Intermittant diagonal layer shift, how to diagnose?

Posted by dlc60

|

Intermittant diagonal layer shift, how to diagnose? June 13, 2020 01:43PM |

Registered: 7 years ago Posts: 619 |

I have a scratch built CoreXY that I recently completed. For a couple of weeks it has worked flawlessly, but now I am getting intermittent diagonal layer shifts toward the "X" stepper (the right one looking from the front). I know this is the direction traveled with the X stepper is running and the Y stepper is not. It seems to happen "mostly" on larger models, more compact models 90% of the time will run.

My frame is 300mmx400mm using 37oz.in(26Ncm) 12V 0.4Amp 1.8deg steppers.

Controller: Duet 2 Maestro, running the steppers at 800ma

Acceleration 700mm/s^2

Jerk 10mm/s

Max travel speed 120mm/s (print speed typically under 40mm/s)

I do not think that it is mechanical, I am using a pretty typical (unstacked) CoreXY design, and this is a pretty small printer (200mm bed). Nothing seems to be binding, grinding, catching or skipping when I move it manually. But definitely have heard the "bonking" sound of a stepper balking or a belt skip on a pulley. I don't THINK that my belts are either too tight or too loose, they feel the same as another CoreXY machine that I have. My idlers are free moving and there is nothing, that I can see, that is binding.

CoreXY printers are new to me, I have only had them for the last two months or so. I am not sure where to go to troubleshoot this problem. I have read enough to know that a 45 degree shift to the "back right" means that the "X" stepper is moving when the "Y" stepper is not moving. So, if both steppers should be moving and the "Y" stepper jams, that would shift everything to the diagonal pointing to the "X" stepper. The steppers get a little warm, nothing to worry about. The "bonking" sound sounds like the motor is either balking, or trying to move too fast and the belt is skipping.

Does anyone have a process that they use to troubleshoot this kind of thing? Is my current too low, acceleration too high, steppers too weak, ???

I don't usually start replacing mechanical things when trouble starts, belts, pulleys and motors are really reliable. What are some good steps to take in settings or speeds that can point me to a cause?

EDIT

I increased the current. No effect.

I reduced accel down from 1000mm/s to 200mm/s No effect.

I reduced jerk down from 15mm/s to 5mm/s No effect.

I have slowed my speeds down by 30% No effect.

When I abort the print, I hear the printer "gronk" like a belt skip as it tries, and fails to home X/Y - It never homes X all the way. CORRECTION, it is Y that doesn't home.

So, now I AM thinking something is catching in the mechanical system - Time for a tear-down.

Hmm.

Many thanks,

DLC

Edited 2 time(s). Last edit at 06/14/2020 03:44PM by dlc60.

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

My frame is 300mmx400mm using 37oz.in(26Ncm) 12V 0.4Amp 1.8deg steppers.

Controller: Duet 2 Maestro, running the steppers at 800ma

Acceleration 700mm/s^2

Jerk 10mm/s

Max travel speed 120mm/s (print speed typically under 40mm/s)

I do not think that it is mechanical, I am using a pretty typical (unstacked) CoreXY design, and this is a pretty small printer (200mm bed). Nothing seems to be binding, grinding, catching or skipping when I move it manually. But definitely have heard the "bonking" sound of a stepper balking or a belt skip on a pulley. I don't THINK that my belts are either too tight or too loose, they feel the same as another CoreXY machine that I have. My idlers are free moving and there is nothing, that I can see, that is binding.

CoreXY printers are new to me, I have only had them for the last two months or so. I am not sure where to go to troubleshoot this problem. I have read enough to know that a 45 degree shift to the "back right" means that the "X" stepper is moving when the "Y" stepper is not moving. So, if both steppers should be moving and the "Y" stepper jams, that would shift everything to the diagonal pointing to the "X" stepper. The steppers get a little warm, nothing to worry about. The "bonking" sound sounds like the motor is either balking, or trying to move too fast and the belt is skipping.

Does anyone have a process that they use to troubleshoot this kind of thing? Is my current too low, acceleration too high, steppers too weak, ???

I don't usually start replacing mechanical things when trouble starts, belts, pulleys and motors are really reliable. What are some good steps to take in settings or speeds that can point me to a cause?

EDIT

I increased the current. No effect.

I reduced accel down from 1000mm/s to 200mm/s No effect.

I reduced jerk down from 15mm/s to 5mm/s No effect.

I have slowed my speeds down by 30% No effect.

When I abort the print, I hear the printer "gronk" like a belt skip as it tries, and fails to home X/Y - It never homes X all the way. CORRECTION, it is Y that doesn't home.

So, now I AM thinking something is catching in the mechanical system - Time for a tear-down.

Hmm.

Many thanks,

DLC

Edited 2 time(s). Last edit at 06/14/2020 03:44PM by dlc60.

