Ultimate z axis accuracy?

Posted by witor

|

Ultimate z axis accuracy? October 18, 2019 01:52PM |

Registered: 6 years ago Posts: 63 |

As Digital Dentist demonstrated in his UMMD a belt driven z axis is the way to go. Unfortunately precision worm gear reducers are very expensive (especially in Europe). DD has already tried the DIY version of worm gear and showed that it is not a viable option.

I am wondering if someone has ever tried using a linear encoder to get the actual accurate position of the bed. I came across this:

[www.banggood.com]

and I am wondering if it would be possible to use a cheap worm gear/ belt system and a position feedback from the above linear scale to achieve an ultimate accuracy of the z axis. I am thinking about some sort of microcontroler (arduino?) getting information about required z movements from the printer control board and then driving the motor until z axis gets to a required position.

Accurate z axis movements are essential for high quality prints.

Has anyone considered using linear scales? Is it doable?

I am wondering if someone has ever tried using a linear encoder to get the actual accurate position of the bed. I came across this:

[www.banggood.com]

and I am wondering if it would be possible to use a cheap worm gear/ belt system and a position feedback from the above linear scale to achieve an ultimate accuracy of the z axis. I am thinking about some sort of microcontroler (arduino?) getting information about required z movements from the printer control board and then driving the motor until z axis gets to a required position.

Accurate z axis movements are essential for high quality prints.

Has anyone considered using linear scales? Is it doable?

|

Re: Ultimate z axis accuracy? October 18, 2019 06:51PM |

Registered: 11 years ago Posts: 5,780 |

My attempt to use a single pair of cheapo gears failed, but I wouldn't say there are no inexpensive gears that will work acceptably. There are other printers out there with belt lifted Z axes that use inexpensive gear sets built into printed housings, and some of them seem to work OK.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Ultimate z axis accuracy? October 18, 2019 07:22PM |

Registered: 6 years ago Posts: 63 |

But what do you think about the idea of using a linear encoder? It should allow very, very accurate positioning, shouldn't it?

I can't find any printers with DIY (printed housing) gears which give acceptable results. Which one do you have in mind? Would you mind posting a link or point me in the right direction?

I also considered using NMRV30 which is considerably cheaper than Rino but I have no idea what its quality is.

By the way is it possible that your home made worm gearbox was not good enough because of the play between the worm and the shaft of the motor which resulted in worm not being perfectly axially aligned with the shaft, which resulted in the worm effectively moving towards and away from the gear during each revolution which resulted in periodically repeated defect of the print? Maybe worm shaft nested in bearings on both sides and then coupled with the motor would give better results.

I can't find any printers with DIY (printed housing) gears which give acceptable results. Which one do you have in mind? Would you mind posting a link or point me in the right direction?

I also considered using NMRV30 which is considerably cheaper than Rino but I have no idea what its quality is.

By the way is it possible that your home made worm gearbox was not good enough because of the play between the worm and the shaft of the motor which resulted in worm not being perfectly axially aligned with the shaft, which resulted in the worm effectively moving towards and away from the gear during each revolution which resulted in periodically repeated defect of the print? Maybe worm shaft nested in bearings on both sides and then coupled with the motor would give better results.

|

Re: Ultimate z axis accuracy? October 23, 2019 04:20AM |

Registered: 12 years ago Posts: 103 |

|

Re: Ultimate z axis accuracy? November 17, 2019 09:52PM |

Registered: 10 years ago Posts: 24 |

What about a harmonic drive reduction instead? I've seen some injection molded versions including one that Igus makes, or there's the possibility of 3D printing one yourself, but either way, the lower cost options don't have to sacrifice precision the way a worm drive would. This 3D printed one's too large for a Z axis, but the overall idea could work. 3D Printed Harmonic Drive

|

Re: Ultimate z axis accuracy? November 18, 2019 12:17AM |

Registered: 11 years ago Posts: 250 |

I was looking for better Z accuracy as well.

