Hypercube - Uneven Layer Lines / Z axis banding

Posted by jcoelho

|

Hypercube - Uneven Layer Lines / Z axis banding October 21, 2019 07:04PM |

Registered: 4 years ago Posts: 7 |

Hello,

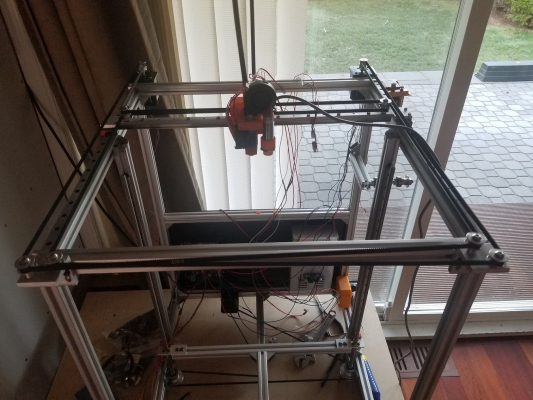

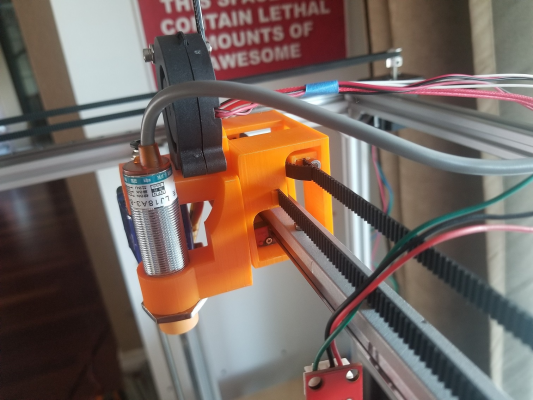

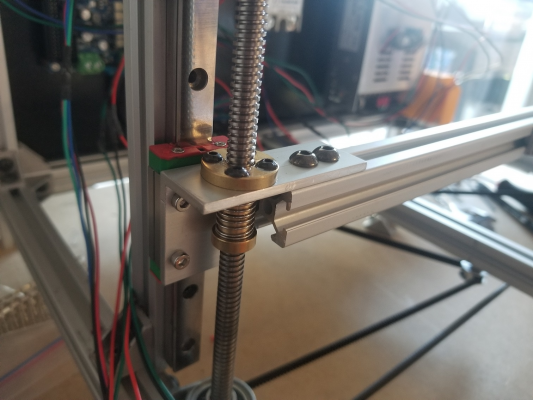

I build a Hypercube and it has been printing very well. Recently I noticed that the print quality has significantly dropped. I checked all bolts to make sure they were tight, I replaced the belts as they were loose and almost "cut" on one side. I'm getting irregular walls on the prints vertical faces, but I can't seem to find a pattern. I don't get any play on the X-carriage if I try to move/shake/rotate it by hand.

Any ideas on what is causing this? Some pictures here.

I'm thinking on replacing the Z lead screw by an integrated one and using some sort of anti backslash nut and replacing the RAMPS board by a Duet (will any of that help)?

Thanks in advance!

Edited 1 time(s). Last edit at 10/21/2019 07:04PM by jcoelho.

I build a Hypercube and it has been printing very well. Recently I noticed that the print quality has significantly dropped. I checked all bolts to make sure they were tight, I replaced the belts as they were loose and almost "cut" on one side. I'm getting irregular walls on the prints vertical faces, but I can't seem to find a pattern. I don't get any play on the X-carriage if I try to move/shake/rotate it by hand.

Any ideas on what is causing this? Some pictures here.

I'm thinking on replacing the Z lead screw by an integrated one and using some sort of anti backslash nut and replacing the RAMPS board by a Duet (will any of that help)?

Thanks in advance!

Edited 1 time(s). Last edit at 10/21/2019 07:04PM by jcoelho.

|

Re: Hypercube - Uneven Layer Lines / Z axis banding October 23, 2019 06:27AM |

Registered: 5 years ago Posts: 31 |

I'd start by making sure your e-steps and flow rate are correct.

then I'd check if the hotend has any play

then I'd check if the z axis or the bearings/y axis or literally anything has play to it

then I'd check if the z axis has any binding and does move freely.

Then I'd wait for more answers

I use acetal POM trapozoidal nuts and they're fantastic. they helped increase the print quality of my anycubic i3 mega-s so much! but yeah. if you don't wanna go and buy them you can print them in pla and they work surprisingly well. the only issue being pla melts at a relatively low temperature and the nut is printed in a way that the z is where the load is on. but again they're not that expensive I think? I forgot how much mine cost

also I assume your axis are all well lubricated.

also are your belts maybe gettnig worn or not aligned? In a corexy the belt system is a huge fuss. one tiny mistake and you get horribly irregular layers due the changing tension. one of the reasons I don't like corexy as great as it is!

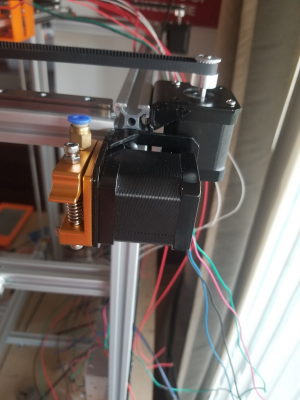

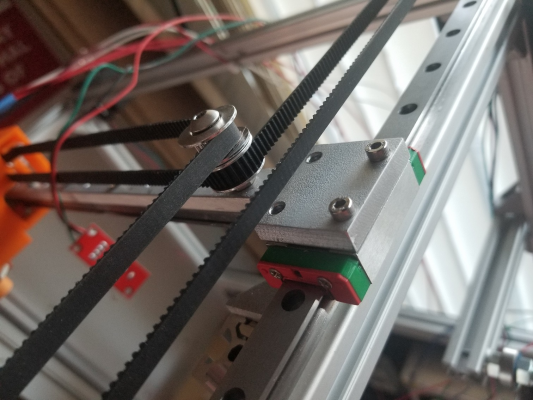

EDIT: I just noticed you have the toothed side of the belt on smooth idlers (beaings) I heard that's not a good idea whatsoever. you could either twist the belt(not sure whatsoever on how it affects it. but only do it on the long side of each stepper) or switch to a toothed idler

Edited 1 time(s). Last edit at 10/23/2019 06:29AM by AmyTheBun.

then I'd check if the hotend has any play

then I'd check if the z axis or the bearings/y axis or literally anything has play to it

then I'd check if the z axis has any binding and does move freely.

