Belts pitch: 2 or 3 mm ? Your opinion ?

Posted by ARG

|

Belts pitch: 2 or 3 mm ? Your opinion ? January 24, 2021 02:09PM |

Registered: 3 years ago Posts: 3 |

Hello, I am new here. After starting at 3D printing with a Bibo printer, and spent a lot of time to ... fix it... I have understood 2 or 3 basic things:

- Industrial FDM printer are out of my price range.

- The consumers FDM manufacturing industry is driven by the price consideration and flooded by Chinese crap parts.

- Technical solutions are also driven by the profit consideration.

So, I decided, like many of you, to start from scratch, and build my own printer:

Briefly:

- Core X/Y geometry

- Inspired from the DD UMMD ( thank you DD really useful writings ): rails, belted/worm gear lifted Z axis , separate Z frame, etc...

really useful writings ): rails, belted/worm gear lifted Z axis , separate Z frame, etc...

- careful attention to basics technical details: rigidity, for example.

I would like to hear you about this question :

Belts to move the X and Y axes :

My though was to use 12 or 15mm wide belts in order to reduce the ''spring effect'' of the belts driving a quite heavy carriage: probably near 2Kg once built.

I found GT2 12 mm wide 2mm pitch belts, and 15mm wide GT3 3mm pitch belts.

In your opinion, is there a real down side to use a 3mm pitch ( 0.9° motor) on the X / Y axes, instead of 2 mm ?

( from an accuracy point of view, with a standard 0.4mm nozzle)

The devil is in the detail.

- Industrial FDM printer are out of my price range.

- The consumers FDM manufacturing industry is driven by the price consideration and flooded by Chinese crap parts.

- Technical solutions are also driven by the profit consideration.

So, I decided, like many of you, to start from scratch, and build my own printer:

Briefly:

- Core X/Y geometry

- Inspired from the DD UMMD ( thank you DD

really useful writings ): rails, belted/worm gear lifted Z axis , separate Z frame, etc...

really useful writings ): rails, belted/worm gear lifted Z axis , separate Z frame, etc...- careful attention to basics technical details: rigidity, for example.

I would like to hear you about this question :

Belts to move the X and Y axes :

My though was to use 12 or 15mm wide belts in order to reduce the ''spring effect'' of the belts driving a quite heavy carriage: probably near 2Kg once built.

I found GT2 12 mm wide 2mm pitch belts, and 15mm wide GT3 3mm pitch belts.

In your opinion, is there a real down side to use a 3mm pitch ( 0.9° motor) on the X / Y axes, instead of 2 mm ?

( from an accuracy point of view, with a standard 0.4mm nozzle)

The devil is in the detail.

|

Re: Belts pitch: 2 or 3 mm ? Your opinion ? February 06, 2021 01:23AM |

Registered: 8 years ago Posts: 1,671 |

|

Re: Belts pitch: 2 or 3 mm ? Your opinion ? February 06, 2021 07:59AM |

Registered: 11 years ago Posts: 5,780 |

Yes, super wide belts will stretch less, but you will pay an arm and a leg for drive pulleys to fit your motors, if you can find them. The stretchiness of the belts is a small problem compared to the springiness of the motors.

And don't forget the flexibility of the frame. There would be no point in using extra wide belts if you're going to make the frame from 2020 t-slot.

I don't think 2 or 3 mm pitch makes any difference, especially if it is GT profile. My first printer had 5 mm pitch XL belts (steel core!) and it produced beautiful prints.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

And don't forget the flexibility of the frame. There would be no point in using extra wide belts if you're going to make the frame from 2020 t-slot.

I don't think 2 or 3 mm pitch makes any difference, especially if it is GT profile. My first printer had 5 mm pitch XL belts (steel core!) and it produced beautiful prints.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Belts pitch: 2 or 3 mm ? Your opinion ? February 06, 2021 10:16AM |

Registered: 8 years ago Posts: 1,671 |

|

Re: Belts pitch: 2 or 3 mm ? Your opinion ? February 06, 2021 03:35PM |

Registered: 11 years ago Posts: 5,780 |

Why would the belt pitch have any effect on the speed?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Belts pitch: 2 or 3 mm ? Your opinion ? February 06, 2021 03:49PM |

Registered: 5 years ago Posts: 71 |

I've read 2mm pitch GT2 has better positional accuracy vs 3mm (4x according to the Shapeoko wiki: [wiki.shapeoko.com]), though as the digital dentist mentioned, it probably doesn't have much effect in practice, as there are other larger contributing factors to accuracy. I would still use 10 or 12mm wide belts though for stiffness (and GT2 2mm can be sourced in 15mm wide as well).