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Intermittant diagonal layer shift, how to diagnose? June 13, 2020 07:16PM |

Registered: 11 years ago Posts: 5,780 |

Can you post a few pix of the printer and prints?

It sounds like a mechanical problem...

Are you using steel core belts?

Edited 2 time(s). Last edit at 06/13/2020 07:28PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

It sounds like a mechanical problem...

Are you using steel core belts?

Edited 2 time(s). Last edit at 06/13/2020 07:28PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Intermittant diagonal layer shift, how to diagnose? June 14, 2020 11:23AM |

Registered: 9 years ago Posts: 294 |

I also have a scratch built coreXY. The layer shift I was experiencing on mine was a result of missing steps. That was caused by two issues. One was flyback voltage on the steppers that was eliminated with diode blocks obtained from AliExpress. They are cheap and come in different configs. One is a simple plugin under your driver.

The other was a Marlin issue that produced minor shifts that made the walls look rough. It appears to have been solved late last year. If you have not updated to at least 2.0.5 released or a bugfix, you should.

However, with the noise your printer is making and not homing properly, a mechanical issue is a high probability.

The other was a Marlin issue that produced minor shifts that made the walls look rough. It appears to have been solved late last year. If you have not updated to at least 2.0.5 released or a bugfix, you should.

However, with the noise your printer is making and not homing properly, a mechanical issue is a high probability.

|

Re: Intermittant diagonal layer shift, how to diagnose? June 14, 2020 11:28AM |

Registered: 6 years ago Posts: 61 |

I had this in Y instead of X when I made a mistake putting together my pulley stack-up so that aluminum was rubbing on aluminum, and so it was dripping tiny bits of aluminum dust, some of which got into the linear rails and would sometimes jam. For reasons that were never fully clear to me but probably was related to where the stackup was, it only happened in one direction (towards the back). I ended up replacing the rails with higher-quality rails after I fixed the stack and cleaned everything thoroughly, and the problem never returned.

(I ended up replacing all the possibly-damaged bearings in the affected rail with new bearings; the replacements were clearly larger, so then I carefully stoned the rail with diamond and arkansas stones until the new bearings ran smooth. That was useful to me only as an experiment, since it turned out to take several hours and a replacement chiwin rail would have been dozens of dollars. )

)

I was originally concerned that the jammed bearings might have been damaged by being pushed into the carriage or rail when rolling over bits of aluminum. In retrospect, that seems extremely unlikely and it was more likely that if I had thoroughly cleaned out the carriages, rails, and bearings, it would have been fine.

But this left me with three working rails to use to build another printer, so in the end it was a win.

(I ended up replacing all the possibly-damaged bearings in the affected rail with new bearings; the replacements were clearly larger, so then I carefully stoned the rail with diamond and arkansas stones until the new bearings ran smooth. That was useful to me only as an experiment, since it turned out to take several hours and a replacement chiwin rail would have been dozens of dollars.

)

)I was originally concerned that the jammed bearings might have been damaged by being pushed into the carriage or rail when rolling over bits of aluminum. In retrospect, that seems extremely unlikely and it was more likely that if I had thoroughly cleaned out the carriages, rails, and bearings, it would have been fine.

But this left me with three working rails to use to build another printer, so in the end it was a win.

|

Re: Intermittant diagonal layer shift, how to diagnose? June 14, 2020 02:49PM |

Registered: 7 years ago Posts: 619 |

Quote

the_digital_dentist

Can you post a few pix of the printer and prints?

It sounds like a mechanical problem...

Are you using steel core belts?