Then I'd wait for more answers

I use acetal POM trapozoidal nuts and they're fantastic. they helped increase the print quality of my anycubic i3 mega-s so much! but yeah. if you don't wanna go and buy them you can print them in pla and they work surprisingly well. the only issue being pla melts at a relatively low temperature and the nut is printed in a way that the z is where the load is on. but again they're not that expensive I think? I forgot how much mine cost

also I assume your axis are all well lubricated.

also are your belts maybe gettnig worn or not aligned? In a corexy the belt system is a huge fuss. one tiny mistake and you get horribly irregular layers due the changing tension. one of the reasons I don't like corexy as great as it is!

EDIT: I just noticed you have the toothed side of the belt on smooth idlers (beaings) I heard that's not a good idea whatsoever. you could either twist the belt(not sure whatsoever on how it affects it. but only do it on the long side of each stepper) or switch to a toothed idler

Edited 1 time(s). Last edit at 10/23/2019 06:29AM by AmyTheBun.

|

Re: Hypercube - Uneven Layer Lines / Z axis banding October 23, 2019 12:44PM |

Registered: 11 years ago Posts: 250 |

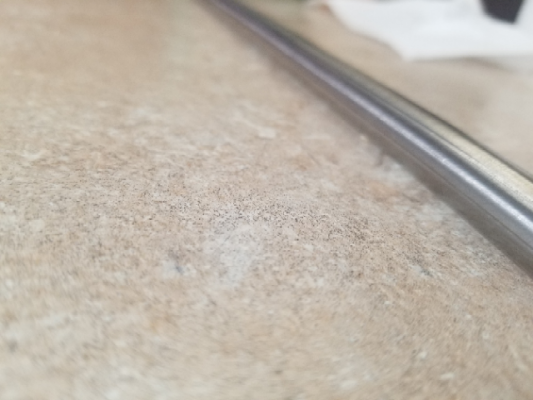

Maybe unrelated, but I had a similar issue. When I first got the printer working and tuned, it was producing amazing prints...

I found my prints slowly degrading in quality... After watching the printer for awhile, I could see the print head 'Float'

(I could actually see the print head wobble) as it was travelling back and forth... took a closer look at the bearings and rails

to find that the bearings had carved a track through the rail. (some of the balls where stuck in the bearing digging a trench in the rails)

Its hard to take a good picture of the groove, but its significant enough to cause quality issues.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

I found my prints slowly degrading in quality... After watching the printer for awhile, I could see the print head 'Float'

(I could actually see the print head wobble) as it was travelling back and forth... took a closer look at the bearings and rails

to find that the bearings had carved a track through the rail. (some of the balls where stuck in the bearing digging a trench in the rails)

Its hard to take a good picture of the groove, but its significant enough to cause quality issues.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Hypercube - Uneven Layer Lines / Z axis banding October 23, 2019 12:49PM |

Registered: 11 years ago Posts: 250 |

Oh, and watch the belt around the pulleys. If there is any misalignment in the belts, you might see the belts flop back and forth on the pulley

as it tried to climb up/down and off the pulley...

- This mostly occurs on the stepper pulley as the mount is not ridged enough and causes a deflection in the belts.

Mogal's Belt deflection on Hypercube

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

as it tried to climb up/down and off the pulley...

- This mostly occurs on the stepper pulley as the mount is not ridged enough and causes a deflection in the belts.

Mogal's Belt deflection on Hypercube

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Hypercube - Uneven Layer Lines / Z axis banding October 24, 2019 04:47AM |

Registered: 5 years ago Posts: 31 |

Quote

Mogal

Oh, and watch the belt around the pulleys. If there is any misalignment in the belts, you might see the belts flop back and forth on the pulley

as it tried to climb up/down and off the pulley...

- This mostly occurs on the stepper pulley as the mount is not ridged enough and causes a deflection in the belts.

Mogal's Belt deflection on Hypercube

the belts tilt like that on the idlers for me. could it be the cause? nowhere near as bad but still

|

Re: Hypercube - Uneven Layer Lines / Z axis banding October 24, 2019 10:02AM |

Registered: 11 years ago Posts: 5,780 |

Belts should not tilt like the ones in the video- there is something seriously wrong with the rest of the mechanism. Pulleys must be mounted on vertical axles that must stay vertical when tension is applied to the belts. Belts should remain at one level throughout their travel- don't vertically cross corexy belts- there's no need for it and it will cause problems.

There are about 1000 different problems that can cause rough Z axis print quality. The type of Z axis problem you're seeing is measured in microns. It is difficult to see that little wiggle in the hot-end/extruder carriage. It may be due to slop in the XY mechanism, the Z mechanism, or both. Troubleshooting is a combo of careful observation and logical thinking. It used to work fine but print quality has degraded. That rules out the controller which has remained constant. Since quality has degraded, it indicates something is wearing out or getting loose compared to when the machine was first built. Hypercubes have a lot of plastic motor and pulley mounts- maybe one or more has cracked or deformed under the strain of heat and belt tension. The OP said that one of the belts had a cut in it- that shouldn't happen, so I'd look carefully around that belt's part of the mechanism. Make sure everything is tight and lubricate bearings.

The Z screws don't move much, so they aren't likely to wear out in your lifetime unless you've got the mechanism so poorly aligned that it takes a lot of force to turn them.

Brass nozzles can wear out, especially if you print with glow-in-the -dark, glass, carbon, or metal particle loaded filaments.

Mogal: the grooves in the guide rails are there because you didn't use hardened guide rails. Whenever you use linear bearings on guide rails, the rails must be the hardened type. When you buy the rails, if they don't say they are hardened, they aren't. Hardened rails cost a little more than the other type. You can tell if rails are hardened by trying to scratch them with a file. A file won't leave more than a barely visible scratch on a hardened rail, and will happily cut into an unhardened rail.

Belt teeth on smooth pulleys is OK. The biggest problem is a zipping noise it causes when you run the mechanism really fast (like 500 mm/sec, which you're unlikely to use in a 3D printer).

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

There are about 1000 different problems that can cause rough Z axis print quality. The type of Z axis problem you're seeing is measured in microns. It is difficult to see that little wiggle in the hot-end/extruder carriage. It may be due to slop in the XY mechanism, the Z mechanism, or both. Troubleshooting is a combo of careful observation and logical thinking. It used to work fine but print quality has degraded. That rules out the controller which has remained constant. Since quality has degraded, it indicates something is wearing out or getting loose compared to when the machine was first built. Hypercubes have a lot of plastic motor and pulley mounts- maybe one or more has cracked or deformed under the strain of heat and belt tension. The OP said that one of the belts had a cut in it- that shouldn't happen, so I'd look carefully around that belt's part of the mechanism. Make sure everything is tight and lubricate bearings.

