Hypercube vs HEVO 200x300 single Z motor

Posted by masterviana

|

Hypercube vs HEVO 200x300 single Z motor December 21, 2019 11:52AM |

Registered: 7 years ago Posts: 47 |

I've already build a version of a hypercube original from tech2c with a 220x220 bed and it's perform great. Now i'm looking for a designer to build a coreXY with 200x300 or a 270x240 (ultrabase bed). And I know that is not a great design to use two dual Z motor to lift the bed, in order avoids the need to re-synchronise the leadscrews after a power cycle or some other syncronise problems. I know its a popular design cbots and hypercube evolution are doing that alot.

So my ideia is keep the design as simple as possible, with one leadscrew pushed by a motor to avoid the belt syncronize system or the dual motor system.

Did you think a hypercube/hypercube evolution with one motor and 2 linear roods with 12mm perform well with a bed of 200x300. It maintain the same Y dimensions i'm only extend the X length.

So my ideia is keep the design as simple as possible, with one leadscrew pushed by a motor to avoid the belt syncronize system or the dual motor system.

Did you think a hypercube/hypercube evolution with one motor and 2 linear roods with 12mm perform well with a bed of 200x300. It maintain the same Y dimensions i'm only extend the X length.

|

Re: Hypercube vs HEVO 200x300 single Z motor January 07, 2020 02:28AM |

Registered: 8 years ago Posts: 9 |

Hello masterviana,

I am also working on the design of a new printer. I've decided to go with the Hypercube evolution, but adapted to make use of a load of parts I have salvaged from a Kossel. I am also a CAD engineer. However with the release to the market of the Ender 5 + the whole project has become a bit moot. And I have absolutely nowhere to put a printer bigger than my Ender 3.

If you go for a single Z motor and belt linking the leadscrews don't forget that a tensioning system will be needed for the belt. I have seen this done and you can still get syncronisation issues between the leadscrews if there is any springiness in the belts. Got caught this way professionally once. I'm intending to go the dual Z motor route myself. Do you know how this is done controls wise? I suspect that the control signals are cloned onto a spare stepper driver for the second Z motor.

I am using 12mm guided rods too. Rods, bearings, and mounts are harder to find than 8mm or 10mm ,but the rigidity will be much higher. Also, I want to go for TR8 x 2 leadscrews rather than the TR8 x 8. This should improve Z accurcy and avoid the bed falling on a power outage problem, without resorting to anti-backlash nuts.

If you want a hand with the design or just someone to bounce ideas off I would be interested.

I am also working on the design of a new printer. I've decided to go with the Hypercube evolution, but adapted to make use of a load of parts I have salvaged from a Kossel. I am also a CAD engineer. However with the release to the market of the Ender 5 + the whole project has become a bit moot. And I have absolutely nowhere to put a printer bigger than my Ender 3.

If you go for a single Z motor and belt linking the leadscrews don't forget that a tensioning system will be needed for the belt. I have seen this done and you can still get syncronisation issues between the leadscrews if there is any springiness in the belts. Got caught this way professionally once. I'm intending to go the dual Z motor route myself. Do you know how this is done controls wise? I suspect that the control signals are cloned onto a spare stepper driver for the second Z motor.

I am using 12mm guided rods too. Rods, bearings, and mounts are harder to find than 8mm or 10mm ,but the rigidity will be much higher. Also, I want to go for TR8 x 2 leadscrews rather than the TR8 x 8. This should improve Z accurcy and avoid the bed falling on a power outage problem, without resorting to anti-backlash nuts.

If you want a hand with the design or just someone to bounce ideas off I would be interested.

|

Re: Hypercube vs HEVO 200x300 single Z motor January 07, 2020 07:30AM |

Registered: 11 years ago Posts: 5,780 |

Single screw lifted Z axis can be done. It's called a cantilevered bed. Most of them are built because people want to reduce cost, so they tend to skimp on the parts that make it stable and the result is the free edge of the bed bounces. Machines built that way have to print slowly to keep the edge of the bed from bouncing so much that it degrades print quality.

The biggest problem is usually the linear guidance. Most people use flexible 8mm end-supported round rods harvested from a junked printer and then skimp on the bearings (they use short ones instead of longer ones), often mounted in a printed plastic bracket and "secured" with zip ties.

What's wrong with synchronizing screws using a belt (other than the cost...)?

You know, filament costs about $20 per kg. When you're calculating the cost of parts for the machine, try thinking in terms of spools of filament. The cost of building it right will suddenly seem cheaper.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

The biggest problem is usually the linear guidance. Most people use flexible 8mm end-supported round rods harvested from a junked printer and then skimp on the bearings (they use short ones instead of longer ones), often mounted in a printed plastic bracket and "secured" with zip ties.

What's wrong with synchronizing screws using a belt (other than the cost...)?

