Questions about TronXY X5SA

Posted by dlc60

|

Questions about TronXY X5SA April 19, 2020 08:07PM |

Registered: 7 years ago Posts: 619 |

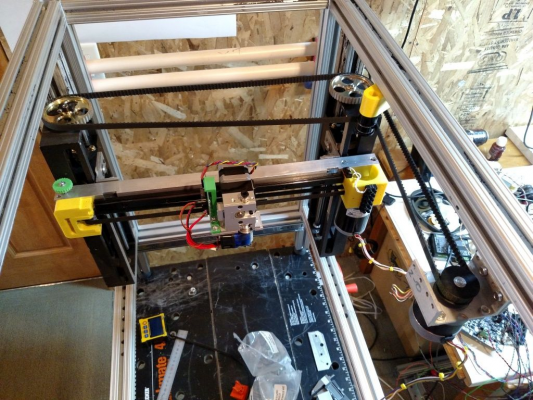

I got a CoreXY kit to learn about corexy and to boost my PPE production for our local Maker group. A lot of this machine is good, solid bones, bolted together, no plastic corner pieces and 99% steel, almost no cut plastic. But there are a few really sucky things about it. Dual Z motors and a gods-forsaken inductive bed sensor instead of a mechanical Z end stop. I don't even know what firmware it is running, it won't tell me and neither will TronXY (so far). It is a 32-bit processor board, but what kind? Dunno - Does anyone out there know? Apparently TronXY changes stuff up fairly often, so it isn't always easy to tell. I have asked these questions below of their tech support, but have not heard back yet.

My next upgrades will be anti-backlash lead screw nuts and an optical Z end-stop. Problem is, I am not sure how the firmware handles just where Z is (there is a way to set the offset, and an interesting "auto level" function, but I don't have any insight into how that works. The rest of this thing is pretty decent. I really need to get this up and working ASAP to print face shield hardware so I'd like the fastest possible way to get it going until I have time to fiddle with correct the junk bits.

For those in the know, is it even possible to put a mechanical end stop on the stock TronXY X5SA Pro controller, or should I just save the pain and install a Duet Maestro that is begging for a printer to control?

Yes, it is not as wonderful as the nice builds out there, but I could get all the pieces in a kit way cheaper than buying ala carte. I like to hack as I learn, so this is a journey. Problem is, this journey is in a hurry with the bad stuff happening all around and kinda need a quick solution to a Z bed that has to be leveled and bed-zeroed after practically every print, which is not terribly convenient...

Many thanks,

Keep safe,

Wash your hands,

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

My next upgrades will be anti-backlash lead screw nuts and an optical Z end-stop. Problem is, I am not sure how the firmware handles just where Z is (there is a way to set the offset, and an interesting "auto level" function, but I don't have any insight into how that works. The rest of this thing is pretty decent. I really need to get this up and working ASAP to print face shield hardware so I'd like the fastest possible way to get it going until I have time to fiddle with correct the junk bits.

For those in the know, is it even possible to put a mechanical end stop on the stock TronXY X5SA Pro controller, or should I just save the pain and install a Duet Maestro that is begging for a printer to control?

Yes, it is not as wonderful as the nice builds out there, but I could get all the pieces in a kit way cheaper than buying ala carte. I like to hack as I learn, so this is a journey. Problem is, this journey is in a hurry with the bad stuff happening all around and kinda need a quick solution to a Z bed that has to be leveled and bed-zeroed after practically every print, which is not terribly convenient...

Many thanks,

Keep safe,

Wash your hands,

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Questions about TronXY X5SA April 20, 2020 12:21AM |

Registered: 7 years ago Posts: 363 |

I mean your answer is to toss in a $130 controller into a $300 printer?

You can get outstanding, reliable results with any widely available board. Then use Klipper, RepRapFirmware (its been ported to at least the LPC series architecture) or Marlin to get out of the closed source malarkey TronXY is pulling.

Hey, it's your cash, the Maestro will certainly do the job and it should at that price but it isn't the only answer to your problem.

Regarding the stock controller, a few pictures of it in high resolution might help.

You can get outstanding, reliable results with any widely available board. Then use Klipper, RepRapFirmware (its been ported to at least the LPC series architecture) or Marlin to get out of the closed source malarkey TronXY is pulling.

Hey, it's your cash, the Maestro will certainly do the job and it should at that price but it isn't the only answer to your problem.

Regarding the stock controller, a few pictures of it in high resolution might help.

|

Re: Questions about TronXY X5SA April 20, 2020 12:52AM |

Registered: 7 years ago Posts: 619 |

Quote

obelisk79

I mean your answer is to toss in a $130 controller into a $300 printer?

You can get outstanding, reliable results with any widely available board. Then use Klipper, RepRapFirmware (its been ported to at least the LPC series architecture) or Marlin to get out of the closed source malarkey TronXY is pulling.

Hey, it's your cash, the Maestro will certainly do the job and it should at that price but it isn't the only answer to your problem.