The Z screws don't move much, so they aren't likely to wear out in your lifetime unless you've got the mechanism so poorly aligned that it takes a lot of force to turn them.

Brass nozzles can wear out, especially if you print with glow-in-the -dark, glass, carbon, or metal particle loaded filaments.

Mogal: the grooves in the guide rails are there because you didn't use hardened guide rails. Whenever you use linear bearings on guide rails, the rails must be the hardened type. When you buy the rails, if they don't say they are hardened, they aren't. Hardened rails cost a little more than the other type. You can tell if rails are hardened by trying to scratch them with a file. A file won't leave more than a barely visible scratch on a hardened rail, and will happily cut into an unhardened rail.

Belt teeth on smooth pulleys is OK. The biggest problem is a zipping noise it causes when you run the mechanism really fast (like 500 mm/sec, which you're unlikely to use in a 3D printer).

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Hypercube - Uneven Layer Lines / Z axis banding October 25, 2019 02:58PM |

Registered: 4 years ago Posts: 7 |

I got a lot of replies, thank you all. I'll try to follow them all and reply to each one.

Yes, the belts are getting worn by the pulleys. They don't seem aligned as they move up/down as the X axis carriage gets closer/away from the motors.

I will try to flip the belts to avoid the teeth on the smooth idlers.

Now that you mention it, my belts always wobble up and down on the motor pulley (not as much as on the video). I started looking more carefully and I can see that the motor mount is actually a bit bent (I mean, the top surface of the printed part isn't horizontal / the motor "wall" isn't parallel to the extrusion). That can explain the belt moving up or down. Should I print a new motor mount? Or perhaps try to design a more sturdier one?

I checked all bolts and all of them were tight. But the belt was really bad. So, as you said, I started inspecting the belt system. As stated before, the motor mounts are getting tilted (most likely due to the belt tension, I would say).

I only print in PLA (sometimes in PETG), but I will replace the nozzle to see if that has any effect.

Glad that you mentioned the hardened steel rods. I did check them when building the hypercube, they were hard as no file did substancial damage to them.

My next steps are probably swapping the CF rods / bearings on the X axis; and try to find/design a new motor as these are a bit deformed. I think it would be helpful if the motors were pressed against the aluminium extrusion. Any opinions on that?

Just rechecked: e-steps are fine; to verify flow rate I printed a 0.8mm thick cube and it measured 0.8mm... I never did a flow rate check so I'm not sure if this is the best option.Quote

AmyTheBun

I'd start by making sure your e-steps and flow rate are correct.

There isn't any play (that I can notice), either on the hotend, x axis carriage, y axis, z axis, bed. For all I can remember to check, nothing appears to have play.Quote

AmyTheBun

then I'd check if the hotend has any play

then I'd check if the z axis or the bearings/y axis or literally anything has play to it

I don't have any binding on the Z axis. It can move freely. The lead screw appears to be straight and isn't "dancing" while the motor is spinning.Quote

AmyTheBun

then I'd check if the z axis has any binding and does move freely.

Then I'd wait for more answers

Are those the usual nuts for the T8 threads? Can you direct me when to find them?Quote

AmyTheBun

I use acetal POM trapozoidal nuts and they're fantastic. they helped increase the print quality of my anycubic i3 mega-s so much! but yeah. if you don't wanna go and buy them you can print them in pla and they work surprisingly well. the only issue being pla melts at a relatively low temperature and the nut is printed in a way that the z is where the load is on. but again they're not that expensive I think? I forgot how much mine cost

I do have all axis well lubricated.Quote

AmyTheBun

also I assume your axis are all well lubricated.

also are your belts maybe gettnig worn or not aligned? In a corexy the belt system is a huge fuss. one tiny mistake and you get horribly irregular layers due the changing tension. one of the reasons I don't like corexy as great as it is!

EDIT: I just noticed you have the toothed side of the belt on smooth idlers (beaings) I heard that's not a good idea whatsoever. you could either twist the belt(not sure whatsoever on how it affects it. but only do it on the long side of each stepper) or switch to a toothed idler

Yes, the belts are getting worn by the pulleys. They don't seem aligned as they move up/down as the X axis carriage gets closer/away from the motors.

I will try to flip the belts to avoid the teeth on the smooth idlers.

I just checked my rails and they are smooth, I didn't find any tracks caused by the ball bearings. I also don't have any play in them, but sometimes they make a "rattling" sound when moving. Should I replace them?Quote

Mogal

Maybe unrelated, but I had a similar issue. When I first got the printer working and tuned, it was producing amazing prints...

I found my prints slowly degrading in quality... After watching the printer for awhile, I could see the print head 'Float'

(I could actually see the print head wobble) as it was travelling back and forth... took a closer look at the bearings and rails

to find that the bearings had carved a track through the rail. (some of the balls where stuck in the bearing digging a trench in the rails)

Its hard to take a good picture of the groove, but its significant enough to cause quality issues.

Quote

Mogal

Oh, and watch the belt around the pulleys. If there is any misalignment in the belts, you might see the belts flop back and forth on the pulley

as it tried to climb up/down and off the pulley...

- This mostly occurs on the stepper pulley as the mount is not ridged enough and causes a deflection in the belts.

Mogal's Belt deflection on Hypercube

Now that you mention it, my belts always wobble up and down on the motor pulley (not as much as on the video). I started looking more carefully and I can see that the motor mount is actually a bit bent (I mean, the top surface of the printed part isn't horizontal / the motor "wall" isn't parallel to the extrusion). That can explain the belt moving up or down. Should I print a new motor mount? Or perhaps try to design a more sturdier one?

My belts do tilt a bit. Nowhere near as much as on the video, but I can see that the motor axle isn't perfectly vertical (the entire motor isn't, the axle relatively to the motor is fine).Quote

the_digital_dentist

Belts should not tilt like the ones in the video- there is something seriously wrong with the rest of the mechanism. Pulleys must be mounted on vertical axles that must stay vertical when tension is applied to the belts. Belts should remain at one level throughout their travel- don't vertically cross corexy belts- there's no need for it and it will cause problems.