Modular Linear Slides for Aluminum Extrusions [www.exoslide.com]

Modular Linear Slides for Aluminum Extrusions [www.exoslide.com]

|

Re: Belts pitch: 2 or 3 mm ? Your opinion ? February 07, 2021 09:01AM |

Registered: 8 years ago Posts: 1,671 |

|

Re: Belts pitch: 2 or 3 mm ? Your opinion ? February 07, 2021 10:38AM |

Registered: 3 years ago Posts: 3 |

Sorry to be back so late. I appreciate your time. I did some researches on my side, and I found :

- some answers here

- and a tool for calculations here

The improvement would be on the accuracy, through a better positioning.

After a lot of researches, if found in this document that GATES sells open belts in those dimensions :

GT2 2mm pitch: 6-9-12mm wide

GT3 2mm pitch: 4-6-9mm wide

GT3 3mm pitch: 6-9-15mm wide

I am not affiliated in any way to Gates. I am just the guy who dont want to buy chewing gum belts from nowhere-land, without any technical other infos than : ''GT2 compatible''

With this project, my goal is to try to remove, or bring back to near zero the most gray zones I can. ( the ''probably'' zones)

One zone/ problem at time.

Today was the belt zone.

Tomorrow will be another day/zone.

A little more precisions about my project: The idea is to collect quality parts for technically proven solutions, and, at the end, to design and build the printer.

At date, I have some components in hand:

- THK HRW17 Rails for all axes.

( I know it is overkill , but I found a good deal)

- Onedrives 1/30 wormgear (UMMD flavour z axis )

- Duet 3 Mainboard 6HC

- Duet PanelDue 7'' display

- 2 NEMA 17 / 60mm / 0.9° motors

For the design: the general idea is to use the ''halo'' solution for the top plate. A T slot rails frame. And rigid aluminum side pannels on all remaining faces. Goal: rigidity / mass / weight.

Mic6 Cast 1/2'' bed. Separate heater. 3 points manual leveling adjustment.

I think seriously to water cooling.

The final goal : a solid, reliable, finely adjustable workhorse printer.

The devil is in the detail.

- some answers here

- and a tool for calculations here

I agree with you. The Prusa calculators helped me to visualise the real difference between 2 and 3mm pitch. It is near nothing in term of accuracy for a tool which extrudes melted plastic.Quote

the_digital_dentist

I don't think 2 or 3 mm pitch makes any difference, especially if it is GT profile

I don't think so : one full turn of a 3mm pitch driving pulley is the same full turn than a 2mm pitch driving pulley of the same diameter: it remains a full turn, and the length of ''moved belt'', is the same. So there is no gain, or loss for speed.Quote

MechaBits

I suppose you get faster with the larger pitch, and a new controller to divide the steps more.

The improvement would be on the accuracy, through a better positioning.

I would be glad if you can point me to a source of Genuine GT2, 2mm pitch, 15mm wide GATES belts.Quote

gmedlicott

(and GT2 2mm can be sourced in 15mm wide as well

After a lot of researches, if found in this document that GATES sells open belts in those dimensions :

GT2 2mm pitch: 6-9-12mm wide

GT3 2mm pitch: 4-6-9mm wide

GT3 3mm pitch: 6-9-15mm wide

I am not affiliated in any way to Gates. I am just the guy who dont want to buy chewing gum belts from nowhere-land, without any technical other infos than : ''GT2 compatible''

Yes you are probably right. But...everything is in the word: ''probably''.Quote

gmedlicott

as the digital dentist mentioned, it probably doesn't have much effect in practice, as there are other larger contributing factors to accuracy

With this project, my goal is to try to remove, or bring back to near zero the most gray zones I can. ( the ''probably'' zones)

One zone/ problem at time.

Today was the belt zone.

Tomorrow will be another day/zone.

A little more precisions about my project: The idea is to collect quality parts for technically proven solutions, and, at the end, to design and build the printer.

At date, I have some components in hand:

- THK HRW17 Rails for all axes.

( I know it is overkill , but I found a good deal)

- Onedrives 1/30 wormgear (UMMD flavour z axis )

- Duet 3 Mainboard 6HC

- Duet PanelDue 7'' display

- 2 NEMA 17 / 60mm / 0.9° motors

For the design: the general idea is to use the ''halo'' solution for the top plate. A T slot rails frame. And rigid aluminum side pannels on all remaining faces. Goal: rigidity / mass / weight.

Mic6 Cast 1/2'' bed. Separate heater. 3 points manual leveling adjustment.

I think seriously to water cooling.

The final goal : a solid, reliable, finely adjustable workhorse printer.

