Home

>

Reprappers

>

Topic

Irregular extrusion

Posted by Yamster

|

Irregular extrusion August 19, 2013 11:45PM |

Registered: 10 years ago Posts: 194 |

A problem after problem...

The latest issue I have is... (I wonder if I'm destined to taste every possible problem there is with 3D printing)

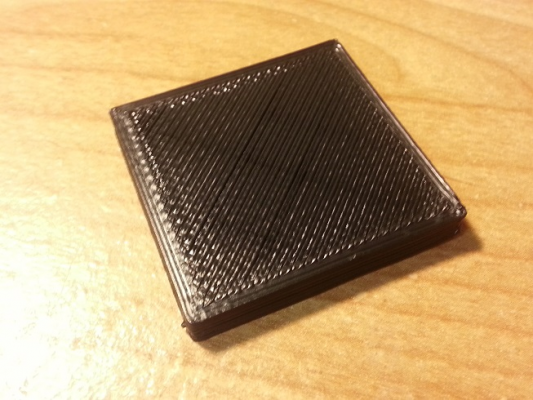

that the extrusion "periodically" gets thinner and then becomes normal.

I have attached some pictures for reference, and you will see that this has nicely (?) created a criscross/checker pattern.

I have tried different feed rate and temperature, even though none of them would explain this "periodic" thinning - if I wasn't getting enough plastic out due to slow rate or low temperature then the extrusion lines should be consistently thin all the time, right? Or.. is it not?

Also, I know it's not the extrutor motor getting too hot and skipping steps. The motor runs quite cold. I would rather consider the possibility of the motor not getting enough current and skipping some steps - so I will also try to increase the current to E motor later.

Has anyone seen symptoms like this?

The latest issue I have is... (I wonder if I'm destined to taste every possible problem there is with 3D printing)

that the extrusion "periodically" gets thinner and then becomes normal.

I have attached some pictures for reference, and you will see that this has nicely (?) created a criscross/checker pattern.

I have tried different feed rate and temperature, even though none of them would explain this "periodic" thinning - if I wasn't getting enough plastic out due to slow rate or low temperature then the extrusion lines should be consistently thin all the time, right? Or.. is it not?

Also, I know it's not the extrutor motor getting too hot and skipping steps. The motor runs quite cold. I would rather consider the possibility of the motor not getting enough current and skipping some steps - so I will also try to increase the current to E motor later.

Has anyone seen symptoms like this?

|

Re: Irregular extrusion August 20, 2013 08:19AM |

Registered: 11 years ago Posts: 112 |

It can be a few things, I'll share what I know. Basically, your extruder has a hard time pushing the filament.

You would hear the extruder if it would skip steps, the filament pushes it back and it is pretty obvious.

You might have wrong temperature, either too hot or too cold, try different values.

Your hot end might be problematic too. With heat, your filament can get soft before the nozzle. It gets harder to push. Try printing faster.

You would hear the extruder if it would skip steps, the filament pushes it back and it is pretty obvious.

You might have wrong temperature, either too hot or too cold, try different values.

Your hot end might be problematic too. With heat, your filament can get soft before the nozzle. It gets harder to push. Try printing faster.

|

Re: Irregular extrusion August 22, 2013 06:24AM |

Registered: 12 years ago Posts: 206 |

|

Re: Irregular extrusion August 22, 2013 10:49AM |

Registered: 10 years ago Posts: 194 |

|

Re: Irregular extrusion August 22, 2013 11:13AM |

Registered: 11 years ago Posts: 342 |

Yam, what woodencase said plus:

If that's PLA make sure you have a fan blowing where your extruder meets you hot end.

Make sure filament isn't binding somewhere and spool is feeding smoothly.

When you get that figured out you should be able to see the layer below the top one. Lines should be touching. If they still arn't double check you e steps.

And, congrats on getting to this point. I know how tough it is.

If that's PLA make sure you have a fan blowing where your extruder meets you hot end.

Make sure filament isn't binding somewhere and spool is feeding smoothly.

When you get that figured out you should be able to see the layer below the top one. Lines should be touching. If they still arn't double check you e steps.

And, congrats on getting to this point. I know how tough it is.

|

Re: Irregular extrusion August 22, 2013 11:46AM |

Registered: 10 years ago Posts: 194 |

Updates...

I've been trying everything to resolve this issue past few days.