There are about 1000 different problems that can cause rough Z axis print quality. The type of Z axis problem you're seeing is measured in microns. It is difficult to see that little wiggle in the hot-end/extruder carriage. It may be due to slop in the XY mechanism, the Z mechanism, or both. Troubleshooting is a combo of careful observation and logical thinking. It used to work fine but print quality has degraded. That rules out the controller which has remained constant. Since quality has degraded, it indicates something is wearing out or getting loose compared to when the machine was first built. Hypercubes have a lot of plastic motor and pulley mounts- maybe one or more has cracked or deformed under the strain of heat and belt tension. The OP said that one of the belts had a cut in it- that shouldn't happen, so I'd look carefully around that belt's part of the mechanism. Make sure everything is tight and lubricate bearings.

The Z screws don't move much, so they aren't likely to wear out in your lifetime unless you've got the mechanism so poorly aligned that it takes a lot of force to turn them.

Brass nozzles can wear out, especially if you print with glow-in-the -dark, glass, carbon, or metal particle loaded filaments.

Mogal: the grooves in the guide rails are there because you didn't use hardened guide rails. Whenever you use linear bearings on guide rails, the rails must be the hardened type. When you buy the rails, if they don't say they are hardened, they aren't. Hardened rails cost a little more than the other type. You can tell if rails are hardened by trying to scratch them with a file. A file won't leave more than a barely visible scratch on a hardened rail, and will happily cut into an unhardened rail.

Belt teeth on smooth pulleys is OK. The biggest problem is a zipping noise it causes when you run the mechanism really fast (like 500 mm/sec, which you're unlikely to use in a 3D printer).

I checked all bolts and all of them were tight. But the belt was really bad. So, as you said, I started inspecting the belt system. As stated before, the motor mounts are getting tilted (most likely due to the belt tension, I would say).

I only print in PLA (sometimes in PETG), but I will replace the nozzle to see if that has any effect.

Glad that you mentioned the hardened steel rods. I did check them when building the hypercube, they were hard as no file did substancial damage to them.

My next steps are probably swapping the CF rods / bearings on the X axis; and try to find/design a new motor as these are a bit deformed. I think it would be helpful if the motors were pressed against the aluminium extrusion. Any opinions on that?

|

Re: Hypercube - Uneven Layer Lines / Z axis banding October 26, 2019 03:42PM |

Registered: 11 years ago Posts: 5,780 |

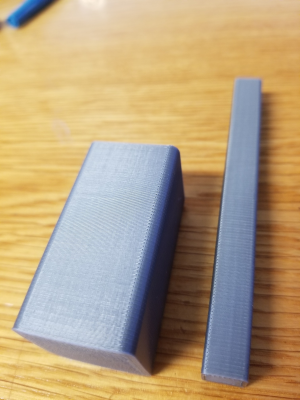

I think the design of the motor mounts has to be made more resistant to the belt tension. That generally means making the mount very "beefy". Think about starting with a solid block and cutting out only as much as you need to mount the motor and pulley, feed the belt, and tighten screws on the drive pulley.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Hypercube - Uneven Layer Lines / Z axis banding October 26, 2019 04:03PM |

Registered: 4 years ago Posts: 7 |

|

Re: Hypercube - Uneven Layer Lines / Z axis banding October 26, 2019 05:16PM |

Registered: 11 years ago Posts: 250 |

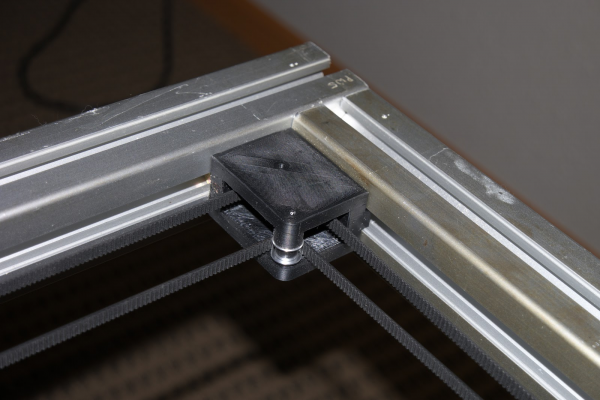

Fixing ANY miss-alignment will increase print quality and print efficiency.

The original mounts are not very robust and offered a lot of flex.

I was able to overcome it with the jacking blocks I made(Again, see that video I posted)

That was my way of overcoming the issue until I was able to get a better mount for the motors.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

The original mounts are not very robust and offered a lot of flex.

I was able to overcome it with the jacking blocks I made(Again, see that video I posted)

That was my way of overcoming the issue until I was able to get a better mount for the motors.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Hypercube - Uneven Layer Lines / Z axis banding October 26, 2019 07:02PM |

Registered: 4 years ago Posts: 7 |

|

Re: Hypercube - Uneven Layer Lines / Z axis banding October 26, 2019 09:24PM |

Registered: 11 years ago Posts: 250 |

Sry, but I never got around to making (or printing) better mounts.

After I made the jacking bolts, The issue (for me) went away.

But it was always on my todo list...

Since I had the bearing/rod issue, I'm converting the entire machine to metal.

(with the exception of the carriage - for now) and using MGN12 bearings and rails.

I did a quick search for hypercube motor mounts and found this one that may be acceptable:

Hypercube x y motor mounts improved and STRONGER

I did however get around to making/printing these:

Beefy XY Idler

Beefy Z Carrage

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

After I made the jacking bolts, The issue (for me) went away.

But it was always on my todo list...

Since I had the bearing/rod issue, I'm converting the entire machine to metal.

(with the exception of the carriage - for now) and using MGN12 bearings and rails.

I did a quick search for hypercube motor mounts and found this one that may be acceptable:

Hypercube x y motor mounts improved and STRONGER

I did however get around to making/printing these:

Beefy XY Idler

Beefy Z Carrage

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Hypercube - Uneven Layer Lines / Z axis banding October 27, 2019 07:35AM |

Registered: 4 years ago Posts: 7 |

Will you be fabricating all the metal parts? What is your opinion on linear rails? Are they much better than the smooth rods/bearings combo?

I've found those motor mounts, I'm thinking on printing them to see if that helps on the long term. But I'll start with the jacks as that's a faster print.

I'm using 8mm for the Y axis, so I cannot use that XY Idler, but I'll look for something similar for 8mm. I sometime ago saw a stronger XY idler.

For the Z carriage, I currently only have LM12LUU so I won't be using that carriage, but I'm thinking on making one with that "gripping" style.

I've found those motor mounts, I'm thinking on printing them to see if that helps on the long term. But I'll start with the jacks as that's a faster print.