I decided to go with 8mm screws with 2mm lead (instead of the usual 8mm lead) then reduced that down 3:1 with a 0.9deg stepper.

I looked into a couple different options with Z, but this just seemed to be the cheapest and easiest way to go.

I couldn't be happier with the improved Z quality over my last printer. 0.3mm nozzle and 0.2mm layer height.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

I decided to go with 8mm screws with 2mm lead (instead of the usual 8mm lead) then reduced that down 3:1 with a 0.9deg stepper.

I looked into a couple different options with Z, but this just seemed to be the cheapest and easiest way to go.

I couldn't be happier with the improved Z quality over my last printer. 0.3mm nozzle and 0.2mm layer height.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Ultimate z axis accuracy? November 18, 2019 03:12AM |

Registered: 6 years ago Posts: 1,007 |

You don't increase "accuracy" by using any kind of reduction gear !!!! Fact is, you are more likely to decrease it because of the gear quality. And forget about printed gears, any kind of.

Digital Dentist used worm gear in combination of belts to replace lead screws for Z.

As for the statement above, using 2mm pitch and 0.9° motor, can you tell what layer height you use and what is the Z displacement for a full step ?

Edited 1 time(s). Last edit at 11/18/2019 03:14AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

Digital Dentist used worm gear in combination of belts to replace lead screws for Z.

As for the statement above, using 2mm pitch and 0.9° motor, can you tell what layer height you use and what is the Z displacement for a full step ?

Edited 1 time(s). Last edit at 11/18/2019 03:14AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Ultimate z axis accuracy? November 18, 2019 04:50AM |

Admin Registered: 16 years ago Posts: 13,884 |

... for DIY-3D-printing this type of harmonic drive is the simplest and most accurate in plastic - [www.thingiverse.com]

Most other with "flex-spline" are more complex an will need better accuracy for the spline.

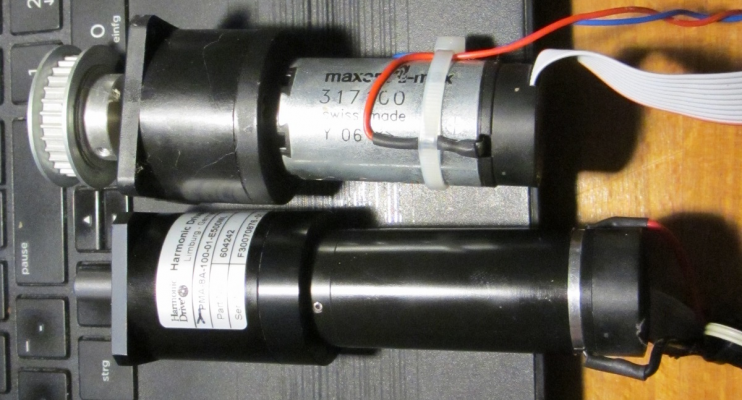

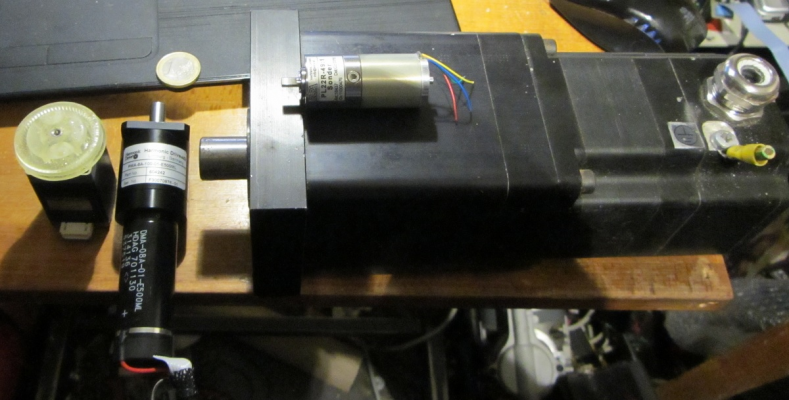

With comercial all-metal harmonic drives the costs will "explode" -- I have small "super-precision" dc-motors and steppers with encoders and planetary gears (400:1 and 800:1) from MAXXON - and one stepper with 50:1 harmonic drive from "Harmonic Drive" ... the prices for them are in the range of some hundred Euros each!