Regarding the stock controller, a few pictures of it in high resolution might help.

You have a great point. I just happen to have a Duet Maestro without a job at this moment. I also have a Rumba and a Rambo whose printers have said bye bye. I'll save the Duet for my scratch build project that is rather more long term... And yeah, I have only had the TronXY for three days, and I am already sick of the controller. The color touch screen is pretty sweet, and it probably won't work with anything else that I have, even the Duet, so I'll just go with the old full graphics display. (Oh, more like a $400 printer, but your point is still well taken.)

Thanks for the reality check!

DLC

Edited 1 time(s). Last edit at 04/20/2020 12:53AM by dlc60.

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Questions about TronXY X5SA April 20, 2020 09:03AM |

Registered: 11 years ago Posts: 5,780 |

$130 controller in a $300 printer? Why not?

One of the things that makes a crappy $300 printer crappy is the crappy controller that comes with it. A lot of people buy crappy printers thinking they are going to upgrade them into good machines, but if the attitude is that you should only replace a $40 controller with a $50 controller because it's only a $300 printer, you're going to end up with a slightly less crappy machine and no real improvement to show for the extra work and expense. One day, when you decide you've had enough of that crappy printer, which parts will you be reusing in the next, hopefully better machine? The $50 controller, or the $130 controller?

If you've used other controllers and a Duet, you know the difference between compiling firmware to make config changes and simply editing a text file and rebooting, and being able to tweak performance on the fly. How much support can you get for that $40 controller board if you don't speak Chinese?

When you spend money on better stuff, you're not just getting better hardware, you're also buying time and reducing frustration. That's gotta be worth something.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

One of the things that makes a crappy $300 printer crappy is the crappy controller that comes with it. A lot of people buy crappy printers thinking they are going to upgrade them into good machines, but if the attitude is that you should only replace a $40 controller with a $50 controller because it's only a $300 printer, you're going to end up with a slightly less crappy machine and no real improvement to show for the extra work and expense. One day, when you decide you've had enough of that crappy printer, which parts will you be reusing in the next, hopefully better machine? The $50 controller, or the $130 controller?

If you've used other controllers and a Duet, you know the difference between compiling firmware to make config changes and simply editing a text file and rebooting, and being able to tweak performance on the fly. How much support can you get for that $40 controller board if you don't speak Chinese?

When you spend money on better stuff, you're not just getting better hardware, you're also buying time and reducing frustration. That's gotta be worth something.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Questions about TronXY X5SA April 20, 2020 09:31AM |

Registered: 7 years ago Posts: 363 |

I admitted in my response that the Maestro would work well. But in a simple 4 motor printer the benefit really comes from the software and not the hardware of the board itself. Like we discussed in the other thread where I brought up Klipper, it also allows for-on-the fly configuration changes. I seriously dislike firmwares like Marlin if for no other reason than the requirement to reflash to make adjustments to the configuration. Klipper, like RRF only requires simple text file adjustments and a literal 3 second firmware restart for changes to take effect. In some facebook 3d printing communities, I smack my forehead watching people gripe about trying to constantly compile their firmware and mess with configuration header files in VSCode. Who needs that stress? No one does, however Marlin remains the most widely known/recognized/used firmware out there.

DC42 is an awesome engineer, and you are correct that he provides EXCELLENT support, although I've been a bit critical of him self-promoting so hard on this forum in the past. That said, he designs using the 'kitchen sink' approach. Most people just don't need that degree of beastly hardware. The STM32F103 arm processor has enough overhead for probably 99% of hobbyist printers out there, and there are large communities of users who help each other for most of the common chinese boards although I find them incredibly simple to figure out. You could argue there's no engineering like over-engineering but if I was going to spend the extra money on a cheap Chinese printer, I'd look at improving the likely mechanical issues it'll have first.

For example, the TronXY 5SA appears to use the V-Slot linear motion system. It's a surprisingly good system, but the delrin wheels typically fail early and also have flex especially if they are cheap chinese-knockoffs. Upgrading to polycarbonate wheels make a noticeable difference. Changing out the bowden tube for a tighter clearance 1.85/1.9mm tube and looser radius into the hot end or something like the flex3drive would provide a dramatic improvement. Then there are general quality of use comfort features like the cheap fans typically found on these printers that are noisy and make sharing a room with one potentially unpleasant. So, if on a limited budget, some decisions have to be made regarding resource allocation that really depends on the person making those decisions. I think there are valid arguments on both sides of the coin.

Edited 3 time(s). Last edit at 04/20/2020 11:33AM by obelisk79.

DC42 is an awesome engineer, and you are correct that he provides EXCELLENT support, although I've been a bit critical of him self-promoting so hard on this forum in the past. That said, he designs using the 'kitchen sink' approach. Most people just don't need that degree of beastly hardware. The STM32F103 arm processor has enough overhead for probably 99% of hobbyist printers out there, and there are large communities of users who help each other for most of the common chinese boards although I find them incredibly simple to figure out. You could argue there's no engineering like over-engineering but if I was going to spend the extra money on a cheap Chinese printer, I'd look at improving the likely mechanical issues it'll have first.