You know, filament costs about $20 per kg. When you're calculating the cost of parts for the machine, try thinking in terms of spools of filament. The cost of building it right will suddenly seem cheaper.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Hypercube vs HEVO 200x300 single Z motor January 07, 2020 09:29AM |

Registered: 12 years ago Posts: 103 |

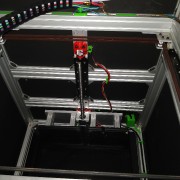

For good cantilever: go BIG and RIGID or don't do it.

I made it big and rigid as possible (see picture) but still not perfect, next printer will be 3 Z.

[ibb.co]

D-BOT custom

HYPERCUBE protocreation

[www.facebook.com]

I made it big and rigid as possible (see picture) but still not perfect, next printer will be 3 Z.

[ibb.co]

D-BOT custom

HYPERCUBE protocreation

[www.facebook.com]

|

Re: Hypercube vs HEVO 200x300 single Z motor January 07, 2020 10:44AM |

Registered: 7 years ago Posts: 47 |

Quote

Seraph1M

Hello masterviana,

I am also working on the design of a new printer. I've decided to go with the Hypercube evolution, but adapted to make use of a load of parts I have salvaged from a Kossel. I am also a CAD engineer. However with the release to the market of the Ender 5 + the whole project has become a bit moot. And I have absolutely nowhere to put a printer bigger than my Ender 3.

If you go for a single Z motor and belt linking the leadscrews don't forget that a tensioning system will be needed for the belt. I have seen this done and you can still get syncronisation issues between the leadscrews if there is any springiness in the belts. Got caught this way professionally once. I'm intending to go the dual Z motor route myself. Do you know how this is done controls wise? I suspect that the control signals are cloned onto a spare stepper driver for the second Z motor.

I am using 12mm guided rods too. Rods, bearings, and mounts are harder to find than 8mm or 10mm ,but the rigidity will be much higher. Also, I want to go for TR8 x 2 leadscrews rather than the TR8 x 8. This should improve Z accurcy and avoid the bed falling on a power outage problem, without resorting to anti-backlash nuts.

If you want a hand with the design or just someone to bounce ideas off I would be interested.

For now on my hypercube I'm using a bed 220x220 and i'm using the 12mm rods with LM12LUU bearing the long version to try increase the stiffness of the bed, my rods are fixed using alu fixes for 12mm not the 3d printed ones, was the designer of printer had used. I'm also using a motor with the screw attach to try avoid issues with couples that sometime are misaligned with screw and could trap you in some z band issues.

In relation with the choice of the pitch and lead of the leadscrew, as far my understanding of that matter the lead are given by the nut not the leadscrew. My screw have 2mm pitch and I could order a nut with 8mm, 4mm and 2mm for Z accuracy I think you need to choice the less lead to give you more resolution in Z. @the_digital_dentist correct me if i'm wrong.

|

Re: Hypercube vs HEVO 200x300 single Z motor January 07, 2020 11:02AM |

Registered: 7 years ago Posts: 47 |

I'd choose cantilevered design instead of dual Z motors, 3 Z motors or synchronize system because It's easy to mount and its my first build of an coreXY machine. Then I've learn with some mistakes in the design time, as you said many parts 3d printed, cheap bearing, not the longer version etc, so I'm try to fix some of that's mistakes and for now I'm pretty happy with the results of that my printer does. The only problem is for scaled to a bigger bed like 300x300.

Designs like HEVO are using dual Z motors run from same motor drive, and I saw some design that are using 3 Z motors, I'd no clue if that 3 motors are running from individual motors drivers or if the signal just came from the same drive. Even you use synchronize belt system you need to make sure that the screws are perfectly aligned in order to avoiding the tilting of the bed. I know that in duet firmware you've have a way to run 3/4 motores from individual drivers and there is a feature to level the bed using these 3 axis, by tilting the bed moving each axid individual so in the beginning of each print you've sure that all the 3 screws are synchronized, for the perfect first layer. As far as I know there is no similar feature on marlin.

Designs like HEVO are using dual Z motors run from same motor drive, and I saw some design that are using 3 Z motors, I'd no clue if that 3 motors are running from individual motors drivers or if the signal just came from the same drive. Even you use synchronize belt system you need to make sure that the screws are perfectly aligned in order to avoiding the tilting of the bed. I know that in duet firmware you've have a way to run 3/4 motores from individual drivers and there is a feature to level the bed using these 3 axis, by tilting the bed moving each axid individual so in the beginning of each print you've sure that all the 3 screws are synchronized, for the perfect first layer. As far as I know there is no similar feature on marlin.

|

Re: Hypercube vs HEVO 200x300 single Z motor January 09, 2020 08:02AM |

Registered: 8 years ago Posts: 9 |

|

Re: Hypercube vs HEVO 200x300 single Z motor January 09, 2020 11:27AM |

Registered: 7 years ago Posts: 47 |

Sorry, only registered users may post in this forum.