*** EDIT ***

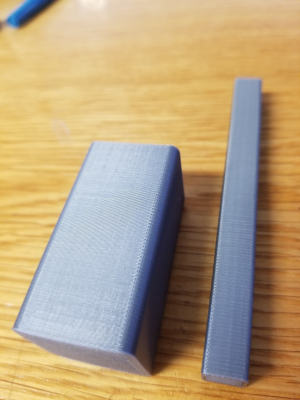

... here an image of the "plastic-HD", I've printed for experimental setups with different motor sizes and forces (still experimenting):

Edited 2 time(s). Last edit at 11/18/2019 04:56AM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Most other with "flex-spline" are more complex an will need better accuracy for the spline.

With comercial all-metal harmonic drives the costs will "explode" -- I have small "super-precision" dc-motors and steppers with encoders and planetary gears (400:1 and 800:1) from MAXXON - and one stepper with 50:1 harmonic drive from "Harmonic Drive" ... the prices for them are in the range of some hundred Euros each!

*** EDIT ***

... here an image of the "plastic-HD", I've printed for experimental setups with different motor sizes and forces (still experimenting):

Edited 2 time(s). Last edit at 11/18/2019 04:56AM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Ultimate z axis accuracy? November 18, 2019 06:01AM |

Registered: 6 years ago Posts: 63 |

Some really good ideas and harmonic drive looks really interesting, but we are going of topic a little bit. My initial question was about using linear scale and encoder and a closed loop system so we don't relay on a mechanical accuracy of the driving system (lead screws, belts motors etc.) to try to get the bed to were it suppose to be, but instead measure the actual position of the bed and move it not buy a set number of steps of the stepper motor but by whatever number is needed to get the bed to where it should be. This system could also be driven by a normal DC motor - like the print head in an inkjet printer.

I am going to experiment with an optical scale and an encoder that I have taken out of an old printer to check if I can create a decent PID position control using arduino. For the actual 3d printer application I am thinking about a glass scale like this:

[www.banggood.com]

What are your thoughts about the whole idea? Is it doable? Does it have a potential to be the most accurate way of moving the z axis, or is it just a waste of time...

Edited 1 time(s). Last edit at 11/18/2019 06:04AM by witor.

I am going to experiment with an optical scale and an encoder that I have taken out of an old printer to check if I can create a decent PID position control using arduino. For the actual 3d printer application I am thinking about a glass scale like this:

[www.banggood.com]

What are your thoughts about the whole idea? Is it doable? Does it have a potential to be the most accurate way of moving the z axis, or is it just a waste of time...

Edited 1 time(s). Last edit at 11/18/2019 06:04AM by witor.

|

Re: Ultimate z axis accuracy? November 18, 2019 09:39AM |

Admin Registered: 16 years ago Posts: 13,884 |

... try to get away with the plastic belt encoders from the inkjet-printer for building size and weight ... the glass scales are maybe too big and heavy ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Ultimate z axis accuracy? November 18, 2019 11:06AM |

Registered: 6 years ago Posts: 63 |

It has been proved my many that z axis is very sensitive to inaccurate movements. If the bed goes down just by tiny bit too much or too little it results with a visible line all the way around the part as there is not enough or too much room for extruded plastic.

I don't think that a plastic encoder strip from a printer provides enough resolution. Glass scale seems to have much more resolution. Weight is not a problem as the scale does not move (only encoder does) and we are talking about z axis only so extra weight doesn't really matter.

Edited 1 time(s). Last edit at 11/18/2019 11:06AM by witor.

