|

Final push to get it running November 14, 2011 05:53AM |

Registered: 14 years ago Posts: 10 |

Hi there, I'm new to this. I have built a mondo reprap and need some help to get it finally up and running.

Using repsnapper i can control the machine and load a part, however if i try to print the part the machine seems to go to one fixed position and stop.

The java based reprap program will sometimes load sometimes control the machine but generally hangs up on loading.

Pronterface will load, control the machine and correctly print a part... apart from it doesn't run the extruder.

All pretty annoying!!!

I have a few bugs to work out with the extruder but some advice with software would help!

Thanks.

Using repsnapper i can control the machine and load a part, however if i try to print the part the machine seems to go to one fixed position and stop.

The java based reprap program will sometimes load sometimes control the machine but generally hangs up on loading.

Pronterface will load, control the machine and correctly print a part... apart from it doesn't run the extruder.

All pretty annoying!!!

I have a few bugs to work out with the extruder but some advice with software would help!

Thanks.

|

Re: Final push to get it running November 14, 2011 06:21AM |

Registered: 14 years ago Posts: 3,742 |

Quote

Cynic-al

Pronterface will load, control the machine and correctly print a part... apart from it doesn't run the extruder.

What slice software are you using?

If you are using Skeinforge (or SFACT) then you must turn on Dimension.

You should attach your gcode file, if no E codes are present then you don't have Dimension turned on.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: Final push to get it running December 02, 2011 09:05AM |

Registered: 14 years ago Posts: 10 |

Hi there, thanks for the reply and sorry for the delay.

Been doing a bit more playing, when I click print all the axis go home but then nothing, I seem to be getting an error "ERROR: GCodeWriter.waitForResponse() - dud response from RepRap:Resend:12 (hex: 52657365e643a3132)". The error seems to be repeated for every line of code. The Gcode is attached as generated by the Java hose software and the part is just a round disk as a trial. I've also tried the 'minimug.stl' and had the same sort of problem.

Bound to be something stupid just not sure what

Been doing a bit more playing, when I click print all the axis go home but then nothing, I seem to be getting an error "ERROR: GCodeWriter.waitForResponse() - dud response from RepRap:Resend:12 (hex: 52657365e643a3132)". The error seems to be repeated for every line of code. The Gcode is attached as generated by the Java hose software and the part is just a round disk as a trial. I've also tried the 'minimug.stl' and had the same sort of problem.

Bound to be something stupid just not sure what

|

Re: Final push to get it running December 02, 2011 09:20AM |

Admin Registered: 12 years ago Posts: 2,569 |

|

Re: Final push to get it running December 02, 2011 10:27AM |

Registered: 12 years ago Posts: 972 |

i did have some problems with my electronics (RAMPS-based). My problem was that USB would get disconnected because of EMI interference, mostly when a motor or extruder hot-end would be started. The error code you get suggests there is a communication problem once the print tries to start but not before. You can try to move each axis and extruder with pronterface manually to see whether the printer stops suddenly responding. You can see that happens because it will stop responding to you commands. If this happens I bet that disconnecting and connecting again may help.

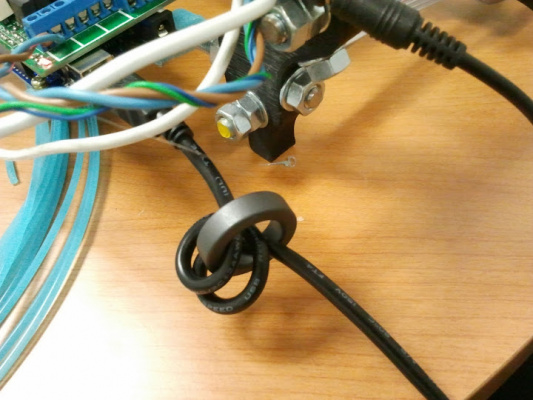

If your problem looks like mine, a ferrite torus in your USB cable is the cure.

misan

If your problem looks like mine, a ferrite torus in your USB cable is the cure.

misan

|

Re: Final push to get it running December 04, 2011 08:31PM |

Registered: 12 years ago Posts: 58 |

misan Wrote:

-------------------------------------------------------

> i did have some problems with my electronics

> (RAMPS-based). My problem was that USB would get

> disconnected because of EMI interference, mostly

> when a motor or extruder hot-end would be started.

