Steel sheet metal frame?

Posted by witor

|

Steel sheet metal frame? November 14, 2019 07:05PM |

Registered: 6 years ago Posts: 63 |

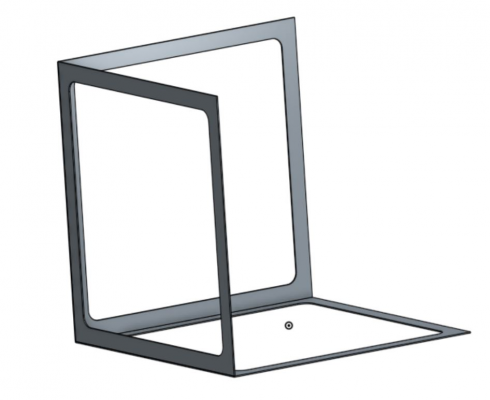

As far as I can see aluminium extrusions are used in most corexy frames. Would it be a good idea to use laser or plasma cut 2-3 mm steel sheets to build the frame? Laser cut pieces should be perfectly square so the frame would be perfectly square and the frame made of 3 mm steel would be rock solid. Sheets could be screwed together or maybe even welded. I do realise that a frame of 50x50x50 cm would weight over 10 kg, but if the printer does not need to be moved around more weight would be a good thing as it would reduce the vibrations caused by the moving parts.

What are your thoughts on the sheet steel frame idea? Picture just roughly shows the concept.

What are your thoughts on the sheet steel frame idea? Picture just roughly shows the concept.

|

Re: Steel sheet metal frame? November 14, 2019 08:03PM |

Registered: 11 years ago Posts: 5,780 |

Solidoodle printers had a folded sheet metal frame with the pieces riveted together. They used to advertise them showing the CEO standing on top of a printer while it was printing. We have one at the makerspace- it is rock solid. Too bad they went too cheap with the other parts...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Steel sheet metal frame? January 01, 2020 06:44PM |

Registered: 7 years ago Posts: 507 |

I wouldn't recommend welding the frame together. Even if it starts off square and flat it wont end up that way. Bolted connections with some angle brackets are a better idea in my opinion. One thing to consider though is that while sheet metal may be strong and rigid in some respects, it can buckle. Not so much an issue with smaller structures like the solidoodle, but on a half meter cube the sides might be more prone to buckling or wobbling.

|

Re: Steel sheet metal frame? January 01, 2020 07:16PM |

Admin Registered: 16 years ago Posts: 13,886 |

... one of my earlier ideas was a sort of "geodetic dome" or a similar structure built from stiff carbon rods and thin steel wires - this can give any internal geometry, is pretty lightweight ... and could be designed "foldable" for mobile use

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Steel sheet metal frame? January 02, 2020 07:02AM |

Registered: 11 years ago Posts: 5,780 |

IRIC the solidoodle frame was riveted together. If you were using thicker steel to make a larger frame I think you could tack weld it without warping the whole thing.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Steel sheet metal frame? January 02, 2020 04:50PM |

Registered: 5 years ago Posts: 155 |

Quote

VDX

... one of my earlier ideas was a sort of "geodetic dome" or a similar structure built from stiff carbon rods and thin steel wires - this can give any internal geometry, is pretty lightweight ... and could be designed "foldable" for mobile use

A Tensegrity would be something to look for. Greetings from Buckminster Fuller for both ideas...

I plan trying to build the Scara arms with this principle. CFK for the stable parts and steel wire for the thin ones.

Edited 1 time(s). Last edit at 01/02/2020 04:52PM by JoergS5.

|

Re: Steel sheet metal frame? January 03, 2020 11:58PM |

Registered: 5 years ago Posts: 155 |

Quote

witor

As far as I can see aluminium extrusions are used in most corexy frames. Would it be a good idea to use laser or plasma cut 2-3 mm steel sheets to build the frame? Laser cut pieces should be perfectly square so the frame would be perfectly square and the frame made of 3 mm steel would be rock solid. Sheets could be screwed together or maybe even welded. I do realise that a frame of 50x50x50 cm would weight over 10 kg, but if the printer does not need to be moved around more weight would be a good thing as it would reduce the vibrations caused by the moving parts.

What are your thoughts on the sheet steel frame idea? Picture just roughly shows the concept.

[attachment 113370 Capture.JPG]

I fully agree with your idea to create a stable frame first as a basis for a high quality printer. But you should think of the six forces involved: three directions XYZ and three rotational forces: rotation around X, Y and Z. In your image you protect against them more or less (less at the "unprotected edges"). The frame can easily twist, so using steel angles, steel corners or triangles should be added. Or the steel must be very thick (6 mm steel e.g.), but even thick steel will result in some vibration, so supporting all "routes/tracks/lines" at both ends is better.

The easiest way to protect against rotation is a closed cube with cornered steel frame at all six sides, but if you want some sides open, you should protect otherwise.

Edited 2 time(s). Last edit at 01/04/2020 12:04AM by JoergS5.

|

Re: Steel sheet metal frame? January 13, 2020 12:22PM |

Registered: 8 years ago Posts: 9 |

The thing against sheetmetal for the one off build printer is that unless you have access to a laser cutter the panels will be expensive; and unless you are a shit hot welder it won't come out square when welded together. For a one off build it is just easier to use aluminium extrusion with metal corner brackets. Inexpensive, readily available, and when you need to modify it due to some unforeseen circumstance, not hard to do.

|

Re: Steel sheet metal frame? January 13, 2020 02:10PM |

Registered: 11 years ago Posts: 5,780 |

I think t-slot is overrated. It's really convenient if you have to mount and unmount different things in different positions over and over, or for prototyping, but once a design is done and you know where things are going to mount, square tubing is better in some ways. It is definitely more rigid than same-size t-slot, and you can always drill holes to mount things later. It's easier to mount things like linear guides on tubing than t-slot. If you must use corner brackets you can use the same ones for tubing that you use for t-slot. Oh yeah, it's usually cheaper than t-slot, too.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.