X axis wobble in corexy printer

Posted by the_digital_dentist

|

X axis wobble in corexy printer December 06, 2020 04:07PM |

Registered: 11 years ago Posts: 5,780 |

I recently noticed the X axis wobbling in my newest sand table mechanism when the magnet carriage moved back and forth along the X axis with Y fixed. That got me thinking that maybe something similar could be happening in UMMD.

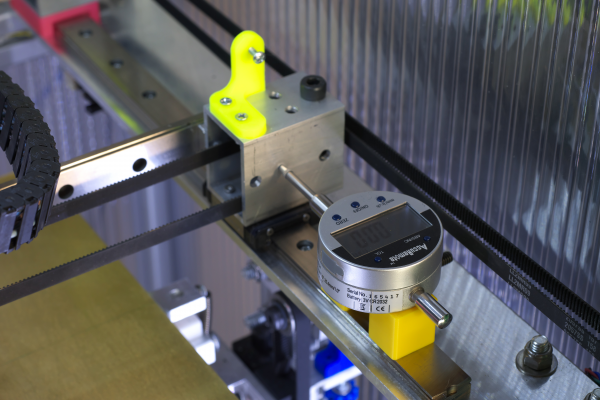

I set up a digital gauge and wrote a simple gcode file to test the machine. The gauge was mounted on the Y axis guide rails and the extruder carriage was made to move across the bed along the X axis, stopping every 5 mm to make a measurement.

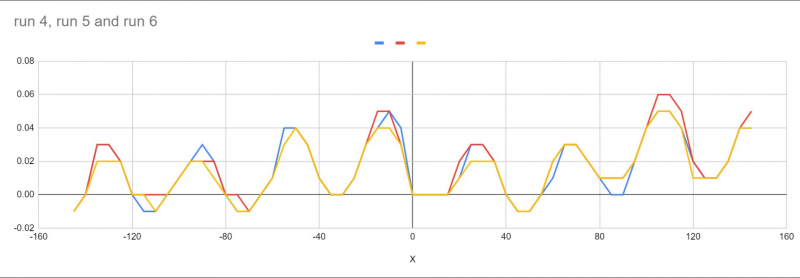

I found some interesting behavior- the movement from one end of the X axis to the other displayed a maximum shift of about 70 um, with a lot of waviness along the way. The wave period is 40 mm which matches the distance traveled by the carriage with one full rotation of the drive pulleys. It looks like the waviness can be attributed to the drive pulleys being either out of round or having poorly drilled center holes for the motor shafts.

I don't yet know if the 70 um error or the waviness has any effect on print quality- as someone pointed out, 70 um is about the diameter of a human hair. The error seems to be consistent with repeated measurements falling within the precision spec of my gauge. That means a vertical wall printed parallel to the X axis should have the layers stacking precisely on top of each other, waves and all, so the effects on print quality should be limited to visibility of the 40 mm periodic waves and not to any Z axis artifacts. I think.

I wrote a blog post on the subject [drmrehorst.blogspot.com]

Edited 2 time(s). Last edit at 12/06/2020 04:14PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I set up a digital gauge and wrote a simple gcode file to test the machine. The gauge was mounted on the Y axis guide rails and the extruder carriage was made to move across the bed along the X axis, stopping every 5 mm to make a measurement.

I found some interesting behavior- the movement from one end of the X axis to the other displayed a maximum shift of about 70 um, with a lot of waviness along the way. The wave period is 40 mm which matches the distance traveled by the carriage with one full rotation of the drive pulleys. It looks like the waviness can be attributed to the drive pulleys being either out of round or having poorly drilled center holes for the motor shafts.

I don't yet know if the 70 um error or the waviness has any effect on print quality- as someone pointed out, 70 um is about the diameter of a human hair. The error seems to be consistent with repeated measurements falling within the precision spec of my gauge. That means a vertical wall printed parallel to the X axis should have the layers stacking precisely on top of each other, waves and all, so the effects on print quality should be limited to visibility of the 40 mm periodic waves and not to any Z axis artifacts. I think.

I wrote a blog post on the subject [drmrehorst.blogspot.com]

Edited 2 time(s). Last edit at 12/06/2020 04:14PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: X axis wobble in corexy printer December 09, 2020 11:56PM |

Registered: 6 years ago Posts: 2 |

I spent a couple months studying this a while back using a test rig I made with just one linear rail on a length of 3030 and a 2" dial indicator to measure over a full revolution.

The effect is insidious with set screw style pullies. I tried many from different manufacturers and could measure it on every one and is caused by non-concentricity, both due to off center holes and the set screws pushing the pulley to one side of any slop in the hole.

The only way I found to minimize it was to buy stepped motors with round shafts and high quality 20t pulleys without a set screw from Misumi and epoxy them on. If you lightly spin the pulley into the shaft with epoxy in the bore the surface tension centers it fairly well. as I remember this reduced the sinusoidal trend by about 70 percent over the best set screw pulley I measured. The epoxy has held up for over two years and probably 20Kg of filament.