For example, the TronXY 5SA appears to use the V-Slot linear motion system. It's a surprisingly good system, but the delrin wheels typically fail early and also have flex especially if they are cheap chinese-knockoffs. Upgrading to polycarbonate wheels make a noticeable difference. Changing out the bowden tube for a tighter clearance 1.85/1.9mm tube and looser radius into the hot end or something like the flex3drive would provide a dramatic improvement. Then there are general quality of use comfort features like the cheap fans typically found on these printers that are noisy and make sharing a room with one potentially unpleasant. So, if on a limited budget, some decisions have to be made regarding resource allocation that really depends on the person making those decisions. I think there are valid arguments on both sides of the coin.

Edited 3 time(s). Last edit at 04/20/2020 11:33AM by obelisk79.

|

Re: Questions about TronXY X5SA April 20, 2020 12:27PM |

Registered: 7 years ago Posts: 619 |

Quote

the_digital_dentist

$130 controller in a $300 printer? Why not?

One of the things that makes a crappy $300 printer crappy is the crappy controller that comes with it. A lot of people buy crappy printers thinking they are going to upgrade them into good machines, but if the attitude is that you should only replace a $40 controller with a $50 controller because it's only a $300 printer, you're going to end up with a slightly less crappy machine and no real improvement to show for the extra work and expense. One day, when you decide you've had enough of that crappy printer, which parts will you be reusing in the next, hopefully better machine? The $50 controller, or the $130 controller?

If you've used other controllers and a Duet, you know the difference between compiling firmware to make config changes and simply editing a text file and rebooting, and being able to tweak performance on the fly. How much support can you get for that $40 controller board if you don't speak Chinese?

When you spend money on better stuff, you're not just getting better hardware, you're also buying time and reducing frustration. That's gotta be worth something.

My time IS worth something, which is why I am super close to ditching the TronXY board so that I can customize what I need. I would normally lean towards a Marlin firmware option because I am super familiar with it and how to customize what I specifically want in a controller. I got the Duet board to control a custom corexy system that I have been getting ready to make. Then came "IT", and the world paused, and other things stopped. I am making PPE for our local "Make4Covid" group, along with hundreds of other "Makers", and need to increase my output. This printer has a large bed, is corexy, and fit my budget without being a stupid poor design (not great, just not stupid). But it has problems that I need to solve fast.

So.

A Rumba or Rambo board can solve many of the problems fast, but not all. I'll leave out the details.

My decision will come down to the Duet's ability to solve a key issue: bed leveling. The TronXY X5SA uses two steppers to move the bed in Z axis. I HATE the two stepper approach! This machine has heavy enough hardware that the bed will "sag" unevenly every time that the stepper power is removed, and jerk when it comes on. Meaning that I have to re-level it, and have to rely upon the "auto level" function, after every print. Not optimal. To fix the various problems, I will have to replace the controller and/or create a mechanical feedback mechanism to keep the bed level.

Can the Duet Maestro controller hardware/software, level a bed by moving each stepper (side) independently to its respective zero end-stop? If it can, then I can level the print surface at that time and never worry again.

If not, I'll save the Maestor for my corexy build and put a Marlin-based board in and a mechanical bed sync solution in place. This will take longer, but, I have to change something.

Thanks for any advice everyone, I am listening,

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Questions about TronXY X5SA April 20, 2020 12:30PM |

Registered: 7 years ago Posts: 619 |

Quote

obelisk79

I admitted in my response that the Maestro would work well. But in a simple 4 motor printer the benefit really comes from the software and not the hardware of the board itself. Like we discussed in the other thread where I brought up Klipper, it also allows for-on-the fly configuration changes. I seriously dislike firmwares like Marlin if for no other reason than the requirement to reflash to make adjustments to the configuration. Klipper, like RRF only requires simple text file adjustments and a literal 3 second firmware restart for changes to take effect. In some facebook 3d printing communities, I smack my forehead watching people gripe about trying to constantly compile their firmware and mess with configuration header files in VSCode. Who needs that stress? No one does, however Marlin remains the most widely known/recognized/used firmware out there.

DC42 is an awesome engineer, and you are correct that he provides EXCELLENT support, although I've been a bit critical of him self-promoting so hard on this forum in the past. That said, he designs using the 'kitchen sink' approach. Most people just don't need that degree of beastly hardware. The STM32F103 arm processor has enough overhead for probably 99% of hobbyist printers out there, and there are large communities of users who help each other for most of the common chinese boards although I find them incredibly simple to figure out. You could argue there's no engineering like over-engineering but if I was going to spend the extra money on a cheap Chinese printer, I'd look at improving the likely mechanical issues it'll have first.