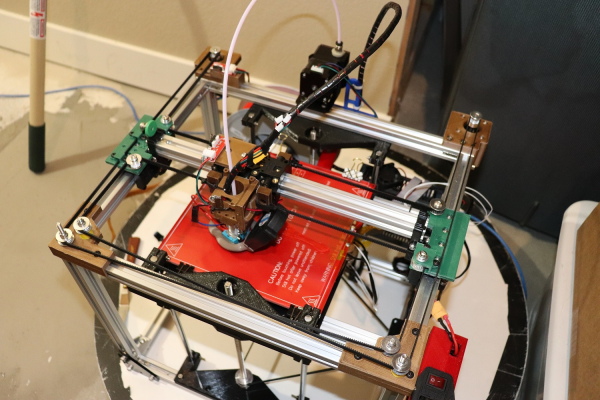

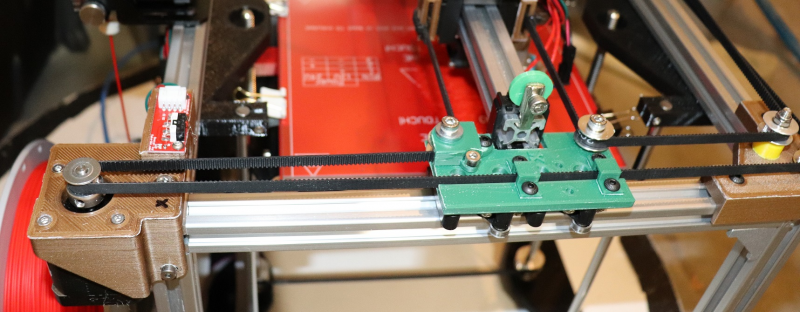

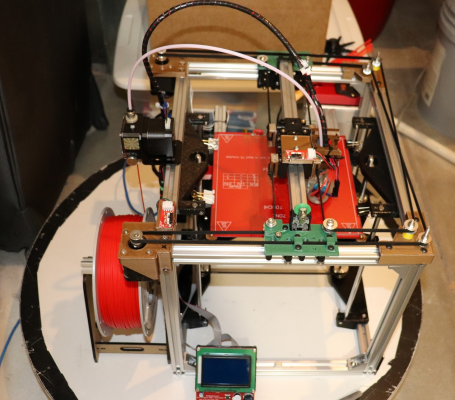

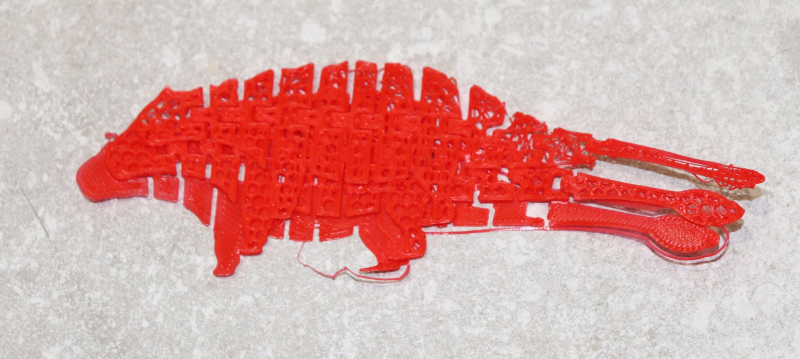

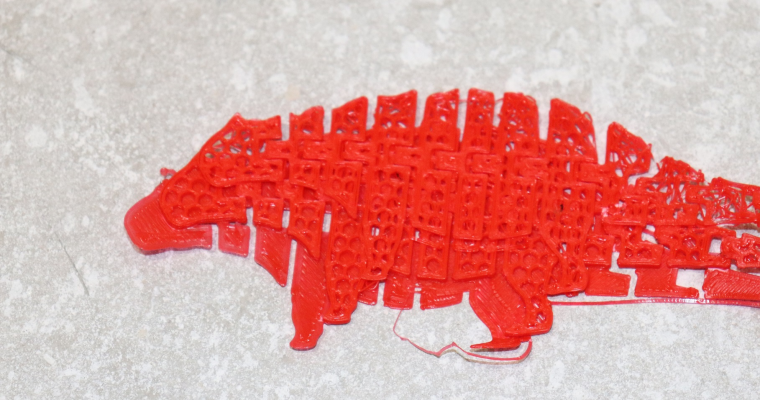

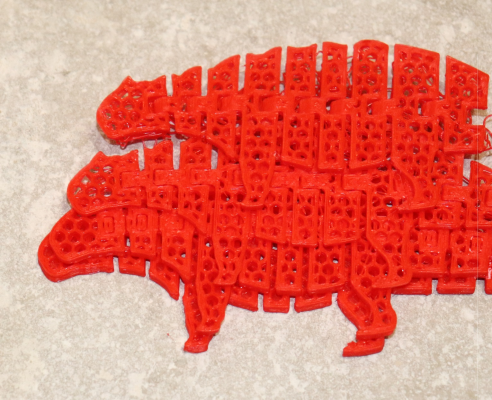

No steel belts, standard fiber/rubber belts. Here are some pics, some of the printer, some of the layer shift fails and one of a perfectly fine print that happened in-between a couple of these fails.

It seems mechanical. When I have had a couple of the layer shifts, and I cancel the print job on the Duet 2 Maestro web interface, the X homes, but the Y "gronches" and does not get home. This latter bit is consistent after several failures. CORRECTION, Y does not home and gronches, X homes.

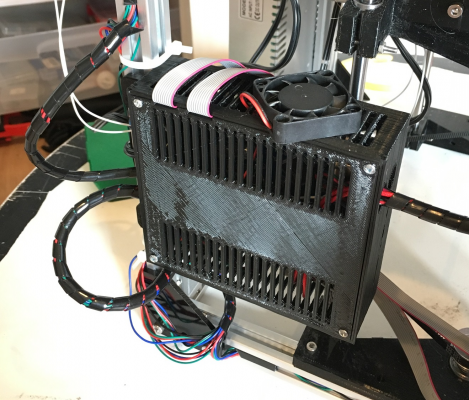

The printer:

Epic fails:

This last print is bent up because I was not patient pulling it from the bed.

