Home

>

Reprappers

>

Topic

Z Ribbing that isn't caused by incorrect layer height?

Posted by Coin3

|

Z Ribbing that isn't caused by incorrect layer height? August 09, 2014 12:38AM |

Registered: 10 years ago Posts: 5 |

Hello,

I am having a problem with my home-designed H-bot. It is experiencing a case of Z ribbing in it's prints, and I don't know what exactly is causing it.

The symptoms are seemingly identical to Z ribbing caused by a layer height that isn't a multiple of the (full)steps/mm of the Z axis. The layers shift inwards and outwards, not side to side. The frequency does match the pitch of the ACME rod.

I did check to make sure that my layer height checks out: 0.2mm layer height. 2mm rod pitch. 200step/rev motors. It checks out with what I've read in the RepRap Magazine article on Z artifacts. There shouldn't be any problems there.

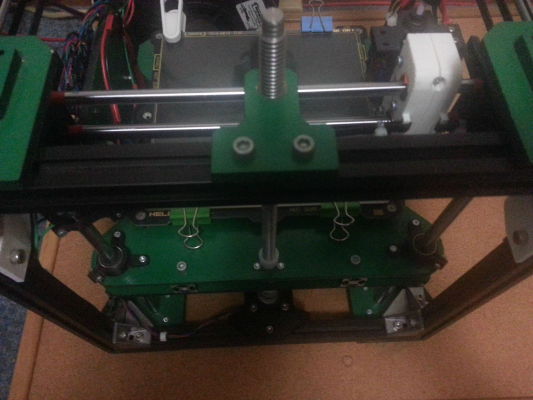

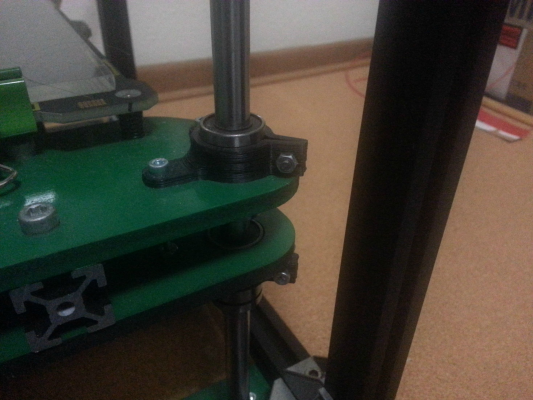

Here are some pictures so that we have something to work with. The first two are of the Z axis structure. The main boards are MDF wood. There are 2 LM10UU bearings on each side being held to the structure by 3d printed mounts. The ACME rod is connected in the middle by a plastic nut. It isn't constrained at the top; the additional part is just to keep it from being moved. There is a considerable amount of wobble in the rod, but that should not be the problem since the result does not match what should happen, and because the 10mm rods are keeping the structure aligned.

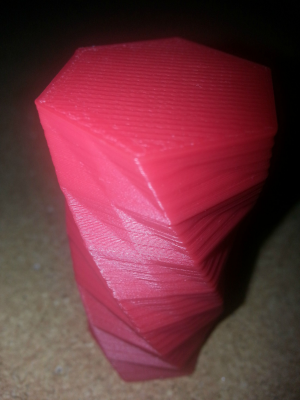

I printed this part because it's tall and I wanted to see if there would be any variation in the ribbing as the height increased. It seems to be consistent.

So that's it. I can't figure out what I should try. Hopefully some of you guys with more experience can pick out what might be the problem, and suggest what I should do to fix it.

Thanks in advance.

I am having a problem with my home-designed H-bot. It is experiencing a case of Z ribbing in it's prints, and I don't know what exactly is causing it.

The symptoms are seemingly identical to Z ribbing caused by a layer height that isn't a multiple of the (full)steps/mm of the Z axis. The layers shift inwards and outwards, not side to side. The frequency does match the pitch of the ACME rod.

I did check to make sure that my layer height checks out: 0.2mm layer height. 2mm rod pitch. 200step/rev motors. It checks out with what I've read in the RepRap Magazine article on Z artifacts. There shouldn't be any problems there.

Here are some pictures so that we have something to work with. The first two are of the Z axis structure. The main boards are MDF wood. There are 2 LM10UU bearings on each side being held to the structure by 3d printed mounts. The ACME rod is connected in the middle by a plastic nut. It isn't constrained at the top; the additional part is just to keep it from being moved. There is a considerable amount of wobble in the rod, but that should not be the problem since the result does not match what should happen, and because the 10mm rods are keeping the structure aligned.

I printed this part because it's tall and I wanted to see if there would be any variation in the ribbing as the height increased. It seems to be consistent.

So that's it. I can't figure out what I should try. Hopefully some of you guys with more experience can pick out what might be the problem, and suggest what I should do to fix it.

Thanks in advance.

|

Re: Z Ribbing that isn't caused by incorrect layer height? August 09, 2014 04:19AM |

Registered: 10 years ago Posts: 67 |

I had a similar problem on my MendelMax 1.5. I use trapezoidal lead screws and it was caused by Z screw wobble, and a loose nut. As the screw wobbles slightly, it engages the nut at different points, and since the screw thread is a ramp, this caused the nut to raise or lower slightly as the screw turned, creating a layer height change depending on the rotation of the screw. It looks exactly like what you have, so Z wobble does not have to make a pattern that rotates around the part.