For example, the TronXY 5SA appears to use the V-Slot linear motion system. It's a surprisingly good system, but the delrin wheels typically fail early and also have flex especially if they are cheap chinese-knockoffs. Upgrading to polycarbonate wheels make a noticeable difference. Changing out the bowden tube for a tighter clearance 1.85/1.9mm tube and looser radius into the hot end or something like the flex3drive would provide a dramatic improvement. Then there are general quality of use comfort features like the cheap fans typically found on these printers that are noisy and make sharing a room with one potentially unpleasant. So, if on a limited budget, some decisions have to be made regarding resource allocation that really depends on the person making those decisions. I think there are valid arguments on both sides of the coin.

Your input is appreciated, and I am considering all my options.

As I stated in another response, time is of the essence for me and Marlin well understood, but I have some issues that the Duet solution may solve quickly too.

BTW, the X5SA uses metal "V-wheels" on raised rails, not delrin. It should be more reliable. It is a Bowden, but I am used to that system too.

Thanks for your insights,

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Questions about TronXY X5SA April 20, 2020 01:55PM |

Registered: 11 years ago Posts: 5,780 |

Two z axis motors can be handled the way that Prusa does it in the i3.

The Z axis motors lose sync on power-up when they jump. They don't lose sync during a print, or as long as the motors have power. In the Prusa machines, the X axis will tilt, in the Tronxy machine the bed will tilt (roll) when the motors lose sync. Prusa resyncs the motors/Z axis screws by driving the X axis to the Zmax position, essentially forcing it into the mechanical stops at the end of the Z axis. Those stops are positioned so that the X axis is perpendicular to the Z axis when it's jammed against the stops, so moving the X axis back down to print position enables you to print again.

You could do the same in the Tronxy machine- run the bed to the bottom of the Z axis right up against the stops by telling it to go further than the stops. If the stops aren't positioned so they will level out the bed (at least in the roll direction), put in spacers or shims or whatever you need to ensure it will be level when it hits the stops. From there you just move the bed back up to print position. If you don't want it to get noisy when you're leveling the bed, reduce the current to the Z axis motors while you're driving the bed into the stops. You can do that with a macro in RRF on the Duet, called every time the board boots up. I'm not sure how you do that with other boards. There's no need for independent control of the Z axis motors.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

The Z axis motors lose sync on power-up when they jump. They don't lose sync during a print, or as long as the motors have power. In the Prusa machines, the X axis will tilt, in the Tronxy machine the bed will tilt (roll) when the motors lose sync. Prusa resyncs the motors/Z axis screws by driving the X axis to the Zmax position, essentially forcing it into the mechanical stops at the end of the Z axis. Those stops are positioned so that the X axis is perpendicular to the Z axis when it's jammed against the stops, so moving the X axis back down to print position enables you to print again.

You could do the same in the Tronxy machine- run the bed to the bottom of the Z axis right up against the stops by telling it to go further than the stops. If the stops aren't positioned so they will level out the bed (at least in the roll direction), put in spacers or shims or whatever you need to ensure it will be level when it hits the stops. From there you just move the bed back up to print position. If you don't want it to get noisy when you're leveling the bed, reduce the current to the Z axis motors while you're driving the bed into the stops. You can do that with a macro in RRF on the Duet, called every time the board boots up. I'm not sure how you do that with other boards. There's no need for independent control of the Z axis motors.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Questions about TronXY X5SA April 20, 2020 02:06PM |

Registered: 7 years ago Posts: 363 |

|

Re: Questions about TronXY X5SA April 20, 2020 02:45PM |

Registered: 11 years ago Posts: 5,780 |

Yes, of course. Then you'd never have to resync the screws because they'd never lose sync in the first place.

In the bad old days, printers had unflat, often flexible beds, on stupid 4 point mounts (many still do) and you had to keep tweaking the bed manually before every print. Some people got the idea that the solution to the problem was to have the printer do all that tweaking for you, so instead of analyzing why the tweaking was necessary, they just accepted it and started applying one kludge after another.

The purpose of leveling the bed is to ensure the first layer of the print sticks for the duration of the print. It's a reliability issue. You can build the printer so the first layer will stick every time without any screwing around, or you can build it so it has to keep releveling itself and compensating for a bed that isn't flat. Does adding more electronics, motors, and cables increase reliability? Judging by the posts I see in forums like this one, I don't think so. Does it cost less than building the printer so it doesn't need all that stuff? I don't think so. Autotramming and flatness compensation do make for some impressive youtube videos. Printers that "just work" are boring.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

In the bad old days, printers had unflat, often flexible beds, on stupid 4 point mounts (many still do) and you had to keep tweaking the bed manually before every print. Some people got the idea that the solution to the problem was to have the printer do all that tweaking for you, so instead of analyzing why the tweaking was necessary, they just accepted it and started applying one kludge after another.