I don't think that a plastic encoder strip from a printer provides enough resolution. Glass scale seems to have much more resolution. Weight is not a problem as the scale does not move (only encoder does) and we are talking about z axis only so extra weight doesn't really matter.

Edited 1 time(s). Last edit at 11/18/2019 11:06AM by witor.

|

Re: Ultimate z axis accuracy? November 18, 2019 01:24PM |

Registered: 11 years ago Posts: 250 |

Quote

MKSA

You don't increase "accuracy" by using any kind of reduction gear !!!! Fact is, you are more likely to decrease it because of the gear quality. And forget about printed gears, any kind of.

Digital Dentist used worm gear in combination of belts to replace lead screws for Z.

As for the statement above, using 2mm pitch and 0.9° motor, can you tell what layer height you use and what is the Z displacement for a full step ?

Oh, so what your saying is MORE steps per mm WILL NOT improve positional accuracy?

- This entire thread is basically based on a reduction of some kind, be it gear, belt, harmonic, worm...

- The second point in this thread is price. You want higher accuracy, you'll need to pay for it. (but we're all trying to keep the price down)

- Without a feedback setup, you'll never know what your truly getting, you'll have to rely on the math and HOPE you getting what you calculated, then measure after to verify accuracy. Then adjust accordingly.

All I'm saying is, for the price, what I have done provides highly acceptable results and it cost me roughly 25 bucks to do it.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Ultimate z axis accuracy? November 18, 2019 02:12PM |

Registered: 12 years ago Posts: 1,450 |

Quote

Mogal

..............

Oh, so what your saying is MORE steps per mm WILL NOT improve positional accuracy?

.................

I have to agree with MKSA here: More steps will definitely not improve positional accuracy if the errors introduced exceed those already in the system. 3D printed gears are seldom of anywhere near the accuracy of machined gears. Backlash, even with the best gears, can introduce catastrophic errors.

Mike

|

Re: Ultimate z axis accuracy? November 18, 2019 02:44PM |

Registered: 6 years ago Posts: 63 |

The whole point of this topic is to find the way the way to reduce the effects of the mechanical imperfections of the z axis driving system. With a perfect mechanical system a particular number of equal angular steps of the stepper motor results in a precise linear movement. Let's say just as example that in perfect world 10 steps equals 1mm of linear movement. Unfortunately the angle of each step might not be exactly the same or there might be some play or imperfections in the gearing and as a result after 10 steps of the motor we might actually end up with just 0.9mm of bed movement. What I am proposing is to actually measure the actual movement of the bed and if after 10 steps the linear movement is only 0.9 mm the controller will ask the motor to take one extra (or whatever number of extra or fewer steps is needed) to move the bed by precisely 1mm.

High gear ratio (30:1 or higher) will be used to reduce the linear motion corresponding to one step and glass scale and encoder will be used to achieve a high precision measurement of the bed movement. All I would really like to know is what you think about the possibility of a closed loop system being used on a z axis.

If the smallest step the bed can take is about 0.01mm, closed system would not care if it is actually 0.01 or 0.005 or 0.012. It would just take the number of steps needed to get to the position which is very close to what is needed.

And as I mentioned I don't even plan to use steppers. Just PID controlled DC motor to get the bed to the exact position. Has anyone tried that? Did it work?

High gear ratio (30:1 or higher) will be used to reduce the linear motion corresponding to one step and glass scale and encoder will be used to achieve a high precision measurement of the bed movement. All I would really like to know is what you think about the possibility of a closed loop system being used on a z axis.

If the smallest step the bed can take is about 0.01mm, closed system would not care if it is actually 0.01 or 0.005 or 0.012. It would just take the number of steps needed to get to the position which is very close to what is needed.

