DIY CoreXY

Posted by Roberts_Clif

|

DIY CoreXY April 16, 2022 04:16PM |

Registered: 6 years ago Posts: 1,863 |

Hello to all

I have three Cartesian style 3D Printers.

But now I am looking a building a CoreXY style 3D Printer.

Would like information on DIY builds that would meet at least 300mm cubed, a nice good fast 3D Printer that will put my Cartesian style 3D Printers on E-Bay.

Was thinking of building a simple inexpensive CoreXY printer that could be upgraded to make a great 3D Printer, One that would replace all three of my Hictops.

Would like a DIY 3D Printer that could be upgraded from a simple inexpensive starter CoreXY to something that would In several inexpensive steps could equal a Voron V2.4 CoreXY

If you have a suggestion please post

Computer Programmer / Electronics Technician

I have three Cartesian style 3D Printers.

But now I am looking a building a CoreXY style 3D Printer.

Would like information on DIY builds that would meet at least 300mm cubed, a nice good fast 3D Printer that will put my Cartesian style 3D Printers on E-Bay.

Was thinking of building a simple inexpensive CoreXY printer that could be upgraded to make a great 3D Printer, One that would replace all three of my Hictops.

Would like a DIY 3D Printer that could be upgraded from a simple inexpensive starter CoreXY to something that would In several inexpensive steps could equal a Voron V2.4 CoreXY

If you have a suggestion please post

Computer Programmer / Electronics Technician

|

Re: DIY CoreXY April 23, 2022 08:08PM |

Registered: 6 years ago Posts: 1,863 |

Found this which will give me a head start into a CoreXY 3D Printer.

It is a Scalable CoreXY V2 (HICTOP Prusa i3 hardware Converted to CoreXY).

If I can get my head wrapped around what to do with this Thingiverse post. I can not find any measurements or how to assemble.

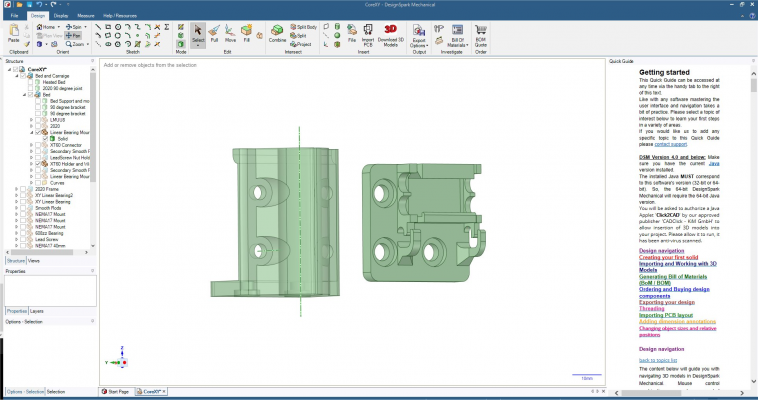

Downloaded DesignSpark Mechanical 5 where I can measure the T-Slots and the Bed, though not much else. Still this is my best shot.

An the designer has no build of materials in their thingiverse post so the basic design is all I have.

Oh well I have worked from less, my 1st Hictop had no assembly instructions so had to use this Youtube video in order to assembly.

Most likely I will have to adjust everything to the original Hictop parts, then after getting them working can upgrade.

This will be to a 300mm square build area. Though I would like to adjust design from start to have dual Z steppers and four Z smooth rods.

This should make it a little nicer when it is finished.

The basic parts will run about $200 then transfering my 3DP12 parts over to finish.

As I have an almost complete set of spare parts this would be where all my Hictop 3DP12 parts would be appropriated from.

I assume that the center T-Slot's should be framed at the height of my original Hictop about 11 1/2 inches.

This would be for the length of my Lead screws and smooth rods. The single back T-Slot is only to support the extruder Motor.

No ideal about the top single T-Slot, though the photos show it holding a wire bundle.

Wow this may be a lot easier than I first thought.

May even start with a BTT 32bit controller

Edited 1 time(s). Last edit at 04/23/2022 08:10PM by Roberts_Clif.

Computer Programmer / Electronics Technician

It is a Scalable CoreXY V2 (HICTOP Prusa i3 hardware Converted to CoreXY).

If I can get my head wrapped around what to do with this Thingiverse post. I can not find any measurements or how to assemble.

Downloaded DesignSpark Mechanical 5 where I can measure the T-Slots and the Bed, though not much else. Still this is my best shot.

An the designer has no build of materials in their thingiverse post so the basic design is all I have.

Oh well I have worked from less, my 1st Hictop had no assembly instructions so had to use this Youtube video in order to assembly.

