|

Which Model as Basis for Rebuild March 04, 2020 01:20PM |

Registered: 4 years ago Posts: 17 |

Hello All,

I am looking to build a fast corexy machine and thought I would start with an existing unit for the first try/testbed.

Here are three potential options - what do you think?

TIA

I am looking to build a fast corexy machine and thought I would start with an existing unit for the first try/testbed.

Here are three potential options - what do you think?

TIA

|

Re: Which Model as Basis for Rebuild March 04, 2020 01:49PM |

Registered: 10 years ago Posts: 651 |

1 isn't a CoreXY. The X axis motor is mounted on the Y gantry, so there's that additional mass there that is going to limit your speed/quality. Can't really tell if 2 or 3 are CoreXY, looks like 2 might be.

Between 2 and 3. Can't really see how 2 is constructed. Though it does appear at least at the top there's no supporting structure. Looks like it's acrylic attached to the vertical extrusions (I don't see any horizontal frame members)

I'd go with 3, but trash those corner braces and attach the extrusions directly together, providing they're cut square enough.

My 3D Printing YouTube Channel

Better Living Through 3D Printing

Follow me on Instagram and Twitter

Instagram

Twitter

Between 2 and 3. Can't really see how 2 is constructed. Though it does appear at least at the top there's no supporting structure. Looks like it's acrylic attached to the vertical extrusions (I don't see any horizontal frame members)

I'd go with 3, but trash those corner braces and attach the extrusions directly together, providing they're cut square enough.

My 3D Printing YouTube Channel

Better Living Through 3D Printing

Follow me on Instagram and Twitter

|

Re: Which Model as Basis for Rebuild March 04, 2020 04:10PM |

Registered: 4 years ago Posts: 17 |

Quote

blt3dp

1 isn't a CoreXY. The X axis motor is mounted on the Y gantry, so there's that additional mass there that is going to limit your speed/quality. Can't really tell if 2 or 3 are CoreXY, looks like 2 might be.

Between 2 and 3. Can't really see how 2 is constructed. Though it does appear at least at the top there's no supporting structure. Looks like it's acrylic attached to the vertical extrusions (I don't see any horizontal frame members)

I'd go with 3, but trash those corner braces and attach the extrusions directly together, providing they're cut square enough.

Thank you.

I knew 1 wasn't a corexy, but thought it looked well made and wondered about a conversion. It probably makes more sense, as you say, to look at corexy machines to start.

|

Re: Which Model as Basis for Rebuild March 04, 2020 04:22PM |

Registered: 5 years ago Posts: 30 |

Do you understand how a core xy works? If so, none of those models will help you as a guide. You're going to end up designing your own thing.

IF you don't understand how a core xy works, just stop and do some research. The first isn't a core xy. The other two have some 'interesting' design choices.

IF you don't understand how a core xy works, just stop and do some research. The first isn't a core xy. The other two have some 'interesting' design choices.

|

Re: Which Model as Basis for Rebuild March 04, 2020 05:59PM |

Registered: 11 years ago Posts: 5,780 |

If you're shopping specifically for a corexy machine, be sure to look carefully at how the XY belts are routed. Many hobbyists and even some commercial printer makers get it wrong. If you can't see the belt layout, don't buy/build it!

If you use a screw to lift the Z axis, how do you position the screw? You put it parallel to the Z axis guide rails. Why? because if you don't, it won't work right. When you tell it to move a specific amount, it will move some other amount, until it binds and stops moving altogether.

Belts are similar. They have to be positioned parallel to the guide rails or you won't get the commanded amount of movement - i.e. prints will be distorted.

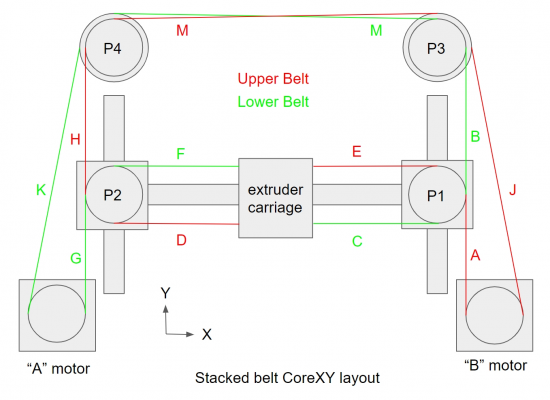

This diagram shows one way of laying out the belts in a corexy mechanism. There are variations in motor position, number of pulleys, etc., but in any of the variations, segments labeled A-H must be kept parallel to the X and Y guide rails.

