Home

>

Reprappers

>

Topic

Longboat Prusa Batch 3 thermistors

Posted by NigeO

|

Longboat Prusa Batch 3 thermistors February 22, 2012 06:56AM |

Registered: 12 years ago Posts: 9 |

I've got an almost-complete Longboat Prusa, using the supplied 3mm PLA. The extruder runs but won't extrude. The supplied bead thermistor is approx 2.3K at 20C, different from the 10K calibration on the wiki, so it initially didn't heat at all. I took a guess that it might be [uk.rs-online.com] as the previous one was noted as being an RS part and this is the nearest, but it doesn't seem to be right. It could be the EPCOS B57550G103J, but that's nearly the same beta.

The hot end is getting hot, but I don't have a thermometer that will go to 185 to check if it is correct, I suspect my guessed calibration is incorrect as I don't know the beta for the thermistor.

Is there a useful setup instruction for the wade's extruder that I could link on the wiki build page? Is there a way to check I've got the right extruder for the supplied 3mm PLA?

Has anyone else got this batch extruding? Can you update the wiki with a working calibration? I've had no luck previously getting replies from the reprapkitstore, so really hoping someone here can help, 'air prints' are starting to lose their appeal :-(

Thanks,

Nige

The hot end is getting hot, but I don't have a thermometer that will go to 185 to check if it is correct, I suspect my guessed calibration is incorrect as I don't know the beta for the thermistor.

Is there a useful setup instruction for the wade's extruder that I could link on the wiki build page? Is there a way to check I've got the right extruder for the supplied 3mm PLA?

Has anyone else got this batch extruding? Can you update the wiki with a working calibration? I've had no luck previously getting replies from the reprapkitstore, so really hoping someone here can help, 'air prints' are starting to lose their appeal :-(

Thanks,

Nige

|

Re: Longboat Prusa Batch 3 thermistors February 22, 2012 02:51PM |

Registered: 12 years ago Posts: 22 |

Hi Nige,

I was a bit impatient, so I ordered the 100K thermistors from RS myself rather than waiting.

When the kit thermistors arrived separately, they looked identical so I just kept them as spares.

But I've just checked them, and they are ~2K, the same as yours.

I think they are this glass bead one, as they appear to match what's in the data sheet.

-Mark

I was a bit impatient, so I ordered the 100K thermistors from RS myself rather than waiting.

When the kit thermistors arrived separately, they looked identical so I just kept them as spares.

But I've just checked them, and they are ~2K, the same as yours.

I think they are this glass bead one, as they appear to match what's in the data sheet.

-Mark

|

Re: Longboat Prusa Batch 3 thermistors February 23, 2012 03:38AM |

Hi Both,

We fitted the supplied 2k thermistors and spent hours getting them to work. Short answer, we couldn't properly. We have now ordered the 100k Epco ones that should have been supplied. From my research, 2k are for up to 70deg C range and innapropriate for the extruder temps of circa 200deg C. I can find no one else using such low value thermistors. The reistance at this temperature is only a few hundred ohms.

By fitting a 2 x 470 ohm resistors in series with the supplied thermistor you can raise the extruder head temp sufficiently to extrude - but beware - you are operating on the flat part of the temperature curve and with our set up the highest setting to achieve extrusion is at the limit ie it will not regulate. We used it cautiously to continue commisioning, manually turning off when things got too hot. With the series resistors fitted, ext temps displayed were 154deg C, actual temp 190 plus. At 153 it would regulate the temp but not extrude too well, at 154 it would extrude but not regulate. The bed similarly reports the wrong readings, (none of the thermistor tables apply), but again by setting it to read a bed temperature of 165deg C it was in fact measured at about 60 deg C - again sufficient to test print etc. We got some suprisingly good first prints.

Mark did the right thing and we will be fitting the 100k Epcos before next use.

