New CoreXY build motor issues

Posted by Waldorfian

|

New CoreXY build motor issues August 17, 2020 10:57AM |

Registered: 3 years ago Posts: 12 |

Hello everyone!

I'm new here and I hope this is the place I should post build issues for my corexy machine.

I have it completely assembled and I'm working on the motion of my axes. I noticed that while using Pronterface that the motors act strangely. I am using a RAMPS 1.4 board with an Arduino Mega 2560. The stepper drivers are A4988. The motors will move but they bind up eventually and just hum. I thought maybe the current was set too low so I adjusted the drivers using the potentiometer to a higher current. I tried increasing the current a number of times but it doesn't improve. Then I thought, maybe the marlin config (1.1.9) is messed up and the homing is set to the center of the bed preventing movement past that point. If I try to home it, the axes travel to the ends then keep grinding.

Anyway, if anyone can give me some ideas I would really appreciate it.

I'm new here and I hope this is the place I should post build issues for my corexy machine.

I have it completely assembled and I'm working on the motion of my axes. I noticed that while using Pronterface that the motors act strangely. I am using a RAMPS 1.4 board with an Arduino Mega 2560. The stepper drivers are A4988. The motors will move but they bind up eventually and just hum. I thought maybe the current was set too low so I adjusted the drivers using the potentiometer to a higher current. I tried increasing the current a number of times but it doesn't improve. Then I thought, maybe the marlin config (1.1.9) is messed up and the homing is set to the center of the bed preventing movement past that point. If I try to home it, the axes travel to the ends then keep grinding.

Anyway, if anyone can give me some ideas I would really appreciate it.

|

Re: New CoreXY build motor issues August 17, 2020 12:43PM |

Registered: 11 years ago Posts: 5,780 |

Is this a custom design/build or was it pulled from thingiverse ro similar repository? How is the belt tension?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: New CoreXY build motor issues August 17, 2020 12:43PM |

Admin Registered: 11 years ago Posts: 3,096 |

Do you have cooling fins on your stepper drivers? It can be the drivers overheating and cutting out. This may happen when the current is set to high. Then they cool down and start moving again, when they reach a thermal equilibrium almost they keep cooling down and moving again in cycles more like microseconds so it may come across as if they stop moving because they immediately overheat when they start moving again. This could be one of the options.

http://www.marinusdebeer.nl/

http://www.marinusdebeer.nl/

|

Re: New CoreXY build motor issues August 17, 2020 01:08PM |

Registered: 3 years ago Posts: 12 |

I was building it similar to this: [axelsdiy.brinkeby.se]

Unfortunately, he isn't willing to share anything other than those pics and a brief description of some of the hardware.

The belts are tight but not to tight. I can manually move the axes by tugging on the belts.

Unfortunately, he isn't willing to share anything other than those pics and a brief description of some of the hardware.

The belts are tight but not to tight. I can manually move the axes by tugging on the belts.

|

Re: New CoreXY build motor issues August 17, 2020 01:13PM |

Registered: 3 years ago Posts: 12 |

I currently don't have a fan on the stepper drivers as the RAMPS/Arduino is currently outside the frame as I tinker with the stepper drivers and other wiring. I increased the current from approximately .685 to 1.115 or so. It didn't change how it operated. I guess I need to try much lower current. Could that over set current account for the buzzing after a movement is requested? Thanks for your reply.