In a corexy mechanism, the X and Y axes are kept square by the belt tension. If you don't position segments A-H parallel to the guide rails, the belt tension will vary depending on the position of the extruder carriage in the XY plane. That means the squareness of the axes will vary. That means you will get distorted prints and the nature of the distortion will vary depending on the XY position of the print on the bed. Near the center of the bed distortion is usually smaller, near the corners of the bed it gets worse. If you see clothespin spring belt tensioners (or any other spring loaded tensioner) on a corexy mechanism it is most likely because the belts are not properly positioned in relation to the guide rails. In a properly laid out corexy mechanism, the belt tension doesn't vary as the extruder moves in the XY plane, and the X and Y axes remain square. More info here.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

If you use a screw to lift the Z axis, how do you position the screw? You put it parallel to the Z axis guide rails. Why? because if you don't, it won't work right. When you tell it to move a specific amount, it will move some other amount, until it binds and stops moving altogether.

Belts are similar. They have to be positioned parallel to the guide rails or you won't get the commanded amount of movement - i.e. prints will be distorted.

This diagram shows one way of laying out the belts in a corexy mechanism. There are variations in motor position, number of pulleys, etc., but in any of the variations, segments labeled A-H must be kept parallel to the X and Y guide rails.

In a corexy mechanism, the X and Y axes are kept square by the belt tension. If you don't position segments A-H parallel to the guide rails, the belt tension will vary depending on the position of the extruder carriage in the XY plane. That means the squareness of the axes will vary. That means you will get distorted prints and the nature of the distortion will vary depending on the XY position of the print on the bed. Near the center of the bed distortion is usually smaller, near the corners of the bed it gets worse. If you see clothespin spring belt tensioners (or any other spring loaded tensioner) on a corexy mechanism it is most likely because the belts are not properly positioned in relation to the guide rails. In a properly laid out corexy mechanism, the belt tension doesn't vary as the extruder moves in the XY plane, and the X and Y axes remain square. More info here.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Which Model as Basis for Rebuild March 04, 2020 07:03PM |

Registered: 4 years ago Posts: 17 |

Quote

boredom.is.me

Do you understand how a core xy works? If so, none of those models will help you as a guide. You're going to end up designing your own thing.

IF you don't understand how a core xy works, just stop and do some research. The first isn't a core xy. The other two have some 'interesting' design choices.

Yes, as was discussed above, #1 is not a corexy machine.

Do you have any suggestions for models that don't have any 'interesting" features?

Edited 1 time(s). Last edit at 03/04/2020 07:03PM by Doppler9000.

|

Re: Which Model as Basis for Rebuild March 04, 2020 07:08PM |

Registered: 4 years ago Posts: 17 |

Thank you - I am reading through your blog in my spare time. Thank you for publishing such a great resource.

Are you aware of any Chinese offerings that follow reasonable design and build practices?

Or, any that are structurally sound and could be the frame and guts of a build?

I am not in a position right now to build from scratch, unfortunately.

Are you aware of any Chinese offerings that follow reasonable design and build practices?

Or, any that are structurally sound and could be the frame and guts of a build?

I am not in a position right now to build from scratch, unfortunately.

Quote

the_digital_dentist

If you're shopping specifically for a corexy machine, be sure to look carefully at how the XY belts are routed. Many hobbyists and even some commercial printer makers get it wrong. If you can't see the belt layout, don't buy/build it!

If you use a screw to lift the Z axis, how do you position the screw? You put it parallel to the Z axis guide rails. Why? because if you don't, it won't work right. When you tell it to move a specific amount, it will move some other amount, until it binds and stops moving altogether.

Belts are similar. They have to be positioned parallel to the guide rails or you won't get the commanded amount of movement - i.e. prints will be distorted.

This diagram shows one way of laying out the belts in a corexy mechanism. There are variations in motor position, number of pulleys, etc., but in any of the variations, segments labeled A-H must be kept parallel to the X and Y guide rails.