Dennis

We fitted the supplied 2k thermistors and spent hours getting them to work. Short answer, we couldn't properly. We have now ordered the 100k Epco ones that should have been supplied. From my research, 2k are for up to 70deg C range and innapropriate for the extruder temps of circa 200deg C. I can find no one else using such low value thermistors. The reistance at this temperature is only a few hundred ohms.

By fitting a 2 x 470 ohm resistors in series with the supplied thermistor you can raise the extruder head temp sufficiently to extrude - but beware - you are operating on the flat part of the temperature curve and with our set up the highest setting to achieve extrusion is at the limit ie it will not regulate. We used it cautiously to continue commisioning, manually turning off when things got too hot. With the series resistors fitted, ext temps displayed were 154deg C, actual temp 190 plus. At 153 it would regulate the temp but not extrude too well, at 154 it would extrude but not regulate. The bed similarly reports the wrong readings, (none of the thermistor tables apply), but again by setting it to read a bed temperature of 165deg C it was in fact measured at about 60 deg C - again sufficient to test print etc. We got some suprisingly good first prints.

Mark did the right thing and we will be fitting the 100k Epcos before next use.

Dennis

|

Re: Longboat Prusa Batch 3 thermistors February 23, 2012 05:15AM |

Registered: 12 years ago Posts: 9 |

Dee Cee Wrote:

-------------------------------------------------------

> couldn't properly. We have now ordered the 100k

> Epco ones that should have been supplied.

[...snip...]

> Mark did the right thing and we will be fitting

> the 100k Epcos before next use.

Patience didn't pay off, in this case! I can't believe it, I shouldn't have waited for the back order (and then was pleased when it arrived just when I needed it!) :-(

I tried last night progressively higher temps, but it didn't work, so I will put it on hold and order from RS.

Are there any other tricks to getting it to extrude or should it 'just work'? Are the wing-nut tightnesses critical, I've got the ends of the thread just poking through and it seems to be handling the material OK.

I put a little heat transfer paste on the hot end/extruder thread to make sure there's a good thermal bond.

Does anyone have insulation around the hot end (as I've seen on someone's build of another device)? I tried pressing a piece of PLA against the hot end to see if it would soften/flatten (trying to work out whether the problem was feed or temperature) and guessed that as it didn't soften the temperature was the problem.

Thanks for all the pointers

Nigel

-------------------------------------------------------

> couldn't properly. We have now ordered the 100k

> Epco ones that should have been supplied.

[...snip...]

> Mark did the right thing and we will be fitting

> the 100k Epcos before next use.

Patience didn't pay off, in this case! I can't believe it, I shouldn't have waited for the back order (and then was pleased when it arrived just when I needed it!) :-(

I tried last night progressively higher temps, but it didn't work, so I will put it on hold and order from RS.

Are there any other tricks to getting it to extrude or should it 'just work'? Are the wing-nut tightnesses critical, I've got the ends of the thread just poking through and it seems to be handling the material OK.

I put a little heat transfer paste on the hot end/extruder thread to make sure there's a good thermal bond.

Does anyone have insulation around the hot end (as I've seen on someone's build of another device)? I tried pressing a piece of PLA against the hot end to see if it would soften/flatten (trying to work out whether the problem was feed or temperature) and guessed that as it didn't soften the temperature was the problem.

Thanks for all the pointers

Nigel

|

Re: Longboat Prusa Batch 3 thermistors February 23, 2012 06:09AM |

Registered: 13 years ago Posts: 12 |

Hello

I was made aware of this thread last night.

It has taken me a while to work but what’s happened is on Dec 29th I ordered as part of a larger order and by mistake 100x 2k thermistors these were placed on back order by RS and I believed I had then cancelled them.

The 100x I recently ordered on the 29th of Jan were also placed on back order, they still have not arrived. But the back order 100 from December then turned up a few days later and Chloe mistook them for the recently ordered 100

It means the kits we sent at the end of January did in fact contain 2k thermistors which are of course wrong. I am currently contacting all the effected customers to inform them to disregard the thermistors and await replacement ones.