The devil is in the detail.

|

Re: Belts pitch: 2 or 3 mm ? Your opinion ? February 07, 2021 11:42AM |

Registered: 8 years ago Posts: 1,671 |

|

Re: Belts pitch: 2 or 3 mm ? Your opinion ? February 07, 2021 02:44PM |

Registered: 12 years ago Posts: 1,450 |

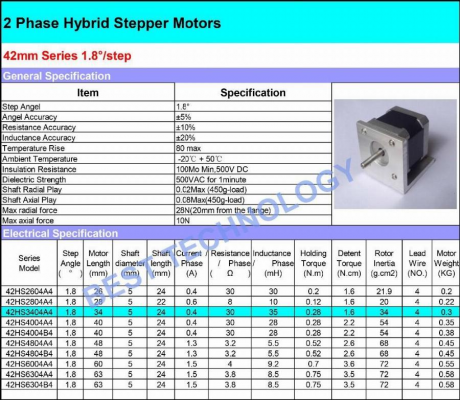

One point with stepper motors and wide belts is that their rated radial load is not too great. Wide belts lever on the shaft more than narrow belts as narrow belts can be set closer to the flange. An excerpt from a datasheet below gives 28 Newtons (about 2.9kg or 6.3 pounds force) as the maximum for a fairly typical NEMA17. I think they are regularly used at or beyond this but think the gains in reduced flexibility from a wide belt could be lost in the flexing of the stepper shaft - besides the reduced service life.

Mike

Mike

|

Re: Belts pitch: 2 or 3 mm ? Your opinion ? February 07, 2021 02:57PM |

Registered: 11 years ago Posts: 5,780 |

Quote

MechaBits

in the same way a 5mm lead on a screw would be faster than a 2mm lead

Belts and screws don't work the same way.

Oh, I see, you're assuming an equal number of teeth on the 2mm and 3mm drive pulleys...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Belts pitch: 2 or 3 mm ? Your opinion ? February 07, 2021 03:22PM |

Admin Registered: 16 years ago Posts: 13,886 |

... hmmm ... I have two machines form Janome with "superfine" pitches belts, which are specified with up to 800mm/s and 0.01mm accuracy -- so finer belts could be of any good too?

Edited 1 time(s). Last edit at 02/07/2021 03:22PM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Edited 1 time(s). Last edit at 02/07/2021 03:22PM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Belts pitch: 2 or 3 mm ? Your opinion ? February 07, 2021 05:41PM |

Registered: 3 years ago Posts: 3 |

Misumi USA has everything to answer this question hereQuote

MechaBits

but I wouldnt know the diam of a 20t gt3

an interesting point: I must to think of it twice, before making the choice of belt widthQuote

leadinglights

Wide belts lever on the shaft more than narrow belts as narrow belts can be set closer to the flange.

Thank you :-)

The devil is in the detail.

|

Re: Belts pitch: 2 or 3 mm ? Your opinion ? February 08, 2021 01:27AM |

Registered: 8 years ago Posts: 1,671 |

|

Re: Belts pitch: 2 or 3 mm ? Your opinion ? February 08, 2021 03:41AM |

Registered: 6 years ago Posts: 1,007 |

|

Re: Belts pitch: 2 or 3 mm ? Your opinion ? February 08, 2021 06:11AM |

Registered: 12 years ago Posts: 1,450 |

A bit more on toothed belts, belt tension, and stepper motors. Firstly though, a bit of a disclaimer: I exceed the recommended figures by quite a bit on my Delta printer and I haven't had any real problems

I worked out the load from a site that has gone missing in the depths of time, but this one [www.mitsuboshi.com] gives about the same results - except that it barfs when I put in the true center distance of 780mm.

Please note though that the shaft load from the recommended tension goes up to 119.43 Newtons with a 15mm wide belt. Again though, a lighter tension will probably work fine, but the engineering specs will lurk in the room like an elephant.

Mike

I worked out the load from a site that has gone missing in the depths of time, but this one [www.mitsuboshi.com] gives about the same results - except that it barfs when I put in the true center distance of 780mm.

Specification Classical Tooth profile T5 Belt width 6mm Number of teeth on large pulley 20 Number of teeth on small pulley 20 Revolution of small pulley 600rpm Center distance 600mm Calculation results Initial tension (min) 12.66N Initial tension (max) 19.12N Static shaft load (min) 25.32N Static shaft load (max) 38.24N Deflection 9.60mm Deflection load (min) 1.04N Deflection load (max) 1.45N

Please note though that the shaft load from the recommended tension goes up to 119.43 Newtons with a 15mm wide belt. Again though, a lighter tension will probably work fine, but the engineering specs will lurk in the room like an elephant.

Mike

Sorry, only registered users may post in this forum.