Most likely I will have to adjust everything to the original Hictop parts, then after getting them working can upgrade.

This will be to a 300mm square build area. Though I would like to adjust design from start to have dual Z steppers and four Z smooth rods.

This should make it a little nicer when it is finished.

The basic parts will run about $200 then transfering my 3DP12 parts over to finish.

As I have an almost complete set of spare parts this would be where all my Hictop 3DP12 parts would be appropriated from.

I assume that the center T-Slot's should be framed at the height of my original Hictop about 11 1/2 inches.

This would be for the length of my Lead screws and smooth rods. The single back T-Slot is only to support the extruder Motor.

No ideal about the top single T-Slot, though the photos show it holding a wire bundle.

Wow this may be a lot easier than I first thought.

May even start with a BTT 32bit controller

Edited 1 time(s). Last edit at 04/23/2022 08:10PM by Roberts_Clif.

Computer Programmer / Electronics Technician

|

Re: DIY CoreXY April 24, 2022 06:56PM |

Registered: 3 years ago Posts: 55 |

Oh, I'd definately recommend going with the RatRig core V3 design. Either that or a Voron.

I think RR is easier and has some very good features. There is also the Havort kind of CoreXY but honestly, there is lots of overkill there and $$$.

Here is a start. There is a discord server, a good group there.

[v-core.ratrig.com]

I'd built one following their design, it is all open source. You can buy parts from them directly but now there are also other suppliers which are very good. I personally sourced all the parts myself directly and also had the extrusions cut locally. Also re-used the parts from my old I3 printer.

NOTE: You need a six stepper board. (Hence the one I'd built in another post here).

I think RR is easier and has some very good features. There is also the Havort kind of CoreXY but honestly, there is lots of overkill there and $$$.

Here is a start. There is a discord server, a good group there.

[v-core.ratrig.com]

I'd built one following their design, it is all open source. You can buy parts from them directly but now there are also other suppliers which are very good. I personally sourced all the parts myself directly and also had the extrusions cut locally. Also re-used the parts from my old I3 printer.

NOTE: You need a six stepper board. (Hence the one I'd built in another post here).

|

Re: DIY CoreXY April 24, 2022 07:39PM |

Registered: 11 years ago Posts: 5,780 |

You have printers that you can use until your corexy machine is operational. Why spend time and effort making something "upgradeable" when you can just take a little longer and build the "final" machine?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: DIY CoreXY May 01, 2022 08:42AM |

Registered: 6 years ago Posts: 1,863 |

I have ran into a snag.

The Scalable CoreXY V2 I have selected has a basic problem all the STL files were not created.

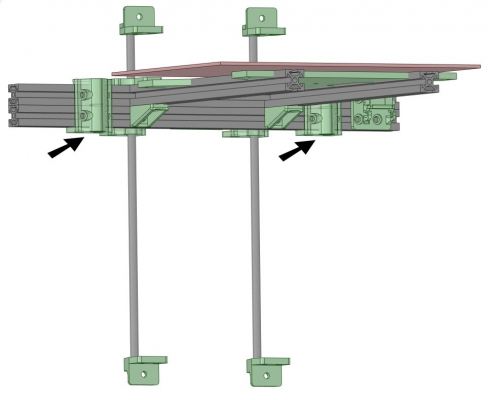

Missing is an important file shown in the image below.

I can not find these models or know how to remove them from the RSDOC file.

or

I am hoping someone has a similar coreXY lift part that can be adapted to this CoreXY or a complete set of plans with a complete set of STL file I could be directed to.

The 2020 smooth rod holder mounts are missing an all the parts have to work in unison.

Computer Programmer / Electronics Technician

The Scalable CoreXY V2 I have selected has a basic problem all the STL files were not created.

Missing is an important file shown in the image below.

I can not find these models or know how to remove them from the RSDOC file.

or

I am hoping someone has a similar coreXY lift part that can be adapted to this CoreXY or a complete set of plans with a complete set of STL file I could be directed to.

The 2020 smooth rod holder mounts are missing an all the parts have to work in unison.

Computer Programmer / Electronics Technician

|

Re: DIY CoreXY May 01, 2022 07:02PM |

Registered: 11 years ago Posts: 5,780 |

You're going to cantilever a bed on end-supported round rails anchored to a 2020 t-slot frame? I think it's going to bounce like a diving board!

This might be a good time to learn some CAD skills. RSDOC is a Design Spark Mechanical format. DSM is free and very easy to learn.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

This might be a good time to learn some CAD skills. RSDOC is a Design Spark Mechanical format. DSM is free and very easy to learn.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: DIY CoreXY May 01, 2022 08:46PM |

Registered: 6 years ago Posts: 1,863 |

Not exactly.