Kind Regards

The RepRap Kit Store

James

I was made aware of this thread last night.

It has taken me a while to work but what’s happened is on Dec 29th I ordered as part of a larger order and by mistake 100x 2k thermistors these were placed on back order by RS and I believed I had then cancelled them.

The 100x I recently ordered on the 29th of Jan were also placed on back order, they still have not arrived. But the back order 100 from December then turned up a few days later and Chloe mistook them for the recently ordered 100

It means the kits we sent at the end of January did in fact contain 2k thermistors which are of course wrong. I am currently contacting all the effected customers to inform them to disregard the thermistors and await replacement ones.

Kind Regards

The RepRap Kit Store

James

|

Re: Longboat Prusa Batch 3 thermistors February 23, 2012 06:11AM |

Registered: 12 years ago Posts: 9 |

Another thought, it looks like the problem is the pullup on the thermistor (4.7K) meaning that at 185C the ADC counts are so low that it's unusable.

If I put 100 ohm across the pullup as a better match for the 2K thermistor, the ADC scaling would be right. Any likely problem with that?

Worst case power dissipation 1/4W on the resistor, can produce the updated tables with the python script, and I can make progress with the supplied thermistors. From [reprap.org] it would be R9/R10, and they are through-hole so shouldn't be hard to solder a resistor across it, giving a total of 98ohm, nearly the same table as the original 100K part, so it might even be possible to not need to reload calibration.

It should avoid the problem DeeCee noted (just adding series resistance to the thermistor), will report back on how it goes...

Nigel

If I put 100 ohm across the pullup as a better match for the 2K thermistor, the ADC scaling would be right. Any likely problem with that?

Worst case power dissipation 1/4W on the resistor, can produce the updated tables with the python script, and I can make progress with the supplied thermistors. From [reprap.org] it would be R9/R10, and they are through-hole so shouldn't be hard to solder a resistor across it, giving a total of 98ohm, nearly the same table as the original 100K part, so it might even be possible to not need to reload calibration.

It should avoid the problem DeeCee noted (just adding series resistance to the thermistor), will report back on how it goes...

Nigel

|

Re: Longboat Prusa Batch 3 thermistors February 23, 2012 06:48AM |

Admin Registered: 17 years ago Posts: 7,879 |

The problem you will get is the thermistor will heat itself, giving a reading too high, assuming it does not burn out. The data sheet will give the maximum power dissipation and the self heating error.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Longboat Prusa Batch 3 thermistors February 23, 2012 11:10AM |

Nigel,

You are right about the low adc volts but I agree with nophead, either wait for James to send you the right type or get one from RS, they have them in stock, picked two up today. Even if you frigged it to work like we did it wouldn't be calibrated if you need to adjust a few degress for different PLA material or ABS etc. The curve is too flat, don't waste your time.

Regards,

Dennis

You are right about the low adc volts but I agree with nophead, either wait for James to send you the right type or get one from RS, they have them in stock, picked two up today. Even if you frigged it to work like we did it wouldn't be calibrated if you need to adjust a few degress for different PLA material or ABS etc. The curve is too flat, don't waste your time.

Regards,

Dennis

|

Re: Longboat Prusa Batch 3 thermistors February 24, 2012 07:39AM |

Registered: 12 years ago Posts: 9 |

nophead Wrote:

-------------------------------------------------------

> The problem you will get is the thermistor will

> heat itself, giving a reading too high, assuming

> it does not burn out. The data sheet will give the

> maximum power dissipation and the self heating

> error.

