Home

>

Reprappers

>

Topic

It's Alive !

Posted by richrap

It's Alive !  September 13, 2010 04:16PM |

Registered: 13 years ago Posts: 818 |

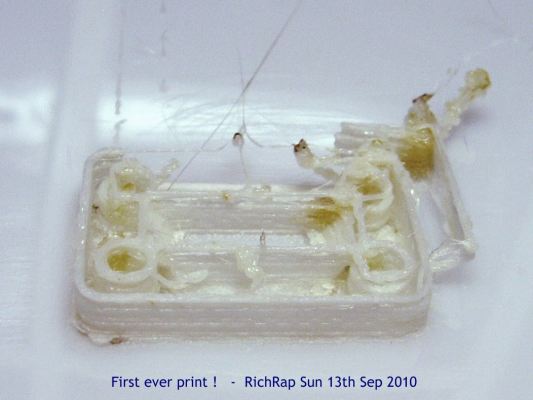

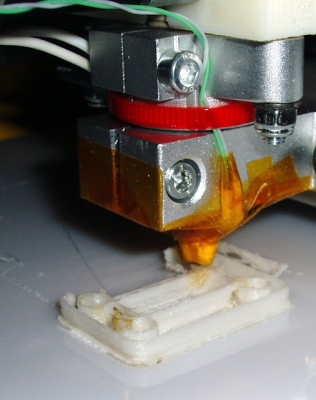

Very late on Sunday I got my Repstrap to print. Here are some photos from its very first go.

I had the nozzle/bed clearance calibrated with sheets of paper as I don’t have easy adjustment yet and in my excitement I didn’t do a test-run so I was slightly alarmed when the nozzle moved down at the start into my Polycarbonate build surface, I should have remembered that Mendel has it’s zero position just off to the side of the build-bed!

I then thought it was not working after waiting a long time at the dump position, by that point I was very tired and about to turn it all off… then movement!

Here is what I ended up with about 10mins later –

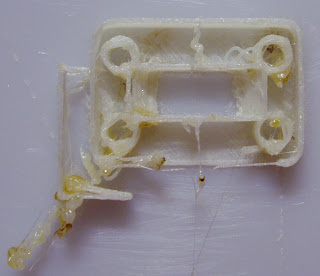

Can you guess what it is? - Nophead's Beefed-up Idle bracket for Wade's Extruder.

I think some of the discoloration is due to excess material from where one wall snapped off (removed that bit), but after a while the spare material started making a bit of a mess so I stopped it and went to bed.

It also seems quite fused to the PC bed, so maybe the bottom layer was a bit to close, maybe melted into the PC?

Registration looks ok, no missed steps?

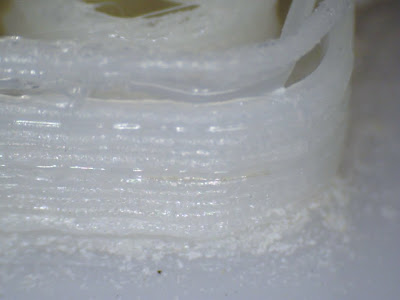

Microscope close-up looks like the walls are well fused?

Do you think enough material is being extruded? Or too much?

Setup –

Extruder hot-end - Hybrid PEEK/PTFE from Brian (http://forums.reprap.org/read.php?1,36084) ,really glad I bought this bit, works well.

Extruder drive – Not geared, loosely based on a basic 8mm direct-pinch drive grip – NEMA17.

Accelerations - OFF

Natural ABS – set to 243 Deg C.

3mm Polycarb bed and 18mm MDF.

I had the fan output turned on, I then realised this must be for interlayer cooling and not just a general fan on/off control as I has assumed, the fan was nowhere near the part being printed, so it just turned on and off and the head moved back home after every layer, quite handy to see progress.

So a few questions now spring to mind –

1) - Reprap Host Documentation states – ExtrusionSize(mm) = “The width of the filament laid down by the extruder” - I have a 0.5mm nozzle so I estimated that 0.7 would be the squashed ‘laid-down width’, should I actually use 0.5 here?

2) - I also changed the material name setting from PLA to ABS and the infill from PLA-infill to ‘null’; I hope that’s why it has not printed anything inside, if so what setting do you use for ABS (ABS-infill)? This does not seem to be documented?

3) - How do I set/calibrate ‘Extruder0_Reverse(ms)’ I expect it should be something other than 400?

I have set a nominal 700mm/min, is that normal for a Repstrap? Seems a bit slow, but I’m not sure quite how fast to crank it up?