In a corexy mechanism, the X and Y axes are kept square by the belt tension. If you don't position segments A-H parallel to the guide rails, the belt tension will vary depending on the position of the extruder carriage in the XY plane. That means the squareness of the axes will vary. That means you will get distorted prints and the nature of the distortion will vary depending on the XY position of the print on the bed. Near the center of the bed distortion is usually smaller, near the corners of the bed it gets worse. If you see clothespin spring belt tensioners (or any other spring loaded tensioner) on a corexy mechanism it is most likely because the belts are not properly positioned in relation to the guide rails. In a properly laid out corexy mechanism, the belt tension doesn't vary as the extruder moves in the XY plane, and the X and Y axes remain square. More info here.

|

Re: Which Model as Basis for Rebuild March 05, 2020 06:04AM |

Registered: 11 years ago Posts: 5,780 |

I don't generally follow the hobby 3D printer market except to add to my collection of errors when I happen to see one.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Which Model as Basis for Rebuild March 05, 2020 01:18PM |

Registered: 11 years ago Posts: 1,049 |

ReBuild?

What is being rebuilt?

What existing parts must you reuse?

What are your NEW requirements?

I have been in search of what factors are important for a good printer?

I am amazed at the performance of the CR-10 I purchased

and just can't figure out what they did right to make a great 3D printer?

What is being rebuilt?

What existing parts must you reuse?

What are your NEW requirements?

I have been in search of what factors are important for a good printer?

I am amazed at the performance of the CR-10 I purchased

and just can't figure out what they did right to make a great 3D printer?

|

Re: Which Model as Basis for Rebuild March 05, 2020 05:27PM |

Registered: 4 years ago Posts: 17 |

I want to improve/replace the parts that are typically below par on Chinese machines.

Probably add a Duet board, maybe Nimble extruder(s), better hot end.

I want a quiet, fast printer that produces great prints with a variety of materials - still debating the full range of materials I want to accommodate.

Probably add a Duet board, maybe Nimble extruder(s), better hot end.

I want a quiet, fast printer that produces great prints with a variety of materials - still debating the full range of materials I want to accommodate.

Quote

cozmicray

ReBuild?

What is being rebuilt?

What existing parts must you reuse?

What are your NEW requirements?

I have been in search of what factors are important for a good printer?

I am amazed at the performance of the CR-10 I purchased

and just can't figure out what they did right to make a great 3D printer?

|

Re: Which Model as Basis for Rebuild May 30, 2020 06:11PM |

Registered: 7 years ago Posts: 168 |

I'm probably too late here, but I had the same thoughts and was talked out of it. If you'e throwing out all the Chinese running gear to replace it with better quality, you're still fitting that good running gear to a cheap Chinese foundation which quite possibly/likely has design flaws built in.

For a few bucks more I've gone this way:

[www.ratrig.com]

Same as you I'm looking to fit a Duet Wifi/Paneldue/S3D V6 (which I have already) and a Bondtech BMG in direct drive configuration. It's cost me AUD 1k delivered in 400x400x600 size, but so would have a Tronxy S5A.

A square and rigid chassis which is actually designed to some of the relevant engineering principles is 80% of the battle won IMHO.

For a few bucks more I've gone this way:

[www.ratrig.com]

Same as you I'm looking to fit a Duet Wifi/Paneldue/S3D V6 (which I have already) and a Bondtech BMG in direct drive configuration. It's cost me AUD 1k delivered in 400x400x600 size, but so would have a Tronxy S5A.

A square and rigid chassis which is actually designed to some of the relevant engineering principles is 80% of the battle won IMHO.

Quote

Doppler9000

I want to improve/replace the parts that are typically below par on Chinese machines.

Probably add a Duet board, maybe Nimble extruder(s), better hot end.

I want a quiet, fast printer that produces great prints with a variety of materials - still debating the full range of materials I want to accommodate.

Quote

cozmicray

ReBuild?

What is being rebuilt?

What existing parts must you reuse?

What are your NEW requirements?

I have been in search of what factors are important for a good printer?

I am amazed at the performance of the CR-10 I purchased

and just can't figure out what they did right to make a great 3D printer?

|

Re: Which Model as Basis for Rebuild June 14, 2020 01:01PM |

Registered: 9 years ago Posts: 294 |

I keep seeing a lot of designs for CoreXY and have a real issue with all the hardware used. Four smooth rods, linear bearings, large plates to hold everything together for the Z axis. Mine is so simple compared to these and has been solid as a rock.