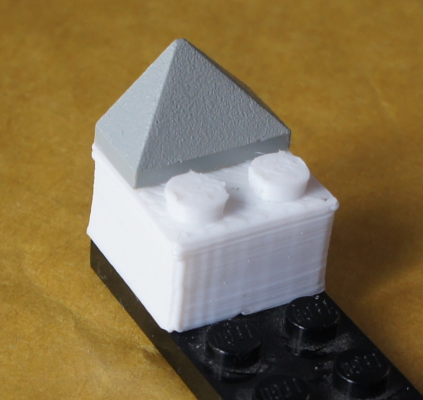

Thanks for the warning. As there are new parts coming anyway and no likely damage to other parts, I did the mod and finally got printing. Quality was what I'd expect for a first print (usable but not very sharp) and after setting the Pololu Vref (Y-axis was 'slipping') and running through the calibration tutorial at [richrap.blogspot.com] I managed to print a lego-compatible block which would fit to a real Lego block. I'll call that success for now and look forward to the real parts arriving!

Many thanks all for the help, I've updated the build wiki with details so others don't do so much head-scratching (as it was my first build I assumed it was something I'd done wrong).

I timed the build, including adding later steps to the wiki and struggling with the thermistor, it was just over 20 hours to first print. I think James's (understated) claim on his website that this is modified for faster production is well and truly proven, it was a really easy build, pretty much at the Ikea furniture level for the hardware, although the software would have been harder if I wasn't already confident with Arduino.

2 very excited kids have trotted off to school today with 3D prints clasped in their hands, they've been trying to explain to their mates who still think it's something like 3D TV printed on paper rather than 'real' 3D...

Nigel

-------------------------------------------------------

> The problem you will get is the thermistor will

> heat itself, giving a reading too high, assuming

> it does not burn out. The data sheet will give the

> maximum power dissipation and the self heating

> error.

Thanks for the warning. As there are new parts coming anyway and no likely damage to other parts, I did the mod and finally got printing. Quality was what I'd expect for a first print (usable but not very sharp) and after setting the Pololu Vref (Y-axis was 'slipping') and running through the calibration tutorial at [richrap.blogspot.com] I managed to print a lego-compatible block which would fit to a real Lego block. I'll call that success for now and look forward to the real parts arriving!

Many thanks all for the help, I've updated the build wiki with details so others don't do so much head-scratching (as it was my first build I assumed it was something I'd done wrong).

I timed the build, including adding later steps to the wiki and struggling with the thermistor, it was just over 20 hours to first print. I think James's (understated) claim on his website that this is modified for faster production is well and truly proven, it was a really easy build, pretty much at the Ikea furniture level for the hardware, although the software would have been harder if I wasn't already confident with Arduino.

2 very excited kids have trotted off to school today with 3D prints clasped in their hands, they've been trying to explain to their mates who still think it's something like 3D TV printed on paper rather than 'real' 3D...

Nigel

|

Re: Longboat Prusa Batch 3 thermistors February 24, 2012 08:22AM |

Registered: 12 years ago Posts: 51 |

|

Re: Longboat Prusa Batch 3 thermistors February 24, 2012 10:07AM |

Registered: 12 years ago Posts: 4 |

|

Re: Longboat Prusa Batch 3 thermistors February 24, 2012 03:18PM |

Registered: 12 years ago Posts: 22 |

Hi Nigel,

Great to hear you've got it working.

I'm also using Slic3r and Pronterface like Dee Cee, and it only required a small amout of tweaking to get some pretty good prints.

However Slic3r does seem to have a problem with some STL files, even after 'fixing' them in MeshLab, or

trying a different layer height which can sometimes make the problem go away.

So I tried skeinforge last night, which has been a complete nightmare.

Despite a great deal of trial and error, and seemingly sensible parameters. It always seem to result in either stripping the filament, a clogged extruder, or a large amorphous blob of plastic.

Has anyone else had better luck with skeinforge?

-Mark

Great to hear you've got it working.

I'm also using Slic3r and Pronterface like Dee Cee, and it only required a small amout of tweaking to get some pretty good prints.

However Slic3r does seem to have a problem with some STL files, even after 'fixing' them in MeshLab, or

trying a different layer height which can sometimes make the problem go away.

So I tried skeinforge last night, which has been a complete nightmare.

Despite a great deal of trial and error, and seemingly sensible parameters. It always seem to result in either stripping the filament, a clogged extruder, or a large amorphous blob of plastic.

