Home

>

Reprappers

>

Topic

DEFAULT_MAX_ACCELERATION

Posted by mohsen

|

DEFAULT_MAX_ACCELERATION April 16, 2016 06:11AM |

Registered: 8 years ago Posts: 6 |

|

Re: DEFAULT_MAX_ACCELERATION April 16, 2016 11:54AM |

Registered: 11 years ago Posts: 198 |

I think that most people find out by trial and error.

If the printer skips steps, chances are that the accleration is set too high, or the current for the steppers too low.

If you get ripple patterns or shadows around sharp bends, the frame isn't stiff enough for the accleration, and you can either back down on the accleration or stiffen the frame.

There is probably a more sceintific approach, but the above has worked out just fine for me.

If the printer skips steps, chances are that the accleration is set too high, or the current for the steppers too low.

If you get ripple patterns or shadows around sharp bends, the frame isn't stiff enough for the accleration, and you can either back down on the accleration or stiffen the frame.

There is probably a more sceintific approach, but the above has worked out just fine for me.

|

Re: DEFAULT_MAX_ACCELERATION April 16, 2016 02:00PM |

Registered: 10 years ago Posts: 580 |

Hi Mohsen,

Ralh is right.

But why not calculate it? Because there are so many factors involved, and they are unique to your specific printer setup, and some factors will be unknown - and change with speed.

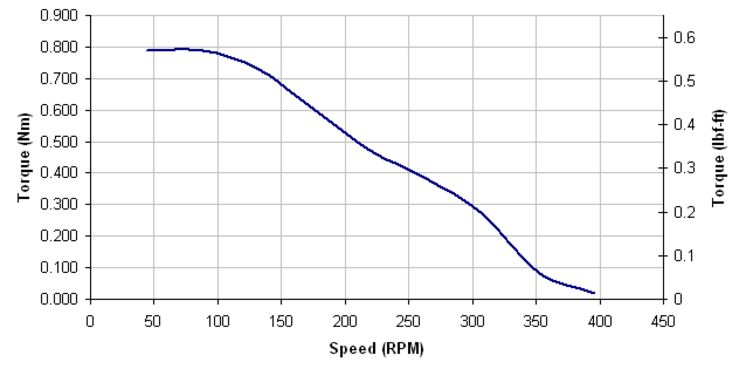

- The torque of the motors varies by speed as shown below (different for every motor model), and is also related to the motor current

- The mass you are moving is unique to your printer, and may be different by axis

- The friction in your printer is unique

- The moment of inertia for the lead screws, etc., etc.

This site has all the formulas. Very complex.

So this is the way I did it.

1) I first determined the maximum safe travel speed my motors will reliably produce without resonating or missing steps. My printer's move speed is not limited by my controller (32-bit Smoothieboard), but if you have an 8-bit controller then that may limit the max speed. Since I have a delta printer I used moves out near the edge of the print area where one of the motors must move the fastest. You can create a macro in Pronterface to test move speeds with moves to different X/Y coordinates formatted like this: G1 X0 Y0 F4000, where F is the feed rate in MM/min. Then I set the max speed in firmware.

2) Then I increased the acceleration in firmware, testing with the same script, until it started having missed steps. Then I backed off the acceleration by about 15%. Over time I lowered the max allowed speed (in firmware) just slightly - mostly relying on the acceleration setting. You can also set acceleration in a test script using the M204 gcode.

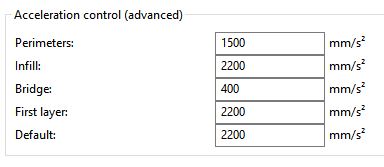

3) After you have set your max acceleration, - if you use Slic3r - you can different accelerations for different kinds of moves. For example:

For this I would use the max acceleration for moves (default), Infill, and First layer. Then I use a lower acceleration for Perimeters to control ringing, and you could use a lower acceleration yet for bridging (that would give the pressure time to build so the beginning of the bridge does not fail).

The bridging acceleration above is just an example, I use something more complex with my post-processor.

Hope that helps.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

Ralh is right.

But why not calculate it? Because there are so many factors involved, and they are unique to your specific printer setup, and some factors will be unknown - and change with speed.

- The torque of the motors varies by speed as shown below (different for every motor model), and is also related to the motor current

- The mass you are moving is unique to your printer, and may be different by axis

- The friction in your printer is unique

- The moment of inertia for the lead screws, etc., etc.

This site has all the formulas. Very complex.

So this is the way I did it.

1) I first determined the maximum safe travel speed my motors will reliably produce without resonating or missing steps. My printer's move speed is not limited by my controller (32-bit Smoothieboard), but if you have an 8-bit controller then that may limit the max speed. Since I have a delta printer I used moves out near the edge of the print area where one of the motors must move the fastest. You can create a macro in Pronterface to test move speeds with moves to different X/Y coordinates formatted like this: G1 X0 Y0 F4000, where F is the feed rate in MM/min. Then I set the max speed in firmware.

2) Then I increased the acceleration in firmware, testing with the same script, until it started having missed steps. Then I backed off the acceleration by about 15%. Over time I lowered the max allowed speed (in firmware) just slightly - mostly relying on the acceleration setting. You can also set acceleration in a test script using the M204 gcode.

3) After you have set your max acceleration, - if you use Slic3r - you can different accelerations for different kinds of moves. For example:

For this I would use the max acceleration for moves (default), Infill, and First layer. Then I use a lower acceleration for Perimeters to control ringing, and you could use a lower acceleration yet for bridging (that would give the pressure time to build so the beginning of the bridge does not fail).

The bridging acceleration above is just an example, I use something more complex with my post-processor.

Hope that helps.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

|

Re: DEFAULT_MAX_ACCELERATION April 17, 2016 06:58AM |

Registered: 8 years ago Posts: 6 |

Sorry, only registered users may post in this forum.