> The error code you get suggests there is a

> communication problem once the print tries to

> start but not before. You can try to move each

> axis and extruder with pronterface manually to see

> whether the printer stops suddenly responding. You

> can see that happens because it will stop

> responding to you commands. If this happens I bet

> that disconnecting and connecting again may help.

>

>

> If your problem looks like mine, a ferrite torus

> in your USB cable is the cure.

>

> misan

Hi all... this is EXACTLY what I am experiencing. Just finished wiring up the motors and installing Pronterface and while jogging or extruding, the power supply would just turn off. I've been thinking that it was too much current draw on the supply causing a dip in the voltage to the cpu.

Do I need to replace the USB cable or just put a ferrite on it. I don't even know where to get one. More information on this please!

Thank you!!!

Ross

-------------------------------------------------------

> i did have some problems with my electronics

> (RAMPS-based). My problem was that USB would get

> disconnected because of EMI interference, mostly

> when a motor or extruder hot-end would be started.

> The error code you get suggests there is a

> communication problem once the print tries to

> start but not before. You can try to move each

> axis and extruder with pronterface manually to see

> whether the printer stops suddenly responding. You

> can see that happens because it will stop

> responding to you commands. If this happens I bet

> that disconnecting and connecting again may help.

>

>

> If your problem looks like mine, a ferrite torus

> in your USB cable is the cure.

>

> misan

Hi all... this is EXACTLY what I am experiencing. Just finished wiring up the motors and installing Pronterface and while jogging or extruding, the power supply would just turn off. I've been thinking that it was too much current draw on the supply causing a dip in the voltage to the cpu.

Do I need to replace the USB cable or just put a ferrite on it. I don't even know where to get one. More information on this please!

Thank you!!!

Ross

|

Re: Final push to get it running December 05, 2011 02:57AM |

Registered: 12 years ago Posts: 972 |

When you say power supply goes off, what happens to make you think this way? How do you recognize power is gone?

In my case, power supply was not gone, but because the board has been reseted, printing was interrupted and all motors became unpowered (as it corresponds to the reset state, where no current is delivered to any motor, so x and y carriages can easily moved by hand).

I just happened to have a ferrite core around, and two loops of the cable did it. Maybe you already have a USB cable with one bulge on it from some other device. Sometimes is a protruding plastic piece on the cable what signals the presence of a ferrite torus inside.

However, if you problem is really that the power supply gives up and stops providing energy to your controller, then it might be due to an overload or shortcircuit you'll need to diagnose and fix.

In my case, power supply was not gone, but because the board has been reseted, printing was interrupted and all motors became unpowered (as it corresponds to the reset state, where no current is delivered to any motor, so x and y carriages can easily moved by hand).

I just happened to have a ferrite core around, and two loops of the cable did it. Maybe you already have a USB cable with one bulge on it from some other device. Sometimes is a protruding plastic piece on the cable what signals the presence of a ferrite torus inside.

However, if you problem is really that the power supply gives up and stops providing energy to your controller, then it might be due to an overload or shortcircuit you'll need to diagnose and fix.

|

Re: Final push to get it running December 05, 2011 10:59AM |

Registered: 12 years ago Posts: 58 |

Thank you for your reply Misan,

I am using Gen7 electronics. The computer power supply is turned on and off as needed in software. The power supply always provides a small current 5 volt supply for the processor but the main supply is turned off and on. There are two led's on board that indicate the small current 5 volt supply and the main supply when it is on.

When I turn on the power supply (with the switch on the power supply itself) the 5 volt led indicates it has power. I then "connect" with Pronterface. When I then "jog" one of the motors or "turn on" the extruder heater, the power supply comes out of sleep mode and the second led indicator comes on to let you know the power supply has turned on.