I'm using 8mm for the Y axis, so I cannot use that XY Idler, but I'll look for something similar for 8mm. I sometime ago saw a stronger XY idler.

For the Z carriage, I currently only have LM12LUU so I won't be using that carriage, but I'm thinking on making one with that "gripping" style.

|

Re: Hypercube - Uneven Layer Lines / Z axis banding October 27, 2019 08:59AM |

Registered: 11 years ago Posts: 5,780 |

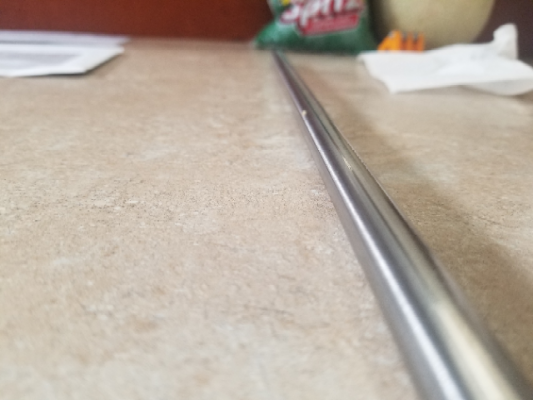

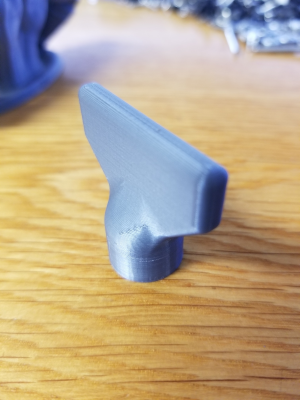

The force applied to the motor comes from the pulley on the shaft. All that plastic around the motor body does little to improve overall rigidity of the mount. I would design the mount something like the one on the right:

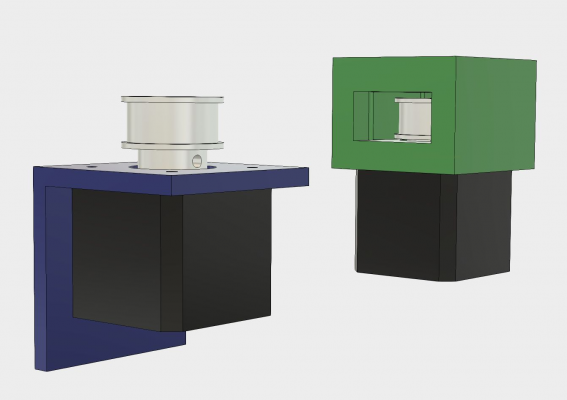

Here's one I used in my corexy sand table project- no visible flex at all (though I'm sure there must be some):

When I design stuff like this, I place the motor in the CAD file in it's ideal location relative to the frame of the printer, then add in a big rectangular solid on top of the motor, then start cutting away anything that interferes with the belt and pulley, and finally the frame. Add tangs to fit in the frame slots and screw holes for the motor and the mount and you're done.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Here's one I used in my corexy sand table project- no visible flex at all (though I'm sure there must be some):

When I design stuff like this, I place the motor in the CAD file in it's ideal location relative to the frame of the printer, then add in a big rectangular solid on top of the motor, then start cutting away anything that interferes with the belt and pulley, and finally the frame. Add tangs to fit in the frame slots and screw holes for the motor and the mount and you're done.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Hypercube - Uneven Layer Lines / Z axis banding October 27, 2019 12:54PM |

Registered: 11 years ago Posts: 250 |

I really like DD mount that he made. Lots of rigidity there. But that wont directly plug in to the hypercube design.

The one I posted looks like the motor actually rests on that inside wall. (ie: no deflection)

Start looking through thingiverse (and others) for different designs. Lots out there.

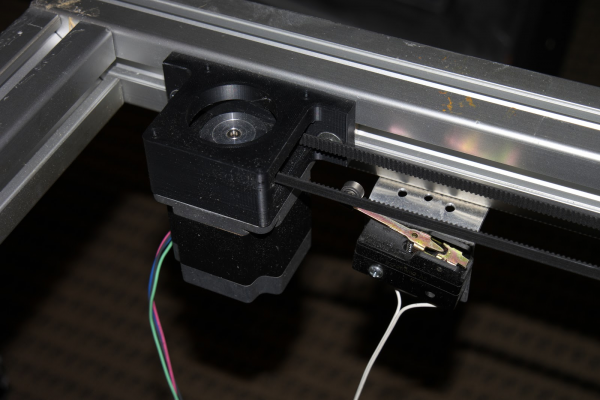

I was using 12mm rods for the z, 10mm for the Y and 8mm for the X.

I'm using some off the shelf parts and some machined Alum. It's still a work in progress...

So far, I'm finding the rails far superior over the rods, but it does seem to be a little more finicky to align.

The rods I had also had a small warp to them...

With the rails, I can straighten them out some when I bolt them down to the extrusions.

Pics for reference:

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

The one I posted looks like the motor actually rests on that inside wall. (ie: no deflection)

Start looking through thingiverse (and others) for different designs. Lots out there.

I was using 12mm rods for the z, 10mm for the Y and 8mm for the X.

I'm using some off the shelf parts and some machined Alum. It's still a work in progress...

So far, I'm finding the rails far superior over the rods, but it does seem to be a little more finicky to align.

The rods I had also had a small warp to them...

With the rails, I can straighten them out some when I bolt them down to the extrusions.

Pics for reference:

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Hypercube - Uneven Layer Lines / Z axis banding October 28, 2019 06:40AM |

Registered: 5 years ago Posts: 31 |

[www.thingiverse.com]

try this if your motor is tilted

[www.thingiverse.com]

i am making this trying to make the printer a tiny bit better

also this is a sample link. I found it online [www.aliexpress.com]

try this if your motor is tilted

[www.thingiverse.com]

i am making this trying to make the printer a tiny bit better

also this is a sample link. I found it online [www.aliexpress.com]

|

Re: Hypercube - Uneven Layer Lines / Z axis banding October 28, 2019 06:47AM |

Registered: 5 years ago Posts: 31 |

Quote

Mogal

I really like DD mount that he made. Lots of rigidity there. But that wont directly plug in to the hypercube design.

The one I posted looks like the motor actually rests on that inside wall. (ie: no deflection)

Hey my belts only slide up and down on the motor pulley. and they only tilt very lightly on the xy idlers on the back of my printer. is this a cause for worry? I mean i tried everything and they just don't seem to be fixed. I have no idea where the misalingment is or how to fix the misalingment

EDIT: Sorry for the horrible video quality but I uploaded a few videos

[photos.app.goo.gl]

Edited 1 time(s). Last edit at 10/28/2019 06:54AM by AmyTheBun.

|

Re: Hypercube - Uneven Layer Lines / Z axis banding October 28, 2019 12:44PM |

Registered: 11 years ago Posts: 250 |

Hard to tell. But I would say there is something loose and/or misaligned.