Has anyone else had better luck with skeinforge?

-Mark

|

Re: Longboat Prusa Batch 3 thermistors February 24, 2012 06:45PM |

Registered: 12 years ago Posts: 51 |

|

Re: Longboat Prusa Batch 3 thermistors February 25, 2012 08:36AM |

Registered: 12 years ago Posts: 22 |

|

Re: Longboat Prusa Batch 3 thermistors February 27, 2012 03:27AM |

Registered: 12 years ago Posts: 9 |

Hi All,

I've just received my back order thermistors, along with a roll of Kapton tape, from the reprapkitstore and I am wondering whether I have received 2K, 10K or 100K items? Is there any way to tell? I am a noob when it comes to thermistors

Having read this thread I am keen to understand which thermistor I have?

Any assistance would be greatly appreciated..

Cheers

Jez

I've just received my back order thermistors, along with a roll of Kapton tape, from the reprapkitstore and I am wondering whether I have received 2K, 10K or 100K items? Is there any way to tell? I am a noob when it comes to thermistors

Having read this thread I am keen to understand which thermistor I have?

Any assistance would be greatly appreciated..

Cheers

Jez

|

Re: Longboat Prusa Batch 3 thermistors February 27, 2012 04:27AM |

Registered: 12 years ago Posts: 1,611 |

|

Re: Longboat Prusa Batch 3 thermistors February 27, 2012 05:50AM |

Registered: 12 years ago Posts: 9 |

No, I received 2 thermistors in a zip lock bag, no markings etc. - I have checked the resistance with a multimeter, and they both read around 1.7/1.8K on the 20K scale. I have a 10K thermistor that I was going to use to monitor the bed temp, and that reads 9.29/9.31 on the same scale - I would think that from that it would seem that the thermistors I received are the 2K ones.

I guess I will need to order a 100k thermistor from RS.... or will the 10k be suitable for the hot-end, and can I reuse the 2k for the bed? Any thoughts?

Cheers

Jez

I guess I will need to order a 100k thermistor from RS.... or will the 10k be suitable for the hot-end, and can I reuse the 2k for the bed? Any thoughts?

Cheers

Jez

|

Re: Longboat Prusa Batch 3 thermistors February 27, 2012 07:01AM |

Registered: 12 years ago Posts: 51 |

|

Re: Longboat Prusa Batch 3 thermistors February 27, 2012 07:10AM |

Registered: 12 years ago Posts: 9 |

|

Re: Longboat Prusa Batch 3 thermistors February 28, 2012 07:24AM |

Registered: 12 years ago Posts: 9 |

jez_a Wrote:

-------------------------------------------------------

> No, I received 2 thermistors in a zip lock bag, no

> markings etc. - I have checked the resistance with

> a multimeter, and they both read around 1.7/1.8K

> on the 20K scale.

I agree that's probably the same as mine, which arrived a week or two ago along with the Kapton tape.

Mine was about 2K3 at room temperature, your room might be warmer or you might have been holding the bead while measuring it...

The Sanguinololu firmware does easily let you use different thermistors for each application by setting up configuration.h and adding data to the thermistor tables, but it's probably easier to use the same for both, and easier still to use the 100K about to be supplied.

I've printed about 10m so far with my R9/R10 100R bodge and a table to match using the Sprinter temperature table python script (beta 3420, 2000 ohm thermistor instead of 100K, 98 ohm resistor instead of 4700) . It's been OK, I'm not planning to fiddle alot with the calibration until James sends out the correct parts as I'd have to do it all again once they're fitted and I guess as RS have them in stock they should arrive 'Real Soon Now'...

Nigel

-------------------------------------------------------

> No, I received 2 thermistors in a zip lock bag, no

> markings etc. - I have checked the resistance with

> a multimeter, and they both read around 1.7/1.8K

> on the 20K scale.

I agree that's probably the same as mine, which arrived a week or two ago along with the Kapton tape.