I've looked at and checked all the "usual suspects", i.e. temperature, feed rate, bed level, and etc, whether they logically make sense to have anything to with the particular characteristic of this issue, I still checked and checked again.

Apparently, the issue I am having is like a "mini jamming" - a jam not bad enough to completely stop the extrusion, but still bad enough to affect the extrusion consistency.

Why it has periodic nature then - the extrusion gets thinned out, comes back normal, and goes thin again, and on and on?

Because of the thinned out extrusion appears periodically, I first thought it had to have something to do with the extrusion gears/mechanism. However, I couldn't find anything wrong with it. There's no wobbling of the gears, all the holes, bolt, gears, and the motor are perfectly aligned. The gears spin smoothly with no backlashing. I checked and tried different current setup to the motor - didn't make a difference.

So, I don't think this has anything to do with the extrusion gears and mechanism, despite the fact it has periodic nature.

This is what I think happens...

As extrusion goes on, the pressure keeps building up inside of the hot end (because of the mini jamming). Once it reaches to the threshold, the extrusion gears cannot push the filament in anymore, and the hobbed bolt starts chewing in (but not too deep).

The pressure is released somehow while the hobbed bolt is turning without pushing, probably when the compressed melted plastic gets extruded out, then the hobbed bolt resumes pushing the filament in and extrusion becomes normal.

However, just before that, there's a moment of slight slippage - the hobbed bolt cannot push the slightly chewed up portion of the filament as efficiently/fast, so for that split second the extrusion becomes thinner.

I have attached a picture of the filaments which I have pulled out. You can see the parts which are slightly chewed up. Each filament has a different distance between those marks and that's because they were fed in different rates - from left to right, from the fastest to the slowest. The far left one is from the actual printing, the second from the left is extrusion at 80 mm/min (from Pronterface), the third one is from 40 mm/min, and the far right one is from 25 mm/min.

It may be a little hard to see from the picture, but the depth of the chewed-out parts also gets shallower as the extrusion rate goes down as well.

So, with this finding, I set up the slicer at very low speed (infill speed of 40 mm/s) and tried to print again.

The result was better, as expected, but the problem is not completely gone. I've attached a couple of pictures.

So.. for some reason, my hot end is currently not capable of extruding plastic with high enough volume for normal printing.... Like I said, I've looked at all the possibilities for this choke up. I've changed the PTFE liner three times, cleaned up the hot end nozzle (one time using a burn method).. Temperature reading is correct - I tried two different themistors (from two different manufactures!). E step value is calibrated (but I've also tried both too low and to high E step values, just to see if they have any impact on this thinning out extrusion - no)...

The only thing left is the nozzle hole.. I have no means to measure the diameter of the nozzle, which is supposed to be 0.5 mm. I wonder if it got deformed somehow and the hole has become smaller. I've ordered some 0.5 mm drill bits. Once I get them, I will see if I can pass it through the hole.

I've been trying everything to resolve this issue past few days.

I've looked at and checked all the "usual suspects", i.e. temperature, feed rate, bed level, and etc, whether they logically make sense to have anything to with the particular characteristic of this issue, I still checked and checked again.

Apparently, the issue I am having is like a "mini jamming" - a jam not bad enough to completely stop the extrusion, but still bad enough to affect the extrusion consistency.

Why it has periodic nature then - the extrusion gets thinned out, comes back normal, and goes thin again, and on and on?

Because of the thinned out extrusion appears periodically, I first thought it had to have something to do with the extrusion gears/mechanism. However, I couldn't find anything wrong with it. There's no wobbling of the gears, all the holes, bolt, gears, and the motor are perfectly aligned. The gears spin smoothly with no backlashing. I checked and tried different current setup to the motor - didn't make a difference.

So, I don't think this has anything to do with the extrusion gears and mechanism, despite the fact it has periodic nature.

This is what I think happens...

As extrusion goes on, the pressure keeps building up inside of the hot end (because of the mini jamming). Once it reaches to the threshold, the extrusion gears cannot push the filament in anymore, and the hobbed bolt starts chewing in (but not too deep).

The pressure is released somehow while the hobbed bolt is turning without pushing, probably when the compressed melted plastic gets extruded out, then the hobbed bolt resumes pushing the filament in and extrusion becomes normal.

However, just before that, there's a moment of slight slippage - the hobbed bolt cannot push the slightly chewed up portion of the filament as efficiently/fast, so for that split second the extrusion becomes thinner.