As the carriage moves one way, the belt moves up, then reverses the opposite direction.

Seems like the XY joiner is higher/lower then the stepper motors and XY idler.

So as the XY joiner moves closer to the stepper, it forces the belt down. then as it moves away, creeps back up...

Make sense?

All the belts have to be on the same plane. And all the pulleys have to be perpendicular (90 degrees) to the belts.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

As the carriage moves one way, the belt moves up, then reverses the opposite direction.

Seems like the XY joiner is higher/lower then the stepper motors and XY idler.

So as the XY joiner moves closer to the stepper, it forces the belt down. then as it moves away, creeps back up...

Make sense?

All the belts have to be on the same plane. And all the pulleys have to be perpendicular (90 degrees) to the belts.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Hypercube - Uneven Layer Lines / Z axis banding October 28, 2019 06:51PM |

Registered: 4 years ago Posts: 7 |

That looks a very nice design (and a very nice print!).Quote

the_digital_dentist

The force applied to the motor comes from the pulley on the shaft. All that plastic around the motor body does little to improve overall rigidity of the mount. I would design the mount something like the one on the right:

Here's one I used in my corexy sand table project- no visible flex at all (though I'm sure there must be some):

When I design stuff like this, I place the motor in the CAD file in it's ideal location relative to the frame of the printer, then add in a big rectangular solid on top of the motor, then start cutting away anything that interferes with the belt and pulley, and finally the frame. Add tangs to fit in the frame slots and screw holes for the motor and the mount and you're done.

Thanks for the design tips, as someone that don't have any design experience, all tips are helpful. Thanks for sharing that tip and the photos!

Quote

Mogal

I really like DD mount that he made. Lots of rigidity there. But that wont directly plug in to the hypercube design.

The one I posted looks like the motor actually rests on that inside wall. (ie: no deflection)

Start looking through thingiverse (and others) for different designs. Lots out there.

I was using 12mm rods for the z, 10mm for the Y and 8mm for the X.

I'm using some off the shelf parts and some machined Alum. It's still a work in progress...

So far, I'm finding the rails far superior over the rods, but it does seem to be a little more finicky to align.

The rods I had also had a small warp to them...

With the rails, I can straighten them out some when I bolt them down to the extrusions.

I'm thinking on printing the ones you posted. They seem to be better than the stock ones (just gave them a quick overview, not a detailed analysis).

Maybe on the next days (whenever I find the time, I'll design something inspired on the mount he posted.

Your printer is looking very nice. Congratulations on the work done so far!

The linear rails are out of my budget so far, so I guess I'll have to stick with the smooth rods.

Quote

AmyTheBun

[www.thingiverse.com]

try this if your motor is tilted

[www.thingiverse.com]

i am making this trying to make the printer a tiny bit better

also this is a sample link. I found it online [www.aliexpress.com]

If I looked at it correctly, it looks to be that the parts on the first link is for 30mm extrusion. I'm using 20mm, so I'm not sure if it will work right out of the box.

Same goes for the second link, is that for the Hypercube Evolution or for the Hypercube (20mm)?

Anyways, thanks for sharing and thanks for the Nut link

Quote

Mogal

Hard to tell. But I would say there is something loose and/or misaligned.

As the carriage moves one way, the belt moves up, then reverses the opposite direction.

Seems like the XY joiner is higher/lower then the stepper motors and XY idler.

So as the XY joiner moves closer to the stepper, it forces the belt down. then as it moves away, creeps back up...

Make sense?

All the belts have to be on the same plane. And all the pulleys have to be perpendicular (90 degrees) to the belts.

My belts are behaving the same way as AmyTheBun: They don't twist as the first video posted a few days ago, but they do move up/down. I think that's being caused by the motor being a bit off and the motor axle isn't perpendicular to the belts. If I push the motor base in the direction of the belt, I check that the belts start to run always at the same level. So the triangle "jacks" might be a good solution to get the motors into place. I couldn't check if that works, as it was almost impossible to keep constant pressure on the motor. I'll update once I got the jacks printed and installed.

Related to my first problem, I noticed some play on the Y axis rods/bearings combo. I can tilt them by hand and they have play. One side (X min) is "naturally resting on one side" and I can rotate it conter clock wise. The other side (X max) is resting on the other side and I can rotate it clock wise. (please let me know if that didn't make sense, I'll try to explain it other way).

I have no idea if those bearings should have such play (I don't feel any play on Z axis), and if they shouldn't do anyone have suggestions on how to remove/minimize it? I was thinking on replacing the LM8LUU with 2 LM8UU and try to use some tape to make them slightly out of alignment (again, let me know if I couldn't make myself clear).

Overall I think I got better print results after a few tests and experiments. Don't get me wrong, there is still a lot of improvements to be done.

Some Photos. On the photos with 2 cubes, left is the first one, the right is the last one.

|

Re: Hypercube - Uneven Layer Lines / Z axis banding October 29, 2019 04:53AM |

Registered: 6 years ago Posts: 1,007 |

Frankly all these 3D printed parts are too flimsy often overcomplicated with many weak, flexible elements.

Note their flexibility is often an advantage as it avoids binding due to poor alignment.

The vast majority of what is found in Thingiverse is like that and perpetuates bad practice. It works, they say, indeed, see remark above.

Oh yeah, they are far more elegant, better looking that bulky, sturdy ones.

An other blatant weakness is the use for assembly of regulars nuts and therefore pockets to house them. Far better to use self tapping screws or threaded inserts.

To check, just pinch your belts and see how the parts bend. Use of a dial indicator helps.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

Note their flexibility is often an advantage as it avoids binding due to poor alignment.

The vast majority of what is found in Thingiverse is like that and perpetuates bad practice. It works, they say, indeed, see remark above.

Oh yeah, they are far more elegant, better looking that bulky, sturdy ones.

An other blatant weakness is the use for assembly of regulars nuts and therefore pockets to house them. Far better to use self tapping screws or threaded inserts.

To check, just pinch your belts and see how the parts bend. Use of a dial indicator helps.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Hypercube - Uneven Layer Lines / Z axis banding October 29, 2019 07:43AM |

Registered: 11 years ago Posts: 5,780 |

Quote

AmyTheBun

Quote

Mogal

I really like DD mount that he made. Lots of rigidity there. But that wont directly plug in to the hypercube design.