And as I mentioned I don't even plan to use steppers. Just PID controlled DC motor to get the bed to the exact position. Has anyone tried that? Did it work?

|

Re: Ultimate z axis accuracy? November 18, 2019 03:31PM |

Admin Registered: 16 years ago Posts: 13,884 |

... I think, the best/optimal setup in respect of price, size and weight, could be done with a "common" rotating encoder fixed to the frame and a spring-tensioned string around the axis, extracted by the moving Z-axis (for longer measuring ranges then better "endless" loops).

Did something similar with my first DIY-laserplotters, driven by steel strings, where an encoder was measuring the exact position of the X and Y axes along 300 and 400 Millimeters.

Then with 500lpi-encoders (so 2000 "steps per rev.") -- actually I'm using 4096lpi encoders, so much higher resolution and accuracy

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Did something similar with my first DIY-laserplotters, driven by steel strings, where an encoder was measuring the exact position of the X and Y axes along 300 and 400 Millimeters.

Then with 500lpi-encoders (so 2000 "steps per rev.") -- actually I'm using 4096lpi encoders, so much higher resolution and accuracy

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Ultimate z axis accuracy? November 18, 2019 04:13PM |

Registered: 11 years ago Posts: 250 |

Quote

leadinglights

Quote

Mogal

..............

Oh, so what your saying is MORE steps per mm WILL NOT improve positional accuracy?

.................

I have to agree with MKSA here: More steps will definitely not improve positional accuracy if the errors introduced exceed those already in the system. 3D printed gears are seldom of anywhere near the accuracy of machined gears. Backlash, even with the best gears, can introduce catastrophic errors.

Mike

Okay, I'm out. Clearly your math is different then my math.

If you have 1 step per mm, then the best resolution you can get is 1 mm.

If you have 10 steps per mm, then the best resolution you can get is 0.1mm.

At least this is what my math tells me.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Ultimate z axis accuracy? November 28, 2019 03:41AM |

Registered: 12 years ago Posts: 103 |

And if I use 14:1 geared NEMA17 like this:

[fr.aliexpress.com]

-with 20T pulley directly connected to the bed (like voron 2.2 belted Z) I won't have drop,

-with 1.8° motor, 200 steps X 14 = 2800 full steps (don't need micro stepping),

-the belts are under tension with the weight of the bed, (possibility of steel core belts)

-teeth inside the reduction are under contact too, with the weight of the bed,

-the torque is big with this amount of reduction, (speed could be an issue ! ? for Auto Bed Leveling ?)

OK no closed loop but could be very good in my mind.

What do you think ?

[fr.aliexpress.com]

-with 20T pulley directly connected to the bed (like voron 2.2 belted Z) I won't have drop,

-with 1.8° motor, 200 steps X 14 = 2800 full steps (don't need micro stepping),

-the belts are under tension with the weight of the bed, (possibility of steel core belts)

-teeth inside the reduction are under contact too, with the weight of the bed,

-the torque is big with this amount of reduction, (speed could be an issue ! ? for Auto Bed Leveling ?)

OK no closed loop but could be very good in my mind.

What do you think ?

|

Re: Ultimate z axis accuracy? November 28, 2019 07:59AM |

Registered: 11 years ago Posts: 5,780 |

You won't need it for resolution, but you'll still want to use microstepping to keep the noise level down.

It's hard to say if it will prevent the bed from dropping. With a 14:1 ratio there may not be enough detent torque multiplication and friction to stop the bed from dropping- it will depend on the weight of the bed and stiction/friction in the Z axis bearings.

Any time you use gears in Z you run the risk of imperfect gears creating repetitive Z artifacts in the prints. Someone at the makerspace recently built a printer using a gearbox for the Z axis belt drive and the resulting prints were a good as any screw driven Z axis I have ever seen. I don't know the exact part number he used, but it looked like this: [www.ebay.com] That type of gearbox has a small worm gear and several other gears inside.