Mine was about 2K3 at room temperature, your room might be warmer or you might have been holding the bead while measuring it...

The Sanguinololu firmware does easily let you use different thermistors for each application by setting up configuration.h and adding data to the thermistor tables, but it's probably easier to use the same for both, and easier still to use the 100K about to be supplied.

I've printed about 10m so far with my R9/R10 100R bodge and a table to match using the Sprinter temperature table python script (beta 3420, 2000 ohm thermistor instead of 100K, 98 ohm resistor instead of 4700) . It's been OK, I'm not planning to fiddle alot with the calibration until James sends out the correct parts as I'd have to do it all again once they're fitted and I guess as RS have them in stock they should arrive 'Real Soon Now'...

Nigel

|

Re: Longboat Prusa Batch 3 thermistors March 01, 2012 05:53AM |

Registered: 12 years ago Posts: 9 |

Hi,

Just a quick update, I ordered 2 x100k thermistors from RS here in Melbourne. Wired one up to the hot end, and with Pronterface I am able to heat the tip, and read the temp... Setting the Temp in Pronterface to 185 Deg C and tested extrusion with no issues.

One question though, I don't have a Bootlace crimping tool, and connections to the heating resistor are not very stable. Does anyone have a better solution to attaching the resistor wires rather than bootlace ferrules?

Thanks to everyone for their assistance so far.

Jez

Just a quick update, I ordered 2 x100k thermistors from RS here in Melbourne. Wired one up to the hot end, and with Pronterface I am able to heat the tip, and read the temp... Setting the Temp in Pronterface to 185 Deg C and tested extrusion with no issues.

One question though, I don't have a Bootlace crimping tool, and connections to the heating resistor are not very stable. Does anyone have a better solution to attaching the resistor wires rather than bootlace ferrules?

Thanks to everyone for their assistance so far.

Jez

|

Re: Longboat Prusa Batch 3 thermistors March 01, 2012 02:16PM |

Registered: 12 years ago Posts: 4 |

Just started building a Prusa, it has a 10K themistor in the hot end (I'm trying just to use the bits I have to hand) if you drop the top resistor to match the hot themistor value then the themistor will indeed self heat, a slightly more technical solution is to replace the top resistor with a constant current source which gives you a much better working range.

As to attaching the heating resistor, I used high temperature solder with no problems yet.

As to attaching the heating resistor, I used high temperature solder with no problems yet.

|

Re: Longboat Prusa Batch 3 thermistors March 01, 2012 04:31PM |

Admin Registered: 17 years ago Posts: 7,879 |

A resistor gives a much more linear response than a constant current would and so gives better resolution at the top end. You can use two resistors to limit the self heating, but it also loses some resolution unless the ADC has a lower range mode. See [hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Longboat Prusa Batch 3 thermistors March 07, 2012 04:29AM |

Registered: 12 years ago Posts: 1 |

Hi,

I have a batch 2 Longboat Prusa, can anyone tell me exactly what thermistor I have and what thermistor table I should be using in sprinter?

I am very close to getting my Longboat up and running but when I start printing it seams the hot ends temperature drops as it extrudes causing worsening adhesion of the PLA to the bed and the extruders stepper misses more and more steps. I'm using Skeinforge and ReplicatorG.

Dan

I have a batch 2 Longboat Prusa, can anyone tell me exactly what thermistor I have and what thermistor table I should be using in sprinter?

I am very close to getting my Longboat up and running but when I start printing it seams the hot ends temperature drops as it extrudes causing worsening adhesion of the PLA to the bed and the extruders stepper misses more and more steps. I'm using Skeinforge and ReplicatorG.

Dan

|

Re: Longboat Prusa Batch 3 thermistors March 07, 2012 08:03AM |

Registered: 12 years ago Posts: 51 |

Dan

I have similar symptoms to you, a skipping extruder motor, I am trying to track down the cause. I intend to put heat sinks and fans on the stepper driver chip to see if that helps.