The one I posted looks like the motor actually rests on that inside wall. (ie: no deflection)

Hey my belts only slide up and down on the motor pulley. and they only tilt very lightly on the xy idlers on the back of my printer. is this a cause for worry? I mean i tried everything and they just don't seem to be fixed. I have no idea where the misalingment is or how to fix the misalingment

EDIT: Sorry for the horrible video quality but I uploaded a few videos

[photos.app.goo.gl]

The corner pulley brackets don't look very well designed to me. They are thin plastic and anchored to one side of the t-slot. As the motors reverse direction and accelerate the tension on the belts varies and that can cause the mounts to flex (and frame members to twist). I'd redesign those corner pulley blocks the same way I'd do the motor mounts, and anchor them on two sides of the t-slot. Start with a solid block and remove enough to mount the pulleys and run the belts. Here's one of the corner pulley blocks in my sand table:

That block is bolted to both of the frame members with t-nuts.

The t-slot for the frame is another potential problem. In some designs, like the OP's hypercube, the belts are all stood over the top horizontal frame members. Think about what the belt tension is doing to the frame, especially if the frame is the typical small size t-slot. That stuff isn't particularly rigid and will bow, and no, corner brackets won't stop the frame member from flexing in the center. I ran into a similar problem in my sand table recently where the belts are all on the inside of of the 45 mm square t-slot frame. The belt tension was causing the Y axis frame members (2m long) to bow outward a few mm. I fixed it by adding a brace to the frame to pull the centers of the Y axis rails back toward each other. In the hypercube the linear guides bolted to the Y frame members will help stiffen them, but there aren't any linear guides between the corner pulley blocks, so the frame member between the two is entirely at the mercy of the belt tension.

As for the belt crawling up and down the pulleys as the thing moves, it doesn't look too bad. That can be caused by poor slicing of low quality belts.

If the design of the printer doesn't allow rigid mounts to be used, I'd say it's a flawed design. Rigid motor and pulley mounts are fundamental to a successful design/build. A lot of people design and print plastic parts that look like cast metal without thinking about the forces applied or the fact that plastic isn't cast metal and needs bulk to be rigid.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Hypercube - Uneven Layer Lines / Z axis banding October 30, 2019 06:25AM |

Registered: 5 years ago Posts: 31 |

My printer IS a hypercube evolution (3030)

I wish there was someone more knowldgeable who would help us design things tbh I'm really bad at cad.

I'm really bad at cad.

but considering that im' a beginner. what would you recommend to me? I don't have much of a money to buy new parts unless I really have to. would you saying squaring up the xy idlers and the motor mount would be enough? Do I have to move my belts and everything to the top of the extrusion?

I wish there was someone more knowldgeable who would help us design things tbh

I'm really bad at cad.

I'm really bad at cad.but considering that im' a beginner. what would you recommend to me? I don't have much of a money to buy new parts unless I really have to. would you saying squaring up the xy idlers and the motor mount would be enough? Do I have to move my belts and everything to the top of the extrusion?

|

Re: Hypercube - Uneven Layer Lines / Z axis banding October 30, 2019 06:48AM |

Registered: 11 years ago Posts: 5,780 |

You don't have to be knowledgeable- just critical. Look at the printer from every angle. Look for anything that isn't ideal. Are the pulley and motor mounts flexing/twisting? Are round guide rails flexing? Etc. Then think about how to make them stop doing non ideal things. Then try to fix them and fail a few times. That's how you get knowledgeable. Then, with that experience, start looking at other designs and see if you can spot the same flaws or others.

A 3D printer is just a toy until you start making your own designs. Start learning CAD. It takes a while, but you'll be able to do so much more with and to your printer once you're no longer at the mercy of hack "designers" on thingiverse. There are a lot of good, free CAD packages available. Pick one and dive in. I started with SketchUp years ago, and quickly realized it was terrible for 3D print designing, switched to DesignSpark Mechanical, almost as easy and about 10x better than SketchUp, and finally to Fusion360 which is better still. The time you spend learning CAD is well spent, and knowledge of one CAD program is usually applicable to another.

And always remember, plastic is flexible. You make it less flexible by adding bulk. If the design for a printed part looks like it's made of cast metal, it's probably too flimsy to stand up to mechanical forces.

Edited 1 time(s). Last edit at 10/30/2019 06:54AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

A 3D printer is just a toy until you start making your own designs. Start learning CAD. It takes a while, but you'll be able to do so much more with and to your printer once you're no longer at the mercy of hack "designers" on thingiverse. There are a lot of good, free CAD packages available. Pick one and dive in. I started with SketchUp years ago, and quickly realized it was terrible for 3D print designing, switched to DesignSpark Mechanical, almost as easy and about 10x better than SketchUp, and finally to Fusion360 which is better still. The time you spend learning CAD is well spent, and knowledge of one CAD program is usually applicable to another.

And always remember, plastic is flexible. You make it less flexible by adding bulk. If the design for a printed part looks like it's made of cast metal, it's probably too flimsy to stand up to mechanical forces.

Edited 1 time(s). Last edit at 10/30/2019 06:54AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Hypercube - Uneven Layer Lines / Z axis banding November 05, 2019 03:09AM |

Registered: 5 years ago Posts: 31 |

|

Re: Hypercube - Uneven Layer Lines / Z axis banding November 05, 2019 02:12PM |

Registered: 11 years ago Posts: 250 |

Quote

AmyTheBun

sadly as someone with a low budget experimenting is not an option for me.

I am thinking of selling the hypercube and buying an artillery sidewinder instead

So instead of tweaking the printer you already have, you'll just buy a new one?

That's a GREAT budget strategy!! Good luck.

DD posted some great info above. I recommend you re-read it, and go from there.

If you plan to stay within the 3D printing community, eventually you will NEED to learn how to CAD.

And no mater what, EVERY printer will have its issues. Even with a new one, you will have to tweak it just right.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Hypercube - Uneven Layer Lines / Z axis banding November 05, 2019 03:16PM |

Registered: 5 years ago Posts: 31 |

[cdn.discordapp.com]

i designed this but it has a lot of flaws. but damn is it strong! the idea of putting a cube on top of the motor and only cutting what you need was brilliant thanks

it's stupidly sturdy compared to scott's but it didn't improve anytrhing. i'll still work on it. it doesn't hurt to have a super stable one right?

in fact if anyone with a hypercube wants to contribute i'd love it i'm making a hypercube-s i'll redesign the idler mounts soon too. and maybe do that to the y carriages!

i'm making a hypercube-s i'll redesign the idler mounts soon too. and maybe do that to the y carriages!

