x-axis supports:

Posted by Regicide

|

x-axis supports: January 10, 2021 11:21AM |

Registered: 3 years ago Posts: 22 |

I'm trying to figure out how to make my x-axis lighter, especially since I'm considering DDDE (Direct Drive Dual Extrusion). However, with the extra weight of the print head, I'm wondering what I can get away with for lightening the x-axis. My design's pretty conventional, and heavily based off of the_digital_dentists' UMMD, with the exception being that I don't currently have access to metal milling capabilities (although I am looking into adapting my Anet machine to be a low quality leadscrew based mill). As such, I'm essentially building entirely with 80/20 profiles and LDO linear rails. My questions are:

1. given the amount of weight I have on my print head, will just the rail be sufficient, or will I have to mount it to an aluminum profile. (I'm fairly sure it's the second, but it can't hurt to check)

2. If I were to use an aluminum profile to support it in addition to the linear rail, what is the minimum size I would need? (For context, I'm currently looking at dual titan/chimera, with possible full-head water cooling much later in design life. I am, however, considering the Itty Bitty Belted Extruder

3. Are there any alternatives to an aluminum profile that would work better: materials, shapes, etc.

Cheers, and I look forwards to seeing your replies!

1. given the amount of weight I have on my print head, will just the rail be sufficient, or will I have to mount it to an aluminum profile. (I'm fairly sure it's the second, but it can't hurt to check)

2. If I were to use an aluminum profile to support it in addition to the linear rail, what is the minimum size I would need? (For context, I'm currently looking at dual titan/chimera, with possible full-head water cooling much later in design life. I am, however, considering the Itty Bitty Belted Extruder

3. Are there any alternatives to an aluminum profile that would work better: materials, shapes, etc.

Cheers, and I look forwards to seeing your replies!

|

Re: x-axis supports: January 10, 2021 12:07PM |

Registered: 11 years ago Posts: 5,780 |

Have you considered tool changing instead of a dual extruder?

A simple aluminum tube is lighter and more rigid than the same size t-slot.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

A simple aluminum tube is lighter and more rigid than the same size t-slot.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: x-axis supports: January 10, 2021 06:02PM |

Registered: 3 years ago Posts: 22 |

I'll have a look at aluminum tubing, that seems like it could be what I'm looking for. My only concern would probably be mounting the linear rails, but it wouldn't be too difficult. Thanks for your suggestion. As for toolchanging, I've indeed looked at that, but I have several concerns:

1. It's expensive, especially if you go with the E3D method.

2. It seems to require fairly high tolerances and repeatability.

3. The E3D method seems to be mainly using Bowden extrusion (having tried both Bowden and Direct Drive, I much prefer Direct Drive)

I'm hesitant to go to toolchanging, although it's certainly an exciting field, and I suspect it's the way forward for FDM and RepRap in general. For now though, I'm actually quite interested in switching dual extruders. There's quite an interesting design here, and I know that Teaching Tech has done a review (although I haven't watched it, so this could well be a bad design).

One possible solution to the weight problem I came up with is to use a hybrid design: one direct drive extruder for the hotend I intend to mainly use for the actual print, and a Bowden extruder to use for supports. Alternatively, I could use traditional bowden extruders feeding into ultra-lightweight direct drive extruders with the lightest Nema 8 stepper motors: This allows for an extremely light print head that has both fine control over the filament with minimum lag, and the ability to print quickly if desired. It would also let me use flexible filament! I'm sure there's many flaws with this idea, but I also hope there aren't.

Anyways, tell me what you think!

1. It's expensive, especially if you go with the E3D method.

2. It seems to require fairly high tolerances and repeatability.

3. The E3D method seems to be mainly using Bowden extrusion (having tried both Bowden and Direct Drive, I much prefer Direct Drive)

I'm hesitant to go to toolchanging, although it's certainly an exciting field, and I suspect it's the way forward for FDM and RepRap in general. For now though, I'm actually quite interested in switching dual extruders. There's quite an interesting design here, and I know that Teaching Tech has done a review (although I haven't watched it, so this could well be a bad design).

One possible solution to the weight problem I came up with is to use a hybrid design: one direct drive extruder for the hotend I intend to mainly use for the actual print, and a Bowden extruder to use for supports. Alternatively, I could use traditional bowden extruders feeding into ultra-lightweight direct drive extruders with the lightest Nema 8 stepper motors: This allows for an extremely light print head that has both fine control over the filament with minimum lag, and the ability to print quickly if desired. It would also let me use flexible filament! I'm sure there's many flaws with this idea, but I also hope there aren't.

Anyways, tell me what you think!

|

Re: x-axis supports: January 17, 2021 11:39AM |

Registered: 11 years ago Posts: 5,780 |

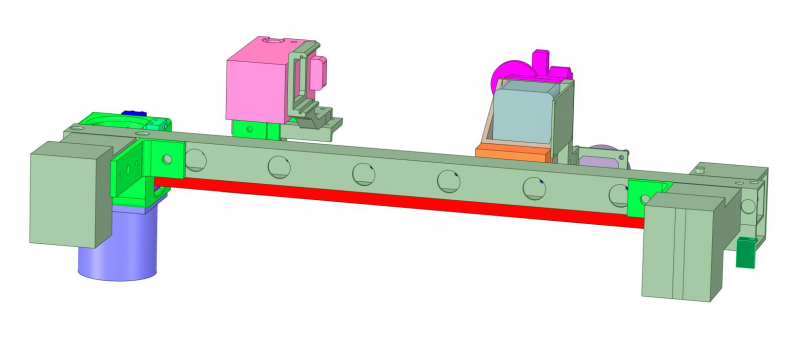

In SoM I used an aluminum tube to mount the X axis guide rail. On the guide rail side of the tube I drilled holes to fit the screws that would hold it down. On the back side of the tube I drilled larger holes that would allow a nut driver to be inserted. Don't try to put the mounting screws all the way through the tube with the nuts on the back side of the tube. That will only crush the tube when you start tightening the guide rail screws. I also mounted the X axis motor and idler pulley on the ends of the tube so the whole X axis can be removed from the printer just by releasing a couple bolts.

I don't have any pictures of the back of the X axis tube, but here's a CAD rendering:

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I don't have any pictures of the back of the X axis tube, but here's a CAD rendering:

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: x-axis supports: February 18, 2021 08:20PM |

Registered: 3 years ago Posts: 4 |

I used c-shaped or u-shaped aluminum extrusion from the hardware store. Just clamp the linear rail down to it and use the rail hole pattern for a template to drill the holes. It's light but gives just enough reinforcement to minimize deflection.

[www.thingiverse.com]

[hackaday.io]

[www.thingiverse.com]

[hackaday.io]

Sorry, only registered users may post in this forum.