Use thermistor table #1 in Sprinter with a 100k thermistor (check the resistance at room temperature to see if it is near 100k ohms). I am currently extruding at 220 oC but will be trying other temperatures as part of trying to diagnose the skipping stepper. It would be interesting to find out if you diagnose this problem.

ps Check out pronterface and slic3r if you haven't already, a few others agree with me they are easier to use.

I have similar symptoms to you, a skipping extruder motor, I am trying to track down the cause. I intend to put heat sinks and fans on the stepper driver chip to see if that helps.

Use thermistor table #1 in Sprinter with a 100k thermistor (check the resistance at room temperature to see if it is near 100k ohms). I am currently extruding at 220 oC but will be trying other temperatures as part of trying to diagnose the skipping stepper. It would be interesting to find out if you diagnose this problem.

ps Check out pronterface and slic3r if you haven't already, a few others agree with me they are easier to use.

|

Re: Longboat Prusa Batch 3 thermistors March 08, 2012 12:36PM |

Registered: 12 years ago Posts: 51 |

|

Re: Longboat Prusa Batch 3 thermistors July 17, 2012 03:06PM |

Registered: 12 years ago Posts: 9 |

jameswalsh Wrote:

-------------------------------------------------------

> course wrong. I am currently contacting all the

> effected customers to inform them to disregard the

> thermistors and await replacement ones.

Did anyone get these replacements or a contact from James? I've tried a few times to contact them through the website and always get an auto-confirmation but never a reply. I'm pretty fed up with the reprap kit store now, and have had to warn several others off them. My printer is great apart from the wrong thermistors, but they have been impossible to contact through the whole process and that's bad news and wouldn't give me any confidence in recommending them to others, which is a shame.

Printer is still struggling along with my bodge fix, but I'd like to think a replacement hot end will appear eventually- anyone had any success in finding a way to contact James or others at [www.thereprapkitstore.co.uk] ?

Nigel

-------------------------------------------------------

> course wrong. I am currently contacting all the

> effected customers to inform them to disregard the

> thermistors and await replacement ones.

Did anyone get these replacements or a contact from James? I've tried a few times to contact them through the website and always get an auto-confirmation but never a reply. I'm pretty fed up with the reprap kit store now, and have had to warn several others off them. My printer is great apart from the wrong thermistors, but they have been impossible to contact through the whole process and that's bad news and wouldn't give me any confidence in recommending them to others, which is a shame.

Printer is still struggling along with my bodge fix, but I'd like to think a replacement hot end will appear eventually- anyone had any success in finding a way to contact James or others at [www.thereprapkitstore.co.uk] ?

Nigel

|

Re: Longboat Prusa Batch 3 thermistors July 17, 2012 03:51PM |

Registered: 12 years ago Posts: 51 |

I did get one thermistor from them but have had to replace thermistors a few times now in the original hot end and also in a couple of J heads I've been using.

I think you should give up and just go and buy them yourself, they are only a few quid each. I bought a few for spares.

RS online in the UK have 2 versions of the standard reprap thermistors, one is slightly bigger than the other but they both have the same spec otherwise. I've used both and it just comes down to personal preference as to whether or not you prefer thick or thin wires. Here is a link

[uk.rs-online.com]

I think you should give up and just go and buy them yourself, they are only a few quid each. I bought a few for spares.

RS online in the UK have 2 versions of the standard reprap thermistors, one is slightly bigger than the other but they both have the same spec otherwise. I've used both and it just comes down to personal preference as to whether or not you prefer thick or thin wires. Here is a link

[uk.rs-online.com]

|

Re: Longboat Prusa Batch 3 thermistors July 17, 2012 04:50PM |

Admin Registered: 17 years ago Posts: 7,879 |

|

Re: Longboat Prusa Batch 3 thermistors December 08, 2012 12:09AM |

Registered: 12 years ago Posts: 9 |

Sorry, only registered users may post in this forum.