Life span of plastic parts?

Posted by aamcle

|

Life span of plastic parts? September 18, 2022 05:19PM |

Registered: 5 years ago Posts: 145 |

I'm interested in building a printer and in CoreXY motion systems.

In most published builds for example the Hypercube Evo the motors and pullies are mounted in printed parts. The parts are under load from the belts and shock loads from rapid direction changes.

If these parts are printed from ABS or other ridged filament do they wear out or do they need continual adjustment?

Othere than ABS what filaments are suitable and are the carbon fibre blends better?

Thanks aamcle

In most published builds for example the Hypercube Evo the motors and pullies are mounted in printed parts. The parts are under load from the belts and shock loads from rapid direction changes.

If these parts are printed from ABS or other ridged filament do they wear out or do they need continual adjustment?

Othere than ABS what filaments are suitable and are the carbon fibre blends better?

Thanks aamcle

|

Re: Life span of plastic parts? September 18, 2022 10:47PM |

Registered: 11 years ago Posts: 5,780 |

I have built multiple machines that use ABS motor and pulley mounts and belt clamps. If they are well designed and printed with appropriate settings, they last without adjustment or replacement (in my case, some under chamber temperatures of 50C for printing ABS). That said, there are reasons to use metal wherever possible. Metal mounts can conduct heat away from motors. Metals can be drilled, milled, and cut more accurately that most 3D prints, if you have access to the appropriate tools.

Whatever you do, don't use PLA for printed parts in your printer!

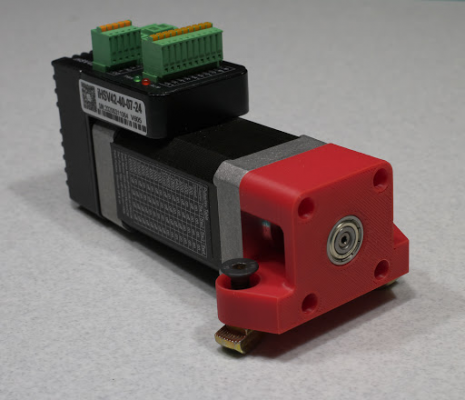

Here's a printed motor mount that should last:

Notice the mount is very bulky. Plastic isn't metal. If you want plastic to be rigid, you need bulk. I design this type of mount by modeling the motor and the thing it will mount on, placed in proper relation to each other. Then I start with a solid block that connects the two, and cut away enough to allow the drive pulley and belt to fit with a little extra space to allow easy assembly. When I print I use at least 3 perimeters (typically 3 mm thick walls) and 50-60% infill. I also add modifiers in the slicer with infill at 95% where screws or bolts are going to put the plastic in compression.

I see a lot of plastic motor mounts designed to look like bent sheet metal. I wouldn't trust them to hold the motor straight against belt tension, or to last very long. I also see a lot of stacked pulleys stood up on posts screwed into plastic. That's not good, either.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Whatever you do, don't use PLA for printed parts in your printer!

Here's a printed motor mount that should last:

Notice the mount is very bulky. Plastic isn't metal. If you want plastic to be rigid, you need bulk. I design this type of mount by modeling the motor and the thing it will mount on, placed in proper relation to each other. Then I start with a solid block that connects the two, and cut away enough to allow the drive pulley and belt to fit with a little extra space to allow easy assembly. When I print I use at least 3 perimeters (typically 3 mm thick walls) and 50-60% infill. I also add modifiers in the slicer with infill at 95% where screws or bolts are going to put the plastic in compression.

I see a lot of plastic motor mounts designed to look like bent sheet metal. I wouldn't trust them to hold the motor straight against belt tension, or to last very long. I also see a lot of stacked pulleys stood up on posts screwed into plastic. That's not good, either.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Life span of plastic parts? September 19, 2022 02:32AM |

Registered: 5 years ago Posts: 145 |

|

Re: Life span of plastic parts? September 19, 2022 05:36PM |

Registered: 3 years ago Posts: 92 |

PLA cracks under continuous high tensile stress and softens with heat, but otherwise holds up just fine. Some parts on my CNC mill have been in use for 2 years now, and the only issues I've had are cracks from the outward pressure of set screws on GT2 pulleys and leadscrew shaft collars. I wrapped the pulley hubs with carbon fiber tow, and replaced the shaft collars with Taulman Tech-G, and both have been fine since. The stepper mounts have never had any problems, despite taking some pretty hard impacts due to my clumsiness. I have overkill NEMA23 steppers which run cool.

I've also had a PLA Petsfang duct on my old CR-10 for many years, and surprisingly the mount has never loosened despite being screwed to the same piece of metal as the hotend. The extruder motor did soften a PLA direct drive mount though, so I replaced that with Tech-G.

I've also had a PLA Petsfang duct on my old CR-10 for many years, and surprisingly the mount has never loosened despite being screwed to the same piece of metal as the hotend. The extruder motor did soften a PLA direct drive mount though, so I replaced that with Tech-G.

|

Re: Life span of plastic parts? September 20, 2022 02:39AM |

Registered: 5 years ago Posts: 145 |

|

Re: Life span of plastic parts? September 20, 2022 09:50AM |

Registered: 11 years ago Posts: 5,780 |

Quote

dekutree64

PLA cracks ... and softens ..., but otherwise holds up just fine.

Otherwise?