I was going to duplicate the lift on the other side as to have dual Z stepper motors with quad smooth rods, believe this should prevent the cantilever.

I Have installed Design Spark Mechanical, this is how I removed all the other parts to display only the Forklift. though do not know how to export the smooth rod models to STL.

Learned how to export the STL files no more problem.

Thank you the_digital_dentist

May be slow but there is nothing I cannot self teach myself.

Computer Programmer / Electronics Technician

I was going to duplicate the lift on the other side as to have dual Z stepper motors with quad smooth rods, believe this should prevent the cantilever.

I Have installed Design Spark Mechanical, this is how I removed all the other parts to display only the Forklift. though do not know how to export the smooth rod models to STL.

Learned how to export the STL files no more problem.

Thank you the_digital_dentist

May be slow but there is nothing I cannot self teach myself.

Computer Programmer / Electronics Technician

|

Re: DIY CoreXY May 02, 2022 12:43PM |

Registered: 11 years ago Posts: 5,780 |

Getting four round rails parallel to each other is going to be tricky. It is much easier to get two linear guides parallel to each other...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: DIY CoreXY May 03, 2022 06:44AM |

Registered: 6 years ago Posts: 1,863 |

Quote

the_digital_dentist

Getting four round rails parallel to each other is going to be tricky. It is much easier to get two linear guides parallel to each other...

OK!

Can you post a link for a CoreXY with complete plans that should suit my purposes. An not cost an arm an a leg.

Computer Programmer / Electronics Technician

|

Re: DIY CoreXY May 03, 2022 08:29AM |

Registered: 11 years ago Posts: 5,780 |

Define "complete".

Define "not an arm and a leg".

Define "your purposes".

You were already talking about modifying an existing design to use 4 guide rails and 2 motors in the Z axis. You can apply the same thought processes to the rest of the machine. Look at multiple designs, be critical and list the good and weak points, then choose one to start your design, and try to fix the weak points as you go. There's nothing wrong with taking the corexy stage from one design and the Z axis from another (or starting from scratch).

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Define "not an arm and a leg".

Define "your purposes".

You were already talking about modifying an existing design to use 4 guide rails and 2 motors in the Z axis. You can apply the same thought processes to the rest of the machine. Look at multiple designs, be critical and list the good and weak points, then choose one to start your design, and try to fix the weak points as you go. There's nothing wrong with taking the corexy stage from one design and the Z axis from another (or starting from scratch).

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: DIY CoreXY May 03, 2022 10:11AM |

Registered: 6 years ago Posts: 1,863 |

I was playing with DSM and the RSDOC for Scalable CoreXY V2 (HICTOP Prusa i3 hardware Converted to CoreXY).

Noted when opening RSDOC file turn off all and select the bed get different smooth rods an holders.

When I turn off bed and turn on the whole project the different different smooth rods an holders still appear along with originals.

[youtu.be]

I am retired learning this new 3D printer technology my resources are quite limited, without getting into details the amount SS pays sucks.

Do not want to get half way into this project an find that a highly necessary 3D printed model is missing.

My income is set, arm and a leg is an old expression meaning " that it is very expensive."

To learn this new technology and maybe allow me to make things that I could never make before 3D Printers.

Edited 1 time(s). Last edit at 05/03/2022 10:12AM by Roberts_Clif.

Computer Programmer / Electronics Technician

Noted when opening RSDOC file turn off all and select the bed get different smooth rods an holders.

When I turn off bed and turn on the whole project the different different smooth rods an holders still appear along with originals.

[youtu.be]

I am retired learning this new 3D printer technology my resources are quite limited, without getting into details the amount SS pays sucks.

Quote

the_digital_dentist

Define "complete".

Define "not an arm and a leg".

Define "your purposes".

There's nothing wrong with taking the corexy stage from one design and the Z axis from another (or starting from scratch).

Do not want to get half way into this project an find that a highly necessary 3D printed model is missing.

My income is set, arm and a leg is an old expression meaning " that it is very expensive."

To learn this new technology and maybe allow me to make things that I could never make before 3D Printers.

Edited 1 time(s). Last edit at 05/03/2022 10:12AM by Roberts_Clif.

Computer Programmer / Electronics Technician

|

Re: DIY CoreXY May 03, 2022 04:48PM |

Registered: 11 years ago Posts: 5,780 |

It sounds like the person who generated the rsdoc file was trying different options or made updates after the initial design and left the original in the file. I do that sort of stuff all the time, especially as I make updates to my printer. I try to give new names to new parts so that I can distinguish between the different designs contained within the same CAD file, and switch on just the ones I want to see.