All that said, I think it will probably work OK, but maybe a higher gear ratio would be better. You don't need a lot of speed in the Z axis. If possible, I'd pick a gear ratio and Z axis drive pulley that gives a good, round number for full-step multiple print layer thickness. The first time I put together the Z axis in my printer I ended up with 18 um per full step which meant I could print in 90 or 180 um layers, for example, but not 100 um or 200 um. It doesn't really matter, but my brain prefers the round numbers. Be careful- planetary gear ratios are often not exact whole number ratios. Your 14:1 gearbox may actually be some odd value like 14.078:1. Check the spec sheet if there is one, or you may have to live with an odd full step multiple print layer thickness.

Edit: I looked at the specs of the motor you linked- notice the description and spec: "Usongshine 4-lead Nema17 stepper motor 42 extruder motor gear stepper motor ratio 5.18: 1 planetary gearbox Nema 17 17HS4401" and "Speed ratio (Exact speed ratio) 5 + 2/11". The odd ratio is typical of planetary gearboxes. Your 14:1 gearbox probably isn't exactly 14:1...

Don't use steel core belts unless you use very large pulleys (including the drive pulley). Flexing around small diameter pulleys will eventually break the wires in the core and then the belt will stretch over the broken core and you'll have all sorts of hard to diagnose print quality issues.

Edited 2 time(s). Last edit at 11/28/2019 08:10AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

It's hard to say if it will prevent the bed from dropping. With a 14:1 ratio there may not be enough detent torque multiplication and friction to stop the bed from dropping- it will depend on the weight of the bed and stiction/friction in the Z axis bearings.

Any time you use gears in Z you run the risk of imperfect gears creating repetitive Z artifacts in the prints. Someone at the makerspace recently built a printer using a gearbox for the Z axis belt drive and the resulting prints were a good as any screw driven Z axis I have ever seen. I don't know the exact part number he used, but it looked like this: [www.ebay.com] That type of gearbox has a small worm gear and several other gears inside.

All that said, I think it will probably work OK, but maybe a higher gear ratio would be better. You don't need a lot of speed in the Z axis. If possible, I'd pick a gear ratio and Z axis drive pulley that gives a good, round number for full-step multiple print layer thickness. The first time I put together the Z axis in my printer I ended up with 18 um per full step which meant I could print in 90 or 180 um layers, for example, but not 100 um or 200 um. It doesn't really matter, but my brain prefers the round numbers. Be careful- planetary gear ratios are often not exact whole number ratios. Your 14:1 gearbox may actually be some odd value like 14.078:1. Check the spec sheet if there is one, or you may have to live with an odd full step multiple print layer thickness.

Edit: I looked at the specs of the motor you linked- notice the description and spec: "Usongshine 4-lead Nema17 stepper motor 42 extruder motor gear stepper motor ratio 5.18: 1 planetary gearbox Nema 17 17HS4401" and "Speed ratio (Exact speed ratio) 5 + 2/11". The odd ratio is typical of planetary gearboxes. Your 14:1 gearbox probably isn't exactly 14:1...

Don't use steel core belts unless you use very large pulleys (including the drive pulley). Flexing around small diameter pulleys will eventually break the wires in the core and then the belt will stretch over the broken core and you'll have all sorts of hard to diagnose print quality issues.

Edited 2 time(s). Last edit at 11/28/2019 08:10AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Ultimate z axis accuracy? December 06, 2019 04:06AM |

Registered: 12 years ago Posts: 103 |

14:1 in real are 13.73  damned. (thanks for this advice before I ordered them)

damned. (thanks for this advice before I ordered them)

I think I'll go for VORON 2.2 design Z belted with 80T pulley and 20T pulley on the motor. Do you think this setup could have backlash ? (me I don't think because the weight of the bed will keep a constant torque)

As you said in your blog the belted Z is closed to be the perfect Z leveling, IF you chose the right parts. (year steel core need big pulleys, I tried them once with 16T and killed them fast)

and killed them fast)

damned. (thanks for this advice before I ordered them)

damned. (thanks for this advice before I ordered them)I think I'll go for VORON 2.2 design Z belted with 80T pulley and 20T pulley on the motor. Do you think this setup could have backlash ? (me I don't think because the weight of the bed will keep a constant torque)