All that, and don't ever transport your printer full of PLA corner braces, motor and pulley mounts in a car on a sunny day and stop for coffee...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Life span of plastic parts? September 22, 2022 03:06PM |

Registered: 6 years ago Posts: 36 |

it really boils down to what you plan to do with the printer. Ive seen PLA motor mounts melt from the heat of the motors. Ive even seen some of my ABS parts soften enough for the screws on them to compress the plastic down a bit. If you plan to enclose the printer for high temps youll want to look into high temp materials. Polycarbonate, or metal. PCB Way offers some metal printing as does JLC PCB. though JLC only does stainless, they are VERY cheap and i currently use them to print the water jackets for my water cooled hotends. PCB Way is next up in low cost but still 5x as expensive as JLC but they do aluminum, stainless and titanium.

Bottom line, it comes down to how you plan to use your machine. Open air, PLA might get you by so long as you dont get it near any heat or even leave it in a car. Enclosed ABS or higher temp materials.

I would also like to point out that there is also a bit of a limit with size for CoreXY designs. Its been generally accepted that anything over 350-400mm wide beds CoreXY tends to have issues with due to stretching of belts. Im sure there is a math formula some where but on my 160mmx160mm CoreXY i find my belts to be nearly 4 times the length of the bed width. Even with reinforced belts there will be some stretch. So again, if you plan to enclose and go big, CoreXY may not be the best option, a cross gantry system may be better.

Edited 1 time(s). Last edit at 09/22/2022 03:15PM by OutcastZeroOne.

Bottom line, it comes down to how you plan to use your machine. Open air, PLA might get you by so long as you dont get it near any heat or even leave it in a car. Enclosed ABS or higher temp materials.

I would also like to point out that there is also a bit of a limit with size for CoreXY designs. Its been generally accepted that anything over 350-400mm wide beds CoreXY tends to have issues with due to stretching of belts. Im sure there is a math formula some where but on my 160mmx160mm CoreXY i find my belts to be nearly 4 times the length of the bed width. Even with reinforced belts there will be some stretch. So again, if you plan to enclose and go big, CoreXY may not be the best option, a cross gantry system may be better.

Edited 1 time(s). Last edit at 09/22/2022 03:15PM by OutcastZeroOne.

|

Re: Life span of plastic parts? September 22, 2022 03:45PM |

Registered: 4 years ago Posts: 285 |

|

Re: Life span of plastic parts? September 22, 2022 04:28PM |

Registered: 5 years ago Posts: 145 |

|

Re: Life span of plastic parts? September 26, 2022 08:27AM |

Registered: 11 years ago Posts: 5,780 |

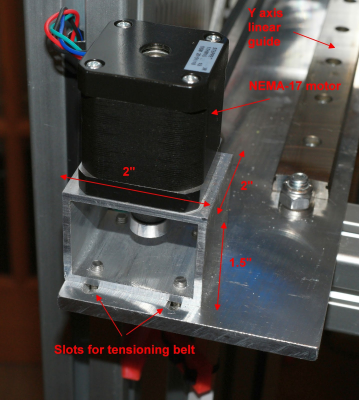

I made motor mounts out of rectangular aluminum tubing- very cheap, and easy DIY, even with limited tools. They don't flex under belt tension, transfer heat away from motors (though in my printer, they may actually be transferring heat to the motor when the chamber heater is in use), and automatically provide an accurate, square mount. You can attach them to the printer's frame with screws in the sides or bottom surface. I drilled motor mounting holes with a drill press and went through the top and bottom of the tube, then enlarged the bottom holes a bit and tapped them. They serve as tool access holes to screw the motor to the tube and as mounting holes to attach the mount to the printer. The wide openings make it easy to access the pulley and belt. I don't remember if I used a hole saw or a fly cutter on a mill to cut the big hole for the motor. Either way will work fine.

I finished with some printed plastic covers to keep curious fingers away from the pulley and belt:

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I finished with some printed plastic covers to keep curious fingers away from the pulley and belt:

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Life span of plastic parts? September 26, 2022 08:35AM |

Admin Registered: 16 years ago Posts: 13,884 |

... by the way -- printed plastic parts can give pretty long lasting elements, if used as casting preforms

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Life span of plastic parts? September 26, 2022 08:36AM |

Registered: 5 years ago Posts: 145 |

|

Re: Life span of plastic parts? September 26, 2022 11:13AM |

Registered: 11 years ago Posts: 5,780 |

No, didn't follow existing design. I did that 4 or 5 years ago, and haven't seen it used by anyone else.

Click the link on Ultra MegaMax Dominator in my sig, below to see more of it.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Click the link on Ultra MegaMax Dominator in my sig, below to see more of it.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Life span of plastic parts? September 26, 2022 11:39AM |

Registered: 5 years ago Posts: 145 |

|

Re: Life span of plastic parts? September 27, 2022 01:42AM |

Registered: 6 years ago Posts: 36 |

|

Re: Life span of plastic parts? September 29, 2022 09:18AM |

Registered: 11 years ago Posts: 5,780 |

You can buy metal mounts from China for $42 each (incl shipping to US), hogged out of a solid billet of aluminum (overkill, I'd say, but pretty)- you still have to add mounting holes or tap the holes for mounting the motor on the mount:

[www.ebay.com]

My tube based mounts are a lot cheaper to make if you have a drill press.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

[www.ebay.com]

My tube based mounts are a lot cheaper to make if you have a drill press.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.