|

Re: New CoreXY build motor issues August 17, 2020 02:51PM |

Registered: 11 years ago Posts: 5,780 |

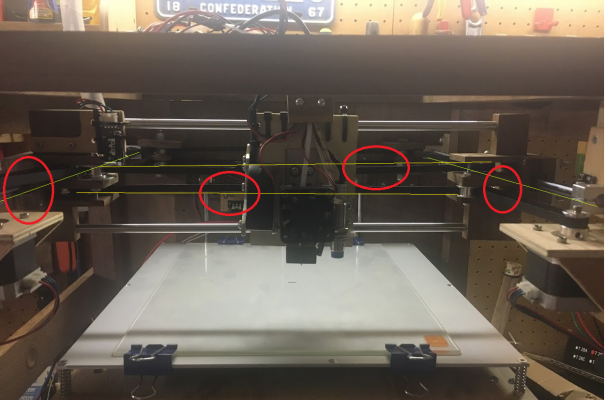

One common problem with corexy designs is that the pulleys aren't positioned correctly which means the belts will not be positioned correctly. The belts must be kept parallel to the guide rails. If they are off by much, you'll find the belt tension varies with the position of the extruder carriage in XY space. In some extreme cases I have seen, the belts can become so loose that the drive pulleys slip in some XY positions, and so tight that the mechanism binds in other positions. More on the topic here: [drmrehorst.blogspot.com]

Edited 1 time(s). Last edit at 08/18/2020 12:09AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Edited 1 time(s). Last edit at 08/18/2020 12:09AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: New CoreXY build motor issues August 17, 2020 06:30PM |

Admin Registered: 11 years ago Posts: 3,096 |

Would you be able to make a video and some photo's of your build and a video of the binding? It would help a great deal to pinpoint the issue.

http://www.marinusdebeer.nl/

http://www.marinusdebeer.nl/

|

Re: New CoreXY build motor issues August 18, 2020 10:00AM |

Registered: 3 years ago Posts: 12 |

Quote

Ohmarinus

Would you be able to make a video and some photo's of your build and a video of the binding? It would help a great deal to pinpoint the issue.

I created a Google Photos album since the video was too large (file size) to upload.

Waldorfian's 3D printer images

|

Re: New CoreXY build motor issues August 18, 2020 10:09AM |

Admin Registered: 11 years ago Posts: 3,096 |

Alright, my first advice would be to move the machine through a host program via usb. This makes movement much smoother. It could be too high feedrate or acceleration settings as well. Furthermore you can already see the top belt on the right side of the X-carriage isn't coming straight out of the carriage. Can it be the belt paths aren't straight?

Also indeed sounds like the motors are skipping steps due too too much torque needing to be applied.

http://www.marinusdebeer.nl/

Also indeed sounds like the motors are skipping steps due too too much torque needing to be applied.

http://www.marinusdebeer.nl/

|

Re: New CoreXY build motor issues August 18, 2020 10:14AM |

Registered: 3 years ago Posts: 12 |

Quote

Ohmarinus

Alright, my first advice would be to move the machine through a host program via usb. This makes movement much smoother. It could be too high feedrate or acceleration settings as well. Furthermore you can already see the top belt on the right side of the X-carriage isn't coming straight out of the carriage. Can it be the belt paths aren't straight?

Also indeed sounds like the motors are skipping steps due too too much torque needing to be applied.

Normally, I use Pronterface on my laptop via USB but the LCD was easier for me while filming. Ya, I had other comments about the importance of Corexy belt angles. I was trying to use handmade wooden connectors instead of paying for a 3D printed set. I figured, if I could get this working, I could print my own parts and improve the printer as I went along. I don't own another 3D printer obviously.

|

Re: New CoreXY build motor issues August 18, 2020 12:41PM |

Registered: 11 years ago Posts: 5,780 |

Driving a printer via USB is so 2010s...

It's much better to use an SD card- far more reliable than a USB connection to a laptop.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

It's much better to use an SD card- far more reliable than a USB connection to a laptop.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: New CoreXY build motor issues August 18, 2020 12:55PM |

Registered: 3 years ago Posts: 12 |

|

Re: New CoreXY build motor issues August 18, 2020 03:04PM |

Registered: 11 years ago Posts: 5,780 |

For testing do whatever you need to get things working. Disconnect the belts and try driving the motors and see if they turn properly. If not, the problem isn't just the load on the motors.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: New CoreXY build motor issues August 19, 2020 11:33AM |

Registered: 3 years ago Posts: 12 |

Quote

the_digital_dentist

For testing do whatever you need to get things working. Disconnect the belts and try driving the motors and see if they turn properly. If not, the problem isn't just the load on the motors.