Mike Anton

[manton.ca]

[laserlight.wikidot.com]

Mike Anton

[manton.ca]

[laserlight.wikidot.com]

|

Re: Z Ribbing that isn't caused by incorrect layer height? August 09, 2014 06:55AM |

Admin Registered: 17 years ago Posts: 7,879 |

Yes if the bottom of the screw is not exactly concentric with the motor shaft then it can cause this effect.

Also I am wondering what constrains the bed to be exactly level? I can see that you have two sets of bearings but on a conventional reprap you have two leads screws and by turning one relative to the other you can level the bed. Is it possible the wobble of the nut causes the bed to slope slightly one way and then the other?

[www.hydraraptor.blogspot.com]

Also I am wondering what constrains the bed to be exactly level? I can see that you have two sets of bearings but on a conventional reprap you have two leads screws and by turning one relative to the other you can level the bed. Is it possible the wobble of the nut causes the bed to slope slightly one way and then the other?

[www.hydraraptor.blogspot.com]

|

Re: Z Ribbing that isn't caused by incorrect layer height? August 09, 2014 03:03PM |

Registered: 10 years ago Posts: 5 |

I would have never thought about that! Thanks for the input.

I'll try to change out the nut with the extra that hasn't loosened up yet(due to it being plastic) to see if there is any change. I removed the current nut and the amount of play between it and the lead screw sure could be enough to confirm your idea. I'll report back with results.

The thing about the bed is that it's not exactly level. I have to give the opposite end of the bed 3mm more clearance between the bed and the mounting structure than on the supported end. This corrects the crookedness. When I was designing the Z axis, I did have doubts about how sturdy a one-sided Z-axis would be, but I ended up going with it because I didn't want to pay another motor/rods.

I wouldn't say that the incorrect slope of the bed is being affected by the nut's wobble though. After removing the lead screw, the structure hasn't lost any stability. It still doesn't move very easily when pushing and pulling on the other end; so despite being crooked, it is quite sturdy. Perhaps the 10mm bearings are secure enough to not have any play, but the weight is still enough to distort the plastic mounts and the MDF structure that holds them. I doubt I could get a perfectly straight Z axis without using a tougher material.

EDIT:

On further inspection I have found that the coupler is not exactly concentric with the lead screw... just like nophead said. haha

It seems that what I have to do then is shift the entire structure forward by about a mm. This shouldn't be too hard since the MDF that holds the ends of the rods have a little bit of play room with the aluminum extrusion that they're bolted onto. The only concern I have is why they didn't line up. They sure did in my CAD assembly. Oh well.

They sure did in my CAD assembly. Oh well.

I'll test this all out. BRB.

EDIT2:

The post-fix test is a success. There is no more Z ribbing. I will still be looking for ways to improve the Z axis however. I do not believe that this is a permanent fix; it may come back. I hope that I am wrong though.

Thanks for the input, guys. I have been sitting on this problem for months now and I never bothered to ask on here. Thanks a lot!

Edited 2 time(s). Last edit at 08/09/2014 05:30PM by Coin3.

I'll try to change out the nut with the extra that hasn't loosened up yet(due to it being plastic) to see if there is any change. I removed the current nut and the amount of play between it and the lead screw sure could be enough to confirm your idea. I'll report back with results.

Quote

nophead

Also I am wondering what constrains the bed to be exactly level? I can see that you have two sets of bearings but on a conventional reprap you have two leads screws and by turning one relative to the other you can level the bed. Is it possible the wobble of the nut causes the bed to slope slightly one way and then the other?

The thing about the bed is that it's not exactly level. I have to give the opposite end of the bed 3mm more clearance between the bed and the mounting structure than on the supported end. This corrects the crookedness. When I was designing the Z axis, I did have doubts about how sturdy a one-sided Z-axis would be, but I ended up going with it because I didn't want to pay another motor/rods.

I wouldn't say that the incorrect slope of the bed is being affected by the nut's wobble though. After removing the lead screw, the structure hasn't lost any stability. It still doesn't move very easily when pushing and pulling on the other end; so despite being crooked, it is quite sturdy. Perhaps the 10mm bearings are secure enough to not have any play, but the weight is still enough to distort the plastic mounts and the MDF structure that holds them. I doubt I could get a perfectly straight Z axis without using a tougher material.

EDIT:

On further inspection I have found that the coupler is not exactly concentric with the lead screw... just like nophead said. haha

It seems that what I have to do then is shift the entire structure forward by about a mm. This shouldn't be too hard since the MDF that holds the ends of the rods have a little bit of play room with the aluminum extrusion that they're bolted onto. The only concern I have is why they didn't line up.

They sure did in my CAD assembly. Oh well.

They sure did in my CAD assembly. Oh well.

I'll test this all out. BRB.

EDIT2:

The post-fix test is a success. There is no more Z ribbing. I will still be looking for ways to improve the Z axis however. I do not believe that this is a permanent fix; it may come back. I hope that I am wrong though.

Thanks for the input, guys. I have been sitting on this problem for months now and I never bothered to ask on here. Thanks a lot!

Edited 2 time(s). Last edit at 08/09/2014 05:30PM by Coin3.

Sorry, only registered users may post in this forum.