When I am having problems, I notice that the power supply indicator turns off and I no longer have any control from the Pronterface panel. But I still have the 5 volt supply (indicated by the 5 volt LED). So it appears that the USB communication get's confused. Either that or the power supply is shutting down to protect over-current... but there's never any indication of heat or smell to indicate I am taxing the supply.

I hope that explains it ok.

Regards!

Ross

You don't need a parachute to skydive. You only need a parachute to skydive twice.

I am using Gen7 electronics. The computer power supply is turned on and off as needed in software. The power supply always provides a small current 5 volt supply for the processor but the main supply is turned off and on. There are two led's on board that indicate the small current 5 volt supply and the main supply when it is on.

When I turn on the power supply (with the switch on the power supply itself) the 5 volt led indicates it has power. I then "connect" with Pronterface. When I then "jog" one of the motors or "turn on" the extruder heater, the power supply comes out of sleep mode and the second led indicator comes on to let you know the power supply has turned on.

When I am having problems, I notice that the power supply indicator turns off and I no longer have any control from the Pronterface panel. But I still have the 5 volt supply (indicated by the 5 volt LED). So it appears that the USB communication get's confused. Either that or the power supply is shutting down to protect over-current... but there's never any indication of heat or smell to indicate I am taxing the supply.

I hope that explains it ok.

Regards!

Ross

You don't need a parachute to skydive. You only need a parachute to skydive twice.

|

Re: Final push to get it running December 05, 2011 11:56AM |

Registered: 12 years ago Posts: 972 |

Hi Ross,

I get it. RAMPS or Gen7 may both have trouble with USB communication and be reset because of this. I am not familiar with Gen7 leds but my first guess is that your problem could be software based (as no smoke has been released just yet).

I am not sure whether your power supply is shutdown or your power led is confusing you. In RAMPS the power led is software controlled and it does not act as a real power indicator (with Sprinter it signals the hotend is being powered).

One thing you can attempt (other than the ferrite torus I mentioned) is to run a print *whithout* the power supply. This will cause no motion at all but if everything is running fine then, you will know that your disconnection is caused by interference to USB from Gen7 board.

I hope it helps,

misan

I get it. RAMPS or Gen7 may both have trouble with USB communication and be reset because of this. I am not familiar with Gen7 leds but my first guess is that your problem could be software based (as no smoke has been released just yet).

I am not sure whether your power supply is shutdown or your power led is confusing you. In RAMPS the power led is software controlled and it does not act as a real power indicator (with Sprinter it signals the hotend is being powered).

One thing you can attempt (other than the ferrite torus I mentioned) is to run a print *whithout* the power supply. This will cause no motion at all but if everything is running fine then, you will know that your disconnection is caused by interference to USB from Gen7 board.

I hope it helps,

misan

|

Re: Final push to get it running December 05, 2011 12:44PM |

Registered: 12 years ago Posts: 58 |

HI Misan,

The power LED indicator comes on when the power supply turns on (out of standby mode). Power from the supply drives the LED.

I'm leaning towards noise generated by the stepper motors. I think noise is interfering with USB communications and sending the control software to "yaya" land. I am going to try powering the AVR from the USB cable and using a different USB cable with a ferrite supressor on it. I'm thinking that's my ticket. I love the idea of running the software with the power supply turned off but I'm not sure yet how to do that. I think the software is waiting for the extruder to heat up before it runs and therefore would not operate with the power supply turned off?

Haven't lost any magic smoke yet!

I'm such a nube! ;-P

I feel so close!!! I'm jogging motors, heating and jogging the extruder, loading an stl file... somebody pinch me!!!

I NEED TO PRINT SOMETHING!!! :-)

Ross

You don't need a parachute to skydive. You only need a parachute to skydive twice.

The power LED indicator comes on when the power supply turns on (out of standby mode). Power from the supply drives the LED.

I'm leaning towards noise generated by the stepper motors. I think noise is interfering with USB communications and sending the control software to "yaya" land. I am going to try powering the AVR from the USB cable and using a different USB cable with a ferrite supressor on it. I'm thinking that's my ticket. I love the idea of running the software with the power supply turned off but I'm not sure yet how to do that. I think the software is waiting for the extruder to heat up before it runs and therefore would not operate with the power supply turned off?