As you said in your blog the belted Z is closed to be the perfect Z leveling, IF you chose the right parts. (year steel core need big pulleys, I tried them once with 16T

and killed them fast)

and killed them fast)

|

Re: Ultimate z axis accuracy? December 06, 2019 10:02AM |

Registered: 11 years ago Posts: 5,780 |

Can you post a link to the voron setup? If it's just a 4 to 1 reduction, I don't think it will keep the bed from dropping. Backlash is unlikely to be a problem.

Edited 1 time(s). Last edit at 12/06/2019 10:23AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Edited 1 time(s). Last edit at 12/06/2019 10:23AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Ultimate z axis accuracy? December 10, 2019 03:12AM |

Registered: 12 years ago Posts: 103 |

It's 1:5 because 16T + 80T.

Droping bed is an issue if you don't use UPS :-)

[github.com]

[vorondesign.com]

But they don't share the STEP :-( need to convert STL to STEP and the file will be huge.

Droping bed is an issue if you don't use UPS :-)

[github.com]

[vorondesign.com]

But they don't share the STEP :-( need to convert STL to STEP and the file will be huge.

|

Re: Ultimate z axis accuracy? January 06, 2020 06:05PM |

Registered: 9 years ago Posts: 294 |

Based on the performance of my CoreXY printer, I keep thinking y'all are overthinking this Z drive.

I have 3 screws driven by 1 motor/belt/pulleys using brass nut mount and Openbuild screws. Even the platform is only centered in the frame with rollers and not confined otherwise. To be honest, I am surprised it works so well.

I have to warn you that the Openbuild screws I got would not work with the brass nuts till I filed down all the burrs on the screws. They do work out of the box with the Openbuild nut mounts, but they are not brass. I do not know if they are any better now, but they were cheap, maybe still are.

My Z positioning is very accurate and stable. The biggest inaccuracy is setting Z0. I use babystepping in Marlin to get that where I want it and the rest is beautiful.

BTW, there was a recent bugfix for Marlin 2.0 that significantly improved the XY stepping to prevent step loss.

Obviously, YMMV

I have 3 screws driven by 1 motor/belt/pulleys using brass nut mount and Openbuild screws. Even the platform is only centered in the frame with rollers and not confined otherwise. To be honest, I am surprised it works so well.

I have to warn you that the Openbuild screws I got would not work with the brass nuts till I filed down all the burrs on the screws. They do work out of the box with the Openbuild nut mounts, but they are not brass. I do not know if they are any better now, but they were cheap, maybe still are.

My Z positioning is very accurate and stable. The biggest inaccuracy is setting Z0. I use babystepping in Marlin to get that where I want it and the rest is beautiful.

BTW, there was a recent bugfix for Marlin 2.0 that significantly improved the XY stepping to prevent step loss.

Obviously, YMMV

|

Re: Ultimate z axis accuracy? January 06, 2020 07:48PM |

Registered: 6 years ago Posts: 1,007 |

|

Re: Ultimate z axis accuracy? January 07, 2020 03:27AM |

Admin Registered: 16 years ago Posts: 13,884 |

... the optimal Z-accuracy (and effort to get there) depends mainly on your target and available parts (or money) -- I'm using different setups in resolution, speed and torque for different applications - the range is from "typical" 3D-printing with something like 0,05mm accuracy/repeatability ... to CNC-milling with 0,0125mm to 0,01mm ... or "micro/nanotech" with 0,001mm to some ten nanometers

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Ultimate z axis accuracy? January 07, 2020 07:13AM |

Registered: 11 years ago Posts: 5,780 |

If the Z axis position goes in 100 um +/- 50 um (or even 200 um +/-50 um) steps print quality is going to be awful. With 50 um error you might get OK results if you're printing in 1 mm layers.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Ultimate z axis accuracy? January 07, 2020 09:47AM |

Admin Registered: 16 years ago Posts: 13,884 |

... the "0,05mm accuracy/repeatability" were meant with "typical" FDM-printers - have some with 10µm too ... or DLP-UV-resin-printers with around 10µm accuracy (step resolution below 1µm) - here the absolute accuracy depends mainly on resin-properties ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Ultimate z axis accuracy? January 07, 2020 11:00AM |

Registered: 9 years ago Posts: 294 |

interesting. I never have been much concerned about that since my prints look pretty good to me.