The purpose of leveling the bed is to ensure the first layer of the print sticks for the duration of the print. It's a reliability issue. You can build the printer so the first layer will stick every time without any screwing around, or you can build it so it has to keep releveling itself and compensating for a bed that isn't flat. Does adding more electronics, motors, and cables increase reliability? Judging by the posts I see in forums like this one, I don't think so. Does it cost less than building the printer so it doesn't need all that stuff? I don't think so. Autotramming and flatness compensation do make for some impressive youtube videos. Printers that "just work" are boring.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Questions about TronXY X5SA April 20, 2020 03:54PM |

Registered: 7 years ago Posts: 619 |

Quote

the_digital_dentist

Two z axis motors can be handled the way that Prusa does it in the i3.

The Z axis motors lose sync on power-up when they jump. They don't lose sync during a print, or as long as the motors have power. In the Prusa machines, the X axis will tilt, in the Tronxy machine the bed will tilt (roll) when the motors lose sync. Prusa resyncs the motors/Z axis screws by driving the X axis to the Zmax position, essentially forcing it into the mechanical stops at the end of the Z axis. Those stops are positioned so that the X axis is perpendicular to the Z axis when it's jammed against the stops, so moving the X axis back down to print position enables you to print again.

You could do the same in the Tronxy machine- run the bed to the bottom of the Z axis right up against the stops by telling it to go further than the stops. If the stops aren't positioned so they will level out the bed (at least in the roll direction), put in spacers or shims or whatever you need to ensure it will be level when it hits the stops. From there you just move the bed back up to print position. If you don't want it to get noisy when you're leveling the bed, reduce the current to the Z axis motors while you're driving the bed into the stops. You can do that with a macro in RRF on the Duet, called every time the board boots up. I'm not sure how you do that with other boards. There's no need for independent control of the Z axis motors.

Ick. That is a 400mm traverse to bottom out the steppers, back and forth 800mm. The steppers are turned off after each print, so the only other thing to worry about is if one side "sags", and then it is re-calibrate all over again. I like the idea of linking the two stepper shafts, kind of a kludge, but DD's Prusa is the only other viable way to assure the level. Just kind of cringe-worthy while the stepper complains.

Hmm,

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Questions about TronXY X5SA April 20, 2020 03:55PM |

Registered: 7 years ago Posts: 619 |

Quote

the_digital_dentist

Yes, of course. Then you'd never have to resync the screws because they'd never lose sync in the first place.

In the bad old days, printers had unflat, often flexible beds, on stupid 4 point mounts (many still do) and you had to keep tweaking the bed manually before every print. Some people got the idea that the solution to the problem was to have the printer do all that tweaking for you, so instead of analyzing why the tweaking was necessary, they just accepted it and started applying one kludge after another.

The purpose of leveling the bed is to ensure the first layer of the print sticks for the duration of the print. It's a reliability issue. You can build the printer so the first layer will stick every time without any screwing around, or you can build it so it has to keep releveling itself and compensating for a bed that isn't flat. Does adding more electronics, motors, and cables increase reliability? Judging by the posts I see in forums like this one, I don't think so. Does it cost less than building the printer so it doesn't need all that stuff? I don't think so. Autotramming and flatness compensation do make for some impressive youtube videos. Printers that "just work" are boring.

I dislike auto-levelers, I level the bed and never think about it again, it isn't all that hard. I may go the path of the linkage between screws, it seems faster and more certain that other methods.

Thanks for the advice!

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Questions about TronXY X5SA April 20, 2020 04:43PM |

Registered: 11 years ago Posts: 5,780 |

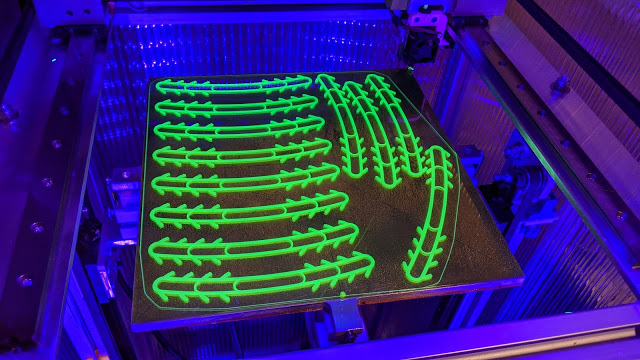

I was running prints of earsavers for local medical people on my printer that doesn't have any autotramming, flatness compensation, or auto zeroing. Just a flat cast tooling plate bed with PEI on a kinematic mount, lifted by two belts driven by one motor.

Look at where the skirt is on the bed. You can print edge to edge without all that other stuff.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Look at where the skirt is on the bed. You can print edge to edge without all that other stuff.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Questions about TronXY X5SA April 20, 2020 05:23PM |

Registered: 7 years ago Posts: 363 |

|

Re: Questions about TronXY X5SA April 20, 2020 05:32PM |

Registered: 7 years ago Posts: 619 |

My "ear savers" we have qualified through local hospitals are straight, but my old Cartesian build plate ends up looking just like yours there.  No auto-level anything, just a flat 5mm aluminum bed, filled nearly to the edge (mechanical limits to reaching the full bed edge).

