Home

>

Reprappers

>

Topic

new printer - heated bed options

Posted by brampie

|

new printer - heated bed options October 25, 2016 04:11PM |

Registered: 7 years ago Posts: 7 |

Hi all,

I'm new here, I've been 3d printing for some time on my wanhao i3, however, it kept breaking down and had several other issues.

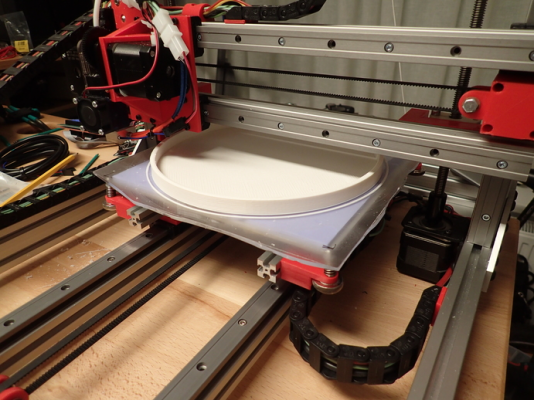

Looking around at the option I figured, I can build one myself and this is what I have done, I'm happy with it.

It's a bit different in that it uses mostly alu extrusions (2040) and igus twe bearings.

For the bed I have a bit of an issue, right now I'm using the wanhao bed but the printer can actually print bigger than 214x214mm (240x250 or so)

Does anyone know of a decent supplier of alu/pcb beds in that size (240x240) or another solution, I'm afraid that an alu bed + silicone heater will be heavy and/or loose me too much Z height and will interfere with my cabling ?

I was thinking, I could also use a larger glass plate and simply have it bigger than the alu print bed, this causes some issues but I think most can be solved (I would use thermal pads or something similar to hold in in place or use a plate of 200x250, this way I can use clamps on the smallest side).

Does anyone know of other better solutions ? I also found a kapton heater mat but I'm unsure how safe that is, it looks fragile.

I only print tritan abs so warping isn't that much of an issue I've found.

ps. Do you think it's an interesting design ? should I put it online somewhere ? any ideas about that ?

ps2. My english isn't perfect, I'm sorry

thx

Bram

I'm new here, I've been 3d printing for some time on my wanhao i3, however, it kept breaking down and had several other issues.

Looking around at the option I figured, I can build one myself and this is what I have done, I'm happy with it.

It's a bit different in that it uses mostly alu extrusions (2040) and igus twe bearings.

For the bed I have a bit of an issue, right now I'm using the wanhao bed but the printer can actually print bigger than 214x214mm (240x250 or so)

Does anyone know of a decent supplier of alu/pcb beds in that size (240x240) or another solution, I'm afraid that an alu bed + silicone heater will be heavy and/or loose me too much Z height and will interfere with my cabling ?

I was thinking, I could also use a larger glass plate and simply have it bigger than the alu print bed, this causes some issues but I think most can be solved (I would use thermal pads or something similar to hold in in place or use a plate of 200x250, this way I can use clamps on the smallest side).

Does anyone know of other better solutions ? I also found a kapton heater mat but I'm unsure how safe that is, it looks fragile.

I only print tritan abs so warping isn't that much of an issue I've found.

ps. Do you think it's an interesting design ? should I put it online somewhere ? any ideas about that ?

ps2. My english isn't perfect, I'm sorry

thx

Bram

|

Re: new printer - heated bed options October 25, 2016 04:51PM |

Registered: 10 years ago Posts: 651 |

It definitely looks like a solid design, I think you should publish it on github. Build an enclosure for the control board and mounts for the power supply, and it'd be as full a featured as any kit.

Your current aluminum bed looks to be pretty thick, Getting an aluminum bed the size you want won't increase the mass that dramatically. You may have to tweak the acceleration and jerk a bit. Dentist's done a bed that big on a Taz printer. You won't lose Z height by making it larger in X & Y. Unless it's thicker aluminum. I'd go with 6mm and a silicone heater.

You may also change the design of your bed mounts a bit so the mounting screws go through a block of PTFE (Teflon) connected directly to those extrusions that are part of your Y axis. You'd have to spread the Y linear guides apart a bit. it'll make for less printed parts. And you may find that the plastic mounts you have in there may warp over time anyway. You could shed some weight by not using the glass, you'd get along perfectly without it.

Edited 4 time(s). Last edit at 10/25/2016 04:59PM by FA-MAS.

Your current aluminum bed looks to be pretty thick, Getting an aluminum bed the size you want won't increase the mass that dramatically. You may have to tweak the acceleration and jerk a bit. Dentist's done a bed that big on a Taz printer. You won't lose Z height by making it larger in X & Y. Unless it's thicker aluminum. I'd go with 6mm and a silicone heater.

You may also change the design of your bed mounts a bit so the mounting screws go through a block of PTFE (Teflon) connected directly to those extrusions that are part of your Y axis. You'd have to spread the Y linear guides apart a bit. it'll make for less printed parts. And you may find that the plastic mounts you have in there may warp over time anyway. You could shed some weight by not using the glass, you'd get along perfectly without it.