I tested the motors again without the belts and they don't seem to buzz or lockup. It must be something to do with the belt load/tension or the belt path.

|

Re: New CoreXY build motor issues August 22, 2020 05:03AM |

Registered: 3 years ago Posts: 11 |

" It must be something to do with the belt load/tension or the belt path"

That could well be but I would looking to make sure the bearings and shafts are also sliding and working together smoothly. With timber and how humidity affects it so easily I would be surprised if you could get any reliable results at all. The way the end grain runs and all sorts of issues could be there to find. With the belts not connected does it move easily and smoothly?If not look at your shaft alignments and bearings. With the belts connected does it still move smoothly when pulled by hand? If not then your belt paths need aligning better.

That could well be but I would looking to make sure the bearings and shafts are also sliding and working together smoothly. With timber and how humidity affects it so easily I would be surprised if you could get any reliable results at all. The way the end grain runs and all sorts of issues could be there to find. With the belts not connected does it move easily and smoothly?If not look at your shaft alignments and bearings. With the belts connected does it still move smoothly when pulled by hand? If not then your belt paths need aligning better.

|

Re: New CoreXY build motor issues August 22, 2020 07:41AM |

Registered: 3 years ago Posts: 12 |

"That could well be but I would looking to make sure the bearings and shafts are also sliding and working together smoothly."

Thanks Rocky. I have been working on the pulleys and belt alignment and the X and Y axes now travel very well and the homing works. Now on to the Z axis and the proximity sensor. I'm thinking I got the wrong type. I have a glass sheet on the heat bed and I'm worried now this sensor won't detect thru glass. No usable info from seller or on the device (all Chinese).

Thanks Rocky. I have been working on the pulleys and belt alignment and the X and Y axes now travel very well and the homing works. Now on to the Z axis and the proximity sensor. I'm thinking I got the wrong type. I have a glass sheet on the heat bed and I'm worried now this sensor won't detect thru glass. No usable info from seller or on the device (all Chinese).

|

Re: New CoreXY build motor issues August 23, 2020 02:31AM |

Registered: 3 years ago Posts: 11 |

I believe that 2mm glass will work alright. You should be able to test it out by hand winding first. I'm still in a similar stage at present with a Tronxy but I am waiting on some bits to tie the Z's together before I see if my glass gets busted. Note: mostly I have seen that people here prefer the touch type sensors but that requires a few more changes on my set up so I will see how it goes first. Freight being what it is these days could be awhile. Best of luck.

|

Re: New CoreXY build motor issues August 23, 2020 02:43AM |

Admin Registered: 11 years ago Posts: 3,096 |

You can test if there is some metal tape available locally that triggers the sensor. Then you can put that on each corner of the glass pane and have the sensor 'sense' the four specific areas to level. That should be enough as glass should be flat.

Edited 1 time(s). Last edit at 08/23/2020 02:43AM by Ohmarinus.

http://www.marinusdebeer.nl/

Edited 1 time(s). Last edit at 08/23/2020 02:43AM by Ohmarinus.

http://www.marinusdebeer.nl/

|

Re: New CoreXY build motor issues August 24, 2020 10:48AM |

Registered: 6 years ago Posts: 134 |

Your horizontal belt planes (driving the carriage and Y) are not flat. It means that belt tension will be different for different carriage positions. Most likely belts are jamming pulleys and motors are not able to move. I tried to line planes they maybe influenced by perspective but problem is visible anyway. That left motor is too high and most likely your major problem.

|

Re: New CoreXY build motor issues August 24, 2020 10:59AM |

Registered: 3 years ago Posts: 12 |

Quote

piper3d

Your horizontal belt planes (driving the carriage and Y) are not flat. It means that belt tension will be different for different carriage positions. Most likely belts are jamming pulleys and motors are not able to move. I tried to line planes they maybe influenced by perspective but problem is visible anyway. That left motor is too high and most likely your major problem.

Thanks for the visuals and all your help. I have worked out (most?) issues with the belt alignments and adjusted the stepper driver voltage, so the motors work as they should now.

I'm now working on the Z axis homing. The inductive sensor I bought is either defective or not wired up correctly. I can't get it to sense metal at all. I was planning to use glass plate over the aluminum heatbed. I've read that these types of sensors have difficulty sensing thru glass.

Sorry, only registered users may post in this forum.