A fine print:

The printer worked fine creating head bands for Make4Covid for a week or so, then this happened.

DLC

Edited 2 time(s). Last edit at 06/14/2020 03:45PM by dlc60.

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Intermittant diagonal layer shift, how to diagnose? June 14, 2020 02:57PM |

Registered: 7 years ago Posts: 619 |

Quote

ruggb

I also have a scratch built coreXY. The layer shift I was experiencing on mine was a result of missing steps. That was caused by two issues. One was flyback voltage on the steppers that was eliminated with diode blocks obtained from AliExpress. They are cheap and come in different configs. One is a simple plugin under your driver.

The other was a Marlin issue that produced minor shifts that made the walls look rough. It appears to have been solved late last year. If you have not updated to at least 2.0.5 released or a bugfix, you should.

However, with the noise your printer is making and not homing properly, a mechanical issue is a high probability.

I am using the latest version of reprap firmware on a Duet 2 Maestro. Yes, it is looking highly likely that it is mechanical, and because it looks like the X stepper (left one looking from the front), that seems to be the belt circuit that is in doubt.

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Intermittant diagonal layer shift, how to diagnose? June 14, 2020 03:37PM |

Registered: 9 years ago Posts: 294 |

Just a reminder:

NOTE; the stepper motors on a coreXY are NOT XY. Technically, they should be referred to as AB. It takes BOTH motors to move the head in a straight X or Y direction. One motor running will only move it on the diagonal.

That shift does appear to be a diagonal shift, so it is likely a drive issue on one motor. If I run mine too fast, even though I have 180° wrap on the belt/motor pulley is will skip and my belts are tight.

Edited 1 time(s). Last edit at 06/14/2020 03:41PM by ruggb.

NOTE; the stepper motors on a coreXY are NOT XY. Technically, they should be referred to as AB. It takes BOTH motors to move the head in a straight X or Y direction. One motor running will only move it on the diagonal.

That shift does appear to be a diagonal shift, so it is likely a drive issue on one motor. If I run mine too fast, even though I have 180° wrap on the belt/motor pulley is will skip and my belts are tight.

Edited 1 time(s). Last edit at 06/14/2020 03:41PM by ruggb.

|

Re: Intermittant diagonal layer shift, how to diagnose? June 14, 2020 03:48PM |

Registered: 7 years ago Posts: 619 |

Quote

ruggb

Just a reminder:

NOTE; the stepper motors on a coreXY are NOT XY. Technically, they should be referred to as AB. It takes BOTH motors to move the head in a straight X or Y direction. One motor running will only move it on the diagonal.

That shift does appear to be a diagonal shift, so it is likely a drive issue on one motor. If I run mine too fast, even though I have 180° wrap on the belt/motor pulley is will skip and my belts are tight.

I get that, motion is chorded between the two motors. The only other CoreXY machine that I have labels the steppers X and Y. I don't see a problem with that, Delta's label their steppers X, Y and Z even though that has nothing to do with direction on them either. When you connect to a controller, you connect to X and Y, not A and B. So it makes sense to label them thus.

I agree with you, something on that left stepper is going awry. But not right away, and only, it appears, when long moves are being done.

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Intermittant diagonal layer shift, how to diagnose? June 14, 2020 03:59PM |

Registered: 11 years ago Posts: 5,780 |

I see pulleys held in place with screws. Is there something that stops the screws from squeezing the pulleys too tight so they don't jam? There are usually two tiny ball bearings in the top and bottom of the pulleys. If the mounting screw is too tight, it can squeeze the inner rings of the two bearings towards each other. That puts a huge load on the balls and races and will quickly destroy them. If the suppliers of those pulleys were smart, there would be a metal spacer between the pulley's inner rings that would prevent that problem. This is one reason why I prefer to use flanged ball bearings for pulleys. You can stack them up and put all the pressure you want on the inner rings- they're already butted up against each other so there's no stress on the balls and races.

Another thing to be careful of is that the outer ring of the bearing doesn't rub against the screw head or washer that is holding the pulley in place. With the tiny bearings in 3D printer pulleys you have to be very careful of that, too.

If you pull the belts off and move the mechanism does it move smoothly and easily? Do the pulleys turn smoothly and easily?

Edited 1 time(s). Last edit at 06/14/2020 04:01PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Another thing to be careful of is that the outer ring of the bearing doesn't rub against the screw head or washer that is holding the pulley in place. With the tiny bearings in 3D printer pulleys you have to be very careful of that, too.

If you pull the belts off and move the mechanism does it move smoothly and easily? Do the pulleys turn smoothly and easily?