Edited 4 time(s). Last edit at 10/25/2016 04:59PM by FA-MAS.

|

Re: new printer - heated bed options October 26, 2016 02:55PM |

Registered: 7 years ago Posts: 7 |

Thx for your advice.

I usually put the ramps in a pc (mini itx) case with an sfx power supply, I usually print a controller box to put on the front of the case, I hope/think the metal case will offer some protection if something goes wrong (I've seem some fires with low voltage electric causes)

It can be built by anyone and doesn't use any special (cnc cut steel or other difficult to obtain) parts,maybe a carriage with a fan would appeal to a larger (PLA printing) audience, on the other hand, many printers print pla well.

-I don't have that much place to put the Y axis wider as the cabling for the bed is in the way, I would like to keep it thas way as I didn't like the cabling on the wanhao (printer sits in an enclosure and that didn't go well with the heated bed cable).

-My worry is that the silicone heater itself will be thick and will hit the extrusions (which would force me to put the bed up), also, cabling wise it would have to fit the cable track, soms of those silicone heaters have thick (unflexible) cables, right now I'm using high flexibility silicon cables.

-I'll try with the thermal pad and a larger glass and see how that goes, I know I'm alone in this but I actually prefer glass over buildtak,pei etc. glass works fine and is easier to clean because it isn't mounted to the printer.

again, thx for your input

I usually put the ramps in a pc (mini itx) case with an sfx power supply, I usually print a controller box to put on the front of the case, I hope/think the metal case will offer some protection if something goes wrong (I've seem some fires with low voltage electric causes)

It can be built by anyone and doesn't use any special (cnc cut steel or other difficult to obtain) parts,maybe a carriage with a fan would appeal to a larger (PLA printing) audience, on the other hand, many printers print pla well.

-I don't have that much place to put the Y axis wider as the cabling for the bed is in the way, I would like to keep it thas way as I didn't like the cabling on the wanhao (printer sits in an enclosure and that didn't go well with the heated bed cable).

-My worry is that the silicone heater itself will be thick and will hit the extrusions (which would force me to put the bed up), also, cabling wise it would have to fit the cable track, soms of those silicone heaters have thick (unflexible) cables, right now I'm using high flexibility silicon cables.

-I'll try with the thermal pad and a larger glass and see how that goes, I know I'm alone in this but I actually prefer glass over buildtak,pei etc. glass works fine and is easier to clean because it isn't mounted to the printer.

again, thx for your input

|

Re: new printer - heated bed options January 03, 2017 02:46AM |

Registered: 7 years ago Posts: 7 |

Hi all,

I have got thing working by simply putting a larger glass on the 20x20 print bed (with thermal pads in between).

This does have some downsides:

-the outsides of the glass aren't very hot, espacially where they hang over the heat bed.

-heating up takes ages, I also can't get it above 85 or so, I do have an enclosure, without it this would be worse.

-thermal pads can be expensive

The plus sides:

-It works well enough to print large flat discs in titan-x abs (see attachment, my glass cutting skills have improved since)

-It's not expensive apart from the thermal pads (I got mine from rs online, I covered the entire bed)

I also bought a custom made heated bed from a german company who makes those (heated bed + silicon heater).

While this looked very nice the bed was 6mm thick and the weight of the bed was 1kg, I don't use it as the solution above is better in a lot of ways.

Maybe in the future I'll change the bed to something else so I can use the heater, on the other hand, it works ok like it is right now.

ps. The printer itself has been very reliable since I built it, it has printed 1000 hours, I did have to adjust the twe bearing on the X axis a bit but this did not require disassembly, I don't think I ever printed a 1000 hours without something breaking on the wanhao i3.

I also calculated the cost, I think it can be built for 1000 euro's, mine was probably more like 1500 (not counting parts I ended up not using like the custom made bed)

thx for your help

Bram

I have got thing working by simply putting a larger glass on the 20x20 print bed (with thermal pads in between).

This does have some downsides:

-the outsides of the glass aren't very hot, espacially where they hang over the heat bed.

-heating up takes ages, I also can't get it above 85 or so, I do have an enclosure, without it this would be worse.

-thermal pads can be expensive

The plus sides:

-It works well enough to print large flat discs in titan-x abs (see attachment, my glass cutting skills have improved since)

-It's not expensive apart from the thermal pads (I got mine from rs online, I covered the entire bed)

I also bought a custom made heated bed from a german company who makes those (heated bed + silicon heater).

While this looked very nice the bed was 6mm thick and the weight of the bed was 1kg, I don't use it as the solution above is better in a lot of ways.

Maybe in the future I'll change the bed to something else so I can use the heater, on the other hand, it works ok like it is right now.

ps. The printer itself has been very reliable since I built it, it has printed 1000 hours, I did have to adjust the twe bearing on the X axis a bit but this did not require disassembly, I don't think I ever printed a 1000 hours without something breaking on the wanhao i3.

I also calculated the cost, I think it can be built for 1000 euro's, mine was probably more like 1500 (not counting parts I ended up not using like the custom made bed)

thx for your help

Bram

Sorry, only registered users may post in this forum.