Mine is a CoreXY FDM and my probe repeatability test (Marlin) gives me a std deviation of 0.002764 and a range of 0.009.

I have no idea how that relates to your numbers.

I have a std 1.8° stepper doing 32 microsteps driving 3 std 8/2 lead screws via a GT2 belt and 16T pulleys.

Nothing I would consider very precision.

Mine is a CoreXY FDM and my probe repeatability test (Marlin) gives me a std deviation of 0.002764 and a range of 0.009.

I have no idea how that relates to your numbers.

I have a std 1.8° stepper doing 32 microsteps driving 3 std 8/2 lead screws via a GT2 belt and 16T pulleys.

Nothing I would consider very precision.

|

Re: Ultimate z axis accuracy? January 07, 2020 01:29PM |

Admin Registered: 16 years ago Posts: 13,884 |

... 0.002764" are slightly above 70µm ... and 0.009" around 0.23mm

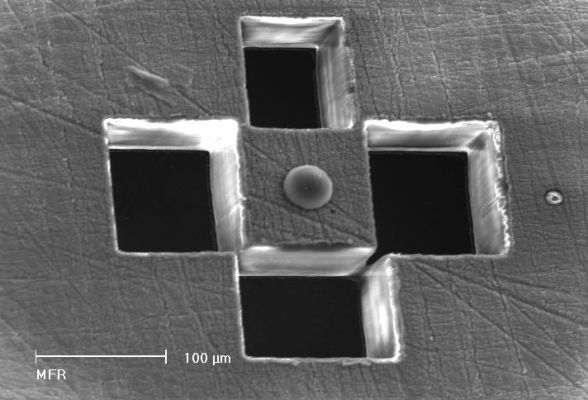

Her some images of the "medium sized" 3D-printed parts:

My yet highest detailled (galvano-formed and laser-engraved) parts were a bit smaller:

... but "on the way" to even higher accuracy and fabbing capabilities

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Her some images of the "medium sized" 3D-printed parts:

My yet highest detailled (galvano-formed and laser-engraved) parts were a bit smaller:

... but "on the way" to even higher accuracy and fabbing capabilities

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Ultimate z axis accuracy? January 08, 2020 09:46AM |

Registered: 9 years ago Posts: 294 |

Nice prints. My primary issue now is with temperature and small areas.

Everything on my unit is in mm so those numbers are also mm numbers.

Does that make it any better?

Considering someone else's numbers for a BL Touch probe are

Range: 0.040

Standard Deviation: 0.015366

mine looks pretty good, wouldn't you say?

I would say a major issue is in the probe response.

Edited 2 time(s). Last edit at 01/08/2020 10:05AM by ruggb.

Everything on my unit is in mm so those numbers are also mm numbers.

Does that make it any better?

Considering someone else's numbers for a BL Touch probe are

Range: 0.040

Standard Deviation: 0.015366

mine looks pretty good, wouldn't you say?

I would say a major issue is in the probe response.

Edited 2 time(s). Last edit at 01/08/2020 10:05AM by ruggb.

|

Re: Ultimate z axis accuracy? January 08, 2020 10:17AM |

Admin Registered: 16 years ago Posts: 13,884 |

... your print looks pretty good for a budget printer! - are the lines at the shoe sole displacements? -- ifs so, then the frame stiffness is maybe an issue too ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Sorry, only registered users may post in this forum.