Edited 1 time(s). Last edit at 06/14/2020 04:01PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Intermittant diagonal layer shift, how to diagnose? June 14, 2020 05:01PM |

Registered: 7 years ago Posts: 619 |

Quote

the_digital_dentist

I see pulleys held in place with screws. Is there something that stops the screws from squeezing the pulleys too tight so they don't jam? There are usually two tiny ball bearings in the top and bottom of the pulleys. If the mounting screw is too tight, it can squeeze the inner rings of the two bearings towards each other. That puts a huge load on the balls and races and will quickly destroy them. If the suppliers of those pulleys were smart, there would be a metal spacer between the pulley's inner rings that would prevent that problem. This is one reason why I prefer to use flanged ball bearings for pulleys. You can stack them up and put all the pressure you want on the inner rings- they're already butted up against each other so there's no stress on the balls and races.

Another thing to be careful of is that the outer ring of the bearing doesn't rub against the screw head or washer that is holding the pulley in place. With the tiny bearings in 3D printer pulleys you have to be very careful of that, too.

If you pull the belts off and move the mechanism does it move smoothly and easily? Do the pulleys turn smoothly and easily?

Yes, I am careful about the idler races - They are tiny. I use nylock nuts, reversed so that the small end of the acorn touches the inner race and totally avoid washers that put both inner and outer races on the same surface. I debated long about what to use for idlers, and was not sure how to get any other kind of idler whose diameters matched the stepper pulleys. On the bottom sides I tapered the plastic surfaces such that they matched the inner race of the idlers.

I have a design question (this printer was put together using spare bits from my printer junk boxes). I have long wondered if there was any problem using smooth idlers that the toothed belt side is in contact with. It seems to me that would cause vibration whereas if I used toothed idlers then everything would be at the correct diameter and "flat" with no vibration. Am I overthinking this? If so, I can use flanged bearings everywhere.

I wrote a bit of g-code that moved the mechanism around at various speeds, did back-n-forth infill type moves and raced from one end of the bed to the other at max move speeds (120mm/s). Everything did fine. I will pop all the belts off and move everything around to see if anything is notching or catching.

I'll report back what I find. Thanks for helping, I really need this machine back on-line. We're trying to fill up that PPE cache in case (or when, depending upon who you listen to) we get another zombie apocalypse spike. And this printer works fabulous, when it works...

Another question, do you think my steppers are too weak? This isn't a big printer, so the 37oz-in steppers _seemed_ to be adequate...

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Intermittant diagonal layer shift, how to diagnose? June 14, 2020 05:34PM |

Registered: 11 years ago Posts: 5,780 |

Those are pretty small steppers. I think I used 64 oz-in steppers, 400 steps/rev, in the XY stage in UMMD. I recently tested some servomotors in the sand table and really liked them, so I'm going to pull them from the sand table and try installing them in UMMD to see how it behaves. The servos are rated for 26 oz-in, but you can't compare that to stepper torque. Servos can deliver much higher peak torque on demand (if your power supply is beefy enough!), and they maintain that torque right up to 3k rpm. In a corexy mechanism, there are a lot of mechanical losses so it's better to oversize the motors than to go too small.

I'm not sure about the belt teeth contacting smooth pulleys- those pulleys are very small diameter so very few teeth will be in contact over a 90 degree wrap. You could twist the belts, if there's a long enough span, so the smooth back sides of the belts ride on the pulleys. With the F608 bearings I used in UMMD, there's no issue of print artifacts from the belt teeth hitting the smooth pulleys. On my sand table I was hearing a lot of zip zip noise from the belts/pulleys but I run that mechanism at 500-1500 mm/sec. Twists in the belts made that noise go away completely.

The pulleys don't have to match the diameter of the drive pulleys, but you do have to keep the belts parallel to the guide rails, so careful lateral placement of pulleys and motors is necessary.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I'm not sure about the belt teeth contacting smooth pulleys- those pulleys are very small diameter so very few teeth will be in contact over a 90 degree wrap. You could twist the belts, if there's a long enough span, so the smooth back sides of the belts ride on the pulleys. With the F608 bearings I used in UMMD, there's no issue of print artifacts from the belt teeth hitting the smooth pulleys. On my sand table I was hearing a lot of zip zip noise from the belts/pulleys but I run that mechanism at 500-1500 mm/sec. Twists in the belts made that noise go away completely.

The pulleys don't have to match the diameter of the drive pulleys, but you do have to keep the belts parallel to the guide rails, so careful lateral placement of pulleys and motors is necessary.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Intermittant diagonal layer shift, how to diagnose? June 14, 2020 05:50PM |

Registered: 7 years ago Posts: 619 |

Quote

the_digital_dentist

Those are pretty small steppers. I think I used 64 oz-in steppers, 400 steps/rev, in the XY stage in UMMD. I recently tested some servomotors in the sand table and really liked them, so I'm going to pull them from the sand table and try installing them in UMMD to see how it behaves. The servos are rated for 26 oz-in, but you can't compare that to stepper torque. Servos can deliver much higher peak torque on demand (if your power supply is beefy enough!), and they maintain that torque right up to 3k rpm. In a corexy mechanism, there are a lot of mechanical losses so it's better to oversize the motors than to go too small.

