Home

>

Reprappers

>

Topic

Threaded rod vs leadscrew print samples?

Posted by eried

|

Threaded rod vs leadscrew print samples? October 07, 2015 10:19AM |

Registered: 11 years ago Posts: 114 |

|

Re: Threaded rod vs leadscrew print samples? October 07, 2015 12:05PM |

Registered: 11 years ago Posts: 5,780 |

Upgrading just the Z axis screws may help, but part of the problem is the flexibility of the frame and Z axis guide rails. Bent threaded rods pull the X axis back and forth if the guide rails and/or frame are flexible enough to allow it to happen, and in machines using threaded rods, they usually are. Fixing Z axis problems should include stiffening up the guide rails and frame. A flexy frame and guide rails will move around just because of extruder carriage inertia.

In other words, the use of threaded rods is a sign of cheesy overall construction and replacing one piece doesn't fix the other problems.

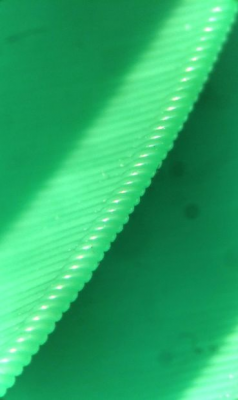

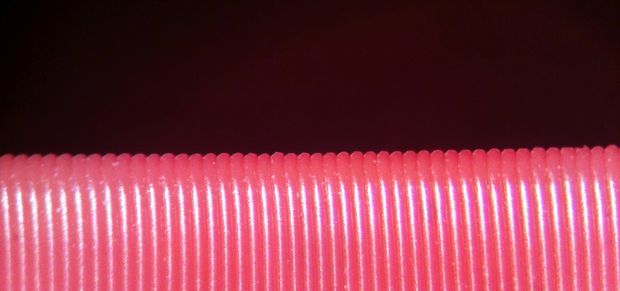

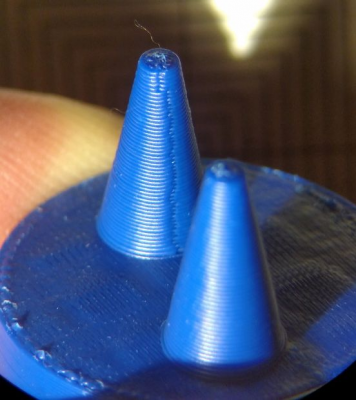

I don't have any before and after photos of results of replacing only threaded rods, but here are results from a rigid frame (1.5" x 1.5" 8020 aluminum extrusion), fully supported Z axis guide rails, Z axis acme screws, and linear guides in X and Y axes:

Edited 1 time(s). Last edit at 10/07/2015 12:06PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

In other words, the use of threaded rods is a sign of cheesy overall construction and replacing one piece doesn't fix the other problems.

I don't have any before and after photos of results of replacing only threaded rods, but here are results from a rigid frame (1.5" x 1.5" 8020 aluminum extrusion), fully supported Z axis guide rails, Z axis acme screws, and linear guides in X and Y axes:

Edited 1 time(s). Last edit at 10/07/2015 12:06PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Threaded rod vs leadscrew print samples? October 07, 2015 12:57PM |

Registered: 11 years ago Posts: 114 |

Pretty nice finish, I was wondering about the discrepancies between each layer height with a thread rod. I noticed what you said about the bent rods, they were moving all the structure with them. So I am trying to get them straight using a small wooden construction full of nuts (as a challenge, not because practicality; buying new rods is cheaper). But I was wondering if after getting pretty straight rods I will get poor results also from the imperfections of the nature of the rod.

|

Re: Threaded rod vs leadscrew print samples? October 07, 2015 05:16PM |

Registered: 11 years ago Posts: 5,780 |

If the frame flexes anything that produces lateral forces, such as a bent screw, an off center shaft coupler, a crooked motor mount, etc., will cause Z axis wobble in the print. Threaded rods have imperfections in the threads but they are probably pretty small and not going be be of much consequence in print quality, especially not compared to the effect of the screws being bent.

You'll see claims about imperial threads creating artifacts due to the limited precision of the math in the controllers, but I have never seen them even though my acme screws have imperial lead. I am told it is because the lead is relatively large at 1/2" and that if the lead were more like the pitch of a threaded rod it would be a problem. I don't know how the math is done in the controller so I don't know if any of that is true.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

You'll see claims about imperial threads creating artifacts due to the limited precision of the math in the controllers, but I have never seen them even though my acme screws have imperial lead. I am told it is because the lead is relatively large at 1/2" and that if the lead were more like the pitch of a threaded rod it would be a problem. I don't know how the math is done in the controller so I don't know if any of that is true.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Threaded rod vs leadscrew print samples? October 07, 2015 05:34PM |

Registered: 11 years ago Posts: 114 |

Thanks for the tips. My frame bends very little is all 2020 extruded aluminum profiles. But the nozzle danced badly with the bent rod. I got a metric 8 mm milimeter that is not bent at all but I still don't cut it to try it in the printer. However I was just wondering because my previous printer was an old thingomatic and I am just beginning to learn about rods :>

Sorry, only registered users may post in this forum.