I’m going to try to refine and calibrate it now, so any suggestions welcome, I then need to print a Geared extruder!

Many lessons learnt in a short period. Albeit a bit late, I’m going to start Blogging my future progress and hopefully some of the past 7 weeks work to get to this point here – www.richrap.blogspot.com

Thanks everyone - Another very happy Repstrapper!

I'm off to try again

RichRap

I had the nozzle/bed clearance calibrated with sheets of paper as I don’t have easy adjustment yet and in my excitement I didn’t do a test-run so I was slightly alarmed when the nozzle moved down at the start into my Polycarbonate build surface, I should have remembered that Mendel has it’s zero position just off to the side of the build-bed!

I then thought it was not working after waiting a long time at the dump position, by that point I was very tired and about to turn it all off… then movement!

Here is what I ended up with about 10mins later –

Can you guess what it is? - Nophead's Beefed-up Idle bracket for Wade's Extruder.

I think some of the discoloration is due to excess material from where one wall snapped off (removed that bit), but after a while the spare material started making a bit of a mess so I stopped it and went to bed.

It also seems quite fused to the PC bed, so maybe the bottom layer was a bit to close, maybe melted into the PC?

Registration looks ok, no missed steps?

Microscope close-up looks like the walls are well fused?

Do you think enough material is being extruded? Or too much?

Setup –

Extruder hot-end - Hybrid PEEK/PTFE from Brian (http://forums.reprap.org/read.php?1,36084) ,really glad I bought this bit, works well.

Extruder drive – Not geared, loosely based on a basic 8mm direct-pinch drive grip – NEMA17.

Accelerations - OFF

Natural ABS – set to 243 Deg C.

3mm Polycarb bed and 18mm MDF.

I had the fan output turned on, I then realised this must be for interlayer cooling and not just a general fan on/off control as I has assumed, the fan was nowhere near the part being printed, so it just turned on and off and the head moved back home after every layer, quite handy to see progress.

So a few questions now spring to mind –

1) - Reprap Host Documentation states – ExtrusionSize(mm) = “The width of the filament laid down by the extruder” - I have a 0.5mm nozzle so I estimated that 0.7 would be the squashed ‘laid-down width’, should I actually use 0.5 here?

2) - I also changed the material name setting from PLA to ABS and the infill from PLA-infill to ‘null’; I hope that’s why it has not printed anything inside, if so what setting do you use for ABS (ABS-infill)? This does not seem to be documented?

3) - How do I set/calibrate ‘Extruder0_Reverse(ms)’ I expect it should be something other than 400?

I have set a nominal 700mm/min, is that normal for a Repstrap? Seems a bit slow, but I’m not sure quite how fast to crank it up?

I’m going to try to refine and calibrate it now, so any suggestions welcome, I then need to print a Geared extruder!

Many lessons learnt in a short period. Albeit a bit late, I’m going to start Blogging my future progress and hopefully some of the past 7 weeks work to get to this point here – www.richrap.blogspot.com

Thanks everyone - Another very happy Repstrapper!

I'm off to try again

RichRap

Re: It's Alive !  September 19, 2010 03:18AM |

Registered: 13 years ago Posts: 818 |

Quick update -

I'm starting to understand Reprap Host, but it's still not doing what I expect from the settings, maybe some bugs? Or I just don't fully know what I'm doing yet!

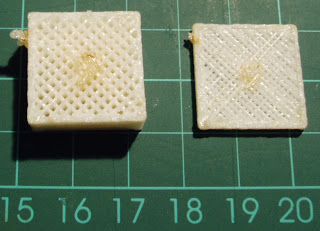

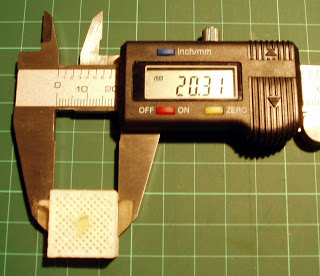

I have printed some test cubes -

And a few frogs today, it's getting better every print now I have turned the wiper shield back on, see the difference with "compare the frog" on my blog -

I'm going to try printing a Whistle today

RichRap

[richrap.blogspot.com]

I'm starting to understand Reprap Host, but it's still not doing what I expect from the settings, maybe some bugs? Or I just don't fully know what I'm doing yet!

I have printed some test cubes -

And a few frogs today, it's getting better every print now I have turned the wiper shield back on, see the difference with "compare the frog" on my blog -

I'm going to try printing a Whistle today

RichRap

[richrap.blogspot.com]

Sorry, only registered users may post in this forum.