I'm not sure about the belt teeth contacting smooth pulleys- those pulleys are very small diameter so very few teeth will be in contact over a 90 degree wrap. You could twist the belts, if there's a long enough span, so the smooth back sides of the belts ride on the pulleys. With the F608 bearings I used in UMMD, there's no issue of print artifacts from the belt teeth hitting the smooth pulleys. On my sand table I was hearing a lot of zip zip noise from the belts/pulleys but I run that mechanism at 500-1500 mm/sec. Twists in the belts made that noise go away completely.

The pulleys don't have to match the diameter of the drive pulleys, but you do have to keep the belts parallel to the guide rails, so careful lateral placement of pulleys and motors is necessary.

I have a pretty small span, only about 300mm, so parts are pretty close together, a twist is not a workable solution. However, every kit I have made used smooth idlers on the tooth side. Not that kit makers are paragons of effective engineering, but a couple of those kits have run for years with no discernible print problems... I will probably upgrade to flanged bearings, the cheesy idlers with such tiny ball races worried me. However, this project was to learn about design trade offs on CoreXY printers, with which I have had no experience until recently. I certainly did learn. I can trace a CoreXY belt path in my sleep now.

I wondered about the steppers, you know, junk box engineering doesn't give you a ton of options. The printer ran great for a couple of weeks, just long enough for any mechanical FOOBAR on my part to show up apparently. Because this project worked so well (until now) I am planning a few upgrades to make the frame a little larger, give both-end support to all of the idlers and now perhaps upgrade the stepper stats on X and Y by 50%.

Anyway, I found an idler that was binding and it was on the X stepper belt path, as I have been postulating. I have corrected the problem (spit-ball engineering error) and am running the print that shows maximal errors so I will see pretty quickly if this corrects it. I will report back.

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Intermittant diagonal layer shift, how to diagnose? June 14, 2020 06:52PM |

Registered: 7 years ago Posts: 619 |

Well,

That binding idler may not have been it, because I still have the problem.

I can't find anything clearly wrong with the printer, other than it does this layer shift thing.

Does anyone know, on a Duet 2, when you cancel a printer, does it try to home X/Y or does it just try to home X?

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

That binding idler may not have been it, because I still have the problem.

I can't find anything clearly wrong with the printer, other than it does this layer shift thing.

Does anyone know, on a Duet 2, when you cancel a printer, does it try to home X/Y or does it just try to home X?

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Intermittant diagonal layer shift, how to diagnose? June 14, 2020 07:10PM |

Registered: 9 years ago Posts: 294 |

When I cancel/kill a print it executed the kill command I have programmed into Repetier Host. Otherwise it just stops where it is.

I was questioning what you were saying but figured you knew where it was coming from. I can't speak to a Duet as I have a ramps

Edited 1 time(s). Last edit at 06/14/2020 07:11PM by ruggb.

I was questioning what you were saying but figured you knew where it was coming from. I can't speak to a Duet as I have a ramps

Edited 1 time(s). Last edit at 06/14/2020 07:11PM by ruggb.

|

Re: Intermittant diagonal layer shift, how to diagnose? June 14, 2020 07:17PM |

Registered: 11 years ago Posts: 5,780 |

The behavior that occurs when you hit "pause" depends on the contents of the pause.g configuration file. Likewise if you then hit "cancel", the next behavior will depend on what's in the cancel.g file (if it exists- it might not). If there's no cancel.g, the tools are deselected and heaters turned off.

Edited 1 time(s). Last edit at 06/14/2020 07:30PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Edited 1 time(s). Last edit at 06/14/2020 07:30PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Intermittant diagonal layer shift, how to diagnose? June 14, 2020 09:34PM |

Registered: 7 years ago Posts: 619 |

Quote

the_digital_dentist

The behavior that occurs when you hit "pause" depends on the contents of the pause.g configuration file. Likewise if you then hit "cancel", the next behavior will depend on what's in the cancel.g file (if it exists- it might not). If there's no cancel.g, the tools are deselected and heaters turned off.

Thanks for the hint. There is no pause.g, there is a cancel, and it should home X/Y. When things go south and I cancel the print, Y homes, but X does not complete the home. Hmm. There is a hint there.

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Intermittant diagonal layer shift, how to diagnose? June 14, 2020 09:53PM |

Registered: 9 years ago Posts: 294 |

does it have mechanical endstops?

do you have pullup or pulldowns?

Possibility of noise if the stop point is random

But not homing can't be the same issue that is causing the missing steps.

If it missed steps on a home it should continue till it hit the endstop.

Or do you have some other form of endstop?

do you have pullup or pulldowns?

Possibility of noise if the stop point is random

But not homing can't be the same issue that is causing the missing steps.