Edited 1 time(s). Last edit at 11/05/2019 03:17PM by AmyTheBun.

i designed this but it has a lot of flaws. but damn is it strong! the idea of putting a cube on top of the motor and only cutting what you need was brilliant thanks

it's stupidly sturdy compared to scott's but it didn't improve anytrhing. i'll still work on it. it doesn't hurt to have a super stable one right?

in fact if anyone with a hypercube wants to contribute i'd love it

i'm making a hypercube-s i'll redesign the idler mounts soon too. and maybe do that to the y carriages!

i'm making a hypercube-s i'll redesign the idler mounts soon too. and maybe do that to the y carriages!Edited 1 time(s). Last edit at 11/05/2019 03:17PM by AmyTheBun.

|

Re: Hypercube - Uneven Layer Lines / Z axis banding November 05, 2019 03:18PM |

Registered: 5 years ago Posts: 31 |

|

Re: Hypercube - Uneven Layer Lines / Z axis banding November 05, 2019 04:18PM |

Registered: 11 years ago Posts: 250 |

Quote

AmyTheBun

also that wasn't very nicesome of us just want a 3d printer that works. specially a lot of us don't have time or money to spend on a printer like this. you know how long it takes to try on a new carriage or y carriage! swapping it takes a day!

Sorry, was just suppose to be a reality check... I didn't mean anything bad.

As for time it takes.. uhm, yeah I know all too well how long it takes.

I started with a hypercube. And although its still a core XY, it's by no means a hypercube anymore.

Just like the troubles your having with rigidity, I too was having those issues. Then the rails started to fail.

So over the last 5-6 months, I've been designing and machining the new machine (mostly out of aluminum)

And over the last couple of days, I've been testing and tweaking the machine.

It takes time, but if you take that time, learn the intricacies, you too can have a great quality printer!

Keep it up like you are, and you'll be there in no time! And you'll be thankful you did!

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Hypercube - Uneven Layer Lines / Z axis banding November 07, 2019 06:02PM |

Registered: 4 years ago Posts: 7 |

@MKSA That actually makes a lot of sense but I guess I never thought on that. Maybe I'll start changing my mindset to look the beauty in bulky, sturdy parts.

One remark on the self tapping screws: Why is that better than nuts? Can't the plastic give a bit and the tapping start to fail?

@the_digital_dentist that xy idler block looks very sturdy. Do you think that 2020 T-Slot isn't sturdy enough? That the belts are able to produce enough forces to bend it, even though they are near the top crossing (meaning that the leverage is low). The T slot span is only arround 35cm in my printer.

@AmyTheBun don't give up on the printer and learn how to CAD. If you are on a low budget, use your time. I do believe that you can find better tuned printers, almost out-of-the-box-ready-to-print, but those came with a higher price tag (not always, but most times). Just keep doing stuff. As you said, sometimes it takes a full day just to do something. Yeah that's frustating if it doesn't work at the end, but at least you learned what not to do next time.

Currently I'm designing a printer based on the hypercube (so that I can reuse all metal parts and the electronics). I felt inspired by the hard work of @Mogal and decided to order linear rails (clones, to see how they behave). Currently still designing and thinking on what some decisions should be (eg should I place the linear rails at the bottom of the extrusion or at the top; should I remove the cantilever bed design, among many others). I don't know the answer to all of them but I will try some, fail, try again and eventually succeed (hope so )

)

@Mogal those prints are looking amazing! I'm somewhat jealous. Congratulations!

Thank you for reminding me why I built a 3D printer. It was to tinker with it, use it to make projects and I started to forget that the printer IS a project.

Also found out one of the biggest problems on mine was the play on the XY joiner bearings. I could see the nozzle move a few mm if I shake that joiner. It doesn't move that much while printing, but I can hear it shaking while the printer moves.

One remark on the self tapping screws: Why is that better than nuts? Can't the plastic give a bit and the tapping start to fail?

@the_digital_dentist that xy idler block looks very sturdy. Do you think that 2020 T-Slot isn't sturdy enough? That the belts are able to produce enough forces to bend it, even though they are near the top crossing (meaning that the leverage is low). The T slot span is only arround 35cm in my printer.

@AmyTheBun don't give up on the printer and learn how to CAD. If you are on a low budget, use your time. I do believe that you can find better tuned printers, almost out-of-the-box-ready-to-print, but those came with a higher price tag (not always, but most times). Just keep doing stuff. As you said, sometimes it takes a full day just to do something. Yeah that's frustating if it doesn't work at the end, but at least you learned what not to do next time.

Currently I'm designing a printer based on the hypercube (so that I can reuse all metal parts and the electronics). I felt inspired by the hard work of @Mogal and decided to order linear rails (clones, to see how they behave). Currently still designing and thinking on what some decisions should be (eg should I place the linear rails at the bottom of the extrusion or at the top; should I remove the cantilever bed design, among many others). I don't know the answer to all of them but I will try some, fail, try again and eventually succeed (hope so

)

)@Mogal those prints are looking amazing! I'm somewhat jealous. Congratulations!

Thank you for reminding me why I built a 3D printer. It was to tinker with it, use it to make projects and I started to forget that the printer IS a project.

Also found out one of the biggest problems on mine was the play on the XY joiner bearings. I could see the nozzle move a few mm if I shake that joiner. It doesn't move that much while printing, but I can hear it shaking while the printer moves.

|

Re: Hypercube - Uneven Layer Lines / Z axis banding November 07, 2019 10:30PM |

Registered: 11 years ago Posts: 5,780 |

Threaded inserts and embedded nuts are very useful for parts in which you're going to be removing the screws frequently. For things that are intended to be assembled and not taken apart on a regular basis, thread rolling screws for plastic are fine. That is why you'll find many of them in every piece of consumer electronics ever made. I have a small box full of such screws removed from old VCRS, etc., and periodically order a few bags of them from amazon. Look for widely spaced threads that will grab the plastic and will not easily strip the hole.

Notice the shank of the screw is a uniform diameter- that's the size of pilot hole you print/drill. The wide spacing between the threads makes it difficult to strip the hole by over-turning the screw.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Notice the shank of the screw is a uniform diameter- that's the size of pilot hole you print/drill. The wide spacing between the threads makes it difficult to strip the hole by over-turning the screw.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.