There is a similar issue I have found with a set of lead screws that were manufactured on a machine that had some form of non-concentricity in its gearing or something. If you measured the displacement of the lead screw nut with a dial indicator it had a definite sinusoidal error in the axial displacement of the thread pitch that caused a distinctive sinusoidal ripple in the walls of prints that looked just like Z wobble until you figured out it was the same in all at directions and was making the walls thiiner/thicker rather than shifting them sideways. Z banding I think was the more appropriate term. Took me weeks to figure out the root cause for that issue. Most people attribute any and all a wobble like artifacts to bent lead screw. I suspect that it is at least sometimes it is actually sinusoidal error in the lead screw thread pitch like what I found instead.

The effect is insidious with set screw style pullies. I tried many from different manufacturers and could measure it on every one and is caused by non-concentricity, both due to off center holes and the set screws pushing the pulley to one side of any slop in the hole.

The only way I found to minimize it was to buy stepped motors with round shafts and high quality 20t pulleys without a set screw from Misumi and epoxy them on. If you lightly spin the pulley into the shaft with epoxy in the bore the surface tension centers it fairly well. as I remember this reduced the sinusoidal trend by about 70 percent over the best set screw pulley I measured. The epoxy has held up for over two years and probably 20Kg of filament.

There is a similar issue I have found with a set of lead screws that were manufactured on a machine that had some form of non-concentricity in its gearing or something. If you measured the displacement of the lead screw nut with a dial indicator it had a definite sinusoidal error in the axial displacement of the thread pitch that caused a distinctive sinusoidal ripple in the walls of prints that looked just like Z wobble until you figured out it was the same in all at directions and was making the walls thiiner/thicker rather than shifting them sideways. Z banding I think was the more appropriate term. Took me weeks to figure out the root cause for that issue. Most people attribute any and all a wobble like artifacts to bent lead screw. I suspect that it is at least sometimes it is actually sinusoidal error in the lead screw thread pitch like what I found instead.

|

Re: X axis wobble in corexy printer December 10, 2020 07:38AM |

Registered: 11 years ago Posts: 5,780 |

Interesting! I'm trying to order pulleys from Misumi now, but having some trouble with the web site. I've seen pulleys for larger belts that use a clamp instead of set screws- I wonder if those might give better "roundness".

I'm going to set the gauge reup to check for runout in the motor shafts this weekend. One of the servomotors I used in the sand table has visible runout in the shaft, so maybe one or both of the steppers in the printer does, too.

Edited 1 time(s). Last edit at 12/10/2020 07:40AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I'm going to set the gauge reup to check for runout in the motor shafts this weekend. One of the servomotors I used in the sand table has visible runout in the shaft, so maybe one or both of the steppers in the printer does, too.

Edited 1 time(s). Last edit at 12/10/2020 07:40AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: X axis wobble in corexy printer December 10, 2020 11:26PM |

Registered: 6 years ago Posts: 2 |

Your plot is interesting. Since it is a distinct sinusoidal in just one direction while both motors are running I THINK that indicates you have one pulley (or possobly) idler with much worse non concentric than the rest? probably pulley since I THINK you use flanges bearings for idlers instead of toothed idlers?.

If both your pulleys were similarly bad they would have to be perfectly in phase to give that trace on a corexy which is possible but a little unlikely. If you can setup a measurement on the +/-45 degrees you can check the two pulleys independently. The other thing to look at is that before fixing all non eccentricities in pulleys and idlers I could feel and hear rhythmic changes in tension and noise while moving around the print head by hand. Once I fixed them all it was noticeably more uniform.

If both your pulleys were similarly bad they would have to be perfectly in phase to give that trace on a corexy which is possible but a little unlikely. If you can setup a measurement on the +/-45 degrees you can check the two pulleys independently. The other thing to look at is that before fixing all non eccentricities in pulleys and idlers I could feel and hear rhythmic changes in tension and noise while moving around the print head by hand. Once I fixed them all it was noticeably more uniform.

|

Re: X axis wobble in corexy printer December 10, 2020 11:53PM |

Registered: 11 years ago Posts: 5,780 |

The tension in one belt affects the tension in the other, so I think the plot represents the sum of the varying tensions in both belts. I'm not sure you can imply anything about the relative phases of the out of round positions of the pulleys or even the relative magnitudes of the out of roundness based on the plot.

The idlers are all stacked bearings and the diameter is 22 mm. If one of those was out of round there would be a 69.1 mm wave superimposed on the 40 mm wave from the drive pulley(s), but probably much lower amplitude than the 40 mm wave because bearings are probably made a little better than drive pulleys. There are 8 idlers spinning in X only motion, so if they are all out of round, there would be a lot of low amplitude "noise" in the plot, and there probably is- it's just hard to see under the drive pulley wave, and likely to be too small to detect with the limited resolution of my cheesy gauge.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

The idlers are all stacked bearings and the diameter is 22 mm. If one of those was out of round there would be a 69.1 mm wave superimposed on the 40 mm wave from the drive pulley(s), but probably much lower amplitude than the 40 mm wave because bearings are probably made a little better than drive pulleys. There are 8 idlers spinning in X only motion, so if they are all out of round, there would be a lot of low amplitude "noise" in the plot, and there probably is- it's just hard to see under the drive pulley wave, and likely to be too small to detect with the limited resolution of my cheesy gauge.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.