No auto-level anything, just a flat 5mm aluminum bed, filled nearly to the edge (mechanical limits to reaching the full bed edge).

No cool lighting though...

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

No auto-level anything, just a flat 5mm aluminum bed, filled nearly to the edge (mechanical limits to reaching the full bed edge).

No auto-level anything, just a flat 5mm aluminum bed, filled nearly to the edge (mechanical limits to reaching the full bed edge).No cool lighting though...

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Questions about TronXY X5SA April 20, 2020 05:54PM |

Registered: 11 years ago Posts: 5,780 |

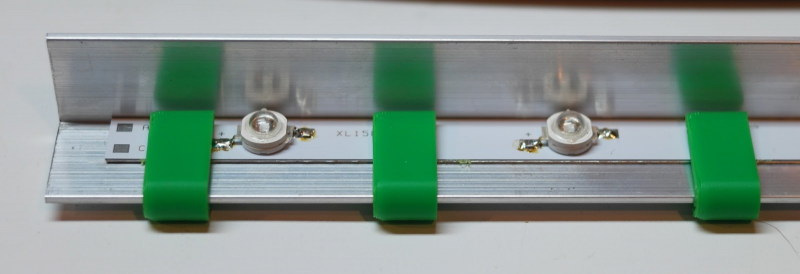

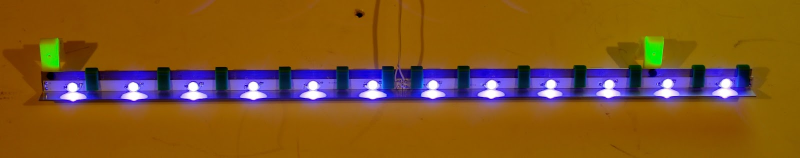

I bought a bunch of 1W UV LEDs and strip-type PCBs, soldered them together, then clipped them to aluminum L stock that serves as heatsink and light baffle.

I made two of those assemblies and installed them on either side of the front door alongside the white LED strips. The printed green brackets snap into the t-slot. I also put a smaller assembly on the top of the printer pointing down on the bed.

Printing a fluorescent TPU vase

More: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I made two of those assemblies and installed them on either side of the front door alongside the white LED strips. The printed green brackets snap into the t-slot. I also put a smaller assembly on the top of the printer pointing down on the bed.

Printing a fluorescent TPU vase

More: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Questions about TronXY X5SA April 21, 2020 03:02AM |

Registered: 6 years ago Posts: 1,007 |

Quote

obelisk79

Couldn't you mechanically link up the two leadscrews with some belt and pulleys and get the same result? It's a bit crude but simple.

If it is simple, it is not crude ! It is the smart way to do it !

I am amazed it is still discussed after so many years !

When you see a machine with two if not three or four leadscrews with their own motor, you know the rest is often over complicated if not blatantly wrong. In any case likely to have problems.

Often solved by additional complexity (eg auto bed leveling (OK for Delta)) introducing their own additional issues.

Plenty of cases just popped up on this forum recently.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Questions about TronXY X5SA April 21, 2020 03:29AM |

Registered: 10 years ago Posts: 14,672 |

Quote

dlc60

Can the Duet Maestro controller hardware/software, level a bed by moving each stepper (side) independently to its respective zero end-stop?

Yes, using either separate endstops or alternatively just the Z probe.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Questions about TronXY X5SA April 21, 2020 07:55AM |

Registered: 7 years ago Posts: 363 |

|

Re: Questions about TronXY X5SA April 21, 2020 08:45AM |

Registered: 6 years ago Posts: 1,007 |

Quote

obelisk79

Quote

MKSA

If it is simple, it is not crude ! It is the smart way to do it !

CRUDE: constructed in a rudimentary way.

Crude still fits. It's a functional, reliable low-tech solution which I use on my own printer.

And what do you consider a high tech, non rudimentary solution then ????

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Questions about TronXY X5SA April 21, 2020 09:32AM |

Registered: 7 years ago Posts: 363 |

Quote

MKSA

And what do you consider a high tech, non rudimentary solution then ????

The unnecessary solutions people use like 2 and 3 motor bed leveling, mesh bed compensation, and quirky bed sensors like bltouch or piezo ones.

Don't take my statements as implying that low-tech is a bad thing. Low tech means simpler, probably more reliable, and most certainly cheaper. But hey, like any other snake-oil solution, 3 motor leveling and automatic mesh compensation using bed sensors looks cool and impresses people to watch. While I'd rather not deal with those types of 'features' personally, they do work for people so I try not to judge.

|

Re: Questions about TronXY X5SA April 21, 2020 10:29AM |

Registered: 6 years ago Posts: 1,007 |

Quote

obelisk79

Quote

MKSA

And what do you consider a high tech, non rudimentary solution then ????

The unnecessary solutions people use like 2 and 3 motor bed leveling, mesh bed compensation, and quirky bed sensors like bltouch or piezo ones.