Haven't lost any magic smoke yet!

I'm such a nube! ;-P

I feel so close!!! I'm jogging motors, heating and jogging the extruder, loading an stl file... somebody pinch me!!!

I NEED TO PRINT SOMETHING!!! :-)

Ross

You don't need a parachute to skydive. You only need a parachute to skydive twice.

|

Re: Final push to get it running December 05, 2011 12:51PM |

Registered: 12 years ago Posts: 972 |

Ross.

Most slicers won't add a command for your board to wait for target temperature. Instead, they use M104 command in your gcode to set the temperature of the print (or nothing at all). However, firmware is waiting for your prusa to go to the home location to start printing. This is most likely the endless wait you see.

You can trick the firmware to think it is printing by pressing end-stops in sequence x,y,z (once or twice). After that you'll see the print process to be progressing (there is an online view of what repsnapper is sending to the printer).

I think you're almost there,

misan

Most slicers won't add a command for your board to wait for target temperature. Instead, they use M104 command in your gcode to set the temperature of the print (or nothing at all). However, firmware is waiting for your prusa to go to the home location to start printing. This is most likely the endless wait you see.

You can trick the firmware to think it is printing by pressing end-stops in sequence x,y,z (once or twice). After that you'll see the print process to be progressing (there is an online view of what repsnapper is sending to the printer).

I think you're almost there,

misan

|

Re: Final push to get it running December 05, 2011 01:17PM |

Registered: 12 years ago Posts: 58 |

|

Re: Final push to get it running December 08, 2011 11:43AM |

Registered: 14 years ago Posts: 10 |

Hi

I've downloaded a file from here (www.3dtoolchain.com) and that runs ok so it must be my gcode. I will try the software above, i'm sire that will help.

Currently trying to get it to print the 40mm test cube from the above site, it runs fine, all axis and motors work however its not extruding even though the motor is turning. I'm using ABS and have done the obvious things of go tighter with the springs and go hotter but its not playing. Its definately getting hot and its reporting what appears to be the correct temperature. Going to strip it down to see if its blocked.

I've downloaded a file from here (www.3dtoolchain.com) and that runs ok so it must be my gcode. I will try the software above, i'm sire that will help.

Currently trying to get it to print the 40mm test cube from the above site, it runs fine, all axis and motors work however its not extruding even though the motor is turning. I'm using ABS and have done the obvious things of go tighter with the springs and go hotter but its not playing. Its definately getting hot and its reporting what appears to be the correct temperature. Going to strip it down to see if its blocked.

|

Re: Final push to get it running December 13, 2011 02:46AM |

Registered: 12 years ago Posts: 3 |

|

Re: Final push to get it running December 13, 2011 03:02AM |

Registered: 12 years ago Posts: 972 |

@Cynic-al: I presume the extruder is not working from Proterface button. Till this is not working I won't be surprised if it does not work while printing. I guess some of the mechanics is not quite right yet. I would check the temperature of the hotend, that the hot-end extrude hole is clear, then that you can extrude by pushing the filament with your hand into the hotend, that the motor turns with the extrude command with no filament, that the big gear turns without filament in the extruder and that the hobbed bolt teeth are properly aligned with the extruder filament guide. If all the above works ok, I think you should up and running once the motor current in the pololu is hgh enough.