I have attached a picture of the filaments which I have pulled out. You can see the parts which are slightly chewed up. Each filament has a different distance between those marks and that's because they were fed in different rates - from left to right, from the fastest to the slowest. The far left one is from the actual printing, the second from the left is extrusion at 80 mm/min (from Pronterface), the third one is from 40 mm/min, and the far right one is from 25 mm/min.

It may be a little hard to see from the picture, but the depth of the chewed-out parts also gets shallower as the extrusion rate goes down as well.

So, with this finding, I set up the slicer at very low speed (infill speed of 40 mm/s) and tried to print again.

The result was better, as expected, but the problem is not completely gone. I've attached a couple of pictures.

So.. for some reason, my hot end is currently not capable of extruding plastic with high enough volume for normal printing.... Like I said, I've looked at all the possibilities for this choke up. I've changed the PTFE liner three times, cleaned up the hot end nozzle (one time using a burn method).. Temperature reading is correct - I tried two different themistors (from two different manufactures!). E step value is calibrated (but I've also tried both too low and to high E step values, just to see if they have any impact on this thinning out extrusion - no)...

The only thing left is the nozzle hole.. I have no means to measure the diameter of the nozzle, which is supposed to be 0.5 mm. I wonder if it got deformed somehow and the hole has become smaller. I've ordered some 0.5 mm drill bits. Once I get them, I will see if I can pass it through the hole.

|

Re: Irregular extrusion August 23, 2013 02:22AM |

Registered: 10 years ago Posts: 194 |

appdev007 Wrote:

-------------------------------------------------------

>

> Make sure filament isn't binding somewhere and

> spool is feeding smoothly.

>

appdev007, maybe this was it...

I have a spool mount on the wall and the spool spins freely without any binding actually... however, the spool mount is a couple of feet behind and above the printer, so the filament forms a loop or two between the spool and the hot end.

This has not caused any issue feeding the filament until now, but as I am getting near to the end of this particular spool, I have noticed that the curvature of the filament is becoming more severe, and now the filament is forming an extra loop or two in the air.

So, I think it is very possible that now the extruder needs more force to pull the filament in, and also that force may not be consistent but changes because of these loops are like a spring...

I also wonder if the curvature of the filament is creating extra friction when it's fed through the hot end, and also requiring extra force from the extruder as well.

There are a couple of other things which also supports this theory:

1. This evening, I switched to another hot end I had, which has a 0.35 mm nozzle.

As soon as I started printing, I realized that I have the same inconsistent extrusion issue! The interval of the thinning out is quite bigger than what I had with 0.5 mm nozzle, but nonetheless it's there for sure!

This kinda killed all my theories which blamed my 0.5 mm hot end. Maybe it wasn't the hot end's fault!

2. I have received a sample ABS today (in orange color - pretty!). I tried it on my 0.35 mm hot end just for the heck of it (I previously had a problem printing cheap white ABS on this hot end - I was only able to print with PLA).

There is no thinning out! The print quality isn't anywhere perfect and I need to make some adjustments for this particular filament, but there are no choked up extrusion.

This sample filament came in as a loop, but that loop is bigger than the last remaining portion of my PLA batch - so it has less severe curve. Also, i was able to mount it directly above the printer with temporary fixture (it was only a small amount, so not much weight).

Come to think of it, that cheap ABS filament I had a problem (it kept on jamming) came in a spool which had a lot smaller radius than that of my PLA spool. So, I wonder if that could've been the reason, or at least one of the contributing factors, for the jamming...

Well, I would try some more experiments tomorrow...

-------------------------------------------------------

>

> Make sure filament isn't binding somewhere and

> spool is feeding smoothly.

>

appdev007, maybe this was it...

I have a spool mount on the wall and the spool spins freely without any binding actually... however, the spool mount is a couple of feet behind and above the printer, so the filament forms a loop or two between the spool and the hot end.

This has not caused any issue feeding the filament until now, but as I am getting near to the end of this particular spool, I have noticed that the curvature of the filament is becoming more severe, and now the filament is forming an extra loop or two in the air.

So, I think it is very possible that now the extruder needs more force to pull the filament in, and also that force may not be consistent but changes because of these loops are like a spring...

I also wonder if the curvature of the filament is creating extra friction when it's fed through the hot end, and also requiring extra force from the extruder as well.

There are a couple of other things which also supports this theory:

1. This evening, I switched to another hot end I had, which has a 0.35 mm nozzle.

As soon as I started printing, I realized that I have the same inconsistent extrusion issue! The interval of the thinning out is quite bigger than what I had with 0.5 mm nozzle, but nonetheless it's there for sure!

