts.

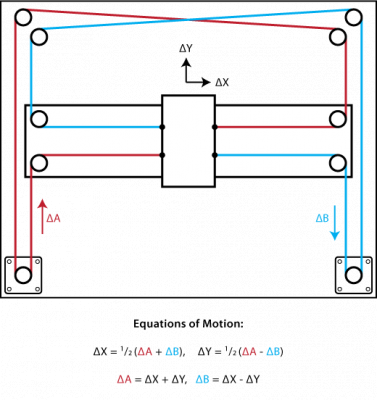

From CoreXY Reference Mechanism

I also have the belts all on the same level. I'd post a picture but I just took it apart yesterday.

Like life, everything's a tradeoff and there's no "right" design. You have to balance esthetics, mass, budget, skill, physical constraints, etc. to get the design that right for each situation.

|

Re: Why is CoreXY so special? July 15, 2019 09:29AM |

Registered: 6 years ago Posts: 90 |

Quote

dlc60

Basically then, it is a Cartesian version of a Delta printer because you don't have to move the X stepper around, which should make it faster, as long as your belts are "stiff" enough to avoid flexing or vibrating too much?

And they look cool.

I wouldn't compare to Delta. It's a totally different animal. But yeah, you're not moving any motors around except maybe an extruder motor and not even that if you're using a remote drive such as a Zesty Nimble or a Bowden setup.

Quote

dlc60

But with their elaborate belt system, aren't they a bit touchy to "tune"?

Yes but once you get it right and get some experience with it, I don't think it's any harder than any other kinematics type.

Quote

dlc60

Beyond the weight of the end effector possibly allowing higher speeds, is there any real difference between a Core XY and a "regular" Cartesian in terms of performance?

None that I've seen so far.

|

Re: Why is CoreXY so special? July 15, 2019 09:53AM |

Registered: 5 years ago Posts: 30 |

|

Re: Why is CoreXY so special? July 15, 2019 10:08AM |

Admin Registered: 16 years ago Posts: 13,884 |

... if you want the motors "fixed" to the frame, than a "normal cartesian" type is possible too - my first CO2-lasercutter was driven with two motors on the frame, but steel wires instead of belts -- see the images here, if interested in the setup:

[reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

[reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Why is CoreXY so special? July 15, 2019 10:10AM |

Registered: 11 years ago Posts: 5,780 |

|

Re: Why is CoreXY so special? July 15, 2019 04:13PM |

Registered: 7 years ago Posts: 619 |

Quote

boredom.is.me

There is one benefit. As the print height increases on a printer, so does the mass on the bed. A normal printer has to move that mass while a core xy does not. A normal printer will technically deteriorate as the print gets longer.

A non-bed-slinger doesn't move the mass in any axis but 'Z'. I guess I should better define my terms. To me a "regular" Cartesian is one where the X&Y are moving the head and the bed is dropped in the Z plane. I think of the Prusa-style as a bed-slinger, not a "regular" Cartesian...

Sorry for being a bit vague.

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Why is CoreXY so special? July 15, 2019 04:19PM |

Registered: 7 years ago Posts: 619 |

Quote

the_digital_dentist

What does "touchy to tune" mean?

I am thinking more about the design path than the maintenance tuning. The belts are really long so I assume that GT2 6mm belts are not optimal. Do you need to worry about damping the belt vibrations?

On my traditional Cartesian, I had to align rods and pulleys to keep things square, so that is kind of obvious, but the Core XY looks like you are angling belts in different planes so that they don't interfere with each other, that is what looks a little touchy.

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Why is CoreXY so special? July 15, 2019 04:49PM |

Registered: 11 years ago Posts: 5,780 |

The belts shouldn't vibrate at all while the mechanism is moving (at least they don't in my printer).

I don't really know if 6mm belts would lead to ringing problems due to stretch, but 9mm belts and pulleys don't cost much more and will certainly stretch less. OTOH, 9 mm pulleys and hardware weigh more so now you have to move more mass that can lead to ringing.

The only way the belts can interfere with each other is if you put them on the same plane. Stacking the belts makes the alignment easier because there are fewer things that need to be aligned to keep the belts parallel to the guide rails.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I don't really know if 6mm belts would lead to ringing problems due to stretch, but 9mm belts and pulleys don't cost much more and will certainly stretch less. OTOH, 9 mm pulleys and hardware weigh more so now you have to move more mass that can lead to ringing.

The only way the belts can interfere with each other is if you put them on the same plane. Stacking the belts makes the alignment easier because there are fewer things that need to be aligned to keep the belts parallel to the guide rails.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Why is CoreXY so special? July 15, 2019 06:18PM |

Registered: 7 years ago Posts: 619 |

Quote

the_digital_dentist

The belts shouldn't vibrate at all while the mechanism is moving (at least they don't in my printer).

