Home

>

Reprappers

>

Topic

Geared Stepper

Posted by elwood127

|

Geared Stepper June 17, 2016 05:39PM |

Registered: 9 years ago Posts: 705 |

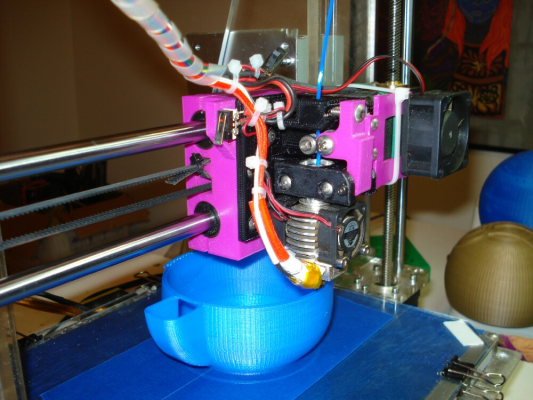

Hey all, Eric Sammut suggested I try this 5:1 stepper and 8mm hob for my direct drive I3. What might I expect for settings changes. I assume that 1/5th the amount of filament would be moving. Where would I speed it up? I mentioned my "high retract print" fails (stripping filament) and he thought that these would help eliminate the problem. He is using a Bowden setup but I prefer direct. Any thoughts? Thanks.

[www.robotdigg.com]

[www.robotdigg.com]

Edited 1 time(s). Last edit at 06/18/2016 12:31AM by elwood127.

[www.robotdigg.com]

[www.robotdigg.com]

Edited 1 time(s). Last edit at 06/18/2016 12:31AM by elwood127.

|

Re: Geared Stepper June 18, 2016 04:09AM |

Admin Registered: 13 years ago Posts: 7,000 |

|

Re: Geared Stepper June 18, 2016 04:23PM |

Registered: 9 years ago Posts: 705 |

|

Re: Geared Stepper June 19, 2016 02:39AM |

Registered: 8 years ago Posts: 5,232 |

The stripped filament problem occurs, when the stepper is to powerful and the acceleration settings are to high.

With a geared stepper, you probably strip your filament even easier.

Try to reduce acceleration and stepper current.

Also check your slicer settings and raise the "minimum filament fed between retracts" value. ( that's how its called in Cura )

With a geared stepper, you probably strip your filament even easier.

Try to reduce acceleration and stepper current.

Also check your slicer settings and raise the "minimum filament fed between retracts" value. ( that's how its called in Cura )

|

Re: Geared Stepper June 20, 2016 11:43PM |

Registered: 9 years ago Posts: 705 |

|

Re: Geared Stepper June 22, 2016 11:11AM |

Registered: 7 years ago Posts: 44 |

I would suggest reducing both the acceleration and retraction speed by a factor of your ratio (5).

If you let the retraction speed as high as it was before, the motor won't probably be able to turn that fast and will skip.

For the E-Step calibration, you can use your eeprom or flash a configured firmware. I strongly suggest to test a 100mm extrusion and measure it to confirm the steps for your extruder!

DYZE DESIGN

Hotends, Extruders, Liquid Cooling and Accessories.

If you let the retraction speed as high as it was before, the motor won't probably be able to turn that fast and will skip.

For the E-Step calibration, you can use your eeprom or flash a configured firmware. I strongly suggest to test a 100mm extrusion and measure it to confirm the steps for your extruder!

DYZE DESIGN

Hotends, Extruders, Liquid Cooling and Accessories.

|

Re: Geared Stepper September 04, 2016 05:21PM |

Registered: 9 years ago Posts: 199 |

The filament does not strip because of high speed or to much stepper current like said above.. You could put the retraction less high and fast, but that doesn't fix the issue.

Try to put the spring tension of the extruder less, that is more probably the problem.

I use a geared stepper myself and it actually needs quite some current (for 3mm atleast), i use drv8825, if i would use a4988 (1.5 A limit) i wouldn't be able to print with 3mm.