Please note that sometimes after some heating and retraction of the filament, its tip might get thicker and it might make imposible to work. If that is the case you need to remove the filament and cut the tip and insert it back.

misan

Please note that sometimes after some heating and retraction of the filament, its tip might get thicker and it might make imposible to work. If that is the case you need to remove the filament and cut the tip and insert it back.

misan

|

Re: Final push to get it running December 21, 2011 08:04AM |

Registered: 14 years ago Posts: 10 |

|

Re: Final push to get it running December 21, 2011 08:38AM |

Registered: 12 years ago Posts: 972 |

|

Re: Final push to get it running February 07, 2012 08:43AM |

Registered: 14 years ago Posts: 10 |

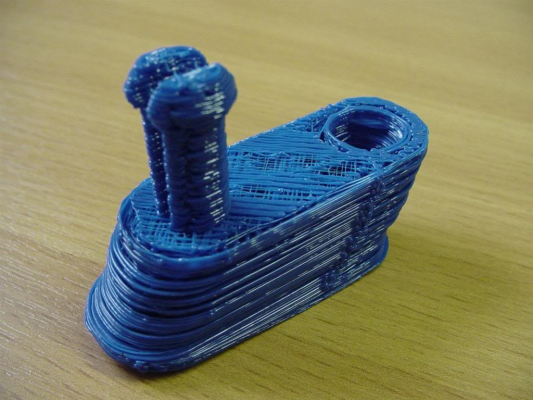

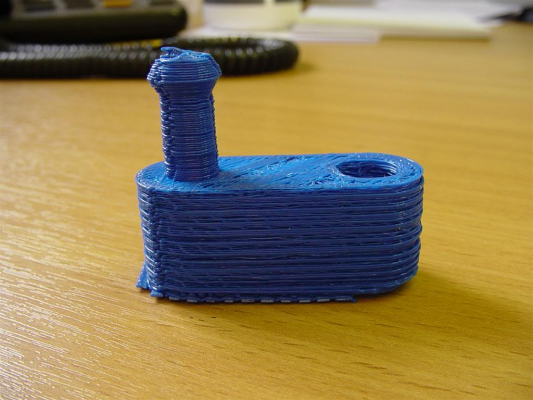

Well apologies for the long delay, I got caught up is some other work and this got put on the fence a little, however with thanks to the above suggestions I got it running so thanks to all who posted. Software wise I ended up creating the part in solidworks then converting with skeinforge and printing with repsnapper.

Photos of the first semi sucessful part are below and I would welcome suggestions for ways to improve the quality. The main issue is the body is not vertical (supposed to have straight sides), at first I thought the machine was not repeating the profile accurately however the post on the top is vertical so this leads me to believe its something else. Also the body seems to have saggged on the left hand side. I'm guessing its due to the fact that the right hand side has a hole through it where as the left is solid. It's currently doing a fairly hollow infill so I wonder if the surface of the hole is creating a more stable structure, do you think making the body infill more solid would help? Any other suggestions?

Thanks all.

Photos of the first semi sucessful part are below and I would welcome suggestions for ways to improve the quality. The main issue is the body is not vertical (supposed to have straight sides), at first I thought the machine was not repeating the profile accurately however the post on the top is vertical so this leads me to believe its something else. Also the body seems to have saggged on the left hand side. I'm guessing its due to the fact that the right hand side has a hole through it where as the left is solid. It's currently doing a fairly hollow infill so I wonder if the surface of the hole is creating a more stable structure, do you think making the body infill more solid would help? Any other suggestions?

Thanks all.

|

Re: Final push to get it running February 07, 2012 09:50AM |

Registered: 14 years ago Posts: 10 |

|

Re: Final push to get it running February 07, 2012 12:11PM |

Registered: 12 years ago Posts: 88 |

The top layers look like the filament isn't being put down evenly. There are thick and thin spots. When you opened up the extruder did it seem to be feeding ok? Were there any little chips of filament in there? If you turn the extruder gears manually does it feed ok?

The layer offset problems could also be caused by the filament not feeding in properly. How is it mounted? If it is pulling too much the carriage could slip on the belt. Check that the belt is snug.

What did you use to slice the object? Skeinforge v40+ has default settings for DC motors. If you have a Prusa with stepper motors make sure the Speed in Skeinforge is set the same for Feed and Flow, I suggest start with 20. I had a problem with that, it was trying to feed filament way too fast and was chewing up the filament and not feeding it reliably.

The layer offset problems could also be caused by the filament not feeding in properly. How is it mounted? If it is pulling too much the carriage could slip on the belt. Check that the belt is snug.