I don't really know if 6mm belts would lead to ringing problems due to stretch, but 9mm belts and pulleys don't cost much more and will certainly stretch less. OTOH, 9 mm pulleys and hardware weigh more so now you have to move more mass that can lead to ringing.

The only way the belts can interfere with each other is if you put them on the same plane. Stacking the belts makes the alignment easier because there are fewer things that need to be aligned to keep the belts parallel to the guide rails.

OK, I can see that. My impression from various drawings made me think that the belts and pulleys had to be angled, not simply on a different plane. That makes quite a difference.

I would really like a Cartesian printer that was not Delta so that I can get the mechanism speed up - I use my Deltas because they are faster than bed-slingers or Cartesian designs. But Deltas are stinkers to level and Z-calibrate and build properly (easy to build, hard to build right). Cartesian printers are far easier to calibrate since their Kinematics are so much simpler. If the Core XY is faster than a "regular" Cartesian, then I am all in for building one, especially for a large bed printer, which REALLY needs speed.

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Why is CoreXY so special? July 16, 2019 07:38AM |

Registered: 11 years ago Posts: 5,780 |

In many corexy designs you see around the web, people have made the error of thinking that the belts need to cross in the vertical plane. That's a terrifically bad idea and there's absolutely no reason to do it.

In some builds, stacked pulleys are mounted on posts that are stood up on printed plastic parts and the belt tension tilts the posts inward. That's not a desirable feature and is evidence of poor construction.

I've gathered a bunch of bad designs/builds that you can see here, with comments on the problems.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

In some builds, stacked pulleys are mounted on posts that are stood up on printed plastic parts and the belt tension tilts the posts inward. That's not a desirable feature and is evidence of poor construction.

I've gathered a bunch of bad designs/builds that you can see here, with comments on the problems.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Why is CoreXY so special? July 16, 2019 09:02AM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

the_digital_dentist

In many corexy designs you see around the web, people have made the error of thinking that the belts need to cross in the vertical plane. That's a terrifically bad idea and there's absolutely no reason to do it.

In some builds, stacked pulleys are mounted on posts that are stood up on printed plastic parts and the belt tension tilts the posts inward. That's not a desirable feature and is evidence of poor construction.

I've gathered a bunch of bad designs/builds that you can see here, with comments on the problems.

If you take good care of the geometry, it can be done correctly. I have one such machine that uses a crossed belt that works really well. It's quite old already but I can try to make a photo some time and you can criticize it