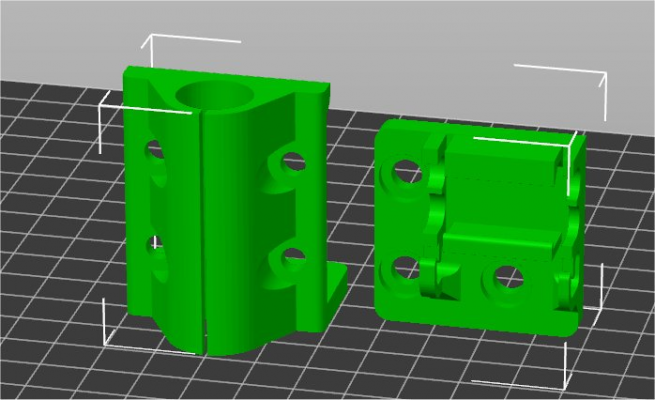

If can can use CAD software, You don't need someone to provide the stl files for you to print. In the design you're looking at, there are guide rails and a frame in their proper positions. Having just that, designing a printable model to connect the two is pretty easy. 99% of modeling 3D printer parts in CAD is modeling the unprinted stuff first and positioning them where they need to be. The printed parts are easy after the guide rails are set parallel to each other and in the right positions relative to the machine's frame. If I'm designing a printable part, I usually start with the idea that thicker, and more solid is better (we're dealing with plastic, not steel, but we want rigidity like steel and the only way you get that with plastic is bulk). Start with a solid block and remove just enough of it to fit the unprinted parts (and to allow assembly and quality printing).

When you print parts for a printer, don't even think about using PLA, unless you don't mind reprinting the parts over and over and replacing them frequently. PLA softens and deforms at low temperatures and has no business being used in anything you want to last a long time.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

If can can use CAD software, You don't need someone to provide the stl files for you to print. In the design you're looking at, there are guide rails and a frame in their proper positions. Having just that, designing a printable model to connect the two is pretty easy. 99% of modeling 3D printer parts in CAD is modeling the unprinted stuff first and positioning them where they need to be. The printed parts are easy after the guide rails are set parallel to each other and in the right positions relative to the machine's frame. If I'm designing a printable part, I usually start with the idea that thicker, and more solid is better (we're dealing with plastic, not steel, but we want rigidity like steel and the only way you get that with plastic is bulk). Start with a solid block and remove just enough of it to fit the unprinted parts (and to allow assembly and quality printing).

When you print parts for a printer, don't even think about using PLA, unless you don't mind reprinting the parts over and over and replacing them frequently. PLA softens and deforms at low temperatures and has no business being used in anything you want to last a long time.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: DIY CoreXY May 09, 2022 07:35PM |

Registered: 6 years ago Posts: 1,863 |

With the Chinese businesses closed down and Covid tests stations everywhere decided to purchase all remaining parts from my Country of origin.

Doing so means I have to make changes to my initial build of materials list.

Will be using two MF128ZZ bearings for each of the 4 Belt idler Pulleys these are a little short of correct width an will include PLA spacer washer.

My other 4 idler Belt pulleys and the Belts were found on E-Bay ordered and will be shipped from a local source.

Now is the time I need to get all my presently necessary model printed, as not to waste time when the ordered parts arrive.

I want to start out using an Atmega2560 I know it will work but wanted to see how far I can push it before failure set starts.

An at a later time can replace the Atmega2560 with a much better 32bit controller.

Computer Programmer / Electronics Technician

Doing so means I have to make changes to my initial build of materials list.

Will be using two MF128ZZ bearings for each of the 4 Belt idler Pulleys these are a little short of correct width an will include PLA spacer washer.

My other 4 idler Belt pulleys and the Belts were found on E-Bay ordered and will be shipped from a local source.

Now is the time I need to get all my presently necessary model printed, as not to waste time when the ordered parts arrive.

I want to start out using an Atmega2560 I know it will work but wanted to see how far I can push it before failure set starts.

An at a later time can replace the Atmega2560 with a much better 32bit controller.

Computer Programmer / Electronics Technician

|

Re: DIY CoreXY May 10, 2022 12:13AM |

Registered: 11 years ago Posts: 5,780 |

|

Re: DIY CoreXY December 26, 2022 09:57AM |

Registered: 1 year ago Posts: 28 |

Greetings everyone;

Not 100% corexy here, 3 printers are in various states of redesign. My instant problem is lack of know how in building Marlin on linux.

Target board is a triplet of MKS Robin Nano 3.1 boards, two of which will get a corexy marlin installed, and one will get whatever combo an Ender 5 Plus is.