This kinda killed all my theories which blamed my 0.5 mm hot end. Maybe it wasn't the hot end's fault!

2. I have received a sample ABS today (in orange color - pretty!). I tried it on my 0.35 mm hot end just for the heck of it (I previously had a problem printing cheap white ABS on this hot end - I was only able to print with PLA).

There is no thinning out! The print quality isn't anywhere perfect and I need to make some adjustments for this particular filament, but there are no choked up extrusion.

This sample filament came in as a loop, but that loop is bigger than the last remaining portion of my PLA batch - so it has less severe curve. Also, i was able to mount it directly above the printer with temporary fixture (it was only a small amount, so not much weight).

Come to think of it, that cheap ABS filament I had a problem (it kept on jamming) came in a spool which had a lot smaller radius than that of my PLA spool. So, I wonder if that could've been the reason, or at least one of the contributing factors, for the jamming...

Well, I would try some more experiments tomorrow...

|

Re: Irregular extrusion August 23, 2013 08:15AM |

Registered: 11 years ago Posts: 342 |

Yes, keep thinkering like that. I was dealing with similar issues and unfortunately probably did an unneeded extruder replacement over it. Don't forget to adjust the filament diameter in your slicer when changing filament. You will need to reslice objects before printing them again. I do this before each print as may change at different points in the spool and that slight variation can result in a difference in your print.

I like the way you have thoroughly documented you issue here. It will be good for others coming along later.

I like the way you have thoroughly documented you issue here. It will be good for others coming along later.

|

Re: Irregular extrusion - Solved August 24, 2013 12:26AM |

Registered: 10 years ago Posts: 194 |

As much as I am glad to be able to report this as resolved... I am so ashamed on how stupid this issue was. Well, I am not even sure if there really was any issue to begin with.

The black PLA filament I've been using (I am near to the end of this 1kg spool) turned out to be ABS. LOL

As unbelievable as it may sound, it is true. Yep, I've ordered a spool of ABS filament, and I have received a spool of ABS filament. Between those two instance of time, something must have happened to my brain, and I somehow confidently believed and thought that I had PLA filament.

So... I got rid of the hot end fan, cranked up the hot end temperature to 225/220, and started printing:

No more thinning out....

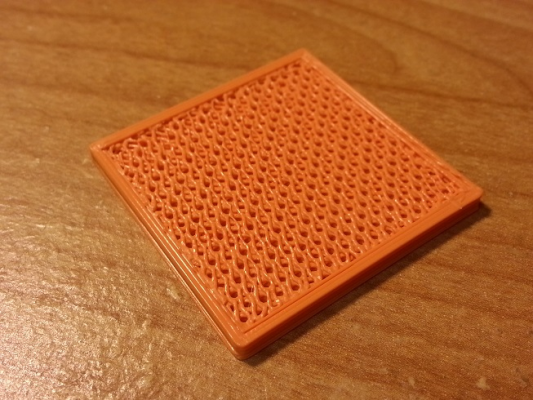

I also tested the sample PLA filament I have received from UltiMachine (with fan on and at 185/185):

It looks pretty good as well. The top shows infill pattern because I stopped printing prematurely - the test was already successful so I had no reason to continue.

I guess I really owe big to UltiMachine that it was thanks to their mystery samples I started wondering what type of plastic my black PLA really was.

Edited 1 time(s). Last edit at 08/24/2013 12:28AM by Yamster.

The black PLA filament I've been using (I am near to the end of this 1kg spool) turned out to be ABS. LOL

As unbelievable as it may sound, it is true. Yep, I've ordered a spool of ABS filament, and I have received a spool of ABS filament. Between those two instance of time, something must have happened to my brain, and I somehow confidently believed and thought that I had PLA filament.

So... I got rid of the hot end fan, cranked up the hot end temperature to 225/220, and started printing:

No more thinning out....

I also tested the sample PLA filament I have received from UltiMachine (with fan on and at 185/185):

It looks pretty good as well. The top shows infill pattern because I stopped printing prematurely - the test was already successful so I had no reason to continue.

I guess I really owe big to UltiMachine that it was thanks to their mystery samples I started wondering what type of plastic my black PLA really was.

Edited 1 time(s). Last edit at 08/24/2013 12:28AM by Yamster.

Sorry, only registered users may post in this forum.