http://www.marinusdebeer.nl/

|

Re: Why is CoreXY so special? July 16, 2019 09:14AM |

Registered: 11 years ago Posts: 5,780 |

|

Re: Why is CoreXY so special? July 16, 2019 12:10PM |

Registered: 6 years ago Posts: 90 |

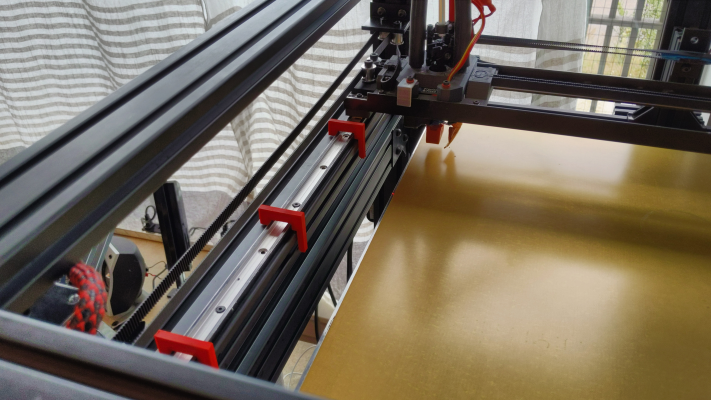

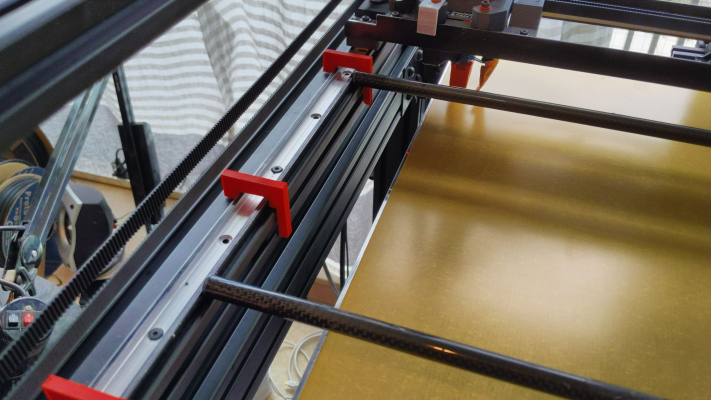

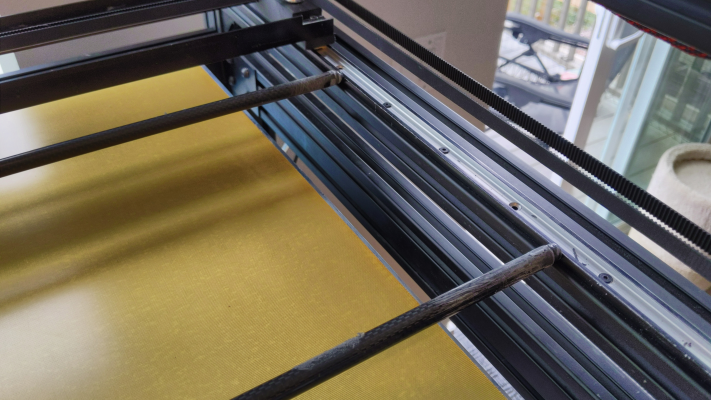

Back to the alignment question. I just did this last night...

I start by making sure the frame is as square as possible. Then I use jigs to make sure that the left stationary motion rail is co-linear with the left frame member.

Then I use precisely trimmed carbon fiber rods to make sure that the right stationary rail is parallel to the left rail (even if the frame is a bit off).

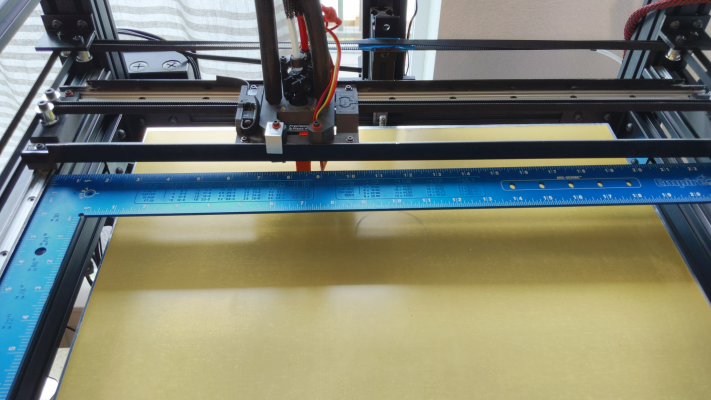

Finally I use a verified square to make sure the front gantry rail is square to the left stationary rail. (ignore the parallax error in the pic )

)

You can also see that I have my belts on the same plane and use a "twist" at the back.

I start by making sure the frame is as square as possible. Then I use jigs to make sure that the left stationary motion rail is co-linear with the left frame member.

Then I use precisely trimmed carbon fiber rods to make sure that the right stationary rail is parallel to the left rail (even if the frame is a bit off).

Finally I use a verified square to make sure the front gantry rail is square to the left stationary rail. (ignore the parallax error in the pic

)

)You can also see that I have my belts on the same plane and use a "twist" at the back.

|

Re: Why is CoreXY so special? September 03, 2019 05:54AM |

Registered: 5 years ago Posts: 31 |

at higher weights it carries less weight. tho the cr-10 is fine. I'm biased with the prusa design. Far less variables and far simpler. isn't sensitive to belt like that and all. IRL the differences are minimal really.

it can print faster (Tho mostly with aluminium-carbon fiber, but I didn't have luck finding aluminium tubes and the carbon fiber I could get is all varying in diameter hugely, two steel rods weight 300-450g) but then again. anything above 60-45mm/s has minimal print time gains really IMO. not worth it whatsoever. and at high speeds there's so many issues that appear. not enough time to cool things, The extruder needs to be very good and all that

also tool changes are mostly possible with corexy printers (you COULD do that with the z axis of a prusa style one but i mean I wouldn't bother)

I'm a newbie tho so keep that in mind. corexy mostly makes sense around 300x300 and above IMO. and if you want a glass bed the prusa can suffer a lot. tho again I see people printing fine with great results on the cr-10

it can print faster (Tho mostly with aluminium-carbon fiber, but I didn't have luck finding aluminium tubes and the carbon fiber I could get is all varying in diameter hugely, two steel rods weight 300-450g) but then again. anything above 60-45mm/s has minimal print time gains really IMO. not worth it whatsoever. and at high speeds there's so many issues that appear. not enough time to cool things, The extruder needs to be very good and all that

also tool changes are mostly possible with corexy printers (you COULD do that with the z axis of a prusa style one but i mean I wouldn't bother)

I'm a newbie tho so keep that in mind. corexy mostly makes sense around 300x300 and above IMO. and if you want a glass bed the prusa can suffer a lot. tho again I see people printing fine with great results on the cr-10

Sorry, only registered users may post in this forum.