The Ender 5 Plus has been modified for a Nema 23 3 phase stepper/servo for Y drive, and will get one of the Nema 17 stepper/servo's for X drive. And an LDO direct extruder. A work in progress IOW.

There is also a tronxy-400-pro, which shipped with a non-functional marlin and has yet to print anything, and tronxy has no support, geared only to waste time for the warranty to expire.

The coupling rod for the Y belts on the E5+ is now a 25mm dia CF tube with 8mm inserts in the ends to fit the OEM bearings and pulley's, driven from the end with a 1NM Nema 23

3 phase stepper/servo and the X axis will be a 20x20 CF tube I was in the process of building when my third printer, a Two Trees SP-5 plus died from re-soldering the black wire of

the X home switch with a soldering station plugged into the same UPS as the printer.

That board WAS an MKS Robin Nano V1.2, but that board has step/dir/en pins so it can drive MUCH bigger motors, so I bought 3 of them but amazon shipped me version 3.1 boards.

They still have the pins for bigger stuff. ANAICT, the diff is two motor sockets now grace the 3rd TMC2209 output on the newer version where the 1.2 board stole the E2 driver for Z2.

And cabling to the TFT35 display is different.

That means I have to build Marlin on my own. And such instructions from Marlin are all geared for experienced winderz or Mac users.

This is a Linux only house with about 11 machines in my /etc/hosts file cuz I have a garage full of assorted LinuxCNC machines I've cnc'd to carve metal with.

I'm not exactly an amateur and I am a CET, many times rarer than EE's, most EE's cannot pass that test.

But I have never built Marlin before...

That I need help with if I can get it. So start me at square one.

Thank you.

Take care, stay warm and well everyone.

Cheers, Gene

Not 100% corexy here, 3 printers are in various states of redesign. My instant problem is lack of know how in building Marlin on linux.

Target board is a triplet of MKS Robin Nano 3.1 boards, two of which will get a corexy marlin installed, and one will get whatever combo an Ender 5 Plus is.

The Ender 5 Plus has been modified for a Nema 23 3 phase stepper/servo for Y drive, and will get one of the Nema 17 stepper/servo's for X drive. And an LDO direct extruder. A work in progress IOW.

There is also a tronxy-400-pro, which shipped with a non-functional marlin and has yet to print anything, and tronxy has no support, geared only to waste time for the warranty to expire.

The coupling rod for the Y belts on the E5+ is now a 25mm dia CF tube with 8mm inserts in the ends to fit the OEM bearings and pulley's, driven from the end with a 1NM Nema 23

3 phase stepper/servo and the X axis will be a 20x20 CF tube I was in the process of building when my third printer, a Two Trees SP-5 plus died from re-soldering the black wire of

the X home switch with a soldering station plugged into the same UPS as the printer.

That board WAS an MKS Robin Nano V1.2, but that board has step/dir/en pins so it can drive MUCH bigger motors, so I bought 3 of them but amazon shipped me version 3.1 boards.

They still have the pins for bigger stuff. ANAICT, the diff is two motor sockets now grace the 3rd TMC2209 output on the newer version where the 1.2 board stole the E2 driver for Z2.

And cabling to the TFT35 display is different.

That means I have to build Marlin on my own. And such instructions from Marlin are all geared for experienced winderz or Mac users.

This is a Linux only house with about 11 machines in my /etc/hosts file cuz I have a garage full of assorted LinuxCNC machines I've cnc'd to carve metal with.

I'm not exactly an amateur and I am a CET, many times rarer than EE's, most EE's cannot pass that test.

But I have never built Marlin before...

That I need help with if I can get it. So start me at square one.

Thank you.

Take care, stay warm and well everyone.

Cheers, Gene

|

Re: DIY CoreXY December 27, 2022 07:50AM |

Registered: 11 years ago Posts: 5,780 |

|

Re: DIY CoreXY January 04, 2023 11:34AM |

Registered: 2 years ago Posts: 5 |

|

Re: DIY CoreXY January 15, 2023 03:36PM |

Registered: 1 year ago Posts: 15 |

TH3D has some DIY videos and guides to get VSCode and Marlin sorted. They also have links to pages with repositories for various code you need and how tos.

[support.th3dstudio.com]

There guide on installing a boot loader to a Melzi board was the only one I found.

Bill

Bill

[support.th3dstudio.com]

There guide on installing a boot loader to a Melzi board was the only one I found.

Bill

Bill

|

Re: DIY CoreXY January 23, 2023 07:36AM |

Registered: 1 year ago Posts: 5 |

Sorry, only registered users may post in this forum.