Don't take my statements as implying that low-tech is a bad thing. Low tech means simpler, probably more reliable, and most certainly cheaper. But hey, like any other snake-oil solution, 3 motor leveling and automatic mesh compensation using bed sensors looks cool and impresses people to watch. While I'd rather not deal with those types of 'features' personally, they do work for people so I try not to judge.

Then instead of low tech, the correct word would be "ingenious" ! The "simple" solution often requires more thinking than the complex, obvious ....ones. Fact is the people going the "complex" route even fail in implementing it while the ingenious could but choose not to implement it. Not to mention arguing that it must be better because it is complex backed with the ultimate argument: "everybody does it" or "it works for me" !

To simplify is a complex process !

Edited 1 time(s). Last edit at 04/21/2020 10:30AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Questions about TronXY X5SA April 21, 2020 01:02PM |

Registered: 7 years ago Posts: 619 |

Quote

MKSA

Quote

obelisk79

Quote

MKSA

And what do you consider a high tech, non rudimentary solution then ????

The unnecessary solutions people use like 2 and 3 motor bed leveling, mesh bed compensation, and quirky bed sensors like bltouch or piezo ones.

Don't take my statements as implying that low-tech is a bad thing. Low tech means simpler, probably more reliable, and most certainly cheaper. But hey, like any other snake-oil solution, 3 motor leveling and automatic mesh compensation using bed sensors looks cool and impresses people to watch. While I'd rather not deal with those types of 'features' personally, they do work for people so I try not to judge.

Then instead of low tech, the correct word would be "ingenious" ! The "simple" solution often requires more thinking than the complex, obvious ....ones. Fact is the people going the "complex" route even fail in implementing it while the ingenious could but choose not to implement it. Not to mention arguing that it must be better because it is complex backed with the ultimate argument: "everybody does it" or "it works for me" !

To simplify is a complex process !

The term "hack" had a brief period of "nerd" respect in the early computer years where the meaning was "an elegant after-market solution to a bug or deficiency"; as in "I needed a printer command so I hacked it into the command interpreter". Before and after that brief period of respect, it just meant "a poor job, or fast and crude".

I guess that I am old fashioned, to me a working mechanical/hardware/software hack, is still a respectable act.

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Questions about TronXY X5SA April 21, 2020 01:04PM |

Registered: 7 years ago Posts: 619 |

Quote

dc42

Quote

dlc60

Can the Duet Maestro controller hardware/software, level a bed by moving each stepper (side) independently to its respective zero end-stop?

Yes, using either separate endstops or alternatively just the Z probe.

Thanks! I thought that it could. My printer uses the dual-stepper approach to raise and lower the bed. I hate that since on power-up, those steppers jump, and bed level goes away.

Appreciated,

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Questions about TronXY X5SA April 21, 2020 02:50PM |

Registered: 7 years ago Posts: 363 |

|

Re: Questions about TronXY X5SA April 21, 2020 10:06PM |

Registered: 6 years ago Posts: 61 |

Wow, coming to this thread late and yet only two days after it started!

Here's my build log of using several parts from my old Tronxy X5S to make something approaching a Real Printer ("Here's a nickel, kid, go buy yourself a real printer" would be the new Dilbert comic I guess?)

[forum.makerforums.info]

I switched to linear rail, aluminum XY motion components, single-motor belt-synchronized single-start Z lead screws, cast toolplate bed on a kinematic mount with 750W keenovo heater behind an SSR and protected by TCO, XCR3D BP6 hotend, aluminum titan clone extruder (planning to move to the bondtech I already bought), SKR mini e3 v1.2 board running Marlin 2, and 24V DC supply, braced with corner mounts to stiffen the frame, and using quality metric hardware to hold it together instead of the junk screws Tronxy shipped. What's left of the Tronxy is the frame (which was nice and square), the Z linear guides, steppers, the transverse Z stage blocks through which the nuts and guide bearings go, and a few wires. Maybe a couple random small pieces. Not much, really.

I'm waiting for my PEI-coated spring-steel bed to make it from China; in the meantime I'm printing on glass. I was going to install a 330mm x 330mm sheet of PEI I bought, but the vendor lied about the size and shipped a 300mm x 300mm sheet and I didn't measure it in time. So I'll use that elsewhere; in the meantime, the glass isn't perfectly flat like the dentist's bed but it's close enough for printing PPE right now.

Basically, it was a starting point for nearly starting over, and it would have been faster in the end to have started with someone else's good design and BOM. But maybe I learned more this way? I had fun.

I'm planning to use the old controller and "heated bed" (that had .35mm difference in height from place to place, it was so badly warped) to make a filament drying oven.

Here's my build log of using several parts from my old Tronxy X5S to make something approaching a Real Printer ("Here's a nickel, kid, go buy yourself a real printer" would be the new Dilbert comic I guess?)