What did you use to slice the object? Skeinforge v40+ has default settings for DC motors. If you have a Prusa with stepper motors make sure the Speed in Skeinforge is set the same for Feed and Flow, I suggest start with 20. I had a problem with that, it was trying to feed filament way too fast and was chewing up the filament and not feeding it reliably.

|

Re: Final push to get it running February 07, 2012 03:27PM |

Registered: 12 years ago Posts: 972 |

Congratulations on your print. It seems you are almost there :-)

I am not sure I've understand it correctly, but it seems your part walls should be vertical but there are not, right? (You can post the part stl for us to know how the part should look like).

If that is the case, it seems one of your axis (X or Y), the one in the longest dimension, is skipping steps and so you get a slope instead of a vertical wall. Maybe more current is needed for this axis stepper motor.

Bottom layer warping is also noticeable, bed adhesion is kind of low, this may be a problem when printing larger parts (or if better dimensional accuracy is needed).

Skeinforge takes a while for the user to understand the many parameters involved. One of the important tuning factors is to get the extruder steps per mm right in the firmware. Once you have the dimensional test cubes of right size you should make sure you have your extruder steps value right. (And we always talk here about filament millimeters entering the extruder).

I am not sure I've understand it correctly, but it seems your part walls should be vertical but there are not, right? (You can post the part stl for us to know how the part should look like).

If that is the case, it seems one of your axis (X or Y), the one in the longest dimension, is skipping steps and so you get a slope instead of a vertical wall. Maybe more current is needed for this axis stepper motor.

Bottom layer warping is also noticeable, bed adhesion is kind of low, this may be a problem when printing larger parts (or if better dimensional accuracy is needed).

Skeinforge takes a while for the user to understand the many parameters involved. One of the important tuning factors is to get the extruder steps per mm right in the firmware. Once you have the dimensional test cubes of right size you should make sure you have your extruder steps value right. (And we always talk here about filament millimeters entering the extruder).

|

Re: Final push to get it running February 09, 2012 05:46AM |

Registered: 13 years ago Posts: 486 |

looks like your pulley is slipping on the x or y motor shaft (which explains your inconsistent layer placement)

also looks like and your idler is not tight enough to provide consistent feed (or that may also be a partially clogged bolt hobbing).

Edited 1 time(s). Last edit at 02/09/2012 04:28PM by Greg Frost.

also looks like and your idler is not tight enough to provide consistent feed (or that may also be a partially clogged bolt hobbing).

Edited 1 time(s). Last edit at 02/09/2012 04:28PM by Greg Frost.

|

Re: Final push to get it running February 17, 2012 05:16AM |

Registered: 14 years ago Posts: 10 |

Hi again. Apologies for the delay in replies, its something I'm playing with between other jobs so its sat on the back burner a bit. I've had a go at some of the changes you've suggested, a big help, thanks! I've upped the motor current a bit, i'd set it just enough to move which perhaps wasn't enough when printing. The highest temperature is currently 36 degrees so it should be ok. I've spent a bit of time pouring over one of the websites for skeinforge too which has helped my understanding. Updates photos below, its still not extruding consistantly so I'm going to strip the extruder and have a look.

Thanks for all the advice, its appreciated!

Thanks for all the advice, its appreciated!

|

Re: Final push to get it running February 17, 2012 07:43AM |

Registered: 12 years ago Posts: 187 |

Its worth giving Slic3r a shot. RichRap covers setting the program up and tips/tricks on his blog (link).

I was able to get decent prints from the off (I'm a complete newbie).

ps I found the thin wall hollow objects help a lot when your calibrating.

My Reprap blog

jds-reprap.blogspot.com

I was able to get decent prints from the off (I'm a complete newbie).

ps I found the thin wall hollow objects help a lot when your calibrating.

My Reprap blog

jds-reprap.blogspot.com

|

Re: Final push to get it running February 17, 2012 07:46AM |

Registered: 12 years ago Posts: 972 |

|

Re: Final push to get it running February 17, 2012 09:54PM |

Registered: 12 years ago Posts: 88 |

Sorry, only registered users may post in this forum.