The geared stepper you showed is not the right one , this is the one you need. [www.robotdigg.com]

Also if you plan to buy the stepper and use it on your direct drive, buy this driver gear [www.robotdigg.com] ( 8mm one, also the best for a geared stepper )

But i would advice you to buy the full bulldog xl , it will cost you 72 usd instead 38 usd , but might save you alot of trouble. [www.robotdigg.com]

Edited 1 time(s). Last edit at 09/04/2016 05:22PM by Govahnator.

Try to put the spring tension of the extruder less, that is more probably the problem.

I use a geared stepper myself and it actually needs quite some current (for 3mm atleast), i use drv8825, if i would use a4988 (1.5 A limit) i wouldn't be able to print with 3mm.

The geared stepper you showed is not the right one , this is the one you need. [www.robotdigg.com]

Also if you plan to buy the stepper and use it on your direct drive, buy this driver gear [www.robotdigg.com] ( 8mm one, also the best for a geared stepper )

But i would advice you to buy the full bulldog xl , it will cost you 72 usd instead 38 usd , but might save you alot of trouble. [www.robotdigg.com]

Edited 1 time(s). Last edit at 09/04/2016 05:22PM by Govahnator.

|

Re: Geared Stepper September 09, 2016 04:22PM |

Registered: 8 years ago Posts: 318 |

Quote

Govahnator

The filament does not strip because of high speed or to much stepper current like said above..

Yes, it does. Well, not the filament itself but that's not what he meant. Stepper motors can only move so fast, too fast and it will loose a lot of torque, faster and it will flat out skip steps. I have a 80:16 (5:1) geared stepper bowden setup and this was an actual problem

Edited 1 time(s). Last edit at 09/09/2016 04:22PM by DaGameFace.

|

Re: Geared Stepper September 09, 2016 05:58PM |

Registered: 8 years ago Posts: 601 |

Stripped filament can be solved by using a better design of hobbed bolt. I've only used the MK8 and the e3d titan one, but the mk8 certainly stripped less. The titan also prefers the idler to be very tight on the filament, the mk8 was not so important.

For reference, my mk8 was used on an ungeared direct drive extruder run on a large nema 17. The E3D titan uses a pancake nema 17 motor with 3:1 gearing on the titan extruder. They both output the same amount of power. Perhaps the motor gearing is to blame for the stripping on the titan? Either way, the issue disappeared once I tightened up the idler.

For reference, my mk8 was used on an ungeared direct drive extruder run on a large nema 17. The E3D titan uses a pancake nema 17 motor with 3:1 gearing on the titan extruder. They both output the same amount of power. Perhaps the motor gearing is to blame for the stripping on the titan? Either way, the issue disappeared once I tightened up the idler.

|

Re: Geared Stepper September 10, 2016 05:49PM |

Registered: 9 years ago Posts: 705 |

Funny that this topic came back to life. I recently noticed two issues. One was that the my (new) nema 17 shaft was flexing when pressure was applied. So much that clicking was heard. The second problem was that my extruder mount redesign had the hob gear slightly short of perfect alignment with the entry hole for the filament and the hole in the hotend. This allowed the bearing to go under the hob slightly (past center) causing a little bow in the filament. I redrew the mount moving the motor .030 toward the front which made the bearing hit perfectly on the filament and hob. Now the filament goes straight through with no bending. I also reinstalled my old motor which doesn't flex under pressure. Your call on which made the most difference. Been printing without jamming for two days straight now. What a relief. The bitch was baby sitting the new mount print. Had 5 strips that I caught during the print. 1.5 hours of staring at the bearing to make sure it was turning.

P.s. I'm applying very little bearing pressure without a spring. .2mm retract @ 40mm/sec.

P.s. I'm applying very little bearing pressure without a spring. .2mm retract @ 40mm/sec.

Sorry, only registered users may post in this forum.