If it missed steps on a home it should continue till it hit the endstop.

Or do you have some other form of endstop?

|

Re: Intermittant diagonal layer shift, how to diagnose? June 14, 2020 10:13PM |

Registered: 7 years ago Posts: 619 |

Mechanical endstops.Quote

ruggb

does it have mechanical endstops?

do you have pullup or pulldowns?

Possibility of noise if the stop point is random

But not homing can't be the same issue that is causing the missing steps.

If it missed steps on a home it should continue till it hit the endstop.

Or do you have some other form of endstop?

The end stops are fully powered, and give a digital signal, no passive pullups

stop point is not random, it is always just short of its target

The machine had neither symptom until it had both. This makes it pretty clear that they are related, IMO. But how?

But it doesn't continue hope, it just stops moving.

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Intermittant diagonal layer shift, how to diagnose? June 14, 2020 10:57PM |

Registered: 9 years ago Posts: 294 |

|

Re: Intermittant diagonal layer shift, how to diagnose? June 14, 2020 11:20PM |

Registered: 11 years ago Posts: 5,780 |

You might try posting a message to the Duet3d forums...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Intermittant diagonal layer shift, how to diagnose? June 14, 2020 11:41PM |

Registered: 7 years ago Posts: 619 |

Worth a shot. I am out of ideas.

Thanks,

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Intermittant diagonal layer shift, how to diagnose? June 15, 2020 07:39AM |

Registered: 6 years ago Posts: 61 |

Quote

dlc60

This isn't a big printer, so the 37oz-in steppers _seemed_ to be adequate...

The size of the printer isn't highly relevant to how much torque is needed for XY/AB steppers in your corexy.

One more thought: Have you tried swapping stepper motors between stations and see if the problem follows the stepper or the station? If you swapped X and Y (or A and

and the problem changed direction, you probably have a bad or fouled stepper. You might swap either of them with Z? Or if you have extras lying around, just swap with another one?

and the problem changed direction, you probably have a bad or fouled stepper. You might swap either of them with Z? Or if you have extras lying around, just swap with another one?

|

Re: Intermittant diagonal layer shift, how to diagnose? June 15, 2020 11:05AM |

Registered: 7 years ago Posts: 619 |

Quote

mcdanlj

Quote

dlc60

This isn't a big printer, so the 37oz-in steppers _seemed_ to be adequate...

The size of the printer isn't highly relevant to how much torque is needed for XY/AB steppers in your corexy.

One more thought: Have you tried swapping stepper motors between stations and see if the problem follows the stepper or the station? If you swapped X and Y (or A andand the problem changed direction, you probably have a bad or fouled stepper. You might swap either of them with Z? Or if you have extras lying around, just swap with another one?

I will consider that. In looking back, I think that my problems started when I dressed the cables and mounted the Maestro in this enclosure.

I wonder if some of you have been correct and the problem might be electrical interference since cables go every which way in an enclosure and cable isolation just doesn't happen...

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Intermittant diagonal layer shift, how to diagnose? June 15, 2020 12:25PM |

Registered: 9 years ago Posts: 294 |

noise is going to produce random results.

It is going to affect higher Z circuits like thermistors and endstops not stepper motors.

It will come from stepper motors and fans.

Stepper motor noise can be reduced using flyback diodes, which in my case stopped the layer shift I was having.

Most all boards have filter caps on higher Z circuits, but that didn't help my thermistors when the wires were bundles with the fan wires.

It is going to affect higher Z circuits like thermistors and endstops not stepper motors.

It will come from stepper motors and fans.

Stepper motor noise can be reduced using flyback diodes, which in my case stopped the layer shift I was having.

Most all boards have filter caps on higher Z circuits, but that didn't help my thermistors when the wires were bundles with the fan wires.

|

Re: Intermittant diagonal layer shift, how to diagnose? June 15, 2020 12:44PM |

Registered: 7 years ago Posts: 619 |

Quote

ruggb

noise is going to produce random results.

It is going to affect higher Z circuits like thermistors and endstops not stepper motors.

It will come from stepper motors and fans.

Stepper motor noise can be reduced using flyback diodes, which in my case stopped the layer shift I was having.

Most all boards have filter caps on higher Z circuits, but that didn't help my thermistors when the wires were bundles with the fan wires.

I have scoffed at flyback-diodes as snake oil that only coincidentally fixed things, in the past, having never seen such problems in my systems. If the solution is simple and cheap, I will experiment with them.

The first step is to "undress" certain cable clusters and remove the Maestro from the enclosure and see what happens.

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Intermittant diagonal layer shift, how to diagnose? June 15, 2020 06:12PM |

Registered: 6 years ago Posts: 61 |

Like ruggb, I can't come up for a mental model by which noise would account for precisely this symptom.

