COREXY Motion Asymmetry

Posted by johnny49r

|

COREXY Motion Asymmetry February 13, 2020 01:34AM |

Registered: 5 years ago Posts: 3 |

I have built several FDM printers using the COREXY motion system with good success.

I recently decided to try and improve print quality where motion induced artifacts were visible.

I used a typical test cube with letters X Y Z on the sides and top to evaluate improvements (available on Thingiverse).

In looking closer I noticed that a ringing artifact that happened during Y movement was not symmetrical - it was more pronounced on the Y- side of an object.

This seemed very odd until I realized that generally speaking, COREXY construction is not symmetrical.

In a typical COREXY system there are two mirrored belt paths that occupy different levels so they don't conflict. The stepper motor that drives the belt is placed at one end of the belt path so that the motor drives very unequal lengths of belt depending on the direction of motion.

GT2 rubber belts stretch and resonate depending on length and tension which can cause some amount of motion induced 'ringing'. So could the unequal belt length be the cause of my anomaly?

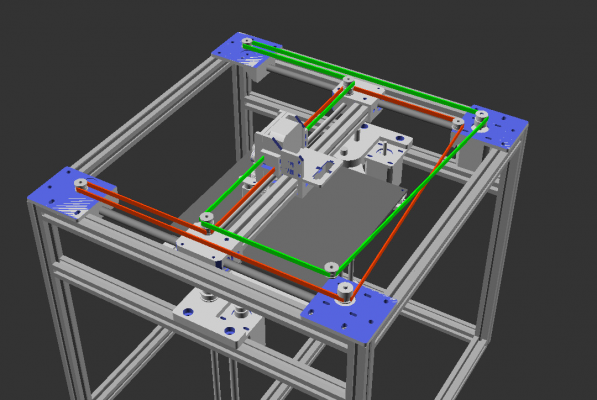

To test this theory I modified a COREXY machine such that the stepper motors were very close to the middle of the belt path. You can see how that is done in this image:

After reprinting the test objects I can see that the asymmetry has been eliminated or dramatically reduced.

This does not improve motion induced artifacts but the asymmetry was not a good thing and I think it is a positive improvement for COREXY mechanics.

I would be very interested to hear your opinions or comments on this subject. Thanks

I recently decided to try and improve print quality where motion induced artifacts were visible.

I used a typical test cube with letters X Y Z on the sides and top to evaluate improvements (available on Thingiverse).

In looking closer I noticed that a ringing artifact that happened during Y movement was not symmetrical - it was more pronounced on the Y- side of an object.

This seemed very odd until I realized that generally speaking, COREXY construction is not symmetrical.

In a typical COREXY system there are two mirrored belt paths that occupy different levels so they don't conflict. The stepper motor that drives the belt is placed at one end of the belt path so that the motor drives very unequal lengths of belt depending on the direction of motion.

GT2 rubber belts stretch and resonate depending on length and tension which can cause some amount of motion induced 'ringing'. So could the unequal belt length be the cause of my anomaly?

To test this theory I modified a COREXY machine such that the stepper motors were very close to the middle of the belt path. You can see how that is done in this image:

After reprinting the test objects I can see that the asymmetry has been eliminated or dramatically reduced.

This does not improve motion induced artifacts but the asymmetry was not a good thing and I think it is a positive improvement for COREXY mechanics.

I would be very interested to hear your opinions or comments on this subject. Thanks

|

Re: COREXY Motion Asymmetry February 13, 2020 06:32AM |

Registered: 11 years ago Posts: 5,780 |

I think you missed something...

When the mechanism moves the extruder in the X direction it moves only the extruder carriage (plus belt and pulleys). When it move the extruder in the Y direction, it moves the much more massive X axis which includes the extruder carriage.

No amount of playing with belts will eliminate the asymmetry of the moving masses.

The 20mm XYZ cube is almost useless for any sort of calibration because it is too small. The sides are so short that the printer, limited by the acceleration and jerk settings in the firmware, will never achieve the print speed set in the slicer.

Photos of the prints would be helpful here...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

When the mechanism moves the extruder in the X direction it moves only the extruder carriage (plus belt and pulleys). When it move the extruder in the Y direction, it moves the much more massive X axis which includes the extruder carriage.

No amount of playing with belts will eliminate the asymmetry of the moving masses.

The 20mm XYZ cube is almost useless for any sort of calibration because it is too small. The sides are so short that the printer, limited by the acceleration and jerk settings in the firmware, will never achieve the print speed set in the slicer.

Photos of the prints would be helpful here...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: COREXY Motion Asymmetry February 13, 2020 09:15PM |

Registered: 5 years ago Posts: 3 |

Hi digital dentist,

I do appreciate your comments.

The issue I observed was an asymmetrical artifact that occurs during Y movement. With the classic COREXY layout, if moving in the Y+ direction, both steppers are taking up a much shorter stretch of belt and releasing a much longer stretch of belt. And of course the opposite if moving Y-. My point is that the stepper should ideally drive from the mid point in the belt path - not offset towards one end. I suppose it was originally done this way as a convenience of design but if you agree with my contention it's not difficult to create a more ideal layout.

Changing stepper location will not do anything to reduce artifacts, but it does reduce or eliminate the asymmetry of the artifact.

This is not a huge deal but why not make a more balanced system if it's not too difficult? On my system I had to move two belt idlers and re-route the belts. I also had to swap X and Y motor connectors on the controller board.

BTW a 20mm cube face is long enough to insure that the gantry has reached full speed (100mm/s in my test case). I had also seen this anomaly on many other prints but had not previously identified the cause.

You are right - I should have provided photos of the artifact. I will have to reproduce on another machine and submit later.

I do appreciate your comments.

The issue I observed was an asymmetrical artifact that occurs during Y movement. With the classic COREXY layout, if moving in the Y+ direction, both steppers are taking up a much shorter stretch of belt and releasing a much longer stretch of belt. And of course the opposite if moving Y-. My point is that the stepper should ideally drive from the mid point in the belt path - not offset towards one end. I suppose it was originally done this way as a convenience of design but if you agree with my contention it's not difficult to create a more ideal layout.

Changing stepper location will not do anything to reduce artifacts, but it does reduce or eliminate the asymmetry of the artifact.

This is not a huge deal but why not make a more balanced system if it's not too difficult? On my system I had to move two belt idlers and re-route the belts. I also had to swap X and Y motor connectors on the controller board.

BTW a 20mm cube face is long enough to insure that the gantry has reached full speed (100mm/s in my test case). I had also seen this anomaly on many other prints but had not previously identified the cause.

You are right - I should have provided photos of the artifact. I will have to reproduce on another machine and submit later.

|

Re: COREXY Motion Asymmetry February 16, 2020 09:35PM |

Registered: 7 years ago Posts: 249 |

It's recommended that you get 180 degree of belt loop on driven pulleys, to prevent tooth skipping under load, especially during accel/decel.

CoreXYU better balances the loads, not perfect, but does give you a second X carriage to play with.

You can find the math here: Hlidskjalf CoreXYU

CoreXYU better balances the loads, not perfect, but does give you a second X carriage to play with.

You can find the math here: Hlidskjalf CoreXYU

|

Re: COREXY Motion Asymmetry February 18, 2020 02:05AM |

Registered: 5 years ago Posts: 3 |

I agree that the belt should use a 180 deg wrap but for sake of a quick experiment I used 90 deg.

So far so good, it runs nicely and I managed to shave a bit off the belt length. I haven't observed any skipping and I think that would occur if the belt tension was low.

Now I'm on to making the cube frame more rigid as I suspect its not as good as it could be.

Thanks, John

So far so good, it runs nicely and I managed to shave a bit off the belt length. I haven't observed any skipping and I think that would occur if the belt tension was low.

Now I'm on to making the cube frame more rigid as I suspect its not as good as it could be.

Thanks, John

Sorry, only registered users may post in this forum.