Home

>

Reprappers

>

Topic

Deviant Behavior

Posted by degroof

|

Deviant Behavior March 14, 2008 05:24PM |

Registered: 16 years ago Posts: 447 |

As I've been (slowly) building my Darwin, I've deviated from the standard design in a number of places:

- used metal gears for X, Y and Z axes

- used metal couplings for Y and Z motors

- added a tensioner on the Z belt

- omitted the backlash springs

The first two were done mainly for the sake of durability. The other two were an attempt to get the Z belt to stop slipping.

Has anyone else done any interesting tweaks?

- used metal gears for X, Y and Z axes

- used metal couplings for Y and Z motors

- added a tensioner on the Z belt

- omitted the backlash springs

The first two were done mainly for the sake of durability. The other two were an attempt to get the Z belt to stop slipping.

Has anyone else done any interesting tweaks?

|

Re: Deviant Behavior March 14, 2008 10:52PM |

Registered: 16 years ago Posts: 225 |

|

Re: Deviant Behavior March 14, 2008 11:51PM |

Registered: 16 years ago Posts: 622 |

Windshield washer tubing for your car. Got mine at Shucks. Costs about a buck or two a foot. You only need one foot. Works like a dream. Allows much deviation in your construction method--as pointed out by Forest--and won't bind up horribly if you chance to run your stages into things (#@$%!!!!). I have a time or twenty... ;-)

Demented

Demented

|

Re: Deviant Behavior March 15, 2008 11:52AM |

Admin Registered: 17 years ago Posts: 1,915 |

|

Re: Deviant Behavior March 15, 2008 03:49PM |

Registered: 16 years ago Posts: 622 |

|

Re: Deviant Behavior March 15, 2008 04:07PM |

Admin Registered: 17 years ago Posts: 1,915 |

|

Re: Deviant Behavior March 16, 2008 08:07PM |

Registered: 16 years ago Posts: 622 |

Forest,

You might take a peak in a fish store. Their air lines are sometimes really small. Not as elastic as the stuff I'm using but could work. Also, don't rule out a solid chunck of rubber. 80 thousandths is small enough that if you make a slit in it you can just put in a bit of rubber cement or some such and push the shaft in. Or, zip-ties work well for holding those things together too.

Demented

You might take a peak in a fish store. Their air lines are sometimes really small. Not as elastic as the stuff I'm using but could work. Also, don't rule out a solid chunck of rubber. 80 thousandths is small enough that if you make a slit in it you can just put in a bit of rubber cement or some such and push the shaft in. Or, zip-ties work well for holding those things together too.

Demented

|

Re: Deviant Behavior March 18, 2008 05:47PM |

Registered: 16 years ago Posts: 246 |

|

Re: Deviant Behavior March 19, 2008 12:36PM |

Registered: 16 years ago Posts: 622 |

Or that heat-shrink tubing stuff that we use for bundles of wires. comes in different sizes so you could layer up quite a hefty wall thickness on your joint. Just thought of it because of Sean's idea of shrink wrap. Essentially the same idea. Could apply both of these together if you needed greater wall thickness. Also, I don't think the tubing would be as brittle.

Demented

Demented

|

Re: Deviant Behavior March 19, 2008 01:02PM |

Registered: 16 years ago Posts: 447 |

|

Re: Deviant Behavior March 19, 2008 01:10PM |

Registered: 16 years ago Posts: 447 |

Another hack. I ditched the flexible shaft on the extruder, shortened the motor mount and added a filament guide (paperclip).

|

Re: Deviant Behavior March 19, 2008 01:12PM |

Admin Registered: 17 years ago Posts: 1,915 |

|

Re: Deviant Behavior March 19, 2008 03:00PM |

Admin Registered: 16 years ago Posts: 13,886 |

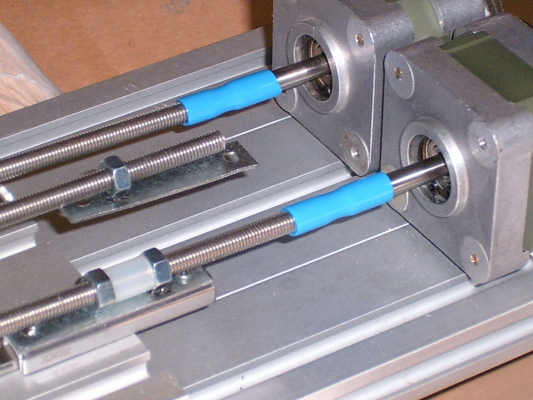

... i used pneumatic hoses for coupling, they are stiff enough but have some inherent elasticity, so you can push them over thicker rods or threads:

Here: [forums.reprap.org] we discussed some of the specs ...

Viktor

Here: [forums.reprap.org] we discussed some of the specs ...

Viktor

|

Re: Deviant Behavior March 20, 2008 10:51PM |

Registered: 16 years ago Posts: 246 |

Sorry, I misspoke

Shrinkwrap is like saran, only designed to shrink up under heat. It'd actually probably be lousy.

Shrink tubing is what I intended to say, but I work with shrinkwrap nearly every day. (Heat sealer at work.)

shrinkwrap won't just get brittle if you keep applying heat. It'll burn through.

Shrinkwrap is like saran, only designed to shrink up under heat. It'd actually probably be lousy.

Shrink tubing is what I intended to say, but I work with shrinkwrap nearly every day. (Heat sealer at work.)

shrinkwrap won't just get brittle if you keep applying heat. It'll burn through.

Sorry, only registered users may post in this forum.