I suggest it's just as likely that in bundling everything together, you ended up with an intermittent connection. Connector not quite firmly seated. Wire broken at crimp and only most of the time connecting. Something like that.

Quote

dlc60

I will consider that. In looking back, I think that my problems started when I dressed the cables and mounted the Maestro in this enclosure.

...

I wonder if some of you have been correct and the problem might be electrical interference since cables go every which way in an enclosure and cable isolation just doesn't happen...

I suggest it's just as likely that in bundling everything together, you ended up with an intermittent connection. Connector not quite firmly seated. Wire broken at crimp and only most of the time connecting. Something like that.

|

Re: Intermittant diagonal layer shift, how to diagnose? June 15, 2020 07:10PM |

Registered: 9 years ago Posts: 294 |

the solution is simpler now than it was when I implemented it. It is also very cheap.

For reference when DC is applied or removed from a coil a significant reverse voltage spike is prduced. That spike can fry components, produce extra steps in stepper motors or cause them to miss steps, as it did on my printer. Look at any commercial product driving a relay or other type of coil. There is a diode across the coil. Why it isn't standard for stepper motor, I do not know. Another thing the diodes did was to significantly quiet the steppers.

This is what I used;

[www.aliexpress.com]

This is even simpler; but I didn't find it till after I installed the above.

[www.aliexpress.com]

It mounts under the driver if you have one of these, TMC2100 A4988 Drv8825

I can't vouch for this as I did not order any.

For reference when DC is applied or removed from a coil a significant reverse voltage spike is prduced. That spike can fry components, produce extra steps in stepper motors or cause them to miss steps, as it did on my printer. Look at any commercial product driving a relay or other type of coil. There is a diode across the coil. Why it isn't standard for stepper motor, I do not know. Another thing the diodes did was to significantly quiet the steppers.

This is what I used;

[www.aliexpress.com]

This is even simpler; but I didn't find it till after I installed the above.

[www.aliexpress.com]

It mounts under the driver if you have one of these, TMC2100 A4988 Drv8825

I can't vouch for this as I did not order any.

|

Re: Intermittant diagonal layer shift, how to diagnose? June 15, 2020 11:42PM |

Registered: 7 years ago Posts: 619 |

Quote

ruggb

the solution is simpler now than it was when I implemented it. It is also very cheap.

For reference when DC is applied or removed from a coil a significant reverse voltage spike is prduced. That spike can fry components, produce extra steps in stepper motors or cause them to miss steps, as it did on my printer. Look at any commercial product driving a relay or other type of coil. There is a diode across the coil. Why it isn't standard for stepper motor, I do not know. Another thing the diodes did was to significantly quiet the steppers.

This is what I used;

[www.aliexpress.com]

This is even simpler; but I didn't find it till after I installed the above.

[www.aliexpress.com]

It mounts under the driver if you have one of these, TMC2100 A4988 Drv8825

I can't vouch for this as I did not order any.

I am using a Duet 2 Maestro, no stepstick drivers, so the second one won't fit. I don't believe that second one will do anything at all because stepper drivers have clamping diodes incorporated into their outputs. Maybe these "flyback" diodes prevent inductive spikes being generated in our admittedly long stepper wires? I am still thinking these are snake-oil You would use free-wheeling diodes for unipolar steppers as a snubber, but not for a bipolar stepper like we use.

Hmm. I am unconvinced, but may try this dodge if I cannot find anything else wrong.

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Intermittant diagonal layer shift, how to diagnose? June 15, 2020 11:44PM |

Registered: 7 years ago Posts: 619 |

Quote

mcdanlj

Like ruggb, I can't come up for a mental model by which noise would account for precisely this symptom.

Quote

dlc60

I will consider that. In looking back, I think that my problems started when I dressed the cables and mounted the Maestro in this enclosure.

...

I wonder if some of you have been correct and the problem might be electrical interference since cables go every which way in an enclosure and cable isolation just doesn't happen...

I suggest it's just as likely that in bundling everything together, you ended up with an intermittent connection. Connector not quite firmly seated. Wire broken at crimp and only most of the time connecting. Something like that.

Occam's razor says your simpler explanation is most likely correct. Time to check connections. My steppers are hard-wired, so no connector at the motors.

Cracking knuckles...

DLC

|

Re: Intermittant diagonal layer shift, how to diagnose? June 16, 2020 02:02AM |

Registered: 10 years ago Posts: 14,672 |

I agree, the most likely explanation is a bad connection somewhere. Most likely a crimp connection, but I once saw and instance of one of the pins of the motor connector not being properly soldered to the PCB. Also possible, but unlikely, is a bad solder joint between the driver chip and the PCB.

Are you using all 5 drivers? If not then you could rule out the driver by reassigning that motor to the spare driver.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Are you using all 5 drivers? If not then you could rule out the driver by reassigning that motor to the spare driver.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Sorry, only registered users may post in this forum.