[forum.makerforums.info]

I switched to linear rail, aluminum XY motion components, single-motor belt-synchronized single-start Z lead screws, cast toolplate bed on a kinematic mount with 750W keenovo heater behind an SSR and protected by TCO, XCR3D BP6 hotend, aluminum titan clone extruder (planning to move to the bondtech I already bought), SKR mini e3 v1.2 board running Marlin 2, and 24V DC supply, braced with corner mounts to stiffen the frame, and using quality metric hardware to hold it together instead of the junk screws Tronxy shipped. What's left of the Tronxy is the frame (which was nice and square), the Z linear guides, steppers, the transverse Z stage blocks through which the nuts and guide bearings go, and a few wires. Maybe a couple random small pieces. Not much, really.

I'm waiting for my PEI-coated spring-steel bed to make it from China; in the meantime I'm printing on glass. I was going to install a 330mm x 330mm sheet of PEI I bought, but the vendor lied about the size and shipped a 300mm x 300mm sheet and I didn't measure it in time. So I'll use that elsewhere; in the meantime, the glass isn't perfectly flat like the dentist's bed but it's close enough for printing PPE right now.

Basically, it was a starting point for nearly starting over, and it would have been faster in the end to have started with someone else's good design and BOM. But maybe I learned more this way? I had fun.

I'm planning to use the old controller and "heated bed" (that had .35mm difference in height from place to place, it was so badly warped) to make a filament drying oven.

|

Re: Questions about TronXY X5SA April 22, 2020 12:28AM |

Registered: 7 years ago Posts: 363 |

I'd only argue that the linear rail 'upgrade' was probably unnecessary. V-wheels really are an excellent linear motion system if assembled properly.

You've done a lot to that printer, good stuff, and for what it's worth... Sometimes, I find doing things the hard way rather enjoyable and educational too.

You've done a lot to that printer, good stuff, and for what it's worth... Sometimes, I find doing things the hard way rather enjoyable and educational too.

|

Re: Questions about TronXY X5SA April 22, 2020 12:44AM |

Registered: 7 years ago Posts: 619 |

Quote

obelisk79

I'd only argue that the linear rail 'upgrade' was probably unnecessary. V-wheels really are an excellent linear motion system if assembled properly.

You've done a lot to that printer, good stuff, and for what it's worth... Sometimes, I find doing things the hard way rather enjoyable and educational too.

Yeah, I could drop $3000 on a perfectly put together industrial printer. But what fun is that?

Oh, this kit doesn't have the traditional "V-slot wheels", the wheels have the "V" and they run on rails, rather like a roller coaster. Quite smooth and well tracking. The belts are not perfectly parallel however, in the vertical. They ride up and down their idlers and "gronch" when they reach the rims - I am trying to track down what is making that happen, it would be perfectly silent except for the sounds of the belt teeth "gronching" on the idler rims. After I tie the Z steppers together so they stay in sync, those belts are next. Then... But that will have to wait, I have to crank out more PPE for the foreseeable future.

Still have some Covid butt to kick.

Still have some Covid butt to kick. I plan to heavily modify my X5SA Pro as well. I like to get the kits to get decent "bones" and see how things go together for the first time. Kits allow a certain economy of scale, then I get to hack. I am not am ME, but I am pretty mechanically inclined, and I have EE and CS backgrounds, so I can hack any of the rest of it while I learn my CAD "wings".

In other words, I agree,

DLC

Edited 1 time(s). Last edit at 04/22/2020 12:49AM by dlc60.

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Questions about TronXY X5SA April 22, 2020 10:35PM |

Registered: 3 years ago Posts: 3 |

I have the X5SA and my Z axis has never jumped with power on. Just lucky? After having problems with the bed staying at height with the prox switch and hating the original bed surface, I went with an Anycubic ultrabase and a very sensitive endstop switch. the bed stays put and I don't have to relevel unless there is a crash when I do something stupid.

|

Re: Questions about TronXY X5SA April 22, 2020 11:34PM |

Registered: 6 years ago Posts: 61 |

Quote

obelisk79

I'd only argue that the linear rail 'upgrade' was probably unnecessary. V-wheels really are an excellent linear motion system if assembled properly.

You've done a lot to that printer, good stuff, and for what it's worth... Sometimes, I find doing things the hard way rather enjoyable and educational too.

The wheels that came with the printer were terrible and shed plastic fibers everywhere; they weren't the higher-quality OpenBuilds stuff. I use OpenBuilds v-wheel in my large-format OX router.

The acrylic "supports" that tronxy used for supporting the wheels weren't strong enough to build a good system, and their hotend carriage had no way to set preload for the wheels. It was actually easier for me to design a new motion system on higher-quality chiwin rail than to rebuild it using v-wheel. I might have been able to build something from OpenBuilds plate instead of using linear rail, but it would have been harder to preserve full 330mm X and Y be size in that case, as there's not a lot of extra room in that frame, and I was able to design custom components instead.

But having experienced both, linear rail is an upgrade. I won't have to tweak preload from time to time on the linear rail! I'm happy with my choice.

Edited 1 time(s). Last edit at 04/23/2020 08:24AM by mcdanlj.

Sorry, only registered users may post in this forum.