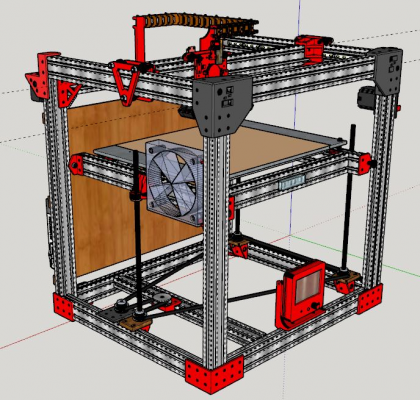

Here is a rendering of my printer that may give you some ideas. The belts/motors are offset to eliminate belt crossover. The belts mostly run inside the V grove rails. Platform is leveled with 3 screws and I can easily get a matrix with 3 point leveling within 0.000100. After that, the adjustment is so small it is hard to implement. The high corner screw is locked down and I adjust the other 2. I also have a nozzle mounted piezo endstop/probe and I can't imagine using anything else. It gives me a 0.002mm std deviation for probe repeatability.

Here is a rendering of my printer that may give you some ideas. The belts/motors are offset to eliminate belt crossover. The belts mostly run inside the V grove rails. Platform is leveled with 3 screws and I can easily get a matrix with 3 point leveling within 0.000100. After that, the adjustment is so small it is hard to implement. The high corner screw is locked down and I adjust the other 2. I also have a nozzle mounted piezo endstop/probe and I can't imagine using anything else. It gives me a 0.002mm std deviation for probe repeatability.

|

Re: Which Model as Basis for Rebuild July 01, 2020 11:56AM |

Registered: 3 years ago Posts: 2 |

Quote

blt3dp

1 isn't a CoreXY. The X axis motor is mounted on the Y gantry, so there's that additional mass there that is going to limit your speed/quality. Can't really tell if 2 or 3 are CoreXY, looks like 2 might be.

Between 2 and 3. Can't really see how 2 is constructed. Though it does appear at least at the top there's no supporting structure. Looks like it's acrylic attached to the vertical extrusions (I don't see any horizontal frame members)

I'd go with 3, but trash those corner braces and attach the extrusions directly together, providing they're cut square enough.

What is the system in model 1, I want to do something like that, but I could not find it. Corexy seems to me inefficient. I can do it in Utimaker, but the system in model 1 makes more sense.

Edited 1 time(s). Last edit at 07/01/2020 11:57AM by M3D.11-09.

|

Re: Which Model as Basis for Rebuild July 01, 2020 12:23PM |

Registered: 3 years ago Posts: 29 |

|

Re: Which Model as Basis for Rebuild July 01, 2020 01:23PM |

Registered: 3 years ago Posts: 2 |

Quote

dustinoff

Quote

M3D.11-09

What is the system in model 1, I want to do something like that, but I could not find it. Corexy seems to me inefficient. I can do it in Utimaker, but the system in model 1 makes more sense.

Just curious as to what you think is inefficient about a coreXY.

The CoreXY is the that long belt length and tension distribution throughout the X & Y axis's the smallest belt flexibility ruins the entire output.

|

Re: Which Model as Basis for Rebuild July 01, 2020 02:07PM |

Registered: 11 years ago Posts: 5,780 |

I don't know what corexy machines you've seen or used, but they are quite capable of delivering high quality prints. There are a LOT of poor builds out there, maybe more with corexy than other cartesian architectures, but it doesn't mean corexy has some inherent problems that other don't. It mostly means that the people building them don't understand how linear motion systems work.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Which Model as Basis for Rebuild July 01, 2020 02:43PM |

Registered: 3 years ago Posts: 29 |

I 2nd DD's comment. The one you see earlier is mine (I modeled it in Sketchup) built from Carl Feniak's post and modified to make narrower and use 3 screws. Now if I could only get PLA to stick to the PEI it would be near perfect. Take another look at it. Belts run mostly in the V channels and they are offset so they do not cross. not much hanging out of the frame except 2 motors and the electronics - all on the back side. It is very solid. No frame movement even though the table shakes.

Those G2 timing belts are pretty solid even for the long span. I see many more posts of print issues with cartesians, Deltas, etc.

Those G2 timing belts are pretty solid even for the long span. I see many more posts of print issues with cartesians, Deltas